Professional Documents

Culture Documents

Strength Characteristic of Lateritic Soil Replaced by Recycled Asphalt Pavement IJERTV8IS050382

Uploaded by

Rabnawaz ImamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strength Characteristic of Lateritic Soil Replaced by Recycled Asphalt Pavement IJERTV8IS050382

Uploaded by

Rabnawaz ImamCopyright:

Available Formats

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 8 Issue 05, May-2019

Strength Characteristic of Lateritic Soil Replaced

by Recycled Asphalt Pavement

Weeraya Chimoye Tustha Sriwalai

Associate Prof. School of Engineering, Thammasat University

School of Engineering, Thammasat University Phatumthani, Thailand

Phatumthani, Thailand

Abstract— The objective of this project is to study the physical, and subbase layers [2,3,4]. The objective of this research is to

compaction, and strength properties of lateritic soil, recycled study the strength characteristic of lateritic soil replaced by the

asphalt, and the combination of them according to subbase recycled asphaltic pavement (RAP). The effect of RAP on

material standard of Department of Highways, DH.-S 205/2532. compaction behavior, strength and swelling were investigated.

The used lateritic soil is selected material which the grain size

distribution base on the standard of Type A, Type B, and Type

E. The lateritic soil Type E was mixed with the recycled asphalt II. MATERIALS USE

pavement (RAP) to be material ARAP and BRAP. The modified

compaction test of all five types of the material were carried out. A. Lateritic Soil

It is found that the RAP can improve the compaction behavior The lateritic soil used in this research is the selected grain

of the lateritic soil. The maximum dry density increased and the

size in order to classify as Type A, Type B and Type E

optimum water content decreased when mixed with the RAP.

The compacted all materials were prepared for CBR test with according to subbase material standard of Department of

95% of maximum dry density with optimum water content and Highways, DH.-S 205/2532 of Thailand [5]. The grain size

optimum water content+2%. It is found that the CBR of the distributions of each types are shown in Fig. 1. The nature of

mixed material decreased rapidly when compared with the same the lateritic soil is shown in Fig. 2. The lateritic soil has liquid

type of lateritic soil. It can be seen that recycled asphalt limit as 29.8%, plastic limit as 19.6% and plasticity index as

pavement cannot improve the strength of the lateritic soil. This 10.2% which pass the criteria of the subbase standard. The

cause by size of the recycled asphalt pavement is the size of specific gravity is 2.72.

packed gravel by asphalt and break out to be smaller size after

compaction. Compared with the subbase standard, the unsoaked

CBR of all types of materials were higher than 25 which passed

B. Recycled asphalt pavements (RAP)

the standard. The recycled asphalt pavements were supplied from the

Daokanong – ThaRue Highway as shown in Fig. 3. The

Keywords—Recycled concrete, recycled asphalt pavement, asphaltic pavement was Wearing course standard mixed with

lateritic soil, subbase 60 – 70 penetration grade of Industrial standard of Thailand.

The RAP was selected by sieving passing 1” and retained on

I. INTRODUCTION 3/8”.

In highway or road construction, the lateritic soil or

crushed rock are commonly used as the embankment fill or III. METHODOLOGY

subbase materials. For the pavement, both asphaltic pavement

(AP) and concrete pavement (CP) are typical pavements for The lateritic soil Type E were mixed with RAP to be the

highway or rural road in Thailand. With the construction Type A and B as the same grain size distribution as shown in

growth for urban area development, tremendous amounts of Fig.1, named ARAP and BRAP respectively. The RAP was

natural materials are consumed in urban industry and huge sieved with the selected grained size as Type A. The lateritic

energy is used. And also the amount of waste materials soil and the lateritic soil mixed with the RAP and the RAP

generated from road maintenance or re-constructed during were compacted with modified standard. The behavior of the

service period is increasing. The construction solid waste compaction curves is shown in Fig. 4. The maximum dry

materials have become one of the main concerns of the densities (dmax) and the optimum water contents (OPT) of all

environmental concern. Reusing recycled construction and types of material were shown in Table 1. It can be seen that

demolition (C&D) materials in transportation infrastructure the RAP can be compacted with least optimum water content

construction can benefit environmental and economic aspects. and highest maximum dry density. The RAP can improve the

The utilization of the recycled construction materials has been compaction property of the lateritic soil by increasing the

considered as a significant solution to minimize the use of maximum dry density and decreasing the optimum water

natural resources and reduce the cost for waste management. content. From the results of the compaction, the unsoaked and

[1]. There are at least 3 advantages to use recycled soaked CBR of all types of material were test at optimum

construction material as natural resource preservation, water content and optimum water content + 2% and the dry

construction expense reduce due to the transportation and density over than 95% of maximum dry density. For each

reduction of the accumulated C&D waste materials in deposits condition, two samples were tested for repeated. Fig. 5 shows

[2]. Recently recycled asphaltic pavement (RAP) either, itself the dry density of all CBR samples which pass the criteria of

or stabilized with cement have been studied for used as base testing.

IJERTV8IS050382 www.ijert.org 596

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 8 Issue 05, May-2019

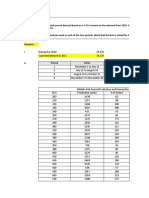

TABLE I. MAXIMUM DRY DENSITY AND OPTIMUM WATER

CONTENT

Type

Soil dmax OPT

condition g/cm3 %

Type A Lateritic soil 1.956 9.6

Type B Lateritic soil 1.940 10.2

Type E Lateritic soil 1.894 12.0

Type E +

ARAP 2.044 7.9

RAP

Type E +

BRAP 1.996 9.8

RAP

RAP RAP 2.092 6.9

Fig. 1 Grain size of selected soil Type A, B and E.

Fig. 2 The natural lateritic soil.

Fig. 5 Dry density of all CBR samples.

IV. RESULTS

A. Compaction tests

Fig. 6 shows the maximum dry density of all types of

material. It is found that the maximum dry densities of the

lateritic soil increased when mixed with recycled asphalt

pavement. For the optimum water content, it is found that the

optimum water content decreased when mixed with recycled

asphalt as shown in Fig. 7. It means the recycled asphalt

Fig. 3 The recycled asphalt pavement. pavement can improve the compaction behavior of the lateritic

soil.

Fig. 4 Compaction curve of lateritic soil mixed with RAP

Fig. 6 Maximum dry density with type of material

IJERTV8IS050382 www.ijert.org 597

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 8 Issue 05, May-2019

TABLE II. CBR VALUE OF ALL MATERIAL

CBR

Type Condition

OPT OPT+2%

Unsoaked 1 62.58 26.55

Unsoaked 2 79.65 22.76

Type A

Soaked 1 51.20 16.12

Soaked 2 60.69 18.96

Unsoaked 1 66.38 27.50

Unsoaked 2 60.69 29.40

Type B

Soaked 1 45.51 19.91

Soaked 2 53.10 22.76

Fig. 7 Optimum water content with type of material

Unsoaked 1 49.31 18.96

B. CBR Unsoaked 2 53.10 15.17

Type E

Fig. 8 and 9 shows the typical stress-penetration Soaked 1 32.24 7.11

relationship from the CBR test of Type A and ARAP,

Soaked 2 30.34 7.68

respectively. It can be seen that the stress-penetration curve of

the lateritic soil mixed with RAP is flatter than that of lateritic Unsoaked 1 45.51 17.07

soil. This means that the RAP does not improve the strength Unsoaked 2 29.40 8.53

of the lateritic soil. Table 2 shows the value of CBR of all ARAP

types of the material. Soaked 1 24.65 10.62

Soaked 2 28.45 8.72

Unsoaked 1 26.55 8.53

Unsoaked 2 28.45 7.78

BRAP

Soaked 1 21.81 6.16

Soaked 2 21.81 4.74

Unsoaked 1 29.40 22.76

Unsoaked 2 37.93 32.24

RAP

Soaked 1 22.76 30.34

Soaked 2 30.34 26.55

From the CBR results it can be seen that when mixed the

RAP with the lateritic soil, both to be ARAP or BRAP, the

Fig. 8 Stress-penetration from CBR test of Type A CBR decreased that means the RAP did not improve the

strength of lateritic soil [2]. This cause by the grain size of the

RAP is packed due to the asphalt at the initial and it is broken

after compacted as shown in Fig. 10. The grain size

distribution of the ARAP and BRAP after CBR test has more

fine grain especially the percent finer of 3/8” increases rapidly

from the grain size before test. When the asphalt was removed

from the RAP, it is found that the percent asphalt was about

20% and the grain size of RAP is in the range of 12.5 mm for

pavement standard which means the actual size of particle is

less than 12.5mm. The CBR of OPT+2% of all conditions

decreased rapidly compared with that of OPT except for RAP

case. Since the RAP has a little fine particle and no plasticity

so when compact with the high water content, the water came

out as the surface of the sample as shown in Fig. 11.

Compared with the subbase and base material standard of

Department of Highways, the CBR of the all conditions did

not pass the base material standard. For the unsoaked sample,

Fig. 9 Stress-penetration from CBR test of ARAP

in case of optimum water content of all conditions, the CBRs

IJERTV8IS050382 www.ijert.org 598

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 8 Issue 05, May-2019

were more than 25 which passed the subbase material

standard. For others condition, the CBRs were about 25 and

less which not pass the standard as shown in Fig. 12.

C. Swelling of samples

Fig. 13 shows swelling of the soaked CBR sample. It can

be seen that the swelling of all the cases are quite low less

than 0.6%. The swelling of lateritic soil Type E is the highest

with the large difference between OPT samples and OPT+2%

samples. Since the lateritic soil Type E contained with high

amount of fine grained soil. For the RAP, there is no swelling

since it has no plasticity and has small about of fine grain soil.

Fig. 13 Swelling of the soaked sample.

V. CONCLUSION

From the results, it can be concluded that

1. The RAP can improve the compaction properties of the

lateritic soil by increasing the maximum dry density and

decreasing the optimum water content.

2. The RAP did not improve the strength of the lateritic soil.

The CBR of lateritic soil mixed with RAP decreased when

compare with the lateritic soil itself. The RAP reduced the

swelling of the lateritic soil in case of OPT, but has little

effect with OPT +2%.

3. Compared with the subbase standard of Highway

Department, it is found that the unsoaked CBRs of all

condition with OPT were higher than 25% which passed

Fig. 10 Grain size distribution before and after CBR test. the standard. For soaked CBR with OPT, almost all

condition passed the standard, except BRAP type. For the

condition of OPT+2%, the CBRs of all the conditions did

not pass the standard.

ACKNOWLEDGMENT

Authors would like to thank Mr.Sanhant Dulpinitthamma

and Mr.Apidet Tunvutgijaroen for carry out the laboratory

test. Authors also acknowledge Faculty of Engineering,

Thammasat University for facilitating for the laboratory

a) CBR sample at OPT b) CBR sample at OPT+2% equipment.

Fig. 11 CBR sample of RAP

REFERENCES

[1] M. Arshat and M.F. Ahmed, “Potential use of reclaimed asphalt

pavement and recycled concrete aggregate in base/subbase layers of

flexible pavements” Construction and Building Materials, 151, pp. 83-

97, 2017.

[2] J. Suebsuk, B. Khunviset, A. Sukhsan, C. Suksiripattanapong and K.

Chaidechatorn, “Unconfined compressive strength and microstructure

of marginal lateritic soil improved by recycled asphalt pavement and

cement” Ladkrabang Engineering Journal, Vol. 33, No.2, pp. 111-116,

2016.

[3] S. Fatemi and R. Imaninasab, “Performance evaluation of recycled

asphalt mixtures by construction and demolition waste materials”

Construction and Building Materials, 120, pp. 450-456, 2016

[4] A. Arulrajah, M.M. Disfani, S. Horpibulsuk and C. Suksiripattanapong,

“Physical properties and shear strength responses of recycled

construction and demolition materials in unbound pavement

base/subbase applications” Construction and Building Materials, 58,

pp. 245-257, 2014

[5] Department of Highway, “Stardard No. DH-S 205/2532 Highway

subbase material, 1989.

Fig. 12 CBR of all samples.

IJERTV8IS050382 www.ijert.org 599

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

You might also like

- Athletic KnitDocument31 pagesAthletic KnitNish A0% (1)

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Botswana Ref Ranges PaperDocument7 pagesBotswana Ref Ranges PaperMunyaradzi MangwendezaNo ratings yet

- Performance of Recycled Asphalt Mixtures Formulated With Modified BitumenDocument9 pagesPerformance of Recycled Asphalt Mixtures Formulated With Modified BitumenPhearüm PotNo ratings yet

- JETIR1901809Document5 pagesJETIR1901809Nirman rodNo ratings yet

- Bitumen Modification With Waste Plastic and Crumb Rubber: Athira R Prasad, DR Sowmya N JDocument6 pagesBitumen Modification With Waste Plastic and Crumb Rubber: Athira R Prasad, DR Sowmya N JDejan MilosavljevicNo ratings yet

- Characterization of Indian Reclaimed Asphalt Pavement (Rap) On The Basis of Sources of Rap and Gradation Characteristics of Rap AggregatesDocument7 pagesCharacterization of Indian Reclaimed Asphalt Pavement (Rap) On The Basis of Sources of Rap and Gradation Characteristics of Rap AggregatesAnil YadavaNo ratings yet

- A Laboratory Investigation On Dense Bituminous Macadam Containing Different Fractions of Coars and Fine RAPDocument12 pagesA Laboratory Investigation On Dense Bituminous Macadam Containing Different Fractions of Coars and Fine RAPRobel TeweldeNo ratings yet

- An Experimental Investigation On PartialDocument5 pagesAn Experimental Investigation On PartialAzhar MohamedNo ratings yet

- Improvement of Geotechnical Properties oDocument5 pagesImprovement of Geotechnical Properties obature bunieNo ratings yet

- Performance of Recycled Asphalt Pavement As Coarse Aggregate in ConcreteDocument12 pagesPerformance of Recycled Asphalt Pavement As Coarse Aggregate in ConcreteBrayan Stiven VIVIESCA GIRALDO100% (1)

- Mix Design of DBM With Rap Aggregates Construction Materials IJERTCONV11IS02019Document9 pagesMix Design of DBM With Rap Aggregates Construction Materials IJERTCONV11IS02019bineetmishra1990No ratings yet

- Study On Strength Characteristics of River Sand in Combination With Cement and Waste Tire Rubber Chips IJERTV3IS040513Document5 pagesStudy On Strength Characteristics of River Sand in Combination With Cement and Waste Tire Rubber Chips IJERTV3IS040513Amanulla KhanNo ratings yet

- Minor ProjectDocument30 pagesMinor ProjectSanjayChauhanNo ratings yet

- Use of Waste Tyres in Road ConstructionDocument11 pagesUse of Waste Tyres in Road Constructionvotetorecieve 1100% (1)

- Effect of Nano Chemicals On The Shear Strength Properties of SoilsDocument6 pagesEffect of Nano Chemicals On The Shear Strength Properties of SoilsAkolade adebolaNo ratings yet

- Laboratory Investigation of The Performances of Cement and y Ash Modified Asphalt Concrete MixturesDocument8 pagesLaboratory Investigation of The Performances of Cement and y Ash Modified Asphalt Concrete MixturesMan ManNo ratings yet

- Utilization of Higher Percentages of RAP For Improved Mixture Performance by Adopting The Process of FractionationDocument18 pagesUtilization of Higher Percentages of RAP For Improved Mixture Performance by Adopting The Process of Fractionationvishnu RNo ratings yet

- Technical Seminar Report On PAPERCRETE FINALDocument8 pagesTechnical Seminar Report On PAPERCRETE FINALaditya100% (3)

- Content ServerDocument16 pagesContent Servercinthya tesen bravoNo ratings yet

- Physical Properties of Reclaimed Asphalt PavementDocument10 pagesPhysical Properties of Reclaimed Asphalt PavementAmanulla KhanNo ratings yet

- The Effects of Brick and Gypsum Mix On Weak Subgrade Soil and The Optimum Mix To Be Added To Improve The Soil Strength, EthiopiaDocument6 pagesThe Effects of Brick and Gypsum Mix On Weak Subgrade Soil and The Optimum Mix To Be Added To Improve The Soil Strength, EthiopiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Icid-2018 Te 201Document4 pagesIcid-2018 Te 201vara prasadNo ratings yet

- Crumb Rubber Modified Bitumen and Quarry Dust in Flexible PavementsDocument7 pagesCrumb Rubber Modified Bitumen and Quarry Dust in Flexible PavementsaiplNo ratings yet

- Use of Natural Rubber Latex (NRL) in Improving Properties of Reclaimed Asphalt Pavement (RAP)Document10 pagesUse of Natural Rubber Latex (NRL) in Improving Properties of Reclaimed Asphalt Pavement (RAP)Kongsak AkkharawongwhatthanaNo ratings yet

- PDFDocument7 pagesPDFRaka AdityaNo ratings yet

- A Critical Review On Performance of Flexible Pavement Using HDPE and Crumb Rubber Ijariie12781Document9 pagesA Critical Review On Performance of Flexible Pavement Using HDPE and Crumb Rubber Ijariie12781Romil SharmaNo ratings yet

- A Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionDocument11 pagesA Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionIJRASETPublications100% (1)

- Journal Bitumen Roof 3Document15 pagesJournal Bitumen Roof 3Fai's AlDahlanNo ratings yet

- Utilization of Scrap Tyre Rubber in The Form of Aggregates As Partial Exchange With Existing AggregatesDocument8 pagesUtilization of Scrap Tyre Rubber in The Form of Aggregates As Partial Exchange With Existing AggregatesEditor IJTSRDNo ratings yet

- Review On Partial Replacement of Cement in ConcretDocument6 pagesReview On Partial Replacement of Cement in ConcretElmeerajh JudavarNo ratings yet

- 28 Article - 1519799495 (Yomi Emer Tarekegn)Document42 pages28 Article - 1519799495 (Yomi Emer Tarekegn)emer_quezonNo ratings yet

- Stabilization of Subgrade Soil Using Reclaimed Asphalt Pavement (RAP)Document6 pagesStabilization of Subgrade Soil Using Reclaimed Asphalt Pavement (RAP)Rabnawaz ImamNo ratings yet

- Bituminous Pavement RecyclingDocument4 pagesBituminous Pavement RecyclingMatei PopaNo ratings yet

- Cold In-Place Recycling Using Foamed Bitumen - Step Towards Sustainable Road ConstructionDocument14 pagesCold In-Place Recycling Using Foamed Bitumen - Step Towards Sustainable Road ConstructionBijay Krishna DasNo ratings yet

- Utilization of Red Mud As An Alternative Filler in Asphalt Mastic To Replace Naural Limestone PowderDocument11 pagesUtilization of Red Mud As An Alternative Filler in Asphalt Mastic To Replace Naural Limestone PowderRam VermaNo ratings yet

- Construction and Building Materials: Xunhao Ding, Luchuan Chen, Tao Ma, Haixia Ma, Linhao Gu, Tian Chen, Yuan MaDocument6 pagesConstruction and Building Materials: Xunhao Ding, Luchuan Chen, Tao Ma, Haixia Ma, Linhao Gu, Tian Chen, Yuan MaCamila GómezNo ratings yet

- Infrastructures 07 00066Document18 pagesInfrastructures 07 00066ksjmoon28No ratings yet

- 2015 Utilization of Waste Plastic Water Bottle As A Modifier For Asphalt Mixture PropertiesDocument20 pages2015 Utilization of Waste Plastic Water Bottle As A Modifier For Asphalt Mixture PropertiesKhalil ZaaimiaNo ratings yet

- Experimental Study On Rice Husk Ash in Concrete by Partial ReplacementDocument9 pagesExperimental Study On Rice Husk Ash in Concrete by Partial ReplacementvenkateshNo ratings yet

- Chapter One: 1.1. Problem StatementDocument11 pagesChapter One: 1.1. Problem StatementetayhailuNo ratings yet

- Flyash Based Paper Slurry Building Bricks - An ExpeDocument8 pagesFlyash Based Paper Slurry Building Bricks - An Expe348 Harshal bhoiNo ratings yet

- Jeas 0318 6835Document8 pagesJeas 0318 6835Ram Chandra MeenaNo ratings yet

- Laboratory Investigation of RAP For Various Layers of Flexible and Concrete PavementDocument15 pagesLaboratory Investigation of RAP For Various Layers of Flexible and Concrete PavementAbinash Chandra PalNo ratings yet

- Jurnal TeknologiDocument8 pagesJurnal TeknologiIgbinwole Kehinde SolomonNo ratings yet

- Ijresm V4 I6 41Document6 pagesIjresm V4 I6 41Civil Engineering DepartmentNo ratings yet

- Effect of Polythene Modified Bitumen On Properties of Hot Mix AsphaltDocument6 pagesEffect of Polythene Modified Bitumen On Properties of Hot Mix Asphaltsaurabh agrahariNo ratings yet

- UntitledDocument16 pagesUntitledsuneet kuma meenaNo ratings yet

- Journal Printabs 4haug14esrDocument11 pagesJournal Printabs 4haug14esrBruno CarleteNo ratings yet

- Beerappa 14 ETCE001007Document10 pagesBeerappa 14 ETCE001007Beerappa RamakrishnaNo ratings yet

- Improving Rutting Resistance of Flexible PavementDocument9 pagesImproving Rutting Resistance of Flexible PavementRudra PratapNo ratings yet

- Tyre For ConcreteDocument4 pagesTyre For ConcreteNoble Obeng-AnkamahNo ratings yet

- Soil Stabilization Using Industrial Waste and LimeDocument7 pagesSoil Stabilization Using Industrial Waste and Limeijsret100% (1)

- Shear Strength and Permeability of Bentonite Blended Clay LinerDocument5 pagesShear Strength and Permeability of Bentonite Blended Clay LinerGJESRNo ratings yet

- George 2019Document12 pagesGeorge 2019B RAMUNo ratings yet

- Gireesh Kumar 2020 IOP Conf. Ser. Mater. Sci. Eng. 1006 012041Document7 pagesGireesh Kumar 2020 IOP Conf. Ser. Mater. Sci. Eng. 1006 012041Mallesh MaranurNo ratings yet

- .Experimental Study On Characterization of Bitumen Mixed With Plastic WasteDocument7 pages.Experimental Study On Characterization of Bitumen Mixed With Plastic WasteCivil StructureNo ratings yet

- Ijirstv2i12066 3Document7 pagesIjirstv2i12066 3Sundar GaneshNo ratings yet

- Stabilization of Soil Using Cement and Bale Straw-IJAERDV05I0939611Document6 pagesStabilization of Soil Using Cement and Bale Straw-IJAERDV05I0939611afnan ahmadNo ratings yet

- 2021 - ARTIGO - Blocos de Solo-Cimento de Laterita Modificados Com Látex de Borracha NaturalDocument8 pages2021 - ARTIGO - Blocos de Solo-Cimento de Laterita Modificados Com Látex de Borracha NaturalAmanda AguiarNo ratings yet

- Evaluation of Reclaimed Polyethylene Modified Asphalt Concrete MixturesDocument10 pagesEvaluation of Reclaimed Polyethylene Modified Asphalt Concrete MixturesMa VeloNo ratings yet

- Bitum MəqaləDocument6 pagesBitum Məqaləf.maharramovaNo ratings yet

- Plasticity, Strength and Permeability of Reclaimed Asphalt Pavement and Lateritic Soil BlendsDocument6 pagesPlasticity, Strength and Permeability of Reclaimed Asphalt Pavement and Lateritic Soil BlendsRabnawaz ImamNo ratings yet

- Laterite Mix With RecycleDocument11 pagesLaterite Mix With RecycleRabnawaz ImamNo ratings yet

- Laterite Mix With RecycleDocument11 pagesLaterite Mix With RecycleRabnawaz ImamNo ratings yet

- Stabilization of Subgrade Soil Using Reclaimed Asphalt Pavement (RAP)Document6 pagesStabilization of Subgrade Soil Using Reclaimed Asphalt Pavement (RAP)Rabnawaz ImamNo ratings yet

- Strength Characteristic of Lateritic Soil Replaced by Recycled Asphalt Pavement IJERTV8IS050382Document4 pagesStrength Characteristic of Lateritic Soil Replaced by Recycled Asphalt Pavement IJERTV8IS050382Rabnawaz ImamNo ratings yet

- Plasticity, Strength and Permeability of Reclaimed Asphalt Pavement and Lateritic Soil BlendsDocument6 pagesPlasticity, Strength and Permeability of Reclaimed Asphalt Pavement and Lateritic Soil BlendsRabnawaz ImamNo ratings yet

- tg2 August 2020 PDFDocument221 pagestg2 August 2020 PDFBradley HariramNo ratings yet

- Stabilization of Subgrade Soil Using Reclaimed Asphalt Pavement (RAP)Document6 pagesStabilization of Subgrade Soil Using Reclaimed Asphalt Pavement (RAP)Rabnawaz ImamNo ratings yet

- Parapet Wall Extension - MethodologyDocument2 pagesParapet Wall Extension - MethodologyRabnawaz ImamNo ratings yet

- Method Statement For Hume Pipe CulvertDocument6 pagesMethod Statement For Hume Pipe CulvertRabnawaz Imam0% (1)

- Method Statement For Wet Mix MacadamDocument6 pagesMethod Statement For Wet Mix MacadamRabnawaz ImamNo ratings yet

- MISSION-GATE 2021 FinalDocument30 pagesMISSION-GATE 2021 FinalRabnawaz ImamNo ratings yet

- TUV India Classroom Calendar From October To December 2021Document9 pagesTUV India Classroom Calendar From October To December 2021Rabnawaz ImamNo ratings yet

- Concrete Mixed Design Method (BS Method)Document11 pagesConcrete Mixed Design Method (BS Method)CocoNo ratings yet

- Parapet Wall Extension - MethodologyDocument2 pagesParapet Wall Extension - MethodologyRabnawaz ImamNo ratings yet

- Parapet Wall Extension - MethodologyDocument2 pagesParapet Wall Extension - MethodologyRabnawaz ImamNo ratings yet

- QAP-Rev Muthu's FinalDocument59 pagesQAP-Rev Muthu's FinalRabnawaz ImamNo ratings yet

- Form Work, Reinforcement & Concreting - MethodologyDocument10 pagesForm Work, Reinforcement & Concreting - MethodologyRabnawaz ImamNo ratings yet

- NP4 Pipe Installation and Backfill - MethodologyDocument4 pagesNP4 Pipe Installation and Backfill - MethodologyRabnawaz Imam100% (1)

- Form Work, Reinforcement & Concreting - MethodologyDocument10 pagesForm Work, Reinforcement & Concreting - MethodologyRabnawaz ImamNo ratings yet

- Career Opportunities in Civil EngineeringDocument39 pagesCareer Opportunities in Civil EngineeringRabnawaz ImamNo ratings yet

- Compression Testing MachineDocument2 pagesCompression Testing MachineRabnawaz ImamNo ratings yet

- Wheel Tracker Large DeviceDocument3 pagesWheel Tracker Large DeviceRabnawaz ImamNo ratings yet

- 12-MS For Drain Work Cast in Situ & Pre-Cast R1Document25 pages12-MS For Drain Work Cast in Situ & Pre-Cast R1Rabnawaz ImamNo ratings yet

- Method Statement For Construction of Hume Pipe Culvert WorksDocument23 pagesMethod Statement For Construction of Hume Pipe Culvert WorksRabnawaz ImamNo ratings yet

- Ms For Box Culverts - R3Document22 pagesMs For Box Culverts - R3Rabnawaz ImamNo ratings yet

- Ms For Major Bridges-R2Document52 pagesMs For Major Bridges-R2Rabnawaz ImamNo ratings yet

- Method Statement For WMMDocument6 pagesMethod Statement For WMMRabnawaz Imam100% (1)

- Method Statement For BCDocument4 pagesMethod Statement For BCRabnawaz ImamNo ratings yet

- Do or Does1.1.2Document4 pagesDo or Does1.1.2dzanardipintoNo ratings yet

- Upload A Document To Access Your Download: Social Studies of HealthDocument3 pagesUpload A Document To Access Your Download: Social Studies of Health1filicupENo ratings yet

- Pratham Bhardwaj: Education SkillsDocument1 pagePratham Bhardwaj: Education SkillsashuNo ratings yet

- Dampak HidrokarbonDocument10 pagesDampak HidrokarbonfikririansyahNo ratings yet

- MKTG4471Document9 pagesMKTG4471Aditya SetyaNo ratings yet

- Conflict Management and Negotiation - Team 5Document34 pagesConflict Management and Negotiation - Team 5Austin IsaacNo ratings yet

- The SU Electric Fuel Pump Type Car Reference List AUA 214Document4 pagesThe SU Electric Fuel Pump Type Car Reference List AUA 214Anonymous aOXD9JuqdNo ratings yet

- Body ImageDocument7 pagesBody ImageCristie MtzNo ratings yet

- What Is Degrowth - Demaria Schneider Sekulova Martinez Alier Env ValuesDocument27 pagesWhat Is Degrowth - Demaria Schneider Sekulova Martinez Alier Env ValuesNayara SantosNo ratings yet

- Chapter 4 Higher Order Differential EquationsDocument50 pagesChapter 4 Higher Order Differential EquationsAlaa TelfahNo ratings yet

- Journal of Exceptional Experiences and PDocument62 pagesJournal of Exceptional Experiences and Pbinzegger100% (1)

- Singleton v. Cannizzaro FILED 10 17 17Document62 pagesSingleton v. Cannizzaro FILED 10 17 17Monique Judge100% (1)

- Etsi en 300 019-2-2 V2.4.1 (2017-11)Document22 pagesEtsi en 300 019-2-2 V2.4.1 (2017-11)liuyx866No ratings yet

- A Manual For A Laboratory Information Management System (Lims) For Light Stable IsotopesDocument131 pagesA Manual For A Laboratory Information Management System (Lims) For Light Stable IsotopesAlvaro Felipe Rebolledo ToroNo ratings yet

- Project Definition and DescriptionDocument9 pagesProject Definition and DescriptionEileen VelasquezNo ratings yet

- On Evil - Terry EagletonDocument44 pagesOn Evil - Terry EagletonconelcaballocansadoNo ratings yet

- Amit Singh RF EngineerDocument3 pagesAmit Singh RF EngineerAS KatochNo ratings yet

- King of Chess American English American English TeacherDocument6 pagesKing of Chess American English American English TeacherJuliana FigueroaNo ratings yet

- Creole LanguagesDocument2 pagesCreole LanguagesClaire AlexisNo ratings yet

- Electric Car Project Proposal by SlidesgoDocument46 pagesElectric Car Project Proposal by Slidesgoayusht7iNo ratings yet

- German Employment Visa Application: What Is A German Work Visa and Do I Need One?Document4 pagesGerman Employment Visa Application: What Is A German Work Visa and Do I Need One?FarbodNo ratings yet

- Keong Mas ENGDocument2 pagesKeong Mas ENGRose Mutiara YanuarNo ratings yet

- Assignment 2 Format Baru 17042011Document8 pagesAssignment 2 Format Baru 17042011Noor Zilawati SabtuNo ratings yet

- Excel For MAC Quick Start GuideDocument4 pagesExcel For MAC Quick Start GuideMalaquías HuamánNo ratings yet

- Teaching English in The Elementary Grades (Language Arts)Document21 pagesTeaching English in The Elementary Grades (Language Arts)RENIEL PABONITANo ratings yet

- Affin Bank V Zulkifli - 2006Document15 pagesAffin Bank V Zulkifli - 2006sheika_11No ratings yet

- Defender of Catholic FaithDocument47 pagesDefender of Catholic FaithJimmy GutierrezNo ratings yet

- Rhipodon: Huge Legendary Black DragonDocument2 pagesRhipodon: Huge Legendary Black DragonFigo FigueiraNo ratings yet