Professional Documents

Culture Documents

Point 1 - A) 4M Change Control Tracking Sheet Revised 01

Uploaded by

mahesh KhatalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Point 1 - A) 4M Change Control Tracking Sheet Revised 01

Uploaded by

mahesh KhatalCopyright:

Available Formats

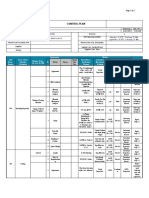

4M Change Control tracking sheet

1. Any Product process Changes with respect to 4 M & abnormal situation, will be recorded controlled and informed to management and customer of EEIPL (if required) for approval. No Change will be implemented

Month without management approval or customer approval (if required).

1. Incase of any Change, kindly fill the Reason for Change, Part name & No, Change Implementation Date at the time of submission every month.

Note : Incase of no change, write : "NO" in the below column. 2. All records related to any change should be maintain by Supplier

Customer Approval Document to be Submitted to Customer

Change Identification Change Implementation Document Change Details

Change Item

(Yes / No)

Reason for Change Part Name & No

Date submission Date (Incase of Change) Remarks

Inspection

Reqd Not Reqd CP/PFD Report /material PPAP PFMEA

TC

Different spec / grade

Raw material size/thickness/weight

Material Different raw material approved supplier

Any Child-part change (Machine/Supplier/MethodMaterial)

Child-part change (Perm Deviation)

Process change Sequence or Addition of process

New Technology

Sub-process supplier change

Method

Packaging change ( Bin/Trolley Dispatches)

Traceability (Batch code) marking change

Inspection method/ Inspection Frequency changed

Die /Tooling change ( Modification)

Machine change

Machine Welding fixtures change

Removal / Addition of Pokayoke

M/c parameter change

Signature

Name Mahesh Khatal Mr.Awdhut Kulkarni

Designation QMS Engineer QA Head Plant Manager

You might also like

- Plating Process Control Plan Template (2738)Document10 pagesPlating Process Control Plan Template (2738)George Hardy100% (1)

- Change Request Form: Supplier Information Change Tracking Number InformationDocument3 pagesChange Request Form: Supplier Information Change Tracking Number Informationswaran autoqaNo ratings yet

- Sample PPAP Level-3Document36 pagesSample PPAP Level-3Mr. Mafia BhargavNo ratings yet

- Brother Sewing Machine InstructionsDocument56 pagesBrother Sewing Machine InstructionsDwaine Webb100% (1)

- Keyprog BrochureDocument52 pagesKeyprog BrochureSimone G. GoularteNo ratings yet

- AIAG & VDA PFMEA FormatDocument1 pageAIAG & VDA PFMEA Formatmahesh KhatalNo ratings yet

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- 4M Change RequestDocument5 pages4M Change RequestNJMU LAB67% (3)

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- Use This As Reference For Painting Process It May Be Similar To YoursDocument7 pagesUse This As Reference For Painting Process It May Be Similar To Yoursabdelnasser hasanNo ratings yet

- 4M Change ManagementDocument2 pages4M Change ManagementManoj KumarNo ratings yet

- 0706 Product Change Request FormDocument2 pages0706 Product Change Request FormulyssesNo ratings yet

- Control Plan ExampleDocument1 pageControl Plan Examplelingkungan.agathaNo ratings yet

- Control PlanDocument2 pagesControl PlanChintamani Giramkar100% (1)

- Engineering Change / Process Change Request Form: MDT ApprovalDocument4 pagesEngineering Change / Process Change Request Form: MDT ApprovalRaja Durai100% (2)

- Process Change NoteDocument1 pageProcess Change NoteSUBODHHNo ratings yet

- 4m Change & Ecn NoteDocument1 page4m Change & Ecn NoteAnurag ChaudharyNo ratings yet

- Sop For Change ManagementDocument1 pageSop For Change ManagementGaurav Wadhwa0% (1)

- Statement of Work AccomplishedDocument42 pagesStatement of Work Accomplishederwinsarmiento100% (1)

- Itp-Inspection & Test Plan: Containment InstallationDocument1 pageItp-Inspection & Test Plan: Containment InstallationwagwahkiabatheNo ratings yet

- HF MG.26.02CRF Change Request FormDocument4 pagesHF MG.26.02CRF Change Request FormGeovanny Hernández0% (1)

- Siegel Robert Automotive Layered Process Audit ChecklistDocument12 pagesSiegel Robert Automotive Layered Process Audit Checklistmahesh KhatalNo ratings yet

- DS-09-01 R0 Communication During ChangeDocument1 pageDS-09-01 R0 Communication During ChangeDhinakaranNo ratings yet

- 4TNV98 ZggeDocument2 pages4TNV98 ZggeMohammed Al-hewaimelNo ratings yet

- PPAP Approval Request (PSW)Document1 pagePPAP Approval Request (PSW)angelokyoNo ratings yet

- Iecee Od-2025-B-2016Document21 pagesIecee Od-2025-B-2016krivitskiNo ratings yet

- 4M Sheet FormatDocument3 pages4M Sheet FormatManikandanNo ratings yet

- Point 1 - B) Procedure For Managemet of ChangeDocument3 pagesPoint 1 - B) Procedure For Managemet of Changemahesh KhatalNo ratings yet

- 4M Change Management Matrix-Rane NSK-signedDocument1 page4M Change Management Matrix-Rane NSK-signednitin rathoreNo ratings yet

- 4M Change Management For Supplier - TennecoDocument1 page4M Change Management For Supplier - TennecoOBSC PerfectionNo ratings yet

- 4M Change Management FormatDocument1 page4M Change Management FormatSUBODHH100% (2)

- 8991 7428 00 Diagrams and Drawings PDFDocument66 pages8991 7428 00 Diagrams and Drawings PDFjuangomezsanNo ratings yet

- Change Control Management Matrix For Vendors (Vendor Name) Report FormatDocument6 pagesChange Control Management Matrix For Vendors (Vendor Name) Report FormatVaruNo ratings yet

- Supplier Change Request (SCR) : Approved PSWDocument3 pagesSupplier Change Request (SCR) : Approved PSWswaran autoqaNo ratings yet

- 4M Change FormatDocument1 page4M Change FormatOBSC PerfectionNo ratings yet

- Plan ControlDocument14 pagesPlan ControlJesus J Paniagua SegoviaNo ratings yet

- Control Plan Template 2011 PDFDocument1 pageControl Plan Template 2011 PDFSenthil_KNo ratings yet

- CP Gear Spindle MkeDocument2 pagesCP Gear Spindle Mkeamol vadnereNo ratings yet

- R&M Manual Partes CXTDocument20 pagesR&M Manual Partes CXTCarlos RomeroNo ratings yet

- EMAG Marketplace API Documentation v4.2.0Document43 pagesEMAG Marketplace API Documentation v4.2.0David AndreicaNo ratings yet

- 4M Change Format SLSPL Jun'22Document1 page4M Change Format SLSPL Jun'22Balasankar PNo ratings yet

- Katyani Apr'23Document1 pageKatyani Apr'23satrughanNo ratings yet

- Katyani Jun'23Document1 pageKatyani Jun'23satrughanNo ratings yet

- Katyani May'23Document1 pageKatyani May'23satrughanNo ratings yet

- 4M Change Format SLSPL Oct''22Document1 page4M Change Format SLSPL Oct''22Balasankar PNo ratings yet

- 4M Change Format SLSPL Nov''22Document1 page4M Change Format SLSPL Nov''22Balasankar P100% (1)

- 4M Change Format SLSPL Jul'22Document1 page4M Change Format SLSPL Jul'22Balasankar PNo ratings yet

- Fm-npd-16 (Temp. Change Request Note)Document1 pageFm-npd-16 (Temp. Change Request Note)akash.vd.1603No ratings yet

- 18 4M Change Request Cum Approval FormDocument1 page18 4M Change Request Cum Approval FormRS MANIKANDANNo ratings yet

- 7.2.6-2-4M Change Data From Supplier - AfterDocument5 pages7.2.6-2-4M Change Data From Supplier - AfterKaran MalhiNo ratings yet

- 4M SheetDocument1 page4M SheetubraghuNo ratings yet

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- 4M SheetDocument1 page4M SheetUttam Saini100% (2)

- H0294281 CP UpdatedDocument2 pagesH0294281 CP UpdatedSandeep SinghNo ratings yet

- 4M SheetDocument1 page4M Sheetmani317No ratings yet

- Pentair PPAP Guideline Level 3 - Rev 2021Document14 pagesPentair PPAP Guideline Level 3 - Rev 2021Cuarto ChinoNo ratings yet

- Change Control Form: Giva Olviana YudhistaDocument4 pagesChange Control Form: Giva Olviana YudhistaFajarRachmadiNo ratings yet

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- TJ PCP 2018 0774 1Document22 pagesTJ PCP 2018 0774 1Welinton Alexander Nivar RuizNo ratings yet

- Describe and Compare Below The Changes Requested To Current Product Features/requirementsDocument1 pageDescribe and Compare Below The Changes Requested To Current Product Features/requirementsdrustagiNo ratings yet

- Quality Inspection Checking Dimensional Measurement: Move Mat'l To Store For Further UsageDocument1 pageQuality Inspection Checking Dimensional Measurement: Move Mat'l To Store For Further UsageRishi GautamNo ratings yet

- Change Control Alaxan FR Capsule 2020Document6 pagesChange Control Alaxan FR Capsule 2020Rio FebriansyahNo ratings yet

- 4M Change FormatDocument1 page4M Change FormatdesigansuryaNo ratings yet

- F-PD-02 Control PlanDocument1 pageF-PD-02 Control PlanTrivesh SharmaNo ratings yet

- Annexure I Change Control FormDocument4 pagesAnnexure I Change Control FormSÜMME AÇIKGÖZNo ratings yet

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiNo ratings yet

- Appendix 1 - Inspection & Test PlanDocument4 pagesAppendix 1 - Inspection & Test PlanwagwahkiabatheNo ratings yet

- Number: Weight (KG)Document2 pagesNumber: Weight (KG)secretNo ratings yet

- FSD 5Document2 pagesFSD 5mahesh KhatalNo ratings yet

- FSD 07Document3 pagesFSD 07mahesh KhatalNo ratings yet

- Requirement 1 - PR No. Is Mandatory in PO For Plants 1100,2200,3300Document3 pagesRequirement 1 - PR No. Is Mandatory in PO For Plants 1100,2200,3300mahesh KhatalNo ratings yet

- FSD-1 Rservation OkDocument2 pagesFSD-1 Rservation Okmahesh KhatalNo ratings yet

- FSD-3 OkDocument2 pagesFSD-3 Okmahesh KhatalNo ratings yet

- Bapi For AllDocument8 pagesBapi For Allmahesh KhatalNo ratings yet

- Chapter 12 - Changes Related: (Clause Description-Paraphrase)Document11 pagesChapter 12 - Changes Related: (Clause Description-Paraphrase)mahesh KhatalNo ratings yet

- Aiag-: Electrica India 1Document12 pagesAiag-: Electrica India 1mahesh KhatalNo ratings yet

- Fifo, Lifo, FefoDocument1 pageFifo, Lifo, Fefomahesh KhatalNo ratings yet

- Supplier Health Check Sheet - Rev 01ADocument9 pagesSupplier Health Check Sheet - Rev 01Amahesh KhatalNo ratings yet

- B-Audit Check ListDocument3 pagesB-Audit Check Listmahesh KhatalNo ratings yet

- CB Communique - 2021 012 IATF ADP Pre Study Requirements For New Auditor CandidatesDocument1 pageCB Communique - 2021 012 IATF ADP Pre Study Requirements For New Auditor Candidatesmahesh KhatalNo ratings yet

- 2022 Calendar With Us Week Numbers Landscape BlueDocument1 page2022 Calendar With Us Week Numbers Landscape Bluemahesh KhatalNo ratings yet

- Part Details: Gauge Type: Snap GaugeDocument2 pagesPart Details: Gauge Type: Snap Gaugemahesh KhatalNo ratings yet

- Electrica Engineers India Pvt. LTD.: Escalation Matrix For DefectsDocument1 pageElectrica Engineers India Pvt. LTD.: Escalation Matrix For Defectsmahesh KhatalNo ratings yet

- Sustainability Rating (S-Rating) FAQ: Verantwortlich: Status: DatumDocument6 pagesSustainability Rating (S-Rating) FAQ: Verantwortlich: Status: Datummahesh KhatalNo ratings yet

- Model Scheme On Fish Cold StoragesDocument23 pagesModel Scheme On Fish Cold StoragesHarry SingadilagaNo ratings yet

- Oracle® MRP: User's Guide Release 12.1Document544 pagesOracle® MRP: User's Guide Release 12.1Vikram ReddyNo ratings yet

- Rev 3Document35 pagesRev 3Rathnakraja0% (1)

- 1490Document8 pages1490Ahmed SaadNo ratings yet

- HCP - December 2019Document135 pagesHCP - December 2019kishna00950% (2)

- E46 AirbagDocument6 pagesE46 AirbagTutzu99No ratings yet

- NACA SeriesDocument31 pagesNACA SeriesAli OkumuşNo ratings yet

- Quality Control Plan TemplateDocument3 pagesQuality Control Plan Templatejon aquinoNo ratings yet

- Water Plane ComputationDocument14 pagesWater Plane ComputationAchonk Gio VelenoNo ratings yet

- Company ProfileDocument20 pagesCompany ProfileTung Bui ThanhNo ratings yet

- Pre SAE AS1946FDocument5 pagesPre SAE AS1946FRangaNo ratings yet

- Hexa Research IncDocument5 pagesHexa Research Incapi-293819200No ratings yet

- Determining Product Leakage From A Package With A Mechanical Pump DispenserDocument2 pagesDetermining Product Leakage From A Package With A Mechanical Pump DispenserMohanadNo ratings yet

- Markets For Air Transport ServicesDocument26 pagesMarkets For Air Transport ServicesMohasin85100% (1)

- Importance and Objectives of Maintenance Types of Maintenance, Maintenance Systems Planned and Unplanned MaintenanceDocument17 pagesImportance and Objectives of Maintenance Types of Maintenance, Maintenance Systems Planned and Unplanned MaintenanceDeblina ChakrabortyNo ratings yet

- TMX800SDocument21 pagesTMX800ScuongNo ratings yet

- Bpo KpoDocument19 pagesBpo KpoRuchita MehtaNo ratings yet

- Contact Type in Oil and Gas - 1Document5 pagesContact Type in Oil and Gas - 1Halimi AyoubNo ratings yet

- Optional Service Bulletin OSB 42-134/1 OSB 42NG-073/1: I Technical DetailsDocument7 pagesOptional Service Bulletin OSB 42-134/1 OSB 42NG-073/1: I Technical DetailsSameer KshitizNo ratings yet

- B+V Manual - CLS-100-150-Rev003-08042010Document28 pagesB+V Manual - CLS-100-150-Rev003-08042010ZEESHAN ASHRAFNo ratings yet

- Shell Omala BrochureDocument2 pagesShell Omala BrochurehuseynseymenNo ratings yet