Professional Documents

Culture Documents

Document 1

Uploaded by

JAN JERICHO MENTOY0 ratings0% found this document useful (0 votes)

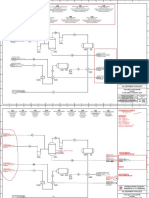

6 views1 pageComponents too heavy to evaporate are sent to the crude vacuum unit for a second distillation attempt. Upgrades were made, including incorporating a new HVGO draw, moving a pump-around cooler, and installing packing in the wash section. These changes increased the preheat temperature and VGO cut point while decreasing pressure and improving heavy oil conversion. The crude and vacuum units process all distillates for downstream conversion, so their operation and fractionation quality significantly impact downstream operations. A major goal is improving the crude/vacuum unit, typically through higher operating temperatures, but reliability must be ensured over the planned operational time frame.

Original Description:

Original Title

Document1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentComponents too heavy to evaporate are sent to the crude vacuum unit for a second distillation attempt. Upgrades were made, including incorporating a new HVGO draw, moving a pump-around cooler, and installing packing in the wash section. These changes increased the preheat temperature and VGO cut point while decreasing pressure and improving heavy oil conversion. The crude and vacuum units process all distillates for downstream conversion, so their operation and fractionation quality significantly impact downstream operations. A major goal is improving the crude/vacuum unit, typically through higher operating temperatures, but reliability must be ensured over the planned operational time frame.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageDocument 1

Uploaded by

JAN JERICHO MENTOYComponents too heavy to evaporate are sent to the crude vacuum unit for a second distillation attempt. Upgrades were made, including incorporating a new HVGO draw, moving a pump-around cooler, and installing packing in the wash section. These changes increased the preheat temperature and VGO cut point while decreasing pressure and improving heavy oil conversion. The crude and vacuum units process all distillates for downstream conversion, so their operation and fractionation quality significantly impact downstream operations. A major goal is improving the crude/vacuum unit, typically through higher operating temperatures, but reliability must be ensured over the planned operational time frame.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

CONCEPT PAER

Components of hydrocarbons that are too heavy to evaporate in the atmosphere

drop into the stream of leftovers drawn at the base of the column (atmospheric

residue). The crude vacuum unit is the next stop for this stream, when a second

attempt is made.

makes use of distillates to recover (vacuum distillates). The fundamental idea behind

how the Along with the pump-around, a new HVGO draw was incorporated in the

update. additionally, a significant portion of the heavy diesel PA heat that had

previously been denied to the The LVGO/HVGO pump-water around's cooler was

moved, making it accessible. to warm the feed following a proper heat-exchanger

train modification.The packing equivalent of two steps was installed in the wash

section. This change resulted in an increase in the preheat temperature from The

VGO cut point increased significantly from 250°C to 315°C. Additionally to the there

was an increase in the VGO's quality and yield, a decrease in the P of the column to

an 8–10 mm Hg level. The VR experience also became better for transforming it into

bitumen. drocarbon chain contains all the hydrogen atoms necessary. Between 2

and 50% of various crude oils include paraffins. The Natural gas primarily consists of

light paraffins, which dissolve in the crude oil found in oil wells. Depending on the oil

well's chemistry and environmental factors, Well classes including gas wells, gas

condensate wells, and crude oil wells can be specified. wells. Methane, ethane, and

propane are the primary light paraffins found in gas wells. and butane, which are all

gases at standard temperatures and pressures (0.1 MPa). Apart In addition to these

hydrocarbon gases, gas wells also include inert gases including nitrogen (N2), argon

(Ar), and helium (He), as well as carbon dioxide and hydrogen sulfide.

He (He), Ne (Ne), and Xe (Xe) (Xe).

The crude and vacuum units no longer produce finished goods, and In units for

downstream conversion or treatment, all distillates are processed. Therefore, The

crude/vacuum unit's operation and fractionation quality significantly influence the

downstream refinery operations. The improvement of the A major goal for all

refineries is the crude/vacuum unit. Typically, a more combative (higher) operating

temperature for the crude and vacuum unit resulting in an improved

unit profitability. However, it is essential to ensure that these reliably over the entire

time frame of the planned operation, which is typically 4 to 5 years.

You might also like

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Hydrogen Gas Production by Partial OxidaDocument69 pagesHydrogen Gas Production by Partial OxidaChinwuba Samuel EbukaNo ratings yet

- Inf Ufc 85Document13 pagesInf Ufc 85Luciano Montellano Abasto100% (2)

- CDU DesignDocument8 pagesCDU DesignAnonymous DcE7fcjSwNo ratings yet

- Petroleum Technology Two MarkDocument26 pagesPetroleum Technology Two Markdhanagopal saiNo ratings yet

- Unit 3Document11 pagesUnit 3Shreyash UtekarNo ratings yet

- HDTB SectorDocument7 pagesHDTB SectorPartha AichNo ratings yet

- 2012 08 ReformateDocument4 pages2012 08 ReformatetotongopNo ratings yet

- Designing Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingDocument7 pagesDesigning Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingdjinxdNo ratings yet

- Naptha Hydrotreating UnitDocument7 pagesNaptha Hydrotreating UnitreetiNo ratings yet

- 2008-04 COLOHydroAromatic MustangDocument10 pages2008-04 COLOHydroAromatic MustangGarry DavidNo ratings yet

- Steam ReformingDocument5 pagesSteam ReformingAshok S. PathakNo ratings yet

- Yg Mau DitranslateDocument13 pagesYg Mau DitranslateTeknik Kimia PLS1 Kelas B 2018No ratings yet

- Fluid Catalytic Cracking ProcessDocument3 pagesFluid Catalytic Cracking ProcessMinh Tuấn PhạmNo ratings yet

- 9 NATURAL GAS LIQUIDS - RecoveryDocument5 pages9 NATURAL GAS LIQUIDS - RecoverysatishchemengNo ratings yet

- Process Selection of Natural Gas Recovery UnitDocument25 pagesProcess Selection of Natural Gas Recovery Unitalexalek200050% (2)

- PGA ADS Gas Monitor Petroleum 103-2911A 200803Document6 pagesPGA ADS Gas Monitor Petroleum 103-2911A 200803Mohamed AlaaNo ratings yet

- Crude Distillation Unit & Vacuum Distillation UnitDocument10 pagesCrude Distillation Unit & Vacuum Distillation Unitsenthilkumarbt100% (1)

- A Novel Route For Converting Aromatics Into Hydrogen Via Steam ReformingDocument8 pagesA Novel Route For Converting Aromatics Into Hydrogen Via Steam ReformingMarcelo Varejão CasarinNo ratings yet

- Biomass GasificationDocument25 pagesBiomass GasificationlucabenedettiNo ratings yet

- Poster RecycledDocument1 pagePoster RecycledEko PriyadiNo ratings yet

- 17 PDFDocument9 pages17 PDFmsmsoft90No ratings yet

- FTDocument29 pagesFTNitin HansaliaNo ratings yet

- Cracking Hydrocarbon Feedstock With A Heavy TailDocument3 pagesCracking Hydrocarbon Feedstock With A Heavy TailErman DurmazNo ratings yet

- FCC PosterDocument1 pageFCC PosterHai PhanNo ratings yet

- Petroleum Fractionation-Overview PDFDocument35 pagesPetroleum Fractionation-Overview PDFRiyad AliNo ratings yet

- DHDS ProcessDocument9 pagesDHDS ProcessSandeep ChallaNo ratings yet

- Reformer Convection Coils Explained PT 1 X 0Document7 pagesReformer Convection Coils Explained PT 1 X 0David PierreNo ratings yet

- Turbo Expander FinalDocument25 pagesTurbo Expander Finalmohamed100% (2)

- Process Description of Ammonia PlantDocument12 pagesProcess Description of Ammonia PlantSridharNo ratings yet

- Lec 18 PDFDocument5 pagesLec 18 PDFGhazy alshyalNo ratings yet

- Hydrocracking Unit PDFDocument9 pagesHydrocracking Unit PDFcrili69No ratings yet

- Chatper Hydrogen Generation Unit (Hgu) : IntrodctionDocument3 pagesChatper Hydrogen Generation Unit (Hgu) : IntrodctionAnkit VermaNo ratings yet

- Cryogenic ProcessDocument25 pagesCryogenic Processmohamed100% (2)

- Advanced Ammonia OptimizeDocument13 pagesAdvanced Ammonia OptimizeShariq AliNo ratings yet

- W3V20 - Refining Processes2 - HandoutDocument9 pagesW3V20 - Refining Processes2 - HandoutgbengaNo ratings yet

- CHE 417 - Module II Unit Processes in Petroleum Refining - 2019-2020 - ModulDocument18 pagesCHE 417 - Module II Unit Processes in Petroleum Refining - 2019-2020 - ModulOmonusi OmoladeNo ratings yet

- IsomerizationDocument8 pagesIsomerizationWaraey50% (2)

- Chapter 4Document26 pagesChapter 4indumathijayakaranNo ratings yet

- Fluidised Catalytic Cracker UnitDocument4 pagesFluidised Catalytic Cracker Unitbhuvanya89No ratings yet

- UOP Fluidized Catalytic Cracking Process: Presented byDocument31 pagesUOP Fluidized Catalytic Cracking Process: Presented byLaurensNo ratings yet

- Fluid Catalytic CrackingDocument9 pagesFluid Catalytic CrackingAntonitoNo ratings yet

- Hydro-Treatment Processes: Kerosene Hydrotreatment (KHT) ProcessDocument3 pagesHydro-Treatment Processes: Kerosene Hydrotreatment (KHT) ProcessDavinci Leonardo100% (3)

- Interview Questions For Chemical EngineeringDocument6 pagesInterview Questions For Chemical EngineeringNikunj PatelNo ratings yet

- Tubular Reforming and Auto Thermal Reforming of NGDocument23 pagesTubular Reforming and Auto Thermal Reforming of NGJeremy Soh'100% (1)

- Optimization of The Naphtha Hydro Treating Unit (NHT) in Order To Increase Feed in The RefineryDocument12 pagesOptimization of The Naphtha Hydro Treating Unit (NHT) in Order To Increase Feed in The RefineryvivekchateNo ratings yet

- 10 Gas Conditioning SystemDocument24 pages10 Gas Conditioning SystemRavi Sankar VenkatesanNo ratings yet

- Hydrogen Production by Steam Reforming Chemical Engineering ProcessingDocument8 pagesHydrogen Production by Steam Reforming Chemical Engineering ProcessingviettiennguyenNo ratings yet

- Deisel Hydrotreating UnitDocument9 pagesDeisel Hydrotreating UnitRittu Paul100% (1)

- Catalytic Cracking3Document12 pagesCatalytic Cracking3Abdurabu AL-MontaserNo ratings yet

- Catalytic Reforming: 2011 Refining Processes HandbookDocument3 pagesCatalytic Reforming: 2011 Refining Processes HandbookGaspar BlaserNo ratings yet

- Hydrogen Production by Steam ReformingDocument10 pagesHydrogen Production by Steam ReformingramiarenasNo ratings yet

- Mahek PresentationDocument13 pagesMahek PresentationAmit GangulyNo ratings yet

- PSH AaaaaaaaaaaaDocument7 pagesPSH AaaaaaaaaaaaEdris SalamNo ratings yet

- Fluid Catalytic CrackingDocument16 pagesFluid Catalytic Crackingbubalazi100% (1)

- Overview of EnvironmentaDocument6 pagesOverview of EnvironmentaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Ammonia ProductionDocument28 pagesAmmonia ProductionMuhammad Ali HashmiNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualFrom EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNo ratings yet

- IV-3. Vector AnalysisDocument16 pagesIV-3. Vector AnalysisJAN JERICHO MENTOYNo ratings yet

- EEEEDocument1 pageEEEEJAN JERICHO MENTOYNo ratings yet

- LaboratoryWork1 Group6Document12 pagesLaboratoryWork1 Group6JAN JERICHO MENTOYNo ratings yet

- Affa FDocument1 pageAffa FJAN JERICHO MENTOYNo ratings yet

- Write RepDocument1 pageWrite RepJAN JERICHO MENTOYNo ratings yet

- Jacobi and Gauss Seidel ExampleDocument2 pagesJacobi and Gauss Seidel ExampleJAN JERICHO MENTOYNo ratings yet

- CCCCDocument1 pageCCCCJAN JERICHO MENTOYNo ratings yet

- Final Project Mentoy Brucal AvanzadoDocument2 pagesFinal Project Mentoy Brucal AvanzadoJAN JERICHO MENTOYNo ratings yet

- BBBBBDocument1 pageBBBBBJAN JERICHO MENTOYNo ratings yet

- Mentoy Probset1 Part2Document23 pagesMentoy Probset1 Part2JAN JERICHO MENTOYNo ratings yet

- Group 13 Avanzado Brucal Mentoy Activity 2Document2 pagesGroup 13 Avanzado Brucal Mentoy Activity 2JAN JERICHO MENTOYNo ratings yet

- MENTOY - Reaction and Preparation of Ethers and EpoxidesDocument2 pagesMENTOY - Reaction and Preparation of Ethers and EpoxidesJAN JERICHO MENTOYNo ratings yet

- BBBDocument1 pageBBBJAN JERICHO MENTOYNo ratings yet

- Written ReportDocument1 pageWritten ReportJAN JERICHO MENTOYNo ratings yet

- Learnings From The WebinarDocument1 pageLearnings From The WebinarJAN JERICHO MENTOYNo ratings yet

- Technical Reporton Obafemi Awolowo University Water Treatment PlantDocument24 pagesTechnical Reporton Obafemi Awolowo University Water Treatment PlantJAN JERICHO MENTOYNo ratings yet

- XCZDocument1 pageXCZJAN JERICHO MENTOYNo ratings yet

- IwsmDocument3 pagesIwsmJAN JERICHO MENTOYNo ratings yet

- Na I I H I C: Reactions and Preparations of Aldehydes and KetonesDocument5 pagesNa I I H I C: Reactions and Preparations of Aldehydes and KetonesJAN JERICHO MENTOYNo ratings yet

- Industrial Waste Management: Che 3101 G1 1/N 00 1/1Document2 pagesIndustrial Waste Management: Che 3101 G1 1/N 00 1/1JAN JERICHO MENTOYNo ratings yet

- Constructed Wetlands - Group 5Document7 pagesConstructed Wetlands - Group 5JAN JERICHO MENTOYNo ratings yet

- Par TechDocument6 pagesPar TechJAN JERICHO MENTOYNo ratings yet

- Process Control Fundamentals: John Romar C. Panopio Che 413 Process Dynamics and ControlDocument44 pagesProcess Control Fundamentals: John Romar C. Panopio Che 413 Process Dynamics and ControlJAN JERICHO MENTOYNo ratings yet

- Book 1Document8 pagesBook 1JAN JERICHO MENTOYNo ratings yet

- General CommentsDocument2 pagesGeneral CommentsJAN JERICHO MENTOYNo ratings yet

- Applications of Thermodynamics To Flow Processes: Che 406 Chemical Engineering ThermodynamicsDocument24 pagesApplications of Thermodynamics To Flow Processes: Che 406 Chemical Engineering ThermodynamicsJAN JERICHO MENTOYNo ratings yet

- Activity 5Document1 pageActivity 5JAN JERICHO MENTOYNo ratings yet

- Particle TechnologyDocument12 pagesParticle TechnologyJAN JERICHO MENTOYNo ratings yet

- US20170204336A1Document10 pagesUS20170204336A1JAN JERICHO MENTOYNo ratings yet

- Quiz II - Engg 404 - 2022Document17 pagesQuiz II - Engg 404 - 2022JAN JERICHO MENTOYNo ratings yet