Professional Documents

Culture Documents

06 - Exhibit D - Scope of Work 26 Dec 06

Uploaded by

Ahmad Abd RabouCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 - Exhibit D - Scope of Work 26 Dec 06

Uploaded by

Ahmad Abd RabouCopyright:

Available Formats

Eastern Bechtel Co. Ltd.

OGD-III Onshore Gas Development Project Phase III

EXHIBIT "D"

SCOPE OF WORK

1. INTRODUCTION

a. Overall Project Description

The Onshore Gas Development Project Phase III (OGD III) is for the turnkey construction

of a gas processing facility adjacent to an existing gas processing facility.

b. Project Location

The Project is located at Habshan, Emirate of Abu Dhabi, UAE approximately 150km

south west of Abu Dhabi. All Project areas are located in the oil fields and are subject to

all associated restrictions and regulations.

The temporary facilities area for SUBCONTRACTOR’s offices, workshops, laydown, etc.

is located in the A4 area approximately 7km from the Jobsite as shown on drawing No.

25113-000-P10-0000-P0005 Rev 1

The Jobsite is located to the south east of the existing plant area as shown on drawing

No. OGDIII-DW-030 Rev 5

c. Subcontract Scope

The scope of work of this subcontract is generally for the supply, fabrication, installation,

and inspection of insulation and cladding for equipment, vessels and piping as further

defined below.

2. GENERAL SCOPE OF WORK

a. Project Management

SUBCONTRACTOR shall be responsible for all Project Management activities required

to execute the WORK to meet the requirements of the Subcontract documents, including

but not limited to the following:

• Provision of sufficient and suitably qualified personnel for the performance of the

work. In order to ensure compliance, SUBCONTRACTOR shall submit CV’s for

key personnel as detailed below for review and acceptance by CONTRACTOR:

o Project Manager

o Site Manager

o Jobsite HSE Manager

o Quality Assurance / Quality Control Manager

o Lead Planner

o Insulation Fabrication Lead Supervisor(s)

o Cladding Fabrication Lead Supervisor(s)

o Installation Superintendent(s)

• Provision of sufficient and suitable equipment required for the performance of the

work.

• Implementation of the approved HSE Program.

Exhibit D, 15 April 2007 Page 1 of 15 Subcontract 25113-000-FC3-NN00-00001

• In addition to the HSE Manager, SUBCONTRACTOR shall provide one (1) safety

officer per fifty (50) craft personnel.

• Management of all SUBCONTRACTOR personnel, sub-tier subcontractors,

suppliers, vendors, etc. to ensure compliance with the SUBCONTRACT

requirements.

• Planning and scheduling of all aspects of the work in accordance with the

requirements of the Special Conditions titled “COMMENCEMENT, PROGRESS

AND COMPLETION OF THE WORK” and “SUBCONTRACT SCHEDULE”

• All home office support required to meet the Subcontract requirements.

b. Engineering & Design

SUBCONTRACTOR shall be responsible for all supplementary engineering and design

required to develop insulation and cladding systems to meet the requirements of the

Subcontract documents.

This shall include but not be limited to the following:

• Material Take Offs

• Fabrication Details

• Installation sketches

• Procedures

• Quality Control Plans

• Inspection and Test Plans

• Method Statements

• Progress quantity calculations

• Production of Certification Dossiers

• As-Built Drawings

• Any other engineering or design activities required

c. Procurement & Materials

SUBCONTRACTOR shall be responsible for all material selection, procurement, logistics,

material receiving, fabrication, testing and verification required for the WORK in

accordance with the Subcontract documents and as detailed below:

• Material Selection

SUBCONTRACTOR shall be responsible for all activities required including but

not limited to the following:

• Identification of all materials required

• Collation of all data required from material suppliers

• Production of Material Approval Requests for each element of the

materials

• Submittal of documents in a timely manner to support schedule

requirements

• Incorporation of all CONTRACTOR and OWNER comments

• Procurement

SUBCONTRACTOR shall be responsible for all activities required including but

not limited to the following:

• Sourcing vendors of the material acceptable under item 2.b.i above

• Ensuring all Subcontract requirements, including technical, commercial

and schedule, are complied with in all Purchase Order terms and

conditions

Exhibit D, 15 April 2007 Page 2 of 15 Subcontract 25113-000-FC3-NN00-00001

• Placement of purchase orders with the approved vendors and submittal

of unpriced copies of all purchase orders to CONTRACTOR

• Monitoring of material status to ensure materials are supplied in sufficient

quantity to meet schedule requirements

• Expediting activities required to ensure materials are produced to

support Project schedule requirements

• CONTRACTOR may at it’s sole discretion elect to perform all or part of

the material procurement activities, provided solely that written notice is

provided to SUBCONTRACTOR in advance.

• In the event CONTRACTOR free-issues material to SUBCONTRACTOR,

SUBCONTRACTOR shall be responsible for taking receipt of the

material directly and immediately on delivery from CONTRACTOR’s

vendor; i.e. Material shall be received and stored in

SUBCONTRACTOR’s area.

• Logistics

SUBCONTRACTOR shall be responsible for all activities required including but

not limited to the following:

• Shipping of materials, including land transportation / sea freight / air

freight / courier as required to support the schedule requirements

• Customs clearance including provision of all documentation required to

allow CONTRACTOR to obtain Customs Clearance Authorizations from

OWNER to allow duty exemptions to apply. CONTRACTOR will not be

held responsible for any delays associated with obtaining Customs

Clearance Authorizations. SUBCONTRACTOR shall be responsible for

all other activities required to complete any customs clearance and

importation requirements.

• Transportation of materials to the A4 Area laydown and fabrication areas

• Transportation of materials to the work fronts at the Jobsite area

• Fabrication

SUBCONTRACTOR shall be responsible for all activities required including but

not limited to the following:

• Supply, construction, testing and commissioning of insulation and

cladding fabrication shop(s) and sheet metal fabrication shop(s) at the

A4 Area for the pre-installation fabrication of all materials required to

complete the WORK.

• Performance of all fabrication activities required for the work

• Testing & Inspection

SUBCONTRACTOR shall be responsible for all activities required including but

not limited to the following:

• Provision of all testing equipment required, including supply of valid

calibration documentation prior to mobilization

• All calibration testing required for test equipment at a frequency to meet

the Subcontract requirements.

• Subcontracting any Third Party Inspection services required.

SUBCONTRACTOR shall submit to CONTRACTOR full details of any

proposed Third Party Inspection service provider for review and approval

prior to engaging them in the WORK.

• Performance of all testing to ensure that the materials, fabrication, and

installation are performed in accordance with the Subcontract

requirements.

Exhibit D, 15 April 2007 Page 3 of 15 Subcontract 25113-000-FC3-NN00-00001

• Submittal to CONTRACTOR of test and inspection reports within forty-

eight (48) hours of completion of the test performed.

• Identification of any non-conformances, submittal of Non-Conformance

Reports including recommended corrective actions, incorporation of any

CONTRACTOR comments, and performance of the corrective actions

required to remove the non-conformance.

d. Construction

• Mobilization

SUBCONTRACTOR shall be responsible for the performance of all activities

required to perform the mobilization to commence work. Mobilization shall

include but not be limited to the following activities:

• Submittal and acceptance by CONTRACTOR of all required

documentation as stated in Item 4.a below

• Construction and operation of SUBCONTRACTOR’s Camp facilities as

detailed in Item 2.d.iii below

• Construction and operation of SUBCONTRACTOR’s A4 Area Temporary

Facilities

• Mobilization of Key Personnel

• Mobilization of resources sufficient to commence work

• Oil Field Passes

It is a legal requirement of the UAE that all manpower and certain types of

equipment require valid oil field passes prior to entering the A4 Area or Jobsite.

SUBCONTRACTOR shall submit to CONTRACTOR a request for a Letter of

Assistance to allow application for oil field passes. Accompanying this request

shall be the following information and documentation:

• Numbers of personnel requiring oil field passes

• A list of equipment types and quantities requiring oil field passes

• A copy of SUBCONTRACTOR’s valid Abu Dhabi trade license showing

“Oil Field Services” as part of the license

• A copy of SUBCONTRACTOR’s valid Abu Dhabi Chamber of Commerce

registration showing “Oil Field Services” as part of the license

• A copy SUBCONTRACTOR’s registration with COMPANY

• A copy of SUBCONTRACTOR’s insurances compliant with the Special

Condition titled “INSURANCE”

Furthermore, all manpower for which the oil field passes are applied shall have

entered the UAE on Abu Dhabi visas. All equipment shall be registered in the

Emirate of Abu Dhabi only.

Upon receipt of the above, CONTRACTOR will apply for a Letter of Assistance

from the Supreme Petroleum Council. This process typically takes Seven (7) to

Ten (10) working days (Based on a 5 day working week).

Letters of Assistance are required independently for all sub-tier subcontractors

who will require oil field passes. The same procedure applies as above but all

documentation is required to be in the sub-tier subcontractor’s name.

SUBCONTRACTOR shall ensure that all requests for Letters of Assistance are

submitted with all supporting documentation and in a timely manner to allow

sufficient time to process the request.

Exhibit D, 15 April 2007 Page 4 of 15 Subcontract 25113-000-FC3-NN00-00001

After receipt of the Letter of Assistance, SUBCONTRACTOR shall be

responsible for all activities required for obtaining oil field passes for manpower

and equipment.

• Camp Accommodation

All camp accommodations either rented or constructed by SUBCONTRACTOR

shall be in accordance with all requirements of the following Volume III, Prime

Contract Exhibits;

• B.18 - Construction Temporary Facilities and Camp Accommodations

Planning

• B.20 – COMPANY’s General Standards for the Living and Working

Conditions of CONTRACTOR’s personnel

• B.21 – Instructions to CONTRACTORs working in or near COMPANY

existing facilities

• B.27 – Camp Accommodations

SUBCONTRACTOR shall be responsible for all activities associated with the

arrangement and / or construction, operation, maintenance, and demobilization

of camp facilities including but not limited to the following requirements:

• Leasing of any land required for the camp construction.

SUBCONTRACTOR shall submit an unpriced copy of the lease

documents to CONTRACTOR. Where SUBCONTRACTOR elects to

lease existing camp space in the local area, SUBCONTRACTOR shall

submit an unpriced copy of the camp lease documents to

CONTRACTOR.

• Submittal of camp layout details prior to commencement of WORK,

identifying compliance with the requirements of the above Prime

Contract Exhibits

• All earthworks required to prepare the location for camp construction.

• Supply of all materials required for the camp construction

• Provision of all services required for the operation of the camp including

but not limited to power, water, catering, waste collection and disposal,

laundry, cleaning, janitorial, sewage collection and disposal, telephones,

IT, manpower, equipment, maintenance, etc.

• Demobilization of the camp and restoration of the location to its original

condition including removal of underground services

CONTRACTOR may at any time perform audits and inspections of

SUBCONTRACTOR’s camp facilities to ensure compliance with the

Subcontract requirements. Any deficiencies shall be corrected by

SUBCONTRACTOR within five (5) calendar days.

• Temporary Facilities

All temporary facilities shall be in accordance with all requirements of the

following Volume III, Prime Contract Exhibits;

• B.18 - Construction Temporary Facilities and Camp Accommodations

Planning

• B.20 – COMPANY’s General Standards for the Living and Working

Conditions of CONTRACTOR’s personnel

• B.21 – Instructions to CONTRACTORs working in or near COMPANY

existing facilities

• B.26 – Field Services

Exhibit D, 15 April 2007 Page 5 of 15 Subcontract 25113-000-FC3-NN00-00001

SUBCONTRACTOR shall be responsible for all activities associated with the

arrangement and / or construction, operation, maintenance, and demobilization

of temporary facilities including but not limited to the following requirements:

• Defining the area required for the temporary facilities. This area shall not

exceed 8,000 m2 and shall be located in the A4 Area at a location to be

nominated by CONTRACTOR.

• Submittal of temporary facilities layout details prior to commencement of

WORK, identifying compliance with the requirements of the above Prime

Contract Exhibits

• All earthworks required to prepare the location for temporary facilities

construction.

• Supply of all materials required for the temporary facilities construction

• As a minimum, SUBCONTRACTOR’s temporary facilities shall include

the following facilities:

o Offices for all non-manual personnel

o Toilet facilities

o Fully staffed First Aid Clinic

o Ambulance

o Material Storage Area(s) (including sheltered material storage

and climate controlled material storage as required by the

material manufacturers).

o Insulation fabrication shop(s)

o Cladding fabrication shop(s)

o QA/QC testing facilities

o Lunch Facility for total workforce (non-manual and manual)

o Car parking area(s) to incorporate bus parking areas for all craft

personnel buses.

• Provision of all services required for the operation of the temporary

facilities including but not limited to power, water, cleaning, janitorial,

waste collection and disposal, sewage collection and disposal,

telephones, IT, manpower, equipment, maintenance, etc.

• Demobilization of the temporary facilities area and restoration of the

location to its original condition including removal of underground

services

• Access

SUBCONTRACTOR is responsible for the construction, maintenance, removal,

and restoration of all required temporary accesses for the performance of the

WORK. This shall include but not be limited to, temporary laydown areas,

access roads, modifications to existing roads, etc.

CONTRACTOR will only provide the following initial accesses:

• East and West main access roads as shown on drawing 25113-000-

CG0-CG00-C0012 Rev 1

• A4 main access road as shown on drawing 25113-000-CG0-CG00-

C0012 Rev 1

• SUBCONTRACTOR shall be responsible for any access required from

the main access road to the assigned temporary facilities area

• Permanent plant roads as shown on drawing 25113-000-P10-0000-

P0001 Rev 1.

Any repairs or modifications required to the CONTRACTOR provided access

will be the responsibility of SUBCONTRACTOR.

Exhibit D, 15 April 2007 Page 6 of 15 Subcontract 25113-000-FC3-NN00-00001

• Manpower

SUBCONTRACTOR shall be responsible for the provision of all manpower

required to execute the work in accordance with the Subcontract requirements

including but not limited to the following:

• Resource planning to meet Project needs

• Recruitment of personnel

• Qualification and testing of personnel

• Obtaining visas and work permits

• Mobilization of personnel to Abu Dhabi

• Obtaining oil field passes

• Provision of accommodation, transportation, and food in accordance with

Section 2.d.iii above

• Provision of all required personal protective equipment

• Provision of all small tools required for performance of the work.

• Demobilization of personnel to their point of origin or further work

locations.

SUBCONTRACTOR’s manpower shall be suitably qualified and experienced

for the performance of the work. For foreman level and above,

SUBCONTRACTOR shall submit work histories for review by CONTRACTOR.

• Equipment & Vehicles

SUBCONTRACTOR shall be responsible for the provision of all equipment and

vehicles required to execute the work in accordance with the Subcontract

requirements including but not limited to the following:

• Resource planning to meet Project needs

• Provision of equipment and vehicles (either hired or owned)

• Inspection and testing (including third party if required) of all equipment

and vehicles.

• Presentation of equipment and vehicles to CONTRACTOR for inspection

prior to entry to the site. Should the equipment or vehicle not pass

CONTRACTOR’s inspection prior to entry to site, SUBCONTRACTOR

shall be responsible for all requirements to either demobilize the item or

perform all required repairs and / or modifications to pass the inspection

at SUBCONTRACTOR’s cost

• Maintenance of all equipment and vehicles

• Operation of all equipment and vehicles

• Demobilization of equipment and vehicles

• Scaffolding

At the time of bidding this Subcontract, it is not determined whether

SUBCONTRACTOR or CONTRACTOR will provide the scaffolding required for

the execution of the work. Prior to award of Subcontract, CONTRACTOR will

elect to perform the scaffolding in one of the two (2) methods below:

1. CONTRACTOR to perform all scaffolding

Under this option, CONTRACTOR will be responsible for the

performance of all scaffolding required to execute the works.

SUBCONTRACTOR shall be responsible for submittal of scaffold

requests a minimum of seven (7) calendar days prior to insulation and

cladding work commencing at the location.

Exhibit D, 15 April 2007 Page 7 of 15 Subcontract 25113-000-FC3-NN00-00001

SUBCONTRACTOR shall liaise with CONTRACTOR’s personnel during

the erection to ensure the scaffold does not clash with the insulation and

cladding installation activities.

SUBCONTRACTOR shall be responsible for submitting scaffold removal

requests immediately on completion of the work. Where scaffold has

been identified as not being used by SUBCONTRACTOR for in excess

of seven (7) calendar days, CONTRACTOR reserves the right to remove

the scaffold without notice to SUBCONTRACTOR.

2. SUBCONTRACTOR to perform all scaffolding

Under this option, SUBCONTRACTOR will be responsible for the

performance of all scaffolding required to execute the works including but

not limited to the following:

• Strict compliance with CONTRACTOR Standard Work Process

Procedures (SWPP) Exhibit “D” Appendix D-4

• Provision of scaffold plans for each area for review by

CONTRACTOR prior to erection commencing

• Coordination with CONTRACTOR and other subcontractors to

ensure minimization of disruption

• Provision of all required resources including, manpower,

equipment, materials, tools, consumables, etc. for the

performance of the work.

• Erection, modification, maintenance and removal of scaffolding

as required for the execution of the work.

Any other party may utilize SUBCONTRACTOR’s scaffold while it is in

position, provided that the use does not impact SUBCONTRACTOR’s

WORK. No other party may be permitted to modify

SUBCONTRACTOR’s scaffold.

3. DETAILED SCOPE OF WORK

3.1 Overall

SUBCONTRACTOR shall be responsible for the provision of all resources required for the supply,

fabrication, installation, testing and completion of hot, cold, acoustic, personal protection, and

miscellaneous other types of insulation and cladding to piping and equipment.

The WORK shall be performed at all locations identified on the drawings.

Piping insulation and cladding shall include but not be limited to the insulation and cladding of:

• Straight and spooled pipe

• Bends, elbows, tees, reducers,

• Pipe supports (as required)

• Flanges

• Valves (Welded and flanged)

• Inline devices and instruments (as required)

• Level gauges

Equipment insulation and cladding shall include but not be limited to the insulation and cladding

of:

• Vessels

• Drums

• Exchangers

Exhibit D, 15 April 2007 Page 8 of 15 Subcontract 25113-000-FC3-NN00-00001

• Boilers

• Rotating Equipment

• Packaged Equipment

• Filters

• Pumps

• Motors

• Tanks

• All associated flanges

• All associated man ways, clean out ports, etc.

• All associated appurtenances

3.2 Releases to Work

All work shall be performed under work release basis. CONTRACTOR shall release pipe and

equipment for insulation and cladding to commence through transmittal of a written Work

Release. CONTRACTOR’s work release shall include all information required for the execution of

the WORK.

Upon receipt of CONTRACTOR’s Work Release, SUBCONTRACTOR shall review and respond

within seven (7) calendar days providing the following information:

• Material take off of all materials required for the work (identifying a separate item for

wastage)

• Reconciliation of materials available showing

o Total Ordered

o Total Delivered

o Total Previously Consumed through other work releases

o Total consumed by this work release

o Balance materials

• Level 3 Schedule for the performance of the work, including resource loading

On a monthly basis, SUBCONTRACTOR shall incorporate all work releases into the Subcontract

Schedule and progress curves and provide updates to CONTRACTOR.

3.3 Prior to Commencement of WORK

SUBCONTRACTOR shall be responsible for the performance of inspections of the location prior

to commencement of any work release. SUBCONTRACTOR’s location inspection shall include

but not be limited to:

• Check of scaffold to ensure erection complete and inspection complete

• Check of location to determine whether other subcontractors are working in the area and

liaise directly to coordinate activities

• Check of accesses to location for SUBCONTRACTOR’s equipment. If required,

SUBCONTRACTOR shall construct any additional accesses required.

• Check of any work restrictions in the area due to introduction of hydrocarbons or other

hazardous materials

Upon completion of the checks above, SUBCONTRACTOR shall take any and all actions

necessary to correct any deficiencies to allow work to commence.

SUBCONTRACTOR shall be responsible for the performance of pre-commencement inspections

of the pipe or equipment being insulated to ensure the work is available.

SUBCONTRACTOR shall identify and prepare an area at the work location for the laydown and

storage of the materials during the work. SUBCONTRACTOR shall be responsible for all

preparation, barricading, maintenance and security required for the location.

Exhibit D, 15 April 2007 Page 9 of 15 Subcontract 25113-000-FC3-NN00-00001

SUBCONTRACTOR shall ensure all personnel have received the correct safety training required

for the performance of the work including but not limited to:

• Jobsite Induction

• Working at Height

• Confined Spaces

• STARRT Card

• Permit To Work

SUBCONTRACTOR shall be responsible for the application and obtaining of any and all permits

to work from either CONTRACTOR or OWNER.

3.4 Work to Be Performed

The work to be performed shall be defined on the Subcontract drawings as detailed in Exhibit E

and as attached to CONTRACTOR’s Work Release. The Insulation Codes used to identify

insulation and cladding requirements on the Line Designation Tables (LDT’s) and all piping and

equipment drawings are as follows:

CODE DESCRIPTION

A Acoustic

C Cold

E Electric Traced

H Heat Conservation

H (VB) Heat Conservation with Vapour Barrier

J Steam Jacket

P Personnel Protection

PAA Personnel Protection with Acoustic Insulation

P (SG) Personnel Protection Safety Guard

S Steam Traced and Insulation

SUBCONTRACTOR shall be responsible for the performance of all activities required for the

performance of the work as follows for each of the different types of insulation and cladding:

a. Hot Insulation and cladding

For insulation codes AH, E, H, H (VB), J, P, P (SG) and S the insulation and cladding will

be applied in accordance with the following specifications:

• DGS-6500-010 titled Hot Insulation for Piping and Equipment

• Project Specification 25113-000-3PS-NN00-N0019 titled Addendum Project

General Specification Hot Insulation For Piping and Equipment

Note - Insulation codes AH, P, and P (SG) may not strictly be governed by the above

referenced specifications. SUBCONTRACTOR shall verify requirements in all other

specifications to determine if other requirements apply.

For insulation code S, SUBCONTRACTOR shall fit one diameter oversize mineral wool

sections to accommodate the tracer(s)

b. Cold Insulation and cladding

For insulation codes C, P, and P (SG) the insulation and cladding will be applied in

accordance with the following specifications:

• Project Specification 25113-000-3PS-NN00-N0020 titled Addendum Project

General Specification Cold Insulation For Piping and Equipment

• 25113-000-3PS-NN00-N0020 Attachment- 001 DGS-6500-020 titled Cold

Insulation for Piping and Equipment

Exhibit D, 15 April 2007 Page 10 of 15 Subcontract 25113-000-FC3-NN00-00001

Note - Insulation codes P and P (SG) may not strictly be governed by the above

referenced specifications. SUBCONTRACTOR shall verify requirements in all other

specifications to determine if other requirements apply.

For pipe supports on cold service lines installed by others, SUBCONTRACTOR shall

remove temporary protection, if any, at cold pipe support, make good the rebated edges

and tie-in the pipe insulation and cladding to the support.

c. Acoustic Insulation and cladding

For insulation codes A, AA, AB, and AC the insulation and cladding will be applied in

accordance with the following specifications:

• Project Specification 25113-000-3PS-NN00-N0040 titled Addendum Project

General Specification Acoustic Insulation for Pipes, Valves and Fittings

• 25113-000-3PS-NN00-N0040 Attchment-001 DGS-6000-003 titled Acoustic

Insulation of Pipe, Valves and Flanges

The second letter indicates the class of acoustic insulation required as follows:

1. Code AA = Acoustic insulation only at 50mm thickness

2. Code AB = Acoustic insulation only at 100mm thickness

3. Code AC = Acoustic insulation only at 100mm thickness with 1.2mm thick steel

coated cladding.

Where acoustic insulation is indicated along with hot or cold insulation, the following shall

apply:

1. Code CAA= indicated thickness of cold insulation under 50 mm of Acoustic

insulation code A. BIDDER shall apply a second vapour barrier over the acoustic

layer of insulation. Refer to para.14.8.2 of appendix 1 of acoustic specification

above.

2. Code CAB = Indicated thickness of cold insulation under 100 mm of Acoustic

insulation code B. BIDDER shall apply a second vapour barrier over the acoustic

layer of insulation. Refer to para.14.8.2 of appendix 1 of acoustic specification

above.

3. Code CAC = Indicated thickness of cold insulation under 100 mm of Acoustic

insulation code AC. BIDDER over the acoustic layer of insulation, with 1.3mm

thick steel coated cladding. Refer to para.14.8.2 of appendix 1 of acoustic

insulation above.

4. Code HAA = Indicated thickness of hot insulation (Spec. 25113-000-3PS-NN00-

N0019.) under 50 mm of Acoustic insulation code AA. Note, where the

designation is HAA00 the acoustic insulation alone is adequate for thermal

purposes.

5. Code HAB = Indicated thickness of hot insulation (Spec.25113- 000-3PS-NN00-

N0019.) under 100 mm of Acoustic insulation code AB.

6. Code HAC = Indicated thickness of hot insulation (Spec. 25113-000-3PS-NN00-

N0019.) under 100 mm of Acoustic insulation with 1.3mm thick steel coated

cladding.

Exhibit D, 15 April 2007 Page 11 of 15 Subcontract 25113-000-FC3-NN00-00001

d. Other Insulation and cladding:

• Refractory Insulation will be in accordance with the following specifications:

1. Project Specification 25113-000-3PS-NR00-N0024 titled Addendum Materials

Installation and Testing Requirements for Refractory Systems.

2. 25113-000-3PS-NR00-N0024 Attachment -001 DGS 6531 020 Rev 0 titled

Materials Installation and Testing Requirements for Refractory Systems.

Materials shall be provided Free Issue to SUBCONTRACTOR.

SUBCONTRACTOR’s scope is insulation of the Radiant, Stack and Transition only

refer to Tag A, G and H of GA drawing No. 25113-V1A-MBH0-BA001 Rev 0

• Insulation of instrument tubing; - stainless steel ½” diameter instrument tubing

(~ 200 linear meters) tails including inline valves. Insulation to be 25mm thick

glass rope with 3mm thick vapours seal mastic.

• Installation of fire boxes around valves: There are approximate 200 ESD valve

boxes and 80 wafer check valve boxes. Boxes shall be provided Free Issue to

SUBCONTRACTOR as flat packs. These boxes will vary from 0.5M x 0.5M x

0.5M up to 4M x 1M x 1M. SUBCONTRACTOR’s responsibility will be to

assemble flat packs, cut holes for pipework, pneumatic and power cables, seal

penetrations and fill the boxes with expandable foam.

3.5 Work After Start-Up and Commissioning

SUBCONTRACTOR’s scope of work also includes correction of any punch list items or

defects including correction of any items identified after start-up and commissioning

activities have been performed including but not limited to modifications to correct items

caused by thermal expansion and contraction.

4. QUANTITY AND PROGRESS MEASUREMENT

a. Piping Insulation and cladding

Piping insulation and cladding quantities shall be measured per linear meter based on

neat-line, centre line to centre line measurements from isometrics. No additional

allowances shall be made for any fittings, bends, tees, trunnions, supports, etc. Lengths

through valves and flanges shall not be measured.

Valves shall be measured per valve box, per valve size only. Valves shall include any

flanges connecting the valve to the pipework.

Other than valve flanges, flanges shall be measured per pair of flanges, per size only.

Progress measurement shall be performed in strict accordance with the following control

points:

For Cold Insulation:

1. First Layer 35%

2. 2nd Layer 30%

3. Vapor Barrier 10%

4. Cladding 10%

Exhibit D, 15 April 2007 Page 12 of 15 Subcontract 25113-000-FC3-NN00-00001

5. Final Inspection / Punchlist Completed 15%

For Hot Insulation:

1. Rock Wool 60%

2. Cladding 25%

3. Final Inspection / Punchlist Completed 15%

b. Equipment Insulation and cladding

Equipment insulation and cladding shall be measured per piece of equipment.

SUBCONTRACTOR shall provide a square meter (m2) quantity measurement for review

and agreement by CONTRACTOR to allow quantity and progress measurement. Such

measurements are for progress information only and shall not be used for adjustments to

the price.

Included in the measurement of the equipment shall be all nozzles, support brackets

flanges, man ways, and appurtenances up to and including the first bolted connection.

Progress measurement shall be performed in strict accordance with the following control

points:

For Cold Insulation:

1. First Layer 35%

2. 2nd Layer 30%

3. Vapor Barrier 10%

4. Cladding 10%

5. Final Inspection / Punchlist Completed 15%

For Hot Insulation:

1. Rock Wool 60%

2. Cladding 25%

3. Final Inspection / Punchlist Completed 15%

5. DELIVERABLES

a. Pre-Mobilization Deliverables

Prior to commencement of mobilization SUBCONTRACTOR shall ensure that the

following documents are submitted to CONTRACTOR for review and are returned with

authorization to proceed:

Item Description Reference

1 Designation of Authorized Representative Exhibit A, GC-2

2 Project Specific HSE Plan Exhibit A, GC-13

3 Full and Comprehensive Risk Assessment Exhibit A, GC-13

4 Project Specific Emergency Plan Exhibit A, GC-13

5 Environmental Compliance Plan Exhibit A, GC-14

6 Insurances Exhibit B, SC-2

7 Subcontract Schedule Exhibit B, SC-9

8 Security Plan Exhibit B, SC-11

9 Bank Guarantee(s) Exhibit B, SC-13

10 Lump Sum Breakdown (For Lump Sum Prices) Exhibit B, SC-14

11 Quality Management System Documentation Exhibit B, SC-17

12 CV’s of Key Personnel Exhibit D, Item 2.a

Exhibit D, 15 April 2007 Page 13 of 15 Subcontract 25113-000-FC3-NN00-00001

13 Material Approval Requests Exhibit D, Item 2.c

14 Request for Letter of Assistance Exhibit D, Item 2.d

15 Camp Layout Details Exhibit D, Item 2.d

16 Temporary Facilities layout details Exhibit D, Item 2.d

b. Pre-Commencement Deliverables

Prior to commencing any activities in the field, SUBCONTRACTOR shall ensure that the

following documents are submitted to CONTRACTOR for review and are returned with

authorization to proceed:

Item Description

1 Quality Control Plans for the work

2 Inspection and Test Plans for the work

3 Valid Calibration documents for test equipment

4 Material Take Offs

5 Fabrication Details

6 Installation sketches / application details

7 Method Statements

8 Sub-Tier Subcontractors for Approval

c. Construction Deliverables

During the course of the work SUBCONTRACTOR shall ensure that the following

documents are submitted to CONTRACTOR for review

Item Description

1 HSE Reports and statistics

2 Progress Reports and Schedule updates

3 Updated Material Take Offs

4 Material Reconciliations

6. WORK EXCLUDED

Any item not specifically detailed elsewhere in the Subcontract required to execute the supply

and installation of insulation and cladding shall be deemed as included in the Subcontract scope

of work and pricing.

7. PROJECT WORK HOURS

The Project working hours are ten (10) hours per day, six (6) days per week, Saturday through

Thursday. Specifically, the working hours are as follows:

Shift Start Finish

Morning 0700hrs 1200hrs

Lunch Break 1200hrs 1300hrs

Afternoon 1300hrs 1800hrs

SUBCONTRACTOR shall as a minimum work the above hours. Should SUBCONTRACTOR

elect to work additional hours to those stated above (Including work on Fridays),

SUBCONTRACTOR shall request permission from CONTRACTOR.

8. SPECIFICATIONS

Exhibit D, 15 April 2007 Page 14 of 15 Subcontract 25113-000-FC3-NN00-00001

The following specifications are included and form part of the Subcontract documents:

Item Specification Number Rev. Title

Addendum Project General

1 25113-000-3PS-NN00-N0019 3 Specification Hot Insulation For Piping

and Equipment

25113-000-3PS-NN00-N0019 Hot Insulation for Piping and Equipment

2 0

Attachment -001- DGS-6500-010

Addendum Project General

3 25113-000-3PS-NN00-N0020 3 Specification Cold Insulation For Piping

and Equipment

25113-000-3PS-NN00-N0020 Cold Insulation for Piping and

4 0 Equipment

Attachment 01 - DGS-6500-020

Addendum Project General

5 25113-000-3PS-NN00-N0040 2 Specification Acoustic Insulation for

Pipes, Valves and Fittings.

25113-000-3PS-NN00-N0040 Acoustic Insulation of Pipe, Valves and

6 0 Flanges

Attachment 001 DGS-6000-003

Addendum Materials installation and

7 25113-000-3PS-NR00-N0024 2 Testing Requirements for Refractory

System

25113-000-3PS-NR00-N0024 Materials Installation and Testing

8 0 Requirements for Refractory Systems.

Attachment 001 DGS 6531 020

Refractory Application and Dryout

9 25113-V1A-MB00-EL001 1

Procedure

10 25113-V1A-MBH0-JE001 1 Refractory Installation Procedure

11 25113-000-V1A-MBH0-ME001 0 Erection Manual

12 25113-000-V1A-MSXN-BE007 1 Thermal Insulation Summary

Exhibit D, 15 April 2007 Page 15 of 15 Subcontract 25113-000-FC3-NN00-00001

You might also like

- Construction Method StatementDocument5 pagesConstruction Method StatementumitNo ratings yet

- LPS-01-HTI-MST-ME-029- FIRE FIGHTING PIPES, VALVES AND ACCESSORIES.Document40 pagesLPS-01-HTI-MST-ME-029- FIRE FIGHTING PIPES, VALVES AND ACCESSORIES.aleemahmed 1090No ratings yet

- Lps 01 Hti MST Me 022 Chemical Dosing SystemDocument24 pagesLps 01 Hti MST Me 022 Chemical Dosing SystemJomy JohnyNo ratings yet

- Scope of WorkDocument13 pagesScope of Worknicko.arya.dharmaNo ratings yet

- T Proc Notices Notices 045 K Notice Doc 42308 18113514Document11 pagesT Proc Notices Notices 045 K Notice Doc 42308 18113514DusanJankovicNo ratings yet

- Lps 01 Hti MST Me 007 GRP Water TankDocument12 pagesLps 01 Hti MST Me 007 GRP Water TankJomy JohnyNo ratings yet

- 10-Exhibit X - Project Management and Project ControlsDocument15 pages10-Exhibit X - Project Management and Project ControlsMartino Ojwok AjangnayNo ratings yet

- Method of Statement - SCS SystemDocument20 pagesMethod of Statement - SCS SystemashifNo ratings yet

- Testing & Commissioning of CCTV System R0Document15 pagesTesting & Commissioning of CCTV System R0vipinkmlNo ratings yet

- EXW P006 0000 CS SHC MT 00096 Method Statement For Landscaping Rev.0Document28 pagesEXW P006 0000 CS SHC MT 00096 Method Statement For Landscaping Rev.0Syed Umair HashmiNo ratings yet

- Resume AZIZ BHAIDocument6 pagesResume AZIZ BHAIkaamNo ratings yet

- Hardcore Method StatementDocument10 pagesHardcore Method Statementirfan khanNo ratings yet

- MS For Installation of TilesDocument6 pagesMS For Installation of TilesImho TepNo ratings yet

- CO-227-2012 Schedule of Annexs PDFDocument441 pagesCO-227-2012 Schedule of Annexs PDFKorupoluNo ratings yet

- Prof. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMDocument43 pagesProf. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMKeristiyantoNo ratings yet

- 014 - G.I Duct, Accessories and FittingsDocument14 pages014 - G.I Duct, Accessories and FittingsJomy JohnyNo ratings yet

- HAC-10143-MS-CIV-001-Method Statement For Cast in Place ConcreteDocument10 pagesHAC-10143-MS-CIV-001-Method Statement For Cast in Place ConcreteHema playsNo ratings yet

- Method - Statement - For Water Proofing RCC WorkDocument10 pagesMethod - Statement - For Water Proofing RCC Workirfan khanNo ratings yet

- Method - Statement - For RCC in Beams and SlabsDocument15 pagesMethod - Statement - For RCC in Beams and Slabsirfan khan75% (4)

- MOS For Installation of HVAC DuctsDocument55 pagesMOS For Installation of HVAC DuctsMonish T MonuNo ratings yet

- Butterfly Damper InstallationDocument5 pagesButterfly Damper InstallationRepl microsoft, PuneNo ratings yet

- Instalaltion, Testing and Commissioning For The Clean Agent Syste..Document15 pagesInstalaltion, Testing and Commissioning For The Clean Agent Syste..Ahmad Omar100% (1)

- QA/QC Plan Ensures Project ComplianceDocument18 pagesQA/QC Plan Ensures Project ComplianceSen IMO67% (3)

- Mathodology-L (Cast in Situ Pile)Document17 pagesMathodology-L (Cast in Situ Pile)rashid01032No ratings yet

- M.S Concrete Works For SLABSDocument26 pagesM.S Concrete Works For SLABSMohamed GamalNo ratings yet

- Method Statement for CCTV InstallationDocument12 pagesMethod Statement for CCTV Installationdiptipatil100% (4)

- DX SplitDocument29 pagesDX Splitsiva_nagesh_2No ratings yet

- Bathroom Refurbishment Method StatementDocument9 pagesBathroom Refurbishment Method Statementadeniyi abiola100% (1)

- Scope of Work Forming Kingsway Project 1.1 GeneralDocument4 pagesScope of Work Forming Kingsway Project 1.1 GeneralYe YintNo ratings yet

- Excavation and Backfilling Method StatementDocument6 pagesExcavation and Backfilling Method StatementAdib SalahNo ratings yet

- Quality Systems Manual Method Statement: Timber Doors FixingDocument8 pagesQuality Systems Manual Method Statement: Timber Doors FixingLloyd MariNo ratings yet

- Aluminum Door and Window Installation Method StatementDocument10 pagesAluminum Door and Window Installation Method Statementirfan khan100% (1)

- GIG PlanDocument22 pagesGIG PlanMojtaba Andalib AzarNo ratings yet

- 9 Method Statement For Floor TilesDocument10 pages9 Method Statement For Floor Tilesirfan khanNo ratings yet

- POX SCRUBBER PROJECT EXECUTION PLANDocument7 pagesPOX SCRUBBER PROJECT EXECUTION PLANPham Thai TuyenNo ratings yet

- General Principles For Construction SupervisionDocument28 pagesGeneral Principles For Construction SupervisionMauro MLRNo ratings yet

- Ms - Ele - 01 - PVC Conduit & Gi BoxDocument17 pagesMs - Ele - 01 - PVC Conduit & Gi BoxromeyleenjosephNo ratings yet

- Special Conditions of Contract-Fit OutDocument66 pagesSpecial Conditions of Contract-Fit OutHemant SharmaNo ratings yet

- Scope of Work for Pipeline InstallationDocument10 pagesScope of Work for Pipeline InstallationAsongwe HansNo ratings yet

- Work Method StatementDocument7 pagesWork Method StatementBOUZAIDANo ratings yet

- SpecsDocument38 pagesSpecsleah yadaoNo ratings yet

- Job Description Form - Site EngineerDocument2 pagesJob Description Form - Site EngineeradelsaqqaNo ratings yet

- Quality Systems Manual Method Statement: Tiling Work (Floors and Walls)Document8 pagesQuality Systems Manual Method Statement: Tiling Work (Floors and Walls)Lloyd MariNo ratings yet

- Client: Method Statement For Construction of Civil WorksDocument17 pagesClient: Method Statement For Construction of Civil WorksAzharudin ZoechnyNo ratings yet

- PDF DocumentDocument23 pagesPDF Documentsallycya9631100% (1)

- Site Survey - Method of StatementDocument11 pagesSite Survey - Method of StatementEng hassan hussienNo ratings yet

- HAC-10143-MS-CIV-002-Method Statement For Mass ConcreteDocument9 pagesHAC-10143-MS-CIV-002-Method Statement For Mass ConcreteHema playsNo ratings yet

- AGCE 0523 MS MEC 001 Drainage SystemDocument24 pagesAGCE 0523 MS MEC 001 Drainage SystemromeyleenjosephNo ratings yet

- 02.method Statement Ver 2Document6 pages02.method Statement Ver 2Peter ade TeacherNo ratings yet

- CIC SITE Multidiscipline Inspector, Rev0Document2 pagesCIC SITE Multidiscipline Inspector, Rev0Nsidibe Michael EtimNo ratings yet

- SOW_KTCFloatationMachinesRepairs_Rev01 REVISED SCOPEDocument23 pagesSOW_KTCFloatationMachinesRepairs_Rev01 REVISED SCOPEm_muchakaziNo ratings yet

- Shaft BBT Installation: Method Statement - 002Document39 pagesShaft BBT Installation: Method Statement - 002Sufiyan KhedekarNo ratings yet

- 3-STAGES of Project Implementation PDFDocument102 pages3-STAGES of Project Implementation PDFDanao ErickNo ratings yet

- Quality PlanDocument29 pagesQuality PlanKareem AlselawyNo ratings yet

- QC ProgramDocument7 pagesQC ProgramHerbert HernandezNo ratings yet

- Duties and Responsibilities of DPWH FEDocument57 pagesDuties and Responsibilities of DPWH FEAl-Gabid Arton100% (2)

- Method Statements Civil by AL HAJRI CORPORATIONDocument156 pagesMethod Statements Civil by AL HAJRI CORPORATIONBhavanishankar ShettyNo ratings yet

- Lps-01-Hti-Mst-Me-024 - Fan Coil UnitDocument12 pagesLps-01-Hti-Mst-Me-024 - Fan Coil UnitJomy JohnyNo ratings yet

- Construction Quality Control PlanDocument10 pagesConstruction Quality Control PlanRawofi Abdul mateenNo ratings yet

- RFI Request for InformationDocument1 pageRFI Request for InformationAhmad Abd RabouNo ratings yet

- Understanding Primavera P6 Database Settings by Paul E HarrisDocument13 pagesUnderstanding Primavera P6 Database Settings by Paul E HarrisAhmad Abd RabouNo ratings yet

- Eastern Bechtel Co. Drawings and Technical Data for InsulationDocument7 pagesEastern Bechtel Co. Drawings and Technical Data for InsulationAhmad Abd RabouNo ratings yet

- 02 - Exhibit B - 15 April 07Document34 pages02 - Exhibit B - 15 April 07Ahmad Abd RabouNo ratings yet

- 01 - Exhibit A - 15 April 07Document30 pages01 - Exhibit A - 15 April 07Ahmad Abd RabouNo ratings yet

- 00 - Form of AgreementDocument2 pages00 - Form of AgreementAhmad Abd RabouNo ratings yet

- 07 - Exhibit D - Appendix D-1 Project ProcedureDocument1 page07 - Exhibit D - Appendix D-1 Project ProcedureAhmad Abd RabouNo ratings yet

- Mit18 06scf11 Ses3.6probDocument2 pagesMit18 06scf11 Ses3.6probAhmad Abd RabouNo ratings yet

- MIT18 06SCF11 FinalRevsum PDFDocument7 pagesMIT18 06SCF11 FinalRevsum PDFDevendraReddyPoreddyNo ratings yet

- Schedule Assessment Guide - Best Practices For Project Schedules Dic15Document240 pagesSchedule Assessment Guide - Best Practices For Project Schedules Dic15José Nolasco100% (1)

- Introduction To Machine Learning - WikipediaDocument456 pagesIntroduction To Machine Learning - WikipediaAnonymous nfkeFRNo ratings yet

- Understanding Machine Learning Theory AlgorithmsDocument449 pagesUnderstanding Machine Learning Theory AlgorithmsHigor EduardoNo ratings yet

- Csi Masterformat 1995 Edition PDFDocument2 pagesCsi Masterformat 1995 Edition PDFrobelineNo ratings yet

- REDOX Reaction: CombustionDocument13 pagesREDOX Reaction: Combustionanwar9602020No ratings yet

- BC Wire Rope 2017 Product Catalog Full PDFDocument88 pagesBC Wire Rope 2017 Product Catalog Full PDFogun tokucNo ratings yet

- Overview of NDE in ASMEDocument19 pagesOverview of NDE in ASMEdhirendarjiNo ratings yet

- S 4 7510 Model BDV 30 Deg. Pneu. Act.Document1 pageS 4 7510 Model BDV 30 Deg. Pneu. Act.aatsh38No ratings yet

- ABC Fire Extinguishers-NAFFCODocument8 pagesABC Fire Extinguishers-NAFFCORamizGollaNo ratings yet

- Hot-Rolled Steel Strip: Range of Supply April 2018Document9 pagesHot-Rolled Steel Strip: Range of Supply April 2018L Mahender ReddyNo ratings yet

- EDS-A-0101: Automotive Restricted Hazardous Substances For PartsDocument14 pagesEDS-A-0101: Automotive Restricted Hazardous Substances For PartsMuthu GaneshNo ratings yet

- Power International - BrochureDocument19 pagesPower International - BrochureSaurabh Kumar SinghNo ratings yet

- Me Pipe Fitting Bending S3199e en 140790Document66 pagesMe Pipe Fitting Bending S3199e en 140790Slim EL-EUCHNo ratings yet

- Review On CarbotaniumDocument20 pagesReview On CarbotaniumSahil DalalNo ratings yet

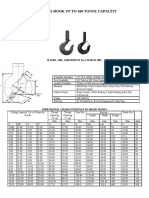

- Shanks Hook Up To 160 Tonne Capacity: IS 15560: 2005 AMENDMENT No:1 MARCH 2007Document2 pagesShanks Hook Up To 160 Tonne Capacity: IS 15560: 2005 AMENDMENT No:1 MARCH 2007liftline engineersNo ratings yet

- Platinum Metals Catalvtic Systems in Nitric Acid Production: by V. I. Chernyshov and I. MDocument8 pagesPlatinum Metals Catalvtic Systems in Nitric Acid Production: by V. I. Chernyshov and I. MJaneNo ratings yet

- Cold Finished Stainless Steel Tube Technology Flow ChartDocument13 pagesCold Finished Stainless Steel Tube Technology Flow ChartGonzalo MazaNo ratings yet

- Steel Track Spikes: Standard Specification ForDocument4 pagesSteel Track Spikes: Standard Specification ForVIKAS DAHIYANo ratings yet

- Petunjuk Pemilihan Valve PDFDocument165 pagesPetunjuk Pemilihan Valve PDFandistwn99No ratings yet

- BOWEN Storage CH1 PalletrackingDocument34 pagesBOWEN Storage CH1 PalletrackingMnttoMecNo ratings yet

- Roof Specialties for Alamein Downtown TowersDocument6 pagesRoof Specialties for Alamein Downtown TowersWENDING HUNo ratings yet

- High Strength Precipitation Hardening and Duplex Stainless Steel Bolting For Special Purpose ApplicationsDocument6 pagesHigh Strength Precipitation Hardening and Duplex Stainless Steel Bolting For Special Purpose ApplicationsDanZel DanNo ratings yet

- (BS 4311-3-1993) - Specification For Gauge Blocks and Accessories.. Gauge Blocks in UseDocument14 pages(BS 4311-3-1993) - Specification For Gauge Blocks and Accessories.. Gauge Blocks in Useboborg8792No ratings yet

- Araldite Standard PDFDocument3 pagesAraldite Standard PDFGRAVYMATRIX VENTURESNo ratings yet

- High Deposition Wire Arc Additive Manufacturing of Mild Steel - Strategies and Heat Input Effect On Microstructure and Mechanical PropertiesDocument12 pagesHigh Deposition Wire Arc Additive Manufacturing of Mild Steel - Strategies and Heat Input Effect On Microstructure and Mechanical PropertiesNabeelNo ratings yet

- Process Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003Document31 pagesProcess Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003m4metzNo ratings yet

- Debeers'S Diamond DilemmaDocument19 pagesDebeers'S Diamond DilemmaTosin GeorgeNo ratings yet

- Harmonized "Cluster" Document: Fasteners Property Classes of Special ServiceDocument7 pagesHarmonized "Cluster" Document: Fasteners Property Classes of Special ServiceIBRNo ratings yet

- Vortex Business Center Construction SpecificationsDocument602 pagesVortex Business Center Construction Specificationsjoe davis100% (2)

- Rust-Guard: Description Product CharacteristicsDocument1 pageRust-Guard: Description Product CharacteristicsDouglas Neves - UnaxNo ratings yet

- Corrosion Failures: Thirunavukarasu.H 13MY12Document47 pagesCorrosion Failures: Thirunavukarasu.H 13MY12soundrapandianNo ratings yet

- MRB & MRB-S: Plate Roll BendingDocument12 pagesMRB & MRB-S: Plate Roll BendingFranpao AtenportNo ratings yet

- IRS-T-12-2009 Incorporated Up To ACS 5, Corrigendum 1 of ACS No 1 and 5Document81 pagesIRS-T-12-2009 Incorporated Up To ACS 5, Corrigendum 1 of ACS No 1 and 5Dwijamani SinghaNo ratings yet

- Evers and Sons Inc.: Welding Procedure Specification (WpsDocument3 pagesEvers and Sons Inc.: Welding Procedure Specification (WpsRaja HoneNo ratings yet