Professional Documents

Culture Documents

Validation Plan L68 (35OBLU, N6729) - 2PM 120722

Validation Plan L68 (35OBLU, N6729) - 2PM 120722

Uploaded by

NUR NAJIHAH BINTI SHAHARRUDENOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Validation Plan L68 (35OBLU, N6729) - 2PM 120722

Validation Plan L68 (35OBLU, N6729) - 2PM 120722

Uploaded by

NUR NAJIHAH BINTI SHAHARRUDENCopyright:

Available Formats

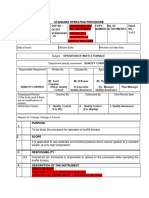

VALIDATION PIC: NAJIHA

Validation Stage : Performance Qualification (PQ)

Validation Line : 68

Validation Date : 7/12/2022

Choice : 20

Size : M size & N/A size

Product : NB-AB-OLPF-035-SE-OBLU-ASTM

Latex : NANTEX 6729 + 7PHR HSD

Validation Reason : New product at Line 64

Target Setting : Normal Chain Speed vs Normal Main Oven Temp.

Chain Speed Range : 43.0 – 49.0k (average)

Main Oven Range : 110-130C

Production

Setting 1 Time Task

A1 2pm - 3pm 1. Record data for line speed, main oven temp., coagulant temp., and latex temp., for every 5 minutes during validation time.

B1 4pm - 5pm 2. Take chlorine sample every half hour and send to lab starting 2pm

C1 6pm - 7pm 3. GL to send the Process Control Checklist and validation form to QAI after complete by 7/13/2022

Packing

Setting Batch Start Time Task

1. Hold glove for all validation batches

A1 2pm 2. Prepare samples for each batch: - 1 inner M size & N/A size and send to lab

B1 4pm - 12pcs M size and send to lab

C1 6pm - 50 pcs M size and send to QAI

- 60pcs M size and send to PSI

*Samples should be taken 45 mins after batch start time.

3. Key in the details for the validation batch into the 'Quarantine Validation Batch' label

4. Before quarantine sticker is printed, please email the 'quarantine form' with details of green column to validation team

5. Paste the 'Quarantine Validation Batch' label onto validation batches pallet before sending to warehouse.

6. Validation team will verify the sticker pasted with packing PIC one day after validation. (Based on the details sent by packing)

7. Validation batch must not be included in sampling carton.

8. If validation batches are included, sampling carton must be quarantined at a designated area in warehouse and must not be

inspected until emailed PASS

Lab

Setting Batch Start Time Task

1. Conduct calibration for main oven at: 1.45pm

A1 2pm 4.30pm

B1 4pm 7pm

C1 6pm 2. Conduct testing on %CN and TSC for all 3 batches

3. Conduct hotbox testing for all 3 batches

4. Conduct powder test 2 times

(1st test: As normal, 2nd test: After 4 days from the first test)

5. Immediately send the extra samples to PSI. Write in the validation log book once the sample has been taken for powder test.

6. Conduct colour test for each batch.

QAI

Setting Batch Start Time Task

1. Provide BQR for all 3 batches with serial no that match the sample provided by packing

A1 2pm 2. Measure the dimension of gloves (3 batches) provided by packing

B1 4pm 3. Enter dimension data into public folder

C1 6pm 4. Please inform immediately if any of the 3 batches are not SP

5. Please send the dimension and BQR including with validation form and checklist from GL production to validation team

6. Retain dimension sample and repeat visual test after 4 days from validation date 7/16/2022

PSI

Setting Batch Start Time Task

1. Please conduct before aging and after aging for ASTM, EN for all 3 batches

A1 2pm 2. Before aging result must be provided to validation team latest 4 days after validation conducted: 7/16/2022

B1 4pm

C1 6pm

You might also like

- APQP PPAP QuestionnaireDocument2 pagesAPQP PPAP QuestionnaireKumaravel81% (16)

- TULIPS - Potted Plant PatternDocument5 pagesTULIPS - Potted Plant PatternAlthea Marie Teston100% (3)

- Tail of The Blue Bird by Parkes, Nii AyikweiDocument140 pagesTail of The Blue Bird by Parkes, Nii AyikweiEduardo Crivelli100% (1)

- Wsc2022se Tp34 en PreDocument13 pagesWsc2022se Tp34 en PreClaudia MontanaresNo ratings yet

- MESB333 Lab Manual (Uniten)Document73 pagesMESB333 Lab Manual (Uniten)Natalie Ninachuu0% (1)

- Complete Popcorn ExerciseDocument26 pagesComplete Popcorn ExerciseNur HidayatiNo ratings yet

- SOP Muff FurnaceDocument2 pagesSOP Muff FurnaceDeepakKumarNo ratings yet

- Recipe Confirmation SOPDocument2 pagesRecipe Confirmation SOPalomNo ratings yet

- Microbiological Test PlanDocument2 pagesMicrobiological Test PlanMansoor AhmedNo ratings yet

- Monthly Activity Plan FEB-2022Document2 pagesMonthly Activity Plan FEB-2022Abhijith jNo ratings yet

- Concrete Quality Control ResponsibilitiesDocument5 pagesConcrete Quality Control ResponsibilitiesOzy SalatigaNo ratings yet

- CRP W.I. SOP For FinecareDocument2 pagesCRP W.I. SOP For Finecareslh labNo ratings yet

- Laboratory Manual PDFDocument81 pagesLaboratory Manual PDFaman badashaalam100% (1)

- Trial Scheme of PF Resin & BrcksDocument26 pagesTrial Scheme of PF Resin & BrcksDevarshi GaurNo ratings yet

- 2.4 Quality Tests On Blown or Oxidized Asphalt-cByPevJNzFDocument13 pages2.4 Quality Tests On Blown or Oxidized Asphalt-cByPevJNzFMike Joseph MorallosNo ratings yet

- Action ListDocument6 pagesAction Listqc1No ratings yet

- USP 797 Proposed Revision September 2021 - Check Your Understanding - Updated USP 797 7.6.22Document3 pagesUSP 797 Proposed Revision September 2021 - Check Your Understanding - Updated USP 797 7.6.22Alan KimNo ratings yet

- NutriFeeds-LAB-SOP-16 SOP Balance VerificationDocument5 pagesNutriFeeds-LAB-SOP-16 SOP Balance VerificationMartellRNo ratings yet

- HMCL Supplier PPAP ChecklistDocument6 pagesHMCL Supplier PPAP ChecklistSumeet RatheeNo ratings yet

- No. Process DescriptionDocument2 pagesNo. Process DescriptionShu ShuadaNo ratings yet

- Autoclave ValidationDocument7 pagesAutoclave ValidationMohanad Alashkar100% (1)

- Review of The Operation Scenarios and Required Manning of The ActivitiesDocument24 pagesReview of The Operation Scenarios and Required Manning of The ActivitieshasanNo ratings yet

- EIA INTERDEPARTMENTAL PANEL NON CONFORMITY (Final)Document4 pagesEIA INTERDEPARTMENTAL PANEL NON CONFORMITY (Final)Devaraj SubrmanayamNo ratings yet

- Incoming Material Testing FormDocument13 pagesIncoming Material Testing FormsatrfiabagusNo ratings yet

- Process Sheet: Express Luck Egypt CompanyDocument169 pagesProcess Sheet: Express Luck Egypt Companymohamed abdullahNo ratings yet

- In House Quality SystemDocument1 pageIn House Quality SystemBem's SquadNo ratings yet

- C 149 - 86 R00 Qze0oqDocument2 pagesC 149 - 86 R00 Qze0oqalucard375No ratings yet

- Autoclave Validation Protocol1Document7 pagesAutoclave Validation Protocol1inesdupres100% (3)

- B IngDocument2 pagesB IngStarsNo ratings yet

- New Project ACI - PoltakDocument13 pagesNew Project ACI - PoltakD.b. TampubolonNo ratings yet

- Apparel China Import Quarantine (CIQ) Material Pre-Qualification ProcessDocument2 pagesApparel China Import Quarantine (CIQ) Material Pre-Qualification ProcessPopper JohnNo ratings yet

- Understanding PCB Assy Process: I. Summary ActivityDocument3 pagesUnderstanding PCB Assy Process: I. Summary ActivityrizkiamandasNo ratings yet

- Process Flow SMTDocument3 pagesProcess Flow SMTrizkiamandasNo ratings yet

- Materi Cara Pembuatan PCB Di SMTDocument3 pagesMateri Cara Pembuatan PCB Di SMTrizkiamandasNo ratings yet

- 0902 0905 QC, QA PT (I II) (Class Notes) (Vanessa 2022)Document90 pages0902 0905 QC, QA PT (I II) (Class Notes) (Vanessa 2022)Vienne Yuen Wing YanNo ratings yet

- Bakery Portal 2019Document10 pagesBakery Portal 2019Nonor skyNo ratings yet

- SKMM 3443 - Project AssignmentDocument1 pageSKMM 3443 - Project AssignmentNorfae'zah MohammadNo ratings yet

- Individual Performance Commitment and Review (Ipcr) : Approved byDocument12 pagesIndividual Performance Commitment and Review (Ipcr) : Approved byEdgar DumagpiNo ratings yet

- C 481 - 99 QZQ4MQ - PDFDocument2 pagesC 481 - 99 QZQ4MQ - PDFJuanNo ratings yet

- General Technical Specifications For CS & SS Pipes and Pipe FittingsDocument10 pagesGeneral Technical Specifications For CS & SS Pipes and Pipe FittingsrajaNo ratings yet

- ClinitekStatusPlus 2019Document2 pagesClinitekStatusPlus 2019An NguyenNo ratings yet

- SOP Thermal CyclerDocument4 pagesSOP Thermal CyclerBioteknologi KelautanNo ratings yet

- Air-Cooled Chillers (ACCL) and Water-Cooled Chillers (WCCL) Certification Program UpdateDocument9 pagesAir-Cooled Chillers (ACCL) and Water-Cooled Chillers (WCCL) Certification Program Updatecs tanNo ratings yet

- Validation of CCPDocument2 pagesValidation of CCPpratishtha nirankariNo ratings yet

- Test Weight ReferenceDocument40 pagesTest Weight ReferenceImus CaviteNo ratings yet

- H8 Operation Flow ChartDocument1 pageH8 Operation Flow Chartgerente soportecNo ratings yet

- Phsophonate Content Solid ContentDocument1 pagePhsophonate Content Solid ContentGovindanayagi PattabiramanNo ratings yet

- Sop Ipc QaDocument8 pagesSop Ipc Qagulmat khanNo ratings yet

- Validation of IncubatorsDocument4 pagesValidation of Incubatorsltrevino100No ratings yet

- Testing Frequency For Revalidation of Vertical Laminar Airflow Cabinet - GOOD VALIDATION PRACTICE (CGVP) - Learnaboutgmp CommunityDocument2 pagesTesting Frequency For Revalidation of Vertical Laminar Airflow Cabinet - GOOD VALIDATION PRACTICE (CGVP) - Learnaboutgmp CommunityNowsathAliNo ratings yet

- A 25 A - Ash Content - tcm50-30933Document2 pagesA 25 A - Ash Content - tcm50-30933Mostafa AlakhliNo ratings yet

- Volatile Matter in Green Petroleum Coke Quartz Crucible ProcedureDocument4 pagesVolatile Matter in Green Petroleum Coke Quartz Crucible ProcedureAli VarmazyarNo ratings yet

- SHT Report 1Document6 pagesSHT Report 1tubagussinggihNo ratings yet

- Design of Batch ProcessesDocument19 pagesDesign of Batch ProcessesMathilda PasaribuNo ratings yet

- Work Method Statement FOR Dynamic Pile TestingDocument2 pagesWork Method Statement FOR Dynamic Pile TestingLynn MailNo ratings yet

- China Buy Equipment Socks List China Buy Apparel Socks ListDocument2 pagesChina Buy Equipment Socks List China Buy Apparel Socks ListPopper JohnNo ratings yet

- APQP+PPAP QuestionnaireDocument3 pagesAPQP+PPAP Questionnaireamit02mech0% (1)

- CHR08011R2.1 Golf China Style Test Process: Sr. Director Global Apparel & Equipment Product IntegrityDocument2 pagesCHR08011R2.1 Golf China Style Test Process: Sr. Director Global Apparel & Equipment Product IntegrityPopper JohnNo ratings yet

- Chapter 14: Exercise Questions: HR K HRDocument5 pagesChapter 14: Exercise Questions: HR K HRnivedhithaNo ratings yet

- Procedure For Calibration of Autoclave - SopDocument2 pagesProcedure For Calibration of Autoclave - SopVinod ChoudharyNo ratings yet

- Capsicum Oleoresin Sr. No 10Document63 pagesCapsicum Oleoresin Sr. No 10Arnold RafiqNo ratings yet

- Building a Successful Board-Test StrategyFrom EverandBuilding a Successful Board-Test StrategyRating: 4 out of 5 stars4/5 (1)

- "Probability": Arun Kumar, Ravindra Gokhale, and Nagarajan KrishnamurthyDocument53 pages"Probability": Arun Kumar, Ravindra Gokhale, and Nagarajan KrishnamurthyNirmal SasidharanNo ratings yet

- CyberbullyingDocument58 pagesCyberbullyingvitorperonaNo ratings yet

- Journal of Dentistry: Andrew Joiner, Wen LuoDocument8 pagesJournal of Dentistry: Andrew Joiner, Wen LuonajibNo ratings yet

- Grade 10 Physical Sciences Platinum Navigation PackDocument63 pagesGrade 10 Physical Sciences Platinum Navigation PackLethabo PhilphNo ratings yet

- Study of Microfine Cement Use On Squeeze CementingDocument5 pagesStudy of Microfine Cement Use On Squeeze CementingLưới DeNo ratings yet

- Poem in The Midst of HardshipDocument4 pagesPoem in The Midst of HardshipHanimaj MinNo ratings yet

- Digital MinimalismDocument22 pagesDigital MinimalismAhmad Sirojuddin100% (1)

- Mental Health Through Forgiveness Exploring The Roots and Benefits PDFDocument16 pagesMental Health Through Forgiveness Exploring The Roots and Benefits PDFshindyNo ratings yet

- Douglas Shine Sentencing OpinionDocument36 pagesDouglas Shine Sentencing OpinionCourtney Nicole100% (1)

- Esson: Regional Literary Compositions of Region 1Document9 pagesEsson: Regional Literary Compositions of Region 1ciedelle arandaNo ratings yet

- Fds - Tierra DiatomeaDocument2 pagesFds - Tierra DiatomeaBlasNo ratings yet

- 0007product CertificationDocument36 pages0007product CertificationbondsivamaniNo ratings yet

- Lesson 3 1Document25 pagesLesson 3 1G41 1SNo ratings yet

- Lord of The Flies (Themes, Messages, Literary Devices)Document20 pagesLord of The Flies (Themes, Messages, Literary Devices)Meltem Işık67% (3)

- Chemistry Sba ProjectDocument10 pagesChemistry Sba Project4L Anisha SieudassNo ratings yet

- Marshall County ScoresDocument4 pagesMarshall County ScoresMike BrownNo ratings yet

- EST Project AP... !..apDocument18 pagesEST Project AP... !..apTejas DeoreNo ratings yet

- Learners Voice SurveyDocument9 pagesLearners Voice SurveyNoel NicartNo ratings yet

- Daily Dose of Anime: Inuyasha!Document21 pagesDaily Dose of Anime: Inuyasha!Raven Tail100% (1)

- Coffee Cafe B PlanDocument33 pagesCoffee Cafe B PlanMayurBhayana75% (4)

- Juvenile Justice and Welfare Law Implementation: The Philippine Urban Poor City CaseDocument7 pagesJuvenile Justice and Welfare Law Implementation: The Philippine Urban Poor City CaseShanen LimNo ratings yet

- Allied Health - Geriatric Care 2Document193 pagesAllied Health - Geriatric Care 2Georgia GrantNo ratings yet

- Cyyz Star Sid Chart AerodromeDocument91 pagesCyyz Star Sid Chart AerodromekyoobumNo ratings yet

- Dv29Rme: Bukh Lifeboat Diesel EngineDocument2 pagesDv29Rme: Bukh Lifeboat Diesel EngineDinescu StefanNo ratings yet

- Details AliDocument1 pageDetails AliNadim SherifNo ratings yet

- Level SwitchDocument2 pagesLevel SwitchIon VairamuthuNo ratings yet

- BloodDocument18 pagesBloodadnankhaNo ratings yet

- Do You Need To Drink 8 Glasses of Water TranscriptDocument2 pagesDo You Need To Drink 8 Glasses of Water TranscriptHarold Saldy CasalemNo ratings yet