Professional Documents

Culture Documents

Barc 303 - Architectural Building Construction

Uploaded by

22Patil RiyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Barc 303 - Architectural Building Construction

Uploaded by

22Patil RiyaCopyright:

Available Formats

BARC 303 – ARCHITECTURAL BUILDING CONSTRUCTION

BARC 303

Question No.-01

What are the types of foundations and specify the criteria for suitable

foundation systems. (Support your answers with suitable sketches).

Foundations are divided into two categories, - shallow and deep foundations. The terms

Shallow and Deep Foundation refer to the depth of the soil at which it is placed. Generally, if

the width of the foundation is greater than the depth, it is labeled as the Shallow Foundation. If

the width is smaller than the depth of the foundation it is called as Deep Foundation.

SHALLOW FOUNDATION

As the shallow foundation depth is low and it is economical, it is the most popular type of foundation for

lightweight structure.

1. ISOLATED SPREAD FOOTING:

Individual footing or an isolated footing is the most common type of foundation used for building

construction. This foundation is constructed for a single column and also called a pad foundation. They

straightforwardly transfer the loads from the column to the soil. It might be rectangular, square, or

roundabout. It can comprise both reinforced or non-reinforced material.

TYPES OF ISOLATED FOOTING ARE:

1) Flat, Pad or Plain footing.

2) Sloped footing.

3) Steeped footing

CRITERIA:

The load of the structure is relatively low.

Columns are not closely placed.

RIYA YOGESH PATIL

ROLL NO.: 20 1

BARC 303

The bearing capacity of the soil is high at a shallow depth.

ADVANTAGES:

Economic

Shallow pad foundation requires less excavation.

Size and shape can be varied depending on site condition.

DISADVANTAGES:

Foundation size may become very large depending on the loads.

Weak against uplift force and lateral forces.

RIYA YOGESH PATIL

ROLL NO.: 20 2

BARC 303

2. COMBINED FOOTING:

Combined footing is constructed when two or more columns are close enough and their

isolated footings overlap each other. It is a combination of isolated footings, but their structural

design differs. The shape of this footing is a rectangle and is used when loads from the structure

is carried by the columns.

TYPES OF COMBINED FOOTING ARE:

1) Rectangular combined footing

2) Trapezoidal combined footing

3) Continuous footing

CRITERIA:

The columns are placed close to each other.

When the column is close to the property line and the isolated footing would cross the

property line or become eccentric.

Dimensions of one side of the footing are restricted to some lower value.

ADVANTAGE:

Cost (affordable) construction is simple material is mostly concrete.

DISADVANTAGE:

Settlement , limit capacity , irregular ground surface , foundation subjected to pull out

RIYA YOGESH PATIL

ROLL NO.: 20 3

BARC 303

3. WALL FOOTING OR STRIP FOOTING:

Wall footing is also known as continuous footing. This type is used to distribute loads of

structural or non- structural load-bearing walls to the ground in such a way that the load-

bearing limit of the soil isn't outperformed. It runs along the direction of the wall. The width of

the wall foundation is usually 2-3 times the width of the wall. The wall footing is a continuous

slab strip along the length of the wall. Stone, brick, reinforced concrete, etc. are used for the

construction of wall foundations.

CRITERIA:

Loads to be transmitted are of small magnitude.

It is placed on dense sand and gravel.

ADVANTAGES:

Ability to withstand great loads.

Easy to build, no special training requirements for personnel.

Very long service life.

They have subtypes from which you can choose the one you need for particular purposes.

RIYA YOGESH PATIL

ROLL NO.: 20 4

BARC 303

The price is much lower than that of cast-in-situ structures, although strip foundations are

not inferior to them in strength.

You can insulate the floors much better if you use a strip foundation.

DISADVANTAGES:

Not suitable for every soil type.

You have to fill all the lot in one go, but preparing such an amount of concrete on your own

is quite problematic.

There is quite a decent amount of work with pouring the concrete, so you can’t do without

help.

RIYA YOGESH PATIL

ROLL NO.: 20 5

BARC 303

4. CANTILEVER OR STRAP FOOTING:

Strap footings are similar to combined footings. Reasons for considering or choosing strap

footing are identical to the combined one. In strap footing, the foundation under the columns is

built individually and connected by a strap beam. Generally, when the edge of the footing

cannot be extended beyond the property line, the exterior footing is connected by a strap

beam with interior footing

CRITERIA:

It is used when the distance between the columns is so great that a combined trapezoidal

footing becomes quite narrow, with high bending moments.

Strap footing When the independent footings of two columns are connected by a beam, it is

called a strap footing.

RIYA YOGESH PATIL

ROLL NO.: 20 6

BARC 303

5. RAFT OR MATT FOUNDATION:

Raft or mat foundations are the types of foundation which are spread across the entire area of

the building to support heavy structural loads from columns and walls. The use of mat

foundation is for columns and walls foundations where the loads from the structure on columns

and walls are very high. Raft foundation is economical when one-half area of the structure is

covered with individual footings and wall footings are provided.These foundations should not

be used where the groundwater table is above the bearing surface of the soil. The use of

foundation in such conditions may lead to scour and liquefaction.

CRITERIA:

The soil is weak and the load has to be spread over a large area.

The structure includes a basement.

Columns are closely placed.

Other kinds of foundations are not feasible.

Differential settlement is to be prevented.

ADVANTAGES:

Mat foundation can be provided where the shallow foundation is necessary but soil

condition is poor.

It resists differential settlement.

Mat foundation requires less earth excavation.

Mat foundation itself can be considered as a floor slab. So it reduces the cost of

constructing floor slab.

Distribute loads over a larger area.

DISADVANTAGES:

Prone to edge erosion.

RIYA YOGESH PATIL

ROLL NO.: 20 7

BARC 303

Special measurements are needed when mat foundation is subjected to the concentrated

load.

DEEP FOUNDATION

1. PILE FOUNDATION:

Pile is a common type of deep foundation. They are used to reduce cost, and when as per soil

condition considerations, it is desirable to transmit loads to soil strata which are beyond the

reach of shallow foundations. The followings are the types of pile foundations.

CRITERIA:

Soil with great bearing capacity is at a greater depth.

Pile foundations are economic when

Soil with great bearing capacity is at a greater depth.

When there are chances of construction of irrigation canals in the nearby area.

When it is very expensive to provide raft or grillage.

When there are chances of construction of irrigation canals in the nearby area.

When it is very expensive to provide raft or grillage.

When the foundation is subjected to a heavily concentrated load.

When the top soil layer is compressible in nature.

RIYA YOGESH PATIL

ROLL NO.: 20 8

BARC 303

In the case of bridges, when the scouring is more in the river bed.

ADVANTAGES:

Less noise or vibration problem , can be installed in conditions of low headroom.

DISADVANTAGES:

Concrete cannot be inspected after installation , raking bored pile are difficult to construct.

2. PIER FOUNDATION:

Pier is an underground structure that transmits a more massive load, which cannot be carried

by shallow foundations. It is usually shallower than piles. The pier foundation is generally

utilized in multi-story structures. Since the base region is determined by the plan strategy for

the regular establishment, the single pier load test is wiped out. Along these lines, it is

increasingly well known under tight conditions. Pier foundation is a cylindrical structural

member that transfer heavy load from superstructure to the soil by end bearing. Unlike piles, it

can only transfer load by bearing and by not skin friction.

RIYA YOGESH PATIL

ROLL NO.: 20 9

BARC 303

CRITERIA:

Sound rock strata lie under a decomposed rock layer at the top.

The topsoil is stiff clay which resists driving the bearing pile.

When a heavy load is to be transferred to the soil.

ADVANTAGES:

It has a broad scope of assortment with regards to structure. There are different materials

we can here to build a stylish view, and it stays in our spending limit.

It sets aside cash and time as it doesn't require broad removal of a ton of cement.

Bearing limits can increment by under-reaming the base.

DISADVANTAGES:

If one post or dock is harmed, it can prompt critical harm to the general establishment.

It can be vitality wasteful if not protected appropriately.

Floors must be intensely, vigorously protected, and shielded from critters.

3. CAISSON FOUNDATION:

Caisson foundation is a watertight retaining structure used as a bridge pier, construction of the

dam, etc. It is generally used in structures that require foundation beneath a river or similar

water bodies. The reason for choosing the caisson is that it can be floated to the desired

location and then sunk into place. Caisson foundation is a ready-made hollow cylinder

RIYA YOGESH PATIL

ROLL NO.: 20 10

BARC 303

depressed into the soil up to the desired level and then filled with concrete, which ultimately

converts to a foundation. It is mostly used as bridge piers. Caissons are sensitive to construction

procedures and lack construction expertise.

TYPES OF CAISSON FOUNDATION:

1) Box Caissons.

2) Floating Caissons.

3) Pneumatic Caissons.

4) Open Caissons.

5) Sheeted Caissons.

6) Excavated Caissons.

CRITERIA:

The pile cap requirement is to be minimized.

Noise and vibration needed to be reduced.

It has to be placed beneath water bodies.

Highly lateral and axial loading capacity is required.

ADVANTAGES:

Caissons are economic.

It is environment-friendly. There are slightly less sound pollution and reduced vibration.

It is easily adaptable to varying underwater soil conditions.

Caisson has high horizontal and lateral loading capacity.

Minimum handling equipment is required for placement of reinforcement cage.

It is sometimes used in types of soils where driving pile could not penetrate.

Caissons can be reached to great depths.

RIYA YOGESH PATIL

ROLL NO.: 20 11

BARC 303

There is a direct and effortless way to go to the bottom of caissons to remove any kind

of obstruction.

Quality control of pneumatic caisson is good as it is built on dry conditions.

DISADVANTAGES:

The construction procedure is extremely sensitive and troublesome.

It is not good for polluted sites.

It needs expert engineers to design the construction.

There is lack of qualified workers.

The workers may suffer from giddiness, breaking of eardrums, bursting of blood vessels

in the nose or ears and end up in paralytic death which is known as caisson disease.

As the pouring of concrete is done underwater, it may not be satisfactory.

The help of divers may be required.

RIYA YOGESH PATIL

ROLL NO.: 20 12

BARC 303

Question No.-02

What are flooring system? Support your report with details and

sketches.

SLAB:

A slab is a structural element, made of concrete, that is used to create flat horizontal surfaces

such as floors, roof decks and ceilings. A slab is generally several inches thick and supported by

beams,columns, walls, or the ground.

Concrete slabs can be prefabricated off-site and lowered into place or may be poured in-situ

using formwork. If reinforcement is required, slabs can be pre-stressed or the concrete can be

poured over rebar positioned within the formwork.

TYPES OF SLABS:

1. FLAT SLAB:

• The flat slab is a reinforced concrete slab supported directly by concrete columns or caps.

• The thickness of the Flat slab is minimum 8″ or 0.2m.

• Flat slab doesn’t have beams so it is also called a beam-less slab. They are supported on

columns itself.

• Loads are directly transferred to columns.

• In this type of construction, a plain ceiling is obtained thus giving an attractive appearance

from an architectural point of view.

• The plain ceiling diffuses the light better and is considered less vulnerable in the case of fire

than the traditional beam slab construction.

RIYA YOGESH PATIL

ROLL NO.: 20 13

BARC 303

• The flat slab is easier to construct and requires less formwork. This is one of the types of

concrete slabs.

FLAT SLAB

2. ONE WAY SLAB:

• One way slab is supported by beams on the two opposite sides to carry the load along one

direction.

• The ratio of longer span (l) to shorter span (b) is equal or greater than 2, considered as One-

way slab. In this type, the slab will bend in one direction i.e in the direction along its shorter

span.

• However minimum reinforcement known as distribution steel is provided along the longer

span above the main reinforcement to distribute the load uniformly and to resist

temperature and shrinkage stresses.

• In general, the length of the slab is 4m. But in one way slab, one side length is 4m and

another side length is more than 4m. So it satisfies the above equation.

• Main reinforcement is provided in shorter span and distribution reinforcement is provided

in the longer span. Main bars are cranked to resist the formation of stresses.

RIYA YOGESH PATIL

ROLL NO.: 20 14

BARC 303

ONE WAY SLAB

3. TWO WAY SLAB:

• The construct of this type of slab is similar to that of one-way slab on beams, but it may

need more formworks since two-way slabs are supported on all sides.

• Slabs on beams are suitable for spans between 6 and 9m, and live loads of 3-6KN/m2 .

• The beams increase the stiffness of the slabs, producing relatively low deflection. Additional

formwork for the beams is needed.

• These types of slabs are used in constructing floors of multi-storeyed building.

TWO WAY SLAB

RIYA YOGESH PATIL

ROLL NO.: 20 15

BARC 303

4. HOLLOW CORE SLAB:

• It is a type of precast slab through which cores are run. Not only do these cores decline slab

self-weight and increase structural efficiency but also act as service ducts.

• It is suitable for cases where fast constructions are desired.

• There is no restriction on the span of the hollow core slab units, and their standard width is

120mm and depth ranges from 110mm to 400mm.

• The slab units are commonly installed between beams using cranes and the gaps between

units are filled with screeds.

• It has been observed that, hollow core slab can support 2.5 kN/m2 over a 16m span. It is

suitable for offices, retail or car park developments.

HOLLOW SLAB

5. HARDY SLAB:

• Hardy slabs are generally seen in Dubai and China. Hardy slab is constructed by hardy Bricks.

Hardy bricks are hollow bricks and made up of concrete Hollow blocks.

• These blocks are used to fill portions of the slab. Hardy slabs save the amount of concrete

and hence the own weight of the slab is reduced.

• This kind of slab has a more thickness 0.27m when compared with the conventional one.

The dimensions of Hardy brick is 40cm x 20cm x 20cm. Hardy slab is used where

temperatures are very high.

RIYA YOGESH PATIL

ROLL NO.: 20 16

BARC 303

To resist the temperature from the top of the slab thickness is increased. The heat coming

from walls are resisted by using special bricks which has thermacol in it. Thermacol is the

best insulator of sunlight.

HARDY SLAB

6. WAFFLE SLAB:

• It is a type of reinforced concrete slab that contains square grids with deep sides. Waffle

slab construction process includes fixing forms, placement of pods on shuttering,

installation of reinforcement between pods, installation of steel mesh on top of pods, and

pouring of concrete.

• Grid slabs are suitable for spans of 9-15m and live loads of 4-7KN/m2. Formwork, including

the use of pans, is quite expensive.

• A waffle slab has a holes underneath, giving an appearance of waffles. It is usually used

where large spans are required (e.g auditorium, cinema halls) to avoid many columns

interfering with space.

• Hence thick slabs spanning between wide beams (to avoid the beams protruding below for

aesthetic reasons) are required.

• Types of Waffle slabs:

1. Triangular pod system

2. Square pod system

RIYA YOGESH PATIL

ROLL NO.: 20 17

BARC 303

WAFFLE SLAB

7. FLAT PLATES:

• Flat plates can be constructed as one-way or two-way slabs and it is directly supported by

columns or walls.

• It is easy to construct and requires simple formworks.

• Flat plates are most suitable for spans of 6 to 8m, and live loads between 3 and 5KN/m2.

Added to that, the range of spans for prestressed flat plates is between 8-12m, and it can

also be constructed as post-tensioned slabs.

• The advantages of adopting flat plates include low-cost formwork, exposed flat ceilings, and

faster construction.

• Flat plates have low shear capacity and relatively low stiffness, which may cause noticeable

deflection.

FLAT PLATES

RIYA YOGESH PATIL

ROLL NO.: 20 18

BARC 303

8. BUBBLE DECK SLAB:

• It is constructed by placing plastic bubbles which are prefabricated and the reinforcement is

then placed between and over plastic bubbles and finally, fresh concrete is poured.

• The plastic bubbles replace the ineffective concrete at the center of the slab.

• Bubble Deck slabs reduce weight, increase strength, larger spans can be provided, fewer

columns needed, no beams or ribs under the ceiling are required.

• Consequently, not only does it decline the total cost of construction but it is also

environmentally friendly since it reduces the amount of concrete.

BUBBLE DECK SLAB

9. COMPOSITE SLAB:

• Commonly, it is constructed from reinforced concrete cast on top of profiled steel

decking.

• The decking acts as formwork and working area during the construction phase, and it

also acts as external reinforcement during service life of the slab.

• For a steel decking of thickness between 50-60mm, the span of the slab can reach up to

3m.

• However, if the steel decking thickness is increased up to 80mm, slabs with span of 4.5m

can be constructed.

RIYA YOGESH PATIL

ROLL NO.: 20 19

BARC 303

COMPOSITE SLAB

10. PRECAST SLAB:

• Precast concrete slabs are cast and cured in manufacturing plants, and then delivered to the

construction site to be erected.

• The most outstanding advantage of the preparation of slabs in manufacturing plants is the

increase in efficiency and higher quality control which may not be achieved on site.

• The most commonly used precast slabs are the channel and double-T types. They can be

used for spans up to 15m. The double-T slabs vary in sizes and spans up to 15m have been

used.

• The tongue-and-groove panel could vary in size based on the design requirement. When

they are placed, the tongue of one panel is placed inside the groove of adjacent panel.

• With regard to the cost of precast slabs, it is reported that precast concrete slabs are

cheaper than cast in situ concrete slab by approximately 24%.

PRECAST SLAB

RIYA YOGESH PATIL

ROLL NO.: 20 20

BARC 303

11. SLAB ON GRADE:

• The slab which is cast on the surface of the earth is called a Ground slab.

• Generally, slab on grade is classified into three type:

• Slab on ground: It is the simplest type of slab on grade which is a composite of stiffening

beams constructed from concrete around perimeter of the slab, and has a slab thickness of

100mm. It is suitable for stable ground which is mostly composed of sand and rock and not

influenced by moisture, and soils that undergo slight movement due to moisture.

• Stiffened raft slab: It is similar to slab on ground apart from stiffening beams which are set

in channels through the middle of the slab. Consequently, it creates a kind of supporting

grid of concrete on the base of the slab. Soil with moderate, high amount, and severe

movement due to moisture.

• Waffle raft slab: It is constructed entirely above the ground by pouring concrete over a grid

of polystyrene blocks known as ‘void forms’. Waffle raft slabs are generally suitable for sites

with less reactive soil, use about 30% less concrete and 20% less steel than a stiffened raft

slab, and are generally cheaper and easier to install than other types. These types of slabs

are suitable only for very flat ground.

RIYA YOGESH PATIL

ROLL NO.: 20 21

BARC 303

12.PROJECTED SLAB:

• The slab which has one side fixed and the other side is free is called a Projected Slab or

Cantilever slab.

• These type of slabs are generally constructed in hotels, Universities, function halls, etc. to

use that area for dropping or picking up zone and for loading and unloading area. This is one

of the types of concrete slabs.

• The slab which is cast on the surface of the earth is called a Ground slab. This type of slab is

used on the Basement floor.

PROJECTED SLAB

RIYA YOGESH PATIL

ROLL NO.: 20 22

BARC 303

FLOORING SYSTEM:

Flooring is the general term for a permanent covering of a floor, or for the work of installing

such a floor covering. Floor covering is a term to generically describe any finish material applied

over a floor structure to provide a walking surface.

TYPES OF FLOORING SYSTEM:

1. Resilient Flooring

2. Wood flooring

3. Carpet & Rugs

4. Ceramic Tiles

5. Seamless chemical flooring

6. Marble flooring

7. Brick Flooring

8. Glass Flooring

9. Stone Flooring

10. Rubber flooring

RESILENT FLOORING:

Resilient flooring, also called vinyl flooring is a flooring created from carefully selected natural

and synthetic materials. Today`s resilient flooring is a highly engineered combination of

polymer materials. Polymers are large molecules composed of repeating structural units, which

allow for increased strength and durability for the lifetime of the product. This product

construction has changed over the years, just as products in other industries have incorporated

new and better technology, resilient flooring has as well.

RIYA YOGESH PATIL

ROLL NO.: 20 23

BARC 303

RESILENT FLOORING

ADVANTAGES:

• Low maintenance.

• Color and pattern versatility.

• Affordable.

• Comfort.

DISADVANTAGES:

• Not eco-friendly.

• Outgassing.

• Difficult repairs.

• Low value and appearance.

CRITERIA:

• Durability: The flooring can be created with any combination of wear layer protectants

that can help minimize scratching, stains and scuffs that come with every day wear and

tear.

• Appearance: One of the prime benefits of working with resilient flooring is the unlimited

possibilities of style and design.

• Maintenance: Resilient flooring is extremely easy to maintain, Resilient tile and plank

with the infused additives in the wear surface allows for easy maintenance.

RIYA YOGESH PATIL

ROLL NO.: 20 24

BARC 303

• Cleanliness: Congoleum has incorporated ingredients such as Scotchgard Protector,

Aluminium Oxide and Silver into the wear layer to provide greater protection against

wear and keep the flooring looking its best.

• Smoothness: Resilient sheet flooring provides a smooth surface free from cracks and

crevices that allows for quick and easy cleanup of dirt, dust and mess.

CERAMIC TILES:

Ceramic tiles is one of the key components used in the construction industry for building

interior and exterior floors, footpaths, swimming pools, walls, partitions, and roofs. Ceramic

tiles are highly durable. Ceramic tiles are stylish, durable, and versatile. They offer protection

from abrasion and stains and they require less maintenance. These tiles are used in the

construction of industrial concrete structures such as food processing factories and

warehouses.

CERAMIC TILES

ADVANTAGES:

• Water resistance.

• Durable.

• Easy maintenance.

• No allergy concern.

• Cost efficient.

RIYA YOGESH PATIL

ROLL NO.: 20 25

BARC 303

DISADVANTAGES:

• Difficult to clean.

• Heavy in weight.

• Ceramic is a cold material.

CRITERIA:

• Maintenance: Because it is so durable, tile doesn’t need much in the way of upkeep.

They’ll need to be cleaned, just like any other surface in your home that gets dirty. You’ll

want to apply a sealant on your tile about once every 4-5 years.

• Durability: Ceramic flooring is very tough, and the tiles are difficult to crack. If installed

properly, ceramic flooring can last 10-20 years and longer if maintained. However, if a

single tile does crack due to a heavy impact, it’s simple to replace.

• Initial Cost: When you factor the initial cost of purchasing the tile and installing them

with their longevity and lack of costly maintenance, it becomes clear that tiles are worth

installing. They’re one of the cheapest flooring surfaces available.

RUBBER FLOORING:

Rubber flooring is a type of resilient flooring, and therein lies its most obvious advantages. Like

other resilient materials, namely vinyl and linoleum, rubber flooring provides a durable, easy-

to-clean surface that's suitable for hard-wearing environments, such as gyms, basements, rec

rooms, playrooms, laundry rooms, and utility areas.

RUBBER FLOORING

RIYA YOGESH PATIL

ROLL NO.: 20 26

BARC 303

ADVANTAGES:

• Durable.

• Soft and Quiet underfoot.

• Easy to install.

• Recyclable.

DISADVANTAGES:

• Can be expensive.

• Slippery when wet.

• Distinct odour.

CRITERIA:

• Appearance: Rubber flooring and rubber matting will appear quite similar to the eye to

PVC flooring and matting.

• Cost: you will get what you pay for in terms of quality and a far superior endurance and

resilience with rubber flooring. Rubber matting and flooring, although costing more

initially, will actually cost you less over its lifetime. Rubber floors and mats will last for

decades – up to 30 years – making it extremely cost effective.

• Durability and Resilance: Rubber matting and flooring is extremely durable and will last

a long time because of its high resilience. ts highly resilient properties mean that rubber

flooring and matting retains its appearance for a long time. Rubber is also safer to use

because it remains anti-slip and isn’t subject to wear and tear which would cause the

flooring to be unsafe.

• Versatility: The beauty of rubber flooring and matting is that it is extremely versatile and

is used for a huge range of applications in a variety of industries and sectors.

• Noise Comfort and Insulation: Another benefit and quality of rubber flooring is that

rubber absorbs sounds and noise. Rubber flooring gives even more noise absorption and

building insulation when it’s combined with acoustic and thermal insulation creating a

RIYA YOGESH PATIL

ROLL NO.: 20 27

BARC 303

thicker sound barrier layer. Rubber floors are also much more comfortable to walk and

stand on.

BRICK FLOORING:

A brick floor is defined as a floor surface constructed out of many individual bricks laid like tiles,

either with or without mortar or grouting. Red brick is used for the flooring which is made from

clay. Red brick is the most popular and leading building material because it is cheap, hard,

durable and easy to handle and to work with. Brick flooring is derived from pavers, which are

thinner than the regular bricks used in walls and other structural elements. Brick Flooring is

commonly used in godowns; ware houses, residential houses, garden, roads and in areas where

good bricks are available. The bricks shall be laid on the edge; in diagonal herring bone bond or

other patterns. They may also be set in the principal direction of the hall.

Over the layer of lean cement concrete mix, flooring shall be laid over well compacted and

levelled ground.

BRICK FLOORING

ADVANTAGES:

• Durable and easy to clean.

• Non-allergenic.

• Fireproof.

• Non-slip surface.

RIYA YOGESH PATIL

ROLL NO.: 20 28

BARC 303

• Good aesthetic values.

• Maintenance free.

DISADVANTAGES:

• Hard surface

• Cold underfoot

• Susceptible to stains

• Requires sealing

• Brick rot.

• Cracks can occur.

CRITERIA:

• Cleanliness: The flooring should be capable of being cleaned easily, and it should be

non-absorbent.

• Resistance: Should have effective resistance against absorption of oil, grease etc.

• Durability: The flooring should have sufficient resistance to wear, temperature changes,

disintegration with time and decay.

• Hardness: It should be sufficiently hard to resist indentation marks, imprints etc. likely

to be caused by shifting of furniture, equipment etc.

• Maintenance: Flooring material should require least maintenance, repairs can be done

easily.

WOOD FLOORING:

Wood flooring is any product manufactured from timber that is designed for use as flooring,

either structural or aesthetic. Wood is a common choice as a flooring material and can come in

various styles, colors, cuts, and species. Bamboo flooring is often considered a form of wood

flooring, although it is made from a grass (bamboo) rather than a timber.

RIYA YOGESH PATIL

ROLL NO.: 20 29

BARC 303

WOOD FLOORING

ADVANTAGES:

• Easy maintenance and hygiene.

• Healthy air quality at home.

• Good acoustics.

• Organic.

• Easy installation.

DISADVANTAGES:

• Expensive.

• Prone to termite attack.

• Not resistance to water.

• Prone to have dents and scratches.

• Limited usage.

• Cupping.

• High-maintenance.

CRITERIA:

• Maintenance & Cleanliness: Hardwood floors are incredibly easy to keep clean. They can

be swept, steam-cleaned, or vacuumed to remove any dirt or debris that has

accumulated.

RIYA YOGESH PATIL

ROLL NO.: 20 30

BARC 303

• Appearance: Many homeowners believe that having hardwood floors even makes the

space look bigger. Wood floors not only add a touch of elegance to your home, but also

a bit of warmth.

• Sound Insulation: They reduce hollow sounds or vibrations that often occur. Hardwood

floors can also improve the acoustics within the room.

• Durability: One of the main reasons this type of flooring is so easy to maintain is partly

due to their durability. Being durable is one of the primary reasons why homeowners

choose to upgrade to solid wood floors.

RIYA YOGESH PATIL

ROLL NO.: 20 31

BARC 303

Question No.-03

Design a staircase for a room which measures 5m x 7m and height 3m.

You can select the type of staircase and support your answers with

proportionate sketches (Plan and Section).

DOUBLE L SHAPED STAIRCASE:

• Staircase is an important component of building providing access to different floors and

roof of the building.

• It consist of flight of steps and one or more intermediated landing slabs between two floor

levels.

• Double L shaped staircase have 2 landings as it consist of two quarter turns.

• Room dimensions: 7000mm x 5000mm x 3000mm.

• Tread dimensions: 270mm

• Riser dimensions: 150mm

• Width: 1000mm

• Total no of steps: 20 steps.

• Consist of 2 intermediated.

RIYA YOGESH PATIL

ROLL NO.: 20 32

BARC 303

RIYA YOGESH PATIL

ROLL NO.: 20 33

BARC 303

RIYA YOGESH PATIL

ROLL NO.: 20 34

BARC 303

RIYA YOGESH PATIL

ROLL NO.: 20 35

BARC 303

RIYA YOGESH PATIL

ROLL NO.: 20 36

BARC 303

WIRTE SHORT NOTES ON THE FOLLOWING:

SN No. – 01

Explain what are pitched roofs support your answers with

proportionate sketches

A pitched roof is a roof that slopes downwards, typically in two parts at an angle from a central

ridge, but sometimes in one part, from one edge to another.

To be more specific – a pitched roof requires a pitch of more than 10 degrees or a roof with two

slopes that meet at a central ridge.

Pitched roofs offer a more classical appearance. They remain the most common and efficient

solution in wet and cold weathers to ensure maximum protection.

PITCH ROOF

GABLE ROOF:

Also known as pitched or peaked roof, gable roofs are some of the most popular roofs in the

US. They are easily recognized by their triangular shape.

ADVANTAGES:

Gable roofs will easily shed water and snow, provide more space for the attic or vaulted

ceilings and allow more ventilation. Their inherently simple design makes it easy to build them

and cheaper than more complex designs.

RIYA YOGESH PATIL

ROLL NO.: 20 37

BARC 303

DISADVANTAGES:

Gable roofs can be problematic in high wind and hurricane areas. If the frames are not properly

constructed with adequate supports, the roof can collapse. High winds can also cause materials

to peel away from gable roofs.

TYPES OF GABLE ROOFS:

Side Gable.

Crossed Gable.

Front Gable.

Dutch gable Roof.

HIP ROOF:

A hip roof has slopes on all four sides. The sides are all equal length and come together at the

top to form a ridge.

ADVANTAGES:

Hip roofs are more stable than gable roofs. The inward slope of all four sides is what makes it

more sturdy and durable.

DISADVANTAGES:

Hip roofs are more expensive to build than a gable roof. It’s a more complex design that

requires more building materials.

TYPES OF HIP ROOFS:

Simple Hip.

Cross Hipped.

Half Hipped.

MANSARD ROOF:

RIYA YOGESH PATIL

ROLL NO.: 20 38

BARC 303

A mansard roof, also known as a French roof, is a four-sided roof with a double slope on each

side that meet forming a low-pitched roof. The lower slope is much steeper than the upper. The

sides can either be flat or curved, depending on the style.

ADVANTAGES:

Mansard roofs can help create a great deal of extra living space. Using the space as a full attic

or living quarters, called a garret, is very popular. The style lends itself to either open or closed

dormers for more aesthetic appeal.

DISADVANTAGES:

A low pitched portion of a mansard roof isn’t ideal for areas receiving heavy snowfall.

GRAMBREL ROOF:

A Gambrel or a barn roof, is much like mansard in a sense that it has two different slopes. The

Gambrel only has two sides, while the mansard has four. The lower side of the Gambrel roof

has an almost vertical, steep slope, while the upper slope is much lower.

ADVANTAGES:

The Gambrel only uses two roof beams, along with gusset joints. The construction is quite

simple with fewer materials needed.

DISADVANTAGES:

Is not recommended for heavy wind areas or regions that receive significant snowfall. The open

design can cause the roof to collapse under extreme pressure.

RIYA YOGESH PATIL

ROLL NO.: 20 39

BARC 303

SKILLION ROOF:

Skillion is also referred to as a shed roof or lean-to. It is a single, sloping roof, usually attached

to a taller wall. Skillion roofs are mostly used for home additions, sheds and porches.

ADVANTAGES:

Skillions are easy to assemble and use much fewer building materials than other roof types.

DISADVANTAGES:

If a roof pitch is too high it can result in ceilings being too low. Also, homes using only a skillion

roof can have problems in high wind areas.

BUTTERFLY ROOF:

A butterfly is a V-shaped roof constructed of two tandem pieces which are angled up on the

outside. The midsection is angled downward where the two pieces meet into a valley. The

overall effect is of a butterfly’s wings in flight.

ADVANTAGES:

Gives the home more natural light. The valley in the midsection of the butterfly roof allows

rainwater to be collected, making it beneficial for high drought areas.

DISADVANTAGES:

The complexity of the design makes the butterfly roof more expensive.

RIYA YOGESH PATIL

ROLL NO.: 20 40

BARC 303

BONNET ROOF:

Bonnet roofs, also known as kicked-eaves, are double sloped with the lower slope set at less of

an angle than the upper slope. The lower slope hangs over the side of the house.

ADVANTAGES:

Water easily runs off the slopes of the roof and the modified hip structure make it more

durable than a gable roof.

DISADVANTAGES:

Requires more building materials and it’s more difficult to construct. Expensive.

SALTBOX ROOF:

A salt box roof is asymmetrical in design, with one side being more of slightly sloping flat roof

and the other more of a lean to, with gables at each end.

ADVANTAGES:

The slope makes it easy for water to run off. The asymmetrical design makes it more durable

than a simple gable roof.

DISADVANTAGES:

The design can be tricky, which makes the building costs higher.

RIYA YOGESH PATIL

ROLL NO.: 20 41

BARC 303

SAWTOOTH ROOF:

A sawtooth roof is two or more parallel pitched roofs in which the sloped and vertical surfaces

alternate. As the name suggests, the roof resembles the side view of a saw blade.

ADVANTAGES:

Allows more natural light inside the home.

DISADVANTAGES:

Adding windows, valleys and varying slopes creates a higher chance for water leaks. It’s also a

high maintenance roof and expensive too.

CURVED ROOFS:

It is very modern and provides a unique, creative roof design. The amount of curve can vary

from slightly curved up to an arch shape.

ADVANTAGES:

Aesthetically pleasing. Covers entire home. Durable.

DISADVANTAGES:

The cost of a curved roof will depend on the complexity of the design.

RIYA YOGESH PATIL

ROLL NO.: 20 42

BARC 303

PYRAMID ROOF:

A pyramid roof is a type of hip roof. All four sides come to a point at the top of the roof. There

are no vertical sides or gables. Pyramid roofs are mostly used for smaller buildings, such as

bungalows and cabins.

ADVANTAGES:

A pyramid roof is extremely resistant to strong winds. The slope provides extra space for

ventilation, attics or high ceilings.

DISADVANTAGES:

The cost of pyramid roofs is higher due to the complexity of the design.

DOME ROOF:

A dome roof is polygonal with an inverted bowl shape. Dome roofs are great for adding unique

and aesthetically pleasing features to any home. They are excellent choices for cupolas,

gazebos or crow’s nests.

ADVANTAGES:

Dome roofs are both beautiful in design as well as durable.

DISADVANTAGES:

The complexity of a dome roof makes them expensive to construct.

RIYA YOGESH PATIL

ROLL NO.: 20 43

BARC 303

COMBINATION ROOF:

A combination roof incorporates a design using various roofs on the same structure for

aesthetic and practical reasons.

ADVANTAGES:

Using a variety of roofs adds architectural interest to a house. It’s also a great way to use the

best type of roof for each section of the home.

DISADVANTAGES:

The more complex the design, the more expensive it will be. Adding different pitches and roof

types will require more building materials and labor costs.

RIYA YOGESH PATIL

ROLL NO.: 20 44

BARC 303

COMPONENTS OF PITCH ROOF:

Span: Span of roof is the clear distance between the two supports on which roof is

positioned by some other elements.

Ridge: The apex of the angle which is developed at top by the inclined surfaces at the top of

slope.

Rise: The vertical distance or height of top of ridge from wall plate is called as rise.

Wall plates: Wall plates are provided at top of wall or supports. And these are generally

made of wood and are used to fix the common rafters.

Pitch: Pitch is nothing but slope of roof with the horizontal plane and is calculated as the

ration of rise to span.

Eaves: The bottom edge of sloped roof surface is called as eaves from which rain water is

drops down during raining.

Hip: Hip is a place where two sloping surfaces meet, where exterior angle is more than

180o.

Hipped end: At the end of a roof sloped triangular surface is formed which is called as

hipped end.

Valley: It is also a place where two sloping surfaces intersects but the exterior angle is less

than 180.

Verge: Verge is the edge of gable roof which runs between ridge and eaves.

Ridge board: Ridge board is a wooden member which is provided long the ridge lie or apex

of the roof. Common rafters are supported by this ridge board. This is also called as ridge

beam or ridge piece.

Common Rafters: Common rafters are wooden members fixed to the ridge board

perpendicularly. They run from ridge to the eaves. These are fixed to the purlins at

intermediate points. Batten or boarding’s are supported by this rafter. In general, the

spacing between rafters is 30 to 45 cm.

Purlins

RIYA YOGESH PATIL

ROLL NO.: 20 45

BARC 303

Purlins are wooden or steel members supported by truss or wall. If the span is large they

are used to support the common rafters.

Hip rafters: These rafters are provided at the hip end. And they run diagonally from ridge to

the corners of the wall.

Valley rafters: Valley rafters run diagonally from ridge to the eaves. They are provided in

sloping positions to bear support valley gutters. The ends of purlins and jack rafters will

receive by the valley rafters.

Jack rafters: The rafters run from hip to the valley are called as jack rafters and usually they

are short in length.

Eaves board: The ends of lower most roof covering materials are rests on eaves board. It is

made of wood and usually 25mm x 25mm thickness and width. It is placed at the feet of

common rafters.

Barge board: To hold the verge formed by the common rafters a wooden board is used

which is called as barge board.

Post plate: Post plate is similar to wall plate. Post plates are parallel to the face of the wall

and run continuous. Post plates provide support for the rafters.

Battens: Battens are usually made of wood and they are nailed to the rafters to give

supports for the roof covering material.

Template: Template is a masonry block made of concrete or stone which is placed under

the truss to provide larger load area of the wall.

Boarding’s: Boarding’s are similar to battens and these are also used to give support for the

roof covering material by nailing them to the rafters.

Truss: Truss is frame which consists of triangles and designed to support the roof tops.

Cleats: To support the purlins, short sections of steel or wood are fixed to the rafters and

these sections are called as Cleats.

RIYA YOGESH PATIL

ROLL NO.: 20 46

BARC 303

RIYA YOGESH PATIL

ROLL NO.: 20 47

BARC 303

SN No. - 02

Explain any 5 types of roofing Materials.

ASPHALT SHINGLES:

An asphalt shingle is a type of wall or roof shingle that uses asphalt for waterproofing. It is one

of the most widely used roofing covers in North America because it has a relatively inexpensive

up-front cost and is fairly simple to install.

ASPHALT SHINGLES

https://www.google.com/search?q=asphalt+shingles&tbm=isch&source=iu&ictx=1&fir=S9Ia4m

tB92HMEM%252CLUi5KbtF4CTOAM%252C_&vet=1

ADVANTAGES:

• Affordable: Probably the biggest reason why asphalt roofing shingles are so popular is

because they are the most affordable roofing option.

• Effective: While not as durable and long-lasting as other roofing materials (such as

metal, slate, clay tiles, and cedar shakes) asphalt shingles provide adequate protection.

• Variety of colors and styles: There are two types of asphalt shingles: organic and

fiberglass. Asphalt coats both types to make them water proof. A fiberglass shingle’s

interior is made with a thin mat of glass fiber. Organic shingles are made with a mat

fabricated from some kind of wood product, usually waste paper.

RIYA YOGESH PATIL

ROLL NO.: 20 48

BARC 303

• Easy Installation: they require less specialized training and can quickly be installed in

one to two days.

DISADVANTAGES:

• Asphalt roofing shingles perform poorly in extreme heat, which can cause shingles to

crack and color to fade.

• They aren’t fit for extreme temperature fluctuations. Expanding and contracting causes

cracking.

• They can become damaged if installed at below freezing temperatures.

• Asphalt shingles are not environmentally friendly.

ROLLED ROOFING:

Rolled roofing material is the mainstay of low-slope residential roofs as well as out-buildings

like shops and sheds and other structures.

Rolled roofing consists of long rolls of mineral-impregnated asphalt-impregnated material

topped with mineral granules. Each roll is about 100 square feet of roofing, about 3 feet wide.

These large-format strips of thin roofing material offer a fast, convenient, and inexpensive way

to cover a sloped-roof building like a workshop where appearances aren't important. Rolled

roofing can be applied either with the torch-down method or with roofing nails.

Rolled roofing is relatively inexpensive. Rolled roofing lasts, on average, about 10 years before

it needs to be replaced.

ROLLED ROOFING

https://jdtconstructionllc.com/what-is-roll-roofing/

RIYA YOGESH PATIL

ROLL NO.: 20 49

BARC 303

ADVANTAGES:

• Rolled roofing is the least expensive roofing material.

• Unlike shingles, which apply one by one, you can roll out a square of mineral surface

rolled roof within minutes.

• Rolled roofing is easy to transport.

• Rolled roofing is very adaptable.

• Is extremely cheap.

• Works on low slope and sloped roofs.

DISADVANTAGES:

• Not the most attractive product.

• Roof repair is not an option.

• Rolled roofing is less durable.

• Rolled roofing has a short lifespan of between five and eight years.

CLAY TILES:

Clay tile is made from earthen clays molded into rolled or interlocking shapes and fired for

hardness. It is often left unglazed, with the characteristic reddish-orange color. Clay tile is a very

good roofing material for hot climates or where salt air is present, which is why these roofs are

seen so often in southern coastal regions or desert regions.

CLAY TILES

http://www.inspiredexpos.com/clay-tile-roofs-have-offered-thousands-of-years-of-benefits/

RIYA YOGESH PATIL

ROLL NO.: 20 50

BARC 303

ADVANTAGES:

• Long-lasting: A tile roof can last over 100 years, especially when installed in the right

climate. Clay and concrete tile roofs have been known to withstand hail, high winds, and

even fire.

• Impervious to rot and insect damage: Unlike wood, tiles roofs will never decay.

• Environmentally friendly material.

• Energy efficient

• Low maintenance: It is very rare for tile roofs to require repairs or maintenance unless

they break due to heavy impact.

• Plenty of choices in color and styles.

DISADVANTAGES:

• High cost

• Difficult installation: Installing tile roofing requires professional roofing contractors with

extensive experience.

• Heavyweight: Your roof structure must be able to handle the weight of a tile roof.

• Tiles are brittle.

• Not suitable for all roof slopes.

STONE-COATED STEEL ROOFING:

Stone-coated steel roofing is finished with a thick layer of stone that permanently adheres to

the surface and provides the decorative look.

Consequently, they’re an economical, effective choice for wet, windy regions or areas prone to

wildfires. Some stone-coated steel roofs are warranted for the lifetime of the house.

RIYA YOGESH PATIL

ROLL NO.: 20 51

BARC 303

STONE-COATED STEEL ROOFING

https://www.indiamart.com/proddetail/stone-coated-metal-roofing-tile-durastar-

19575263162.html

ADVANTAGES:

• LONGEVITY: Their life span ranges from 40–70 years. it's a great investment in the long-

term future of your home.

• DURABILITY: Steel can withstand gusting winds, heavy rain or hail, and many other

adverse weather conditions.

• LOW MAINTENANCE: They create a thick shield around your home, keeping it safer from

poor weather conditions and eliminating most of the repair costs associated with

traditional roofing.

• BEAUTY AND VERSATILITY: Stone-coated steel roofing comes in a wide variety of colors,

textures, and designs to complement almost any style of home.

• ENERGY EFFICIENCY: Metal roofing actually reflects heat from the sun, rather than

absorbing it like a dark asphalt material would.

DISADVANTAGES:

• INITIAL COST: Stone-coated steel roofing is on the high end of the cost range for roofing

materials

• NOISE FROM RAIN OR HAIL: Depending on how a steel roof is installed, more noise from

rain or hail is possible.

RIYA YOGESH PATIL

ROLL NO.: 20 52

BARC 303

WOODEN SHINGLES:

Wood shingles are made by cutting wood into specific sized pieces. After the wood is cut, kiln

and pressure treatments are used to help remove moisture from the wood pieces. The pressure

treatments often make use of some elements like copper, chromium, and arsenic. This helps

increase the lifespan of the roof and reduce the chance of mold, insects, rotting, and fungus

growth.

WOODEN SHINGLES

https://www.google.com/search?q=wooden+shingles&source=lnms&tbm=isch&sa=X&ved=2ah

UKEwi3x8WSuOnqAhWDX3wKHVoUCOMQ_AUoAXoECA0QAw&biw=1536&bih=754#imgrc=Kkv

PnkdVbajOKM&imgdii=ft8OYebr3E1LGM

ADVANTAGES:

• Wood shingles and shakes have a very unique look making them the number one choice

for many.

• Wood shingles and shakes have pretty good wind resistance.

• Wood is a pretty durable material when it comes to impact resistance.

• Installation and repairs are easy to do.

• Wood roof systems are UV resistance.

• Energy Savings: Wood roofs naturally add insulation to your home.

• Wood roofs are a lightweight roof system.

• Wood roofs have many different style options. You can specify the size length of the

shingles, the thickness, the cut shape, the color, the grain, and more.

• Wood shakes and wood shingles are versatile

RIYA YOGESH PATIL

ROLL NO.: 20 53

BARC 303

DISADVANTAGES:

• Wood shingles are not very fire resistant. They are more likely to catch fire than other

types of roofing materials.

• Wood roofs absorb water when it gets wet.

RIYA YOGESH PATIL

ROLL NO.: 20 54

You might also like

- Analysis and Design of Foundation SystemsDocument31 pagesAnalysis and Design of Foundation SystemsJAY PATELNo ratings yet

- Pile Foundation DesignDocument143 pagesPile Foundation DesignVirendra Kumar Pareek100% (2)

- Types of Footi NG: With Its Advantages and DisadvantagesDocument31 pagesTypes of Footi NG: With Its Advantages and DisadvantagesVince Ilagan MaravillasNo ratings yet

- Statics (Joint Method) PDFDocument69 pagesStatics (Joint Method) PDFSteven Dominic AballeNo ratings yet

- Handout-CE 415 RC FootingDocument82 pagesHandout-CE 415 RC FootingbilalNo ratings yet

- Foundations NotesDocument9 pagesFoundations Notesapi-26041653100% (1)

- MANILA-Modified Standard DPWH-Deped (4 S 20 CL)Document90 pagesMANILA-Modified Standard DPWH-Deped (4 S 20 CL)Arch EnemyNo ratings yet

- Isolated Footing PDFDocument21 pagesIsolated Footing PDFNupur Bhadra100% (2)

- Chapter 5.1 Foundation (Part 1)Document53 pagesChapter 5.1 Foundation (Part 1)Issack Mattew100% (1)

- CH 4 FoundationDocument43 pagesCH 4 FoundationEyoatem Teferi100% (1)

- RaftDocument16 pagesRaftpoojaNo ratings yet

- Gulf Precast Hollowcore BrochureDocument20 pagesGulf Precast Hollowcore Brochureselva.uae8207No ratings yet

- Foundation Design LectureDocument59 pagesFoundation Design LectureJamaica MarambaNo ratings yet

- Work Spec - and ScopeDocument3 pagesWork Spec - and Scopejet toledo100% (1)

- Philips Professional Lighting Price - Sept 2013Document103 pagesPhilips Professional Lighting Price - Sept 2013dundi_kumarNo ratings yet

- Details of Construction-Ii - FoundationsDocument78 pagesDetails of Construction-Ii - Foundationspallabi banerjeeNo ratings yet

- Advanced Foundation Systems-Raft Foundation: 1. Definition, Purpose, & General AspectsDocument7 pagesAdvanced Foundation Systems-Raft Foundation: 1. Definition, Purpose, & General Aspects18 FAISAL SHAH100% (1)

- Examples of Historic OrnamentsDocument22 pagesExamples of Historic OrnamentsVincent RTNo ratings yet

- Full Report On Isolated FootingDocument22 pagesFull Report On Isolated Footingabidur77100% (2)

- Brit Andresen - Alvar Aalto and Jørn UtzonDocument8 pagesBrit Andresen - Alvar Aalto and Jørn Utzoncajama79No ratings yet

- BMC Shallow FoundationsDocument6 pagesBMC Shallow Foundationsshenaz AfroseNo ratings yet

- AbstractDocument9 pagesAbstractPhalgun Moturu100% (1)

- CHAPTER 1 PILE FoundationDocument57 pagesCHAPTER 1 PILE FoundationOromo Oromiya EtiophiaNo ratings yet

- Prepared By:: Prof. Alka M. ShahDocument67 pagesPrepared By:: Prof. Alka M. Shahamit kumarNo ratings yet

- Foundation 2Document34 pagesFoundation 2aamaniammuNo ratings yet

- BACLIG, LORNA G. (BSCE 4-2) - CENGR 4220 Assignment No. 4Document14 pagesBACLIG, LORNA G. (BSCE 4-2) - CENGR 4220 Assignment No. 4LORNA BACLIGNo ratings yet

- Plate No. 5Document5 pagesPlate No. 5Zj FerrerNo ratings yet

- Chaitanya Mini Project PDFDocument11 pagesChaitanya Mini Project PDFMàyúr PàwàrNo ratings yet

- RCC Foundation-Unit 3Document18 pagesRCC Foundation-Unit 3ayeshaNo ratings yet

- CH-2 Types of Shallow FoundationsDocument35 pagesCH-2 Types of Shallow Foundations19CE535 Mandar GawandeNo ratings yet

- Lecture - Week 1Document85 pagesLecture - Week 1Asnil PrakashNo ratings yet

- Assignment#2Document13 pagesAssignment#2AMESHANo ratings yet

- FoundationDocument17 pagesFoundationIshita DhingraNo ratings yet

- Infographics DetailsDocument9 pagesInfographics DetailsKYLA MARIE RAMOSNo ratings yet

- RSW 02 - Btech 03Document14 pagesRSW 02 - Btech 03arpigaoNo ratings yet

- Buildings-Types of FoundationsDocument5 pagesBuildings-Types of FoundationsRonit ChariNo ratings yet

- Art306 Building and Construction Materials: Assignment IvDocument19 pagesArt306 Building and Construction Materials: Assignment IvAbhishek SoniNo ratings yet

- Abcm PPT'SDocument79 pagesAbcm PPT'SAnonymous PWdOlxYNo ratings yet

- Raft Foundation 2.0Document6 pagesRaft Foundation 2.0anuragNo ratings yet

- Shakib Sir URP - FoundationDocument48 pagesShakib Sir URP - FoundationHome Tutor Provider KhulnaNo ratings yet

- Form Two Foundation NotesDocument6 pagesForm Two Foundation NotesTEMNo ratings yet

- Building ConstructionDocument22 pagesBuilding ConstructionRAGU IRINNo ratings yet

- Module 3Document149 pagesModule 3Owsu KurianNo ratings yet

- Type of Substructure in High Rise Building Ce-6115 - Tall BuildingDocument25 pagesType of Substructure in High Rise Building Ce-6115 - Tall Buildingїэasħaŗ ēŗ.ďuηĭyąNo ratings yet

- Foundation: S.Manikandaprabhu at SaravananDocument65 pagesFoundation: S.Manikandaprabhu at SaravananpriyaNo ratings yet

- Literature Review. Sub-Structure/FoundationDocument8 pagesLiterature Review. Sub-Structure/FoundationLillian KobusingeNo ratings yet

- Footing (Anmol)Document16 pagesFooting (Anmol)Anmol ChughNo ratings yet

- Presented By: Dr. P.K. SinghaiDocument27 pagesPresented By: Dr. P.K. SinghaiHOD CE LNCTSNo ratings yet

- BCM Assignment Group 8Document18 pagesBCM Assignment Group 8Ashrutha HarshiniNo ratings yet

- Chapter-3 FoundationDocument53 pagesChapter-3 Foundationkader ArefeNo ratings yet

- Chapter-22 FoundationDocument20 pagesChapter-22 Foundationdesubie bireNo ratings yet

- Prepared By:: Prof. Alka M. ShahDocument27 pagesPrepared By:: Prof. Alka M. ShahsalmanNo ratings yet

- Different Methods of Deep Foundation DesignDocument7 pagesDifferent Methods of Deep Foundation DesignMuhammad ArhamNo ratings yet

- Types of FdnsDocument41 pagesTypes of Fdnshiwotnesh girmaNo ratings yet

- Building Components and StructuresDocument15 pagesBuilding Components and Structuresxasoke2145No ratings yet

- Chapter 1Document57 pagesChapter 1Oromo Oromiya EtiophiaNo ratings yet

- CHAPTER 4 FoundationDocument34 pagesCHAPTER 4 Foundationashenafi.aNo ratings yet

- Deep Foundations: Kaidy DuarteDocument22 pagesDeep Foundations: Kaidy DuarteCynthia XiuNo ratings yet

- Lecture 1Document14 pagesLecture 1Erica Jane TatelNo ratings yet

- Types of Foundation 1Document11 pagesTypes of Foundation 1Saad SohailNo ratings yet

- Overview of Shallow & Pile FoundationDocument63 pagesOverview of Shallow & Pile FoundationParth Anajwala100% (1)

- GRP 2 - Soil - Foundation PilesDocument74 pagesGRP 2 - Soil - Foundation PilesFELICITY MONTEFALCONo ratings yet

- Types of Foundation For Buildings and Their Uses (PDF) : The ConstructorDocument9 pagesTypes of Foundation For Buildings and Their Uses (PDF) : The Constructorolowonyo MuizNo ratings yet

- Foundation:: Different Types of FoundationDocument13 pagesFoundation:: Different Types of FoundationDwijendra ChanumoluNo ratings yet

- Types of Footing: Continuous Wall Footing/strip Footing/wall FootingDocument3 pagesTypes of Footing: Continuous Wall Footing/strip Footing/wall FootingJerard BalalaNo ratings yet

- FoundationDocument60 pagesFoundationhabtamu abateNo ratings yet

- Tods Report 1 Sem 4Document17 pagesTods Report 1 Sem 422Patil RiyaNo ratings yet

- 20 Patil Riya Sub No. 02 - TodsDocument12 pages20 Patil Riya Sub No. 02 - Tods22Patil RiyaNo ratings yet

- 20 Patil Riya Sub No. 03 - TodsDocument15 pages20 Patil Riya Sub No. 03 - Tods22Patil RiyaNo ratings yet

- 20 Patil Riya ReportNo.02 - Chain Surveying - ARDDocument35 pages20 Patil Riya ReportNo.02 - Chain Surveying - ARD22Patil RiyaNo ratings yet

- Question No.-01 Write A Short Note On TraversingDocument22 pagesQuestion No.-01 Write A Short Note On Traversing22Patil RiyaNo ratings yet

- Assignment No. 04 Riya Yogesh Patil ROLL NO.: 20 Sem - Iii Viva School of Architecture ACADEMIC YEAR 2020-2021Document15 pagesAssignment No. 04 Riya Yogesh Patil ROLL NO.: 20 Sem - Iii Viva School of Architecture ACADEMIC YEAR 2020-202122Patil RiyaNo ratings yet

- Assignment No. 02 Riya Yogesh Patil ROLL NO.: 20 Sem - Iii Viva School of Architecture ACADEMIC YEAR 2020-2021Document17 pagesAssignment No. 02 Riya Yogesh Patil ROLL NO.: 20 Sem - Iii Viva School of Architecture ACADEMIC YEAR 2020-202122Patil RiyaNo ratings yet

- Barc 308 - Building ServicesDocument10 pagesBarc 308 - Building Services22Patil RiyaNo ratings yet

- Movil 67 Terminadora de AsfaltoDocument339 pagesMovil 67 Terminadora de AsfaltoCARLOSNo ratings yet

- Westinghouse Lighting MO-8 Series Silverliner Roadway Spec Sheet 6-64Document2 pagesWestinghouse Lighting MO-8 Series Silverliner Roadway Spec Sheet 6-64Alan MastersNo ratings yet

- Types of Flat Slab ConstructionDocument17 pagesTypes of Flat Slab ConstructionCharina SupenaNo ratings yet

- MasterformatDocument23 pagesMasterformatssh959No ratings yet

- Detail of Fire Extinguisher MountingDocument1 pageDetail of Fire Extinguisher MountingRenzelNo ratings yet

- Exportlayers DWG AIADocument6 pagesExportlayers DWG AIARahul J JainNo ratings yet

- A Practical Guide For Lighting Shopping Malls - EC&M PDFDocument8 pagesA Practical Guide For Lighting Shopping Malls - EC&M PDFIndujaa PadmanaabanNo ratings yet

- Keenkid's It Report Third YearDocument38 pagesKeenkid's It Report Third YearD A R K S K YNo ratings yet

- Museum Lighting PDFDocument7 pagesMuseum Lighting PDFMubarek KedirNo ratings yet

- Substation Building Design ChecklistDocument5 pagesSubstation Building Design ChecklistMohammed selimNo ratings yet

- Data CollectionDocument45 pagesData CollectionJimmy Wangmo DorjiNo ratings yet

- TT2 Tests Unit 7ADocument2 pagesTT2 Tests Unit 7ACông Trung ĐỗNo ratings yet

- Royal Albert HallDocument26 pagesRoyal Albert HalllcsimalNo ratings yet

- CH08 MasonryDocument16 pagesCH08 Masonrycjones2013No ratings yet

- GST Tax Invoice Format For Services TeachooDocument150 pagesGST Tax Invoice Format For Services TeachooAnonymous dDFZxpKNo ratings yet

- 2 Stories BuildingDocument24 pages2 Stories BuildingAndrew ArahaNo ratings yet

- Chapter Fifteen Grant and Graham InvestigateDocument6 pagesChapter Fifteen Grant and Graham InvestigateJulio PerezNo ratings yet

- Marces Osmeña General SpecificationsDocument5 pagesMarces Osmeña General SpecificationsAlexander Osmeña IINo ratings yet

- PLAINCRETE Blocks Matibay Pa!: Load Bearing Reinforced Concrete Blocks Money ConstructontheDocument7 pagesPLAINCRETE Blocks Matibay Pa!: Load Bearing Reinforced Concrete Blocks Money ConstructontheJim Bryan RazNo ratings yet

- University of Gondar Institute of Technology Department of CotmDocument49 pagesUniversity of Gondar Institute of Technology Department of CotmYasichalew sefineh100% (1)

- Stripline 41 HoDocument2 pagesStripline 41 Howaheed babarNo ratings yet

- Lighting Ceiling-Mounted Regent REGENT Solo Slim LED CW 4000K D530 DIDDocument4 pagesLighting Ceiling-Mounted Regent REGENT Solo Slim LED CW 4000K D530 DIDjorge castroNo ratings yet

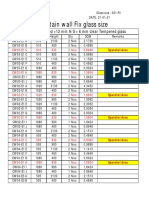

- Glass Size 001 R1 L12Document5 pagesGlass Size 001 R1 L12MA HarNo ratings yet