Professional Documents

Culture Documents

En 2-2004 RC-PN Example 001

Uploaded by

Aashu chaudharyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En 2-2004 RC-PN Example 001

Uploaded by

Aashu chaudharyCopyright:

Available Formats

Software Verification

PROGRAM NAME: ETABS, SAFE

REVISION NO.: 1

EN 2-2004 RC-PN EXAMPLE 001

Slab Punching Shear Design

PROBLEM DESCRIPTION

The purpose of this example is to verify slab punching shear design in ETABS and

SAFE.

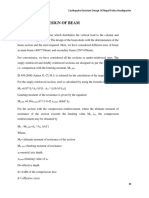

The numerical example is a flat slab that has three 8-m spans in each direction, as

shown in Figure 1.

0.3 m A B C D 0.3 m

8m 8m 8m

0.6 m

4

0.25 m thick flat slab

8m

3

Columns are 0.3 m x 0.9 m

with long side parallel

8m to the Y-axis, typical

2 Concrete Properties

Unit weight = 24 kN/m3

f'c = 30 N/mm2

8m

Y Loading

DL = Self weight + 1.0 kN/m 2

X LL = 4.0 kN/m2

1

0.6 m

Figure 1: Flat Slab for Numerical Example

The slab overhangs beyond the face of the column by 0.15 m along each side of the

structure. The columns are typically 0.3 m x 0.9 m with the long side parallel to

the Y-axis. Thick shell properties are used for the slab.

The concrete has a unit weight of 24 kN/m3 and a f 'c of 30 N/mm2. The dead load

consists of the self weight of the structure plus an additional 1 kN/m2. The live

load is 4 kN/m2.

EN 2-2004 RC-PN EXAMPLE 001 - 1

Software Verification

PROGRAM NAME: ETABS, SAFE

REVISION NO.: 1

TECHNICAL FEATURES TESTED

Calculation of punching shear capacity, shear stress and D/C ratio.

RESULTS COMPARISON

Table 1 shows the comparison of the punching shear capacity, shear stress ratio

and D/C ratio obtained with the punching shear capacity, shear stress ratio and D/C

ratio obtained by the analytical method. They match exactly for this problem.

Table 1 Comparison of Design Results for Punching

Shear at Grid B-2

National Annex Shear Shear

Stress Capacity D/C

Method (N/mm2) (N/mm2) ratio

CEN Default, Norway, Slovenia ETABS, 1.107 0.610

1.82

and Sweden SAFE

Calculated 1.089 0.578 1.89

Bulgaria, Finland, Germany, ETABS, 1.107 0.612

1.82

Ireland, Poland, Portugal, SAFE

Singapore and UK

Calculated 1.089 0.5796 1.88

Denmark ETABS, 1.107 0.639

1.74

SAFE

Calculated 1.089 0.606 1.80

COMPUTER FILE: EN 2-2004 (COUNTRY NA) RC-PN EX001

CONCLUSION

The results show an acceptable comparison with the independent results.

EN 2-2004 RC-PN EXAMPLE 001 - 2

Software Verification

PROGRAM NAME: ETABS, SAFE

REVISION NO.: 1

HAND CALCULATION

Hand Calculation for Interior Column

d= [( 250 − 26 ) + ( 250 − 38)] 2 = 218 mm

Refer to Figure 2.

u1 = u = 2•300 + 2•900 + 2•π•436 = 5139.468 mm

1172 Note: All dimensions in millimeters

Y Critical section for

punching shear

436 150 150 436 shown dashed.

A B

Column

Side 2 436

Side 1

Side 3

450

X

1772

450

Center of column is

point (x1, y1). Set

436

this equal to (0,0). Side 4

D C

Figure 2: Interior Column, Grid B-2 in Model

From the output at Grid B-2:

VEd = 1112.197 kN

k2MEd2 = 38.933 kN-m

k3MEd3 = 17.633 kN-m

EN 2-2004 RC-PN EXAMPLE 001 - 3

Software Verification

PROGRAM NAME: ETABS, SAFE

REVISION NO.: 1

Maximum design shear stress in computed in along major and minor axis of column:

VEd k2 M Ed ,2u1 k3 M Ed ,3u1

vEd = 1 + + (EC2 6.4.4(2))

ud VEdW1,2 VEdW1,3

c2

W1 = 1 + c1c2 + 4c2 d + 16d 2 + 2π dc1

2

9002

W1,2

= + 300 • 900 + 4 • 300 • 218 + 16 • 2182 + 2π • 218 • 900

2

W1,2 = 2,929, 744.957 mm2

9002

W

=1,3 3 + 900 • 300 + 4 • 900 • 218 + 16 • 2182 + 2π • 218 • 300

2

W1,2 = 2, 271,104.319 mm2

VEd k2 M Ed ,2u1 k3 M Ed ,3u1

vEd = 1 + +

ud VEdW1,2 VEdW1,3

1112.197 • 103 38.933 • 106 • 5139.468 17.633 • 106 • 5139.468

vEd = 1 + +

5139.468 • 218 1112.197 • 103 • 2929744.957 1112.197 • 103 • 2271104.319

vEd = 1.089 N/mm2

Thus vmax = 1.089 N/mm2

For CEN Default, Finland, Norway, Singapore, Slovenia, Sweden and UK:

C Rd ,c = 0.18 γ c = 0.18/1.5 = 0.12 (EC2 6.4.4)

For Denmark:

CRd ,c = 0.18 γ c = 0.18/1.45 = 0.124 (EC2 6.4.4)

The shear stress carried by the concrete, VRd,c, is calculated as:

VRd ,c C Rd ,c k (100 ρ1 fck ) + k1σ cp

13

= (EC2 6.4.4)

with a minimum of:

v=

Rd ,c (vmin + k1σ cp ) (EC2 6.4.4)

EN 2-2004 RC-PN EXAMPLE 001 - 4

Software Verification

PROGRAM NAME: ETABS, SAFE

REVISION NO.: 1

200

1+

k= ≤ 2.0 = 1.9578 (EC2 6.4.4(1))

d

k1 = 0.15. (EC2 6.2.2(1))

As1

ρ1 = ≤ 0.02

bw d

Area of reinforcement at the face of column for design strip are as follows:

For CEN Default, Norway, Slovenia and Sweden:

As in Strip Layer A = 9204.985 mm2

As in Strip Layer B = 8078.337 mm2

Average As = ( 9204.985 + 8078.337 ) 2 = 8641.661 mm2

ρ1 = 8641.661 ( 8000 • 218 ) = 0.004955 ≤ 0.02

For Bulgaria:

As in Strip Layer A = 9937 mm2

As in Strip Layer B = 10373 mm2

Average As = ( 9937 + 10373) 2 = 10,155 mm2

ρ1 = 10155 ( 8000 • 218 ) = 0.005823 ≤ 0.02

For Finland, Singapore and UK:

As in Strip Layer A = 9319.248 mm2

As in Strip Layer B = 8174.104 mm2

Average As = ( 9319.248 + 8174.104 ) 2 = 8746.676 mm2

ρ1 = 8746.676 ( 8000 • 218 ) = 0.005015 ≤ 0.02

EN 2-2004 RC-PN EXAMPLE 001 - 5

Software Verification

PROGRAM NAME: ETABS, SAFE

REVISION NO.: 1

For Denmark:

As in Strip Layer A = 9606.651 mm2

As in Strip Layer B = 8434.444 mm2

Average As = ( 9606.651 + 8434.444 ) 2 = 9020.548 mm2

ρ1 = 9020.548 ( 8000 • 218 ) = 0.005172 ≤ 0.02

For CEN Default, Bulgaria, Denmark, Finland, Germany, Ireland, Poland,

Portugal, Norway, Singapore, Slovenia, Sweden and UK:

ν min = 0.035k 3 2 f ck 1 2 = 0.035 (1.9578 ) ( 30 )

3/2 1/2

= 0.525 N/mm2

For CEN Default, Finland, Germany, Ireland, Poland, Portugal, Norway, Norway,

Slovenia and Sweden:

vRd ,c = 0.12 • 1.9578 (100 • 0.004955 • 30 ) + 0 = 0.5777 N/mm2

13

For Bulgaria:

vRd ,c = 0.12 • 1.9578 (100 • 0.005823 • 30 )

13

+ 0 = 0.6096 N/mm2

For Finland, Singapore, and UK:

vRd ,c = 0.12 • 1.9578 (100 • 0.005015 • 30 )

13

+ 0 = 0.5796 N/mm2

For Denmark:

vRd ,c = 0.124 • 1.9578 (100 • 0.005015 • 30 ) + 0 = 0.606 N/mm2

13

For CEN Default, Norway, Slovenia and Sweden:

v max 1.089

Shear Ratio

= = = 1.89

vRd ,c 0.5777

For Bulgaria, Finland, Germany, Ireland, Poland, Portugal, Singapore and UK:

v max 1.089

Shear Ratio

= = = 1.88

vRd ,c 0.5796

EN 2-2004 RC-PN EXAMPLE 001 - 6

Software Verification

PROGRAM NAME: ETABS, SAFE

REVISION NO.: 1

For Denmark:

v max 1.089

Shear Ratio

= = = 1.80

vRd ,c 0.606

EN 2-2004 RC-PN EXAMPLE 001 - 7

You might also like

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Ts 500-2000 RC-PN Example 001Document6 pagesTs 500-2000 RC-PN Example 001121528No ratings yet

- AS 3600-2018 RC-PN Example 001Document4 pagesAS 3600-2018 RC-PN Example 001Aashu chaudharyNo ratings yet

- NZS 3101-06 RC-PN-001 PDFDocument6 pagesNZS 3101-06 RC-PN-001 PDFHaytham ZaghloulNo ratings yet

- Hong Kong CoP-04 RC-PN-001 PDFDocument5 pagesHong Kong CoP-04 RC-PN-001 PDFrenzo1221No ratings yet

- Software Verification: EXAMPLE IS 456-00 RC-PN-001Document6 pagesSoftware Verification: EXAMPLE IS 456-00 RC-PN-001RahulNo ratings yet

- Channel Steel Beam Torsion Design (EN1993)Document5 pagesChannel Steel Beam Torsion Design (EN1993)Anupam AjayanNo ratings yet

- Aerospace Structures Lab Manual - 2018 RegDocument29 pagesAerospace Structures Lab Manual - 2018 Regbasha.arshad.mullaNo ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- Central Expressway Girder Load Testing ReportDocument8 pagesCentral Expressway Girder Load Testing ReportChiranjaya HulangamuwaNo ratings yet

- Design stairway from EL 1500 to 6500Document10 pagesDesign stairway from EL 1500 to 6500Thomas StephenNo ratings yet

- Stub ColumnDocument4 pagesStub ColumnCHRISTOPHER EKIRAPANo ratings yet

- Punching Shear Calculations: Aci - 318 Adapt-PtDocument32 pagesPunching Shear Calculations: Aci - 318 Adapt-PtMahmoud Mohsen HassanNo ratings yet

- 800mm WallDocument12 pages800mm Wallyadav04_abhishekNo ratings yet

- 30 MDocument9 pages30 MChiranjaya HulangamuwaNo ratings yet

- Verify Slab Punching Shear Design in SAFE SoftwareDocument5 pagesVerify Slab Punching Shear Design in SAFE SoftwareKutty MansoorNo ratings yet

- Bend TestDocument14 pagesBend TestAdasi SamuelNo ratings yet

- NZS 3101-2006 PT-SL Example 001Document6 pagesNZS 3101-2006 PT-SL Example 001Fredy Sandro Rosas FloresNo ratings yet

- Appendix A1Document22 pagesAppendix A1Thomas StephenNo ratings yet

- ACI 318-08 RC-SL Example 001Document3 pagesACI 318-08 RC-SL Example 001Novin KamyabNo ratings yet

- Strength Calculation For PlatformDocument2 pagesStrength Calculation For PlatformRaghNo ratings yet

- Mat Foundation Design PDFDocument3 pagesMat Foundation Design PDFCivil Construction And TutorNo ratings yet

- Engineering StrutureDocument12 pagesEngineering Struturemohamedelamari04No ratings yet

- TN 192 Punching Shear Calculation in BuilderDocument24 pagesTN 192 Punching Shear Calculation in BuilderHieu100% (1)

- Steel cable tray design and load calculationsDocument6 pagesSteel cable tray design and load calculationsyusuf_jtNo ratings yet

- 2da Practica ANALISIS 2021 1Document1 page2da Practica ANALISIS 2021 1ProblemSolvedNo ratings yet

- As-Check Punching TrueDocument1 pageAs-Check Punching TrueAnonymous FuZIBPNo ratings yet

- Modeling and Analysis Lab Problems and Solution (17MEL68)Document747 pagesModeling and Analysis Lab Problems and Solution (17MEL68)Mohammed Imran100% (1)

- 03 - Staticki Proracun - Krovna KonstrukcijaDocument7 pages03 - Staticki Proracun - Krovna KonstrukcijaArmin HudutiNo ratings yet

- SAFE VerificationDocument7 pagesSAFE VerificationRahul AggarwalNo ratings yet

- 01 FST Bs 300 Trans Top-1Document8 pages01 FST Bs 300 Trans Top-1avt premiumNo ratings yet

- Reinforced Concrete Design AnalysisDocument10 pagesReinforced Concrete Design AnalysisRomel Remolacio Angngasing100% (1)

- En 2-2004 RC-SL Example 001Document10 pagesEn 2-2004 RC-SL Example 001Aashu chaudharyNo ratings yet

- PT SLAB VERIFICATIONDocument6 pagesPT SLAB VERIFICATIONAashu chaudharyNo ratings yet

- Slab Flexural Design VerificationDocument5 pagesSlab Flexural Design Verificationrenzo1221100% (1)

- Software Verification of Slab Flexural Design in ETABSDocument7 pagesSoftware Verification of Slab Flexural Design in ETABSAnthony Peña TimoteoNo ratings yet

- 1 Input Data: Anchor Type and Size: Hsl-3 M12 or EquivalentDocument4 pages1 Input Data: Anchor Type and Size: Hsl-3 M12 or EquivalentNp PwNo ratings yet

- Steel Column DesignDocument4 pagesSteel Column Designvsnsfb100% (1)

- Checking torsional stability of a building structure according to DIN provisionsDocument3 pagesChecking torsional stability of a building structure according to DIN provisionspile raftNo ratings yet

- Sheet Pile Design: Fspiii S275 Hot RolledDocument1 pageSheet Pile Design: Fspiii S275 Hot Rolledhessian123No ratings yet

- Kem 607 21Document10 pagesKem 607 21Tese ramonNo ratings yet

- 4.1.5.SP ConnectionDocument30 pages4.1.5.SP ConnectionAnh KyNo ratings yet

- Surveying111111 PDFDocument3 pagesSurveying111111 PDFMark Allen MirasNo ratings yet

- Sample Calculations Sag and Tension UNEVEN Max TempDocument2 pagesSample Calculations Sag and Tension UNEVEN Max TempAgnichandra SubediNo ratings yet

- 1415-CE227 Lab Assg3 Bending StressDocument5 pages1415-CE227 Lab Assg3 Bending StressFintanCanavanNo ratings yet

- AISC DG31 Example 001Document11 pagesAISC DG31 Example 001alejandro mantillaNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- Lab Class Manual 2021Document13 pagesLab Class Manual 2021Xiuming ChenNo ratings yet

- Som 2 16Document48 pagesSom 2 16chakravarthimeNo ratings yet

- Project - Kumbakonam Bioenergy: Ajit Gijare & Associates, PuneDocument2 pagesProject - Kumbakonam Bioenergy: Ajit Gijare & Associates, PunemangeshNo ratings yet

- Analysis of Circular Base Plates with Eccentric LoadsDocument6 pagesAnalysis of Circular Base Plates with Eccentric LoadsThinh ViproNo ratings yet

- Design of 3000mm MS Pipe for Sewerage NetworkDocument9 pagesDesign of 3000mm MS Pipe for Sewerage Networknavneet3bawaNo ratings yet

- Pile Design Calculations and SpecificationsDocument13 pagesPile Design Calculations and SpecificationsTri huỳnh100% (3)

- Software Verification: EXAMPLE Eurocode 2-04 PT-SL-001Document7 pagesSoftware Verification: EXAMPLE Eurocode 2-04 PT-SL-001võ hoàng thái100% (1)

- Review Module 12 Surveying 1 Part 1Document2 pagesReview Module 12 Surveying 1 Part 1Ice DelevingneNo ratings yet

- RC Wall Design (EN1992)Document4 pagesRC Wall Design (EN1992)sinu_emailNo ratings yet

- Chequered PlateDocument23 pagesChequered PlateMythili BysaniNo ratings yet

- Rigid Pavement Design Bowzer WeightDocument6 pagesRigid Pavement Design Bowzer WeightAmmad AlizaiNo ratings yet

- Water Tank DesignDocument5 pagesWater Tank DesignYELLAMANDA SANKATINo ratings yet

- HK Cp-2013 PT-SL Example 001Document6 pagesHK Cp-2013 PT-SL Example 001Aashu chaudharyNo ratings yet

- PT slab design verificationDocument6 pagesPT slab design verificationAashu chaudharyNo ratings yet

- M40 Grade Mix Design for Pier ConstructionDocument3 pagesM40 Grade Mix Design for Pier ConstructionAashu chaudharyNo ratings yet

- PT SLAB VERIFICATIONDocument6 pagesPT SLAB VERIFICATIONAashu chaudharyNo ratings yet

- Project ReportDocument41 pagesProject ReportAashu chaudhary100% (1)

- En 2-2004 RC-SL Example 001Document10 pagesEn 2-2004 RC-SL Example 001Aashu chaudharyNo ratings yet

- All Topic TSC and PSCDocument141 pagesAll Topic TSC and PSCAashu chaudharyNo ratings yet

- Mix Design M-40 GradeDocument2 pagesMix Design M-40 GradePruthvi TejaNo ratings yet

- AR20 Mech 081121Document89 pagesAR20 Mech 081121Aashu chaudharyNo ratings yet

- Certificate For COVID-19 Vaccination: Beneficiary DetailsDocument1 pageCertificate For COVID-19 Vaccination: Beneficiary DetailsAashu chaudharyNo ratings yet

- Earthquake Resistant Design Of Nepal Police Headquarter BeamDocument9 pagesEarthquake Resistant Design Of Nepal Police Headquarter BeamAashu chaudharyNo ratings yet

- AR20 Civil 121121Document96 pagesAR20 Civil 121121Aashu chaudharyNo ratings yet

- Design of Beam Theory (Page 65-66)Document2 pagesDesign of Beam Theory (Page 65-66)Aashu chaudharyNo ratings yet

- AR20 Civil 121121Document96 pagesAR20 Civil 121121Aashu chaudharyNo ratings yet

- Elevator Wall Theory (Page 110)Document1 pageElevator Wall Theory (Page 110)Aashu chaudharyNo ratings yet

- C1 RAILWAY ENGINEERING RajanDocument102 pagesC1 RAILWAY ENGINEERING RajanAashu chaudharyNo ratings yet

- District Technical Office: Maintenance of Nepal Telecom BuildingDocument2 pagesDistrict Technical Office: Maintenance of Nepal Telecom BuildingAashu chaudharyNo ratings yet

- Fly Ash Bricks Project ReportDocument46 pagesFly Ash Bricks Project Reportzilangamba_s4535100% (1)

- Center of Mass and Center of Rigidity Calcuation A4Document1 pageCenter of Mass and Center of Rigidity Calcuation A4Aashu chaudharyNo ratings yet

- ACKNOWLEDGEMENTDocument1 pageACKNOWLEDGEMENTAashu chaudharyNo ratings yet

- 550x550 Column Design (Page 96-101)Document6 pages550x550 Column Design (Page 96-101)Aashu chaudharyNo ratings yet

- Project ReportDocument41 pagesProject ReportAashu chaudhary100% (1)

- Project ReportDocument41 pagesProject ReportAashu chaudhary100% (1)

- 5.5 Transportation Engineering-I (PDF) by Akshay ThakurDocument91 pages5.5 Transportation Engineering-I (PDF) by Akshay ThakurAashu chaudharyNo ratings yet

- Unit 4 Construction of Roads and StressesDocument76 pagesUnit 4 Construction of Roads and StressesAashu chaudharyNo ratings yet

- Civil Engineering Aitam SyllabusDocument209 pagesCivil Engineering Aitam SyllabusAashu chaudharyNo ratings yet

- Remote Sensing&GIS (16CE4025) Unit-IIIDocument58 pagesRemote Sensing&GIS (16CE4025) Unit-IIIAashu chaudharyNo ratings yet

- Unit 4 Construction of Roads and StressesDocument76 pagesUnit 4 Construction of Roads and StressesAashu chaudharyNo ratings yet

- 2.5 PsedoCodeErrorsDocument35 pages2.5 PsedoCodeErrorsAli RazaNo ratings yet

- Ai, Iot, Big Data & BlockchainDocument19 pagesAi, Iot, Big Data & BlockchainClick GroupNo ratings yet

- The Origins Development and Possible Decline of The Modern StateDocument65 pagesThe Origins Development and Possible Decline of The Modern StateJasper Jade MartinNo ratings yet

- Robinair Mod 10324Document16 pagesRobinair Mod 10324StoneAge1No ratings yet

- Profile Shakeel Carpentry Joinery WorksDocument46 pagesProfile Shakeel Carpentry Joinery WorksShakeel Ahmad100% (1)

- Handbook Valve Technology 03.04.2020Document132 pagesHandbook Valve Technology 03.04.2020Ramazan YaşarNo ratings yet

- The Future of Luxury Fashion ReportDocument70 pagesThe Future of Luxury Fashion Reportsalma andjaniNo ratings yet

- Pov Aml Threshold Tuning Qualitative Approach ProtivitiDocument5 pagesPov Aml Threshold Tuning Qualitative Approach Protivitisimha1177No ratings yet

- Nursery Price List - Spring ShadehousesDocument2 pagesNursery Price List - Spring ShadehousesRahul RahuNo ratings yet

- DLL Els Quarter 1 Week 5Document4 pagesDLL Els Quarter 1 Week 5alyssa.ballonNo ratings yet

- SPE 63041 Design and Installation of Sand Separation and Handling SystemDocument10 pagesSPE 63041 Design and Installation of Sand Separation and Handling Systemalexalek2000No ratings yet

- No+bake+ing +vol+iiDocument132 pagesNo+bake+ing +vol+iiEugeny TikhomirovNo ratings yet

- Rubrics For Interd TaskDocument3 pagesRubrics For Interd Taskapi-265986384No ratings yet

- Physical-Science11 Q1 MODULE-1 08082020Document27 pagesPhysical-Science11 Q1 MODULE-1 08082020Cristilyn Briones67% (3)

- CAD32M7 Data SheetDocument2 pagesCAD32M7 Data SheetMehmet EngürNo ratings yet

- Ilang - Ilang LP g7Document6 pagesIlang - Ilang LP g7custodiokeizelNo ratings yet

- India: 1UBK7-470E1Document67 pagesIndia: 1UBK7-470E1harish kumar100% (1)

- Unleashing Learner PowerDocument188 pagesUnleashing Learner PowerEka MeilinaNo ratings yet

- Standards and Their ClassificationsDocument3 pagesStandards and Their ClassificationsJoecelle AbleginaNo ratings yet

- TwinCAT 3 Booklet PDFDocument17 pagesTwinCAT 3 Booklet PDFAlaeddin Ben HammedNo ratings yet

- Test Bank For The Human Body in Health and Disease 7th Edition by PattonDocument11 pagesTest Bank For The Human Body in Health and Disease 7th Edition by PattonLaurence Pence100% (23)

- B. Glo Bal Maxima/MinimaDocument15 pagesB. Glo Bal Maxima/MinimalucasNo ratings yet

- Planning River Intake Structure DesignDocument43 pagesPlanning River Intake Structure DesignSandhiya saravanan100% (1)

- Vray Physical Camera GuideDocument4 pagesVray Physical Camera GuideeoghanobrienNo ratings yet

- Katalog Ag-700 To Ag-800Document1 pageKatalog Ag-700 To Ag-800Iqbal AbugindaNo ratings yet

- Container Generator Qac Qec Leaflet EnglishDocument8 pagesContainer Generator Qac Qec Leaflet EnglishGem RNo ratings yet

- Introduction To HAPDocument6 pagesIntroduction To HAPMaheshSukhadiyaNo ratings yet

- Operation and Safety Manual: Ansi As/NzsDocument116 pagesOperation and Safety Manual: Ansi As/NzsMuhammad AwaisNo ratings yet

- Scope of Work - Upgrade Power Grid - Isa Air Base PDFDocument32 pagesScope of Work - Upgrade Power Grid - Isa Air Base PDFHussain AljafariNo ratings yet

- P90X2 Les Mills PUMP HybridDocument7 pagesP90X2 Les Mills PUMP HybridRamonBeltranNo ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionFrom EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionRating: 3.5 out of 5 stars3.5/5 (129)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- ChatGPT: The Future of Intelligent ConversationFrom EverandChatGPT: The Future of Intelligent ConversationRating: 3.5 out of 5 stars3.5/5 (8)