Professional Documents

Culture Documents

001 - WMS - For - Unloading & Erection - of - Pipe Spools in Pipe Rack Area

Uploaded by

alla malikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

001 - WMS - For - Unloading & Erection - of - Pipe Spools in Pipe Rack Area

Uploaded by

alla malikCopyright:

Available Formats

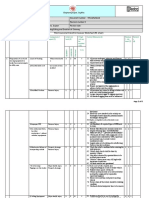

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

Project: Perstorp Elephant Project

Method Statement for Unloading and Erection of Pipe Spools in Pipe Rack Area

Contractor: TRIMURTI FABRICATORS PVT LTD

PMC: Aker Powergas Solutions

Client: Perstorp Industries India Pvt. Ltd.

TFPL Job No: 50611-2041

3 15.01.2022 Issued for Approval Rahmatullah S. JOSEPH

Rev Date APG PEM Document Status Prepared Checked Approved By

Status By by

Rev. Date Revision Details

Doc Title: MS for Erection of structural Column Page 1 of 9

Rev No: 00

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

0 02.12.2021

1 06.12.2021 METHOD 1 & METHOD 2 INCLUDED

Table of Contents

Section Title Page

01 Scope of works 04

02 Personnel rules and responsibilities 04

03 Construction procedures 05

04 Conformance criteria 07

05 Materials 07

06 Plant and equipment 07

07 Storage and handling 07

08 Health and safety 07

09 Environment requirement 08

References

10 08

Attachment:

11 08

Appendix A: Sample test reports

12 Specification of hoisting and lifting 08

Doc Title: MS for Erection of structural Column Page 2 of 9

Rev No: 00

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

1. Scope of work

The scope of this procedure applies specifically and only for the execution of

“Perstorp Elephant Project”. This procedure covers supervision and method used for

Unloading and Erection of Pipe Spools in Pipe Rack Area.

2. Personal Rules and responsibility

Project Manager:

Project Manager is responsible for developing and managing technology projects and

their cost, time and scope. Responsibilities include: project plan, communication plan,

allocating tasks and setting milestone.

Preparation of the work procedure and review

Document and drawing control for lifting works

Calibration and maintenance of equipment

Notification to QA/QC for inspection and testing

Training for Superintendents, Supervisors and Staffs

Site Engineer: A site engineer offers advice in the planning, co-ordination and

supervision of technical aspects of construction projects. A site engineer's role is

vital to a construction project: they have a number of responsibilities including

solving technical issues, providing advice, management and preparing reports.

Apply to approved drawings on site

Provide for inspection/test

Control of workers on site

Preservation of material on site

Supervisor: A Supervisor oversees the construction activities that take place on the

Work site. They are heavily involved in planning, organizing and controlling

Projects.

Construction Supervisors are responsible for supervising the contractors and staff

Doc Title: MS for Erection of structural Column Page 3 of 9

Rev No: 00

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

while maintaining a safe work environment.

Supervision for lifting activities

Distribute the job to workforce

Cooperating with worker on workplace safety and health matters.

Safety officer: The Safety Officer is responsible for monitoring and assessing

hazardous and unsafe situations and developing measures to assure

personnel safety. The Safety Officer ensures the Site Safety and Health Plan is

prepared and implemented. The Safety Officer ensures there

are safety messages in each Incident Action Plan.

Management of the safety control supervisors to check the site condition in the safety

concern

Report to the Site Manager in relation to the health, safety and environment protection

activities.

Workers: The Project Worker's main function is to manage the day-to-day activities of a

project or part of a service. The Project Worker will also assist the Service Manager to

develop and support a range of flexible, creative and responsive community-based

initiatives for people with dementia and their careers.

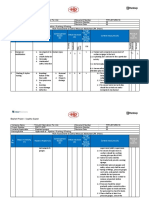

3. Construction procedure to be followed

TBT/Job specific training will be given to all members before starting the activity.

Necessary work permit should be taken by TFPL from APG prior to the start-up of activity.

All equipment, tools & tackles should be having required documents like TPI, Calibration &

MTC etc.

TFPL will inspect that the road is levelled and well compacted and also free from hurdles.

If not, TFPL will inform APG to take necessary action.

Speed of the Mobile crane or Farana should not be more than 10kmph while moving.

TFPL will ensure the signalman’s presence while moving the Mobile crane or Farana.

Mobilizing & Positioning the Mobile Crane or Farana, at material yard.

Only certified Mobile Crane or Farana, and lifting tools & tackles will be used.

Doc Title: MS for Erection of structural Column Page 4 of 9

Rev No: 00

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

Area should be barricaded or cordon off.

Rigger will fix the Lifting Belt on Pipe Spools by adjusting its CG.

Mobile Crane or Farana will slightly lift the Pipe Spools to take a load test.

After successful load test that Pipe Spools will be shifted to the desired location with the

help of Mobile Crane or Farana.

Before erecting the Pipe Spools, its cleaning will be done.

At erection point, lifting belt will be fixed to the Pipe Spools and guide rope will be installed

at both ends of the pipe.

Only signal man will give the signal to the Mobile Crane or Farana, operator.

Supervisor/safety person will ensure that no one comes under suspended load.

Then Pipe Spools will be lifted slightly and placed on the rack with proper locking.

De-slinging of Pipe Spools will be done with the help of boom lift, before which Pipe

Spools will be stabilized.

Same procedure will be repeated for another Pipe Spools erection also.

Adjacent Pipe Spools need to be stabilized on Pipe rack

Before leaving the work location supervisor will ensure that all erected members are

properly stabilized.

Doc Title: MS for Erection of structural Column Page 5 of 9

Rev No: 00

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

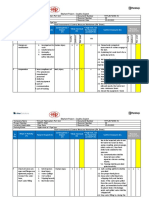

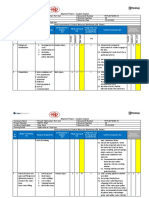

Method 1

Dismantle upper Beam 1 & Beam 2 and placing pipe spools by following below process

1. Belt & Guide Rope to be placed at two ends of Beam 1 (as shown in sketch 1) with the

help of Boom lift (man lift) and other end of the belts to be inserted into Crane Hook.

2. With the help of crane hold the Beam1 without load on crane

3. Remove the Bolts (from the beam) with the help of tools resting on Boom Lift.

4. Remove the Beam 1 with the help of Crane and safely place at the ground.

5. Lift the Pipe spools on 1st Tire and insert into the pipe rack on both sides.

6. After placing Pipe spools tie on support structure with the help of Rope.

7. Place the Beam1 on the 1st Tier with the help of crane and boom lift and fix the beam

with bolts.

8. Repeat the same above steps 1 to 7 for tier 2 and Beam 2.

9. Once work is completed

SKETCH 1

Doc Title: MS for Erection of structural Column Page 6 of 9

Rev No: 00

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

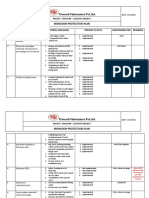

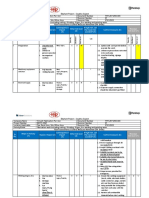

Method 2

1. Place the lifting belt and chain block on pipe spool and Crane as per sketch 2

2. Lift the spool to check the cg and balance of pipe spool at 1 meter height.

3. Lift the pipe spool to required elevation and insert the same into the pipe rack with

the help of Boom lift, Chain block & Mobile Crane or Farana.

4. Once the Pipe spool is inserted and placed on pipe rack then change the position of

belt to further insert into the pipe rack.

5. Once pipe spool is placed at desired location on pipe rack release the load from

Mobile Crane or Farana and tie the pipe spool & remove the belt with the help of

Boom lift.

6. Repeat above steps 1 to 5 for further pipe spools installation.

SKETCH 2

4. Conformance criteria

Doc Title: MS for Erection of structural Column Page 7 of 9

Rev No: 00

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

Motor Vehicles Act as amended in 1993 and The Central Motor

Vehicles Rules, 1989.

IS 13367 (Part 1): 1992: SAFE USE OF CRANES- CODE OF PRACTICE

IS 13834 (Part 1): 1994; CRANES – CLASSIFICATION

5. Materials:

Lifting Belt, Tag Line, Hooks, De shackles., Full body harness, Other Tools & Tackles.

6. Plant and equipment

Lifting Belts – As per requirement

D shackle: As per requirement

Guy ropes/Stay Wires - As per requirement

Mobile Crane or Farana

Boom lift

7. Storage and handling

All material will be maintained cleanly and in good condition.

All tools and tackles must be free from dirt, grease.

8. Health and safety

Assessment shall be done for the activity, access, illumination and work platform.

Ensure that all tools and tackles and lifting equipment has the valid third-party certificates

Ensure that SLI is operational

Reverse horn of the Mobile Crane or Farana is operational and audible

Anti-two block system is provided and is operational

Ensure that Mobile Crane or Farana operator and riggers are qualified and trained

Ensure that job specific PPE with Mandatory PPE are provided to all including full body

harness

Doc Title: MS for Erection of structural Column Page 8 of 9

Rev No: 00

PERSTORPP ELEPHANT PROJECT

Contractor: TRIMURTI FABRICATORS PVT LTD Doc. Ref. No: TFPL/APG/MS001 R3

Contract No.: SER/0153/21-22 Date Issued: 15.01.2022

Ensure to barricades the area with warning signs board & only authorized person allow to

working area.

Do not over load the Mobile Crane or Farana, Safe working capacity (SWL).

Do not lift more than 75 % of the cranes rated capacity.

Before start activity all equipment’s, tools tackle, crane also must be inspected by concern

person.

9. Environmental requirements

Prevent noise pollution by using environment friendly machines and equipment’ s and oils.

Minimize the dust generation as low as practicable.

Follow govt. guidelines on the air pollutions. Must have PUC certificate

Ensure to collect and dispose of the oil spillage (if any) as per local govt. rules

Keep area clean

Submitted separately.

10. References Attachment: Third party certificates of crane and tools and tackles,

submitted separately.

Doc Title: MS for Erection of structural Column Page 9 of 9

Rev No: 00

You might also like

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Perstorp Elephant Project Pipe Erection MethodDocument7 pagesPerstorp Elephant Project Pipe Erection Methodalla malikNo ratings yet

- 011 - WMS For Equipment ErectionDocument7 pages011 - WMS For Equipment Erectionalla malikNo ratings yet

- 002 - WMS - For - Scaffolding & Erection of Pipe Rack Area PS29 To PS38Document7 pages002 - WMS - For - Scaffolding & Erection of Pipe Rack Area PS29 To PS38alla malikNo ratings yet

- 007 - WMS of K2 PasteDocument6 pages007 - WMS of K2 Pastealla malikNo ratings yet

- Perstorp Elephant Project Traffic Management PlanDocument12 pagesPerstorp Elephant Project Traffic Management Planalla malikNo ratings yet

- Installation of Cranes in PS-17Document18 pagesInstallation of Cranes in PS-17Ijaz Mh100% (7)

- MS -37-Proposal For Diversion of Existing 200Φ D.I. Sewer PiDocument13 pagesMS -37-Proposal For Diversion of Existing 200Φ D.I. Sewer PiSyed Umair HashmiNo ratings yet

- METHOD STATEMENT FORMATDocument8 pagesMETHOD STATEMENT FORMATsyed aquibNo ratings yet

- MethodStatementforMechanicalWorksUndergroundRainWaterSewerDrainageSystemDocument19 pagesMethodStatementforMechanicalWorksUndergroundRainWaterSewerDrainageSystemammarsleman356No ratings yet

- 9078 - 13!02!02 - Pull-Out Testmethod Statement Lot 2 Rev 01Document12 pages9078 - 13!02!02 - Pull-Out Testmethod Statement Lot 2 Rev 01Avinash LalNo ratings yet

- Indra: Detail Pre-Commissioning Procedure For Service Test of Nitrogen For Unit 040/041/042/043Document109 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Nitrogen For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- 6.Drain PipingDocument2 pages6.Drain PipingPramod BhintedeNo ratings yet

- 9078 - 13!02!02 - Earthing Method Statement Lot 2 Rev 01Document11 pages9078 - 13!02!02 - Earthing Method Statement Lot 2 Rev 01Avinash LalNo ratings yet

- Method of StatementDocument6 pagesMethod of StatementUnited East Projects TradingNo ratings yet

- ASU (AEI-009) - W-PC 9901 - (EN) Project Excecution Plan LG Project Rev.0.VTSK CommentsDocument12 pagesASU (AEI-009) - W-PC 9901 - (EN) Project Excecution Plan LG Project Rev.0.VTSK CommentsKreshna Wisnu BrataNo ratings yet

- Detail Pre-commissioning Procedure for Service Test of Plant Air UnitsDocument31 pagesDetail Pre-commissioning Procedure for Service Test of Plant Air UnitsAnhTuấnPhanNo ratings yet

- S 1153824 CST G01 0008 MS For Maintenance ToolDocument9 pagesS 1153824 CST G01 0008 MS For Maintenance ToolDedy SupriadiNo ratings yet

- SOP Tadano Crane 25TDocument32 pagesSOP Tadano Crane 25Tmahindra hardinataNo ratings yet

- Indra: Detail Commissioning Procedure For Service Test of Steam For Unit 040/041/042/043Document132 pagesIndra: Detail Commissioning Procedure For Service Test of Steam For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- Indra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043Document28 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- Indra: Detail Pre-Commissioning Procedure For Service Test of IA For Unit 040/041/042/043Document42 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of IA For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- Method Statement For Chlorination & Disinfection of Water Supply SystemDocument9 pagesMethod Statement For Chlorination & Disinfection of Water Supply SystemAhmad OmarNo ratings yet

- Method Statement Manual Loading Concrete Mixture Machine For Concrete Works - R1Document18 pagesMethod Statement Manual Loading Concrete Mixture Machine For Concrete Works - R1Shubham PatelNo ratings yet

- Inspection & NDT ControlDocument2 pagesInspection & NDT ControlRyan Gillespie75% (4)

- Indra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043Document62 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- MS For PEB Erection R1Document16 pagesMS For PEB Erection R1Gabriel GabeNo ratings yet

- Water Proofing Toilets WorksDocument63 pagesWater Proofing Toilets WorksGhaffar Laghari100% (1)

- 7S92-06011-CO-TP-542 MST For EPDM Repair For MOV-041 & 052 r0Document21 pages7S92-06011-CO-TP-542 MST For EPDM Repair For MOV-041 & 052 r0abdelmalek boudjemaaNo ratings yet

- METHOD STATEMENT FOR HYDRO TEST (HDPE PIPES, FIRE FIGHTING PIPELINE, MANHOLES & DOMESTIC WATER AND DRAINAGE NETWORK)Document32 pagesMETHOD STATEMENT FOR HYDRO TEST (HDPE PIPES, FIRE FIGHTING PIPELINE, MANHOLES & DOMESTIC WATER AND DRAINAGE NETWORK)mohdshahul543No ratings yet

- Method Statement For Cable Terminaton (CP3)Document20 pagesMethod Statement For Cable Terminaton (CP3)Jacky TamNo ratings yet

- Method Statement For LaminationDocument17 pagesMethod Statement For Laminationalamfb243No ratings yet

- SOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSDocument159 pagesSOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSVikas SinghNo ratings yet

- Pipeline Construction WorksDocument18 pagesPipeline Construction WorksMostafa Nabil100% (1)

- MS For Concrete Block Mesonry WorkDocument10 pagesMS For Concrete Block Mesonry WorkPandiaraj VNo ratings yet

- Pipeline Construction Works PDFDocument18 pagesPipeline Construction Works PDFAli AbdoulayeNo ratings yet

- Method Satement For Installation of FIRE Pumps 01Document12 pagesMethod Satement For Installation of FIRE Pumps 01VibinNo ratings yet

- North Metro Rail Construction Safety PlanDocument366 pagesNorth Metro Rail Construction Safety PlanTarun KathpaliaNo ratings yet

- Valves Installation Method StatementsDocument16 pagesValves Installation Method StatementsLungisani100% (3)

- Indra: Marine Transportation Management PlanDocument14 pagesIndra: Marine Transportation Management PlanHong Hai PhamNo ratings yet

- 001B Method Statement Form - Internal GlazingDocument7 pages001B Method Statement Form - Internal GlazingJunaid C.K50% (2)

- MS - Road and PavingDocument15 pagesMS - Road and PavingbukhoriNo ratings yet

- Roof Platform Installation MethodDocument7 pagesRoof Platform Installation MethodRisal SinuNo ratings yet

- Dial Hse Plan 12.11.08 Rev.006Document226 pagesDial Hse Plan 12.11.08 Rev.006Pallav Paban BaruahNo ratings yet

- EARTHING - Wp-ODocument11 pagesEARTHING - Wp-OTarun GodiyalNo ratings yet

- MST For Road CuttingDocument13 pagesMST For Road CuttinginbNo ratings yet

- MSDocument11 pagesMSM&N ProjectsNo ratings yet

- DIAPHRAGM WALL REPAIR METHOD STATEMENTDocument17 pagesDIAPHRAGM WALL REPAIR METHOD STATEMENTHemaNo ratings yet

- Work Method Statement For Erection in Loc Start D and End CDocument8 pagesWork Method Statement For Erection in Loc Start D and End CTwin Bulls0% (1)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pages016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- DDDDocument7 pagesDDDmohd as shahiddin jafriNo ratings yet

- MD 04 MT Rssta PD 509Document13 pagesMD 04 MT Rssta PD 509Nguyễn Đặng LâmNo ratings yet

- MS - 5 House Connection ConstructionDocument7 pagesMS - 5 House Connection ConstructionSyed Umair HashmiNo ratings yet

- Concrete RepairDocument13 pagesConcrete Repairkeshav chaturvediNo ratings yet

- 06 Heat ExchangerDocument2 pages06 Heat ExchangerQaisar KhaiyamNo ratings yet

- Jms Civil Work - RGTP p20220019 Esb Con Jms 9243 0005Document12 pagesJms Civil Work - RGTP p20220019 Esb Con Jms 9243 0005amir hakimNo ratings yet

- Method Statement for Installation of Chilled Water Pipe (21!4!2024)Document22 pagesMethod Statement for Installation of Chilled Water Pipe (21!4!2024)sheik.rasith.anvarNo ratings yet

- Hospital Raft Concrete WorksDocument13 pagesHospital Raft Concrete WorksHimanshu KumarNo ratings yet

- Maintenance Plan For Operational Equipment and Construction EquipmentDocument10 pagesMaintenance Plan For Operational Equipment and Construction Equipmenttotok.madriantolubisNo ratings yet

- Method Statement for Installing AIS SwitchgearDocument22 pagesMethod Statement for Installing AIS SwitchgearAbat SayekeyevNo ratings yet

- Transmittal FormatDocument1 pageTransmittal Formatalla malikNo ratings yet

- Safety Observtion Register FarhadDocument2 pagesSafety Observtion Register Farhadalla malikNo ratings yet

- RA-22 For Grating Floorplate Installation ModificationDocument12 pagesRA-22 For Grating Floorplate Installation Modificationalla malikNo ratings yet

- 400 Ton Crane DocumentsDocument7 pages400 Ton Crane Documentsalla malikNo ratings yet

- Pipe Supports z4Document5 pagesPipe Supports z4alla malikNo ratings yet

- Safety Calendar Oct'-22Document3 pagesSafety Calendar Oct'-22alla malikNo ratings yet

- Incident ReportDocument2 pagesIncident Reportalla malikNo ratings yet

- SOR Updated (Sandip Akole)Document20 pagesSOR Updated (Sandip Akole)alla malikNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Elcb-Mcb Inspection On Ele. Equipments-Eb-PdbDocument6 pagesElcb-Mcb Inspection On Ele. Equipments-Eb-Pdballa malikNo ratings yet

- Monsoon Protection Plan for Perstorp - Elephant ProjectDocument4 pagesMonsoon Protection Plan for Perstorp - Elephant Projectalla malikNo ratings yet

- Ra-20 Lifting and Errection of ChimneyDocument8 pagesRa-20 Lifting and Errection of Chimneyalla malikNo ratings yet

- RA For Air Compressor-RA 15Document8 pagesRA For Air Compressor-RA 15alla malikNo ratings yet

- RA Flushing &Hydro-TestingDocument8 pagesRA Flushing &Hydro-Testingalla malikNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- RA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17Document9 pagesRA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17alla malik100% (1)

- Risk Assessment & Control Measure Worksheet (RA Sheet)Document5 pagesRisk Assessment & Control Measure Worksheet (RA Sheet)alla malikNo ratings yet

- Hearing Conservation Program For ConstructionDocument14 pagesHearing Conservation Program For Constructionalla malikNo ratings yet

- Ra Radiography 10Document1 pageRa Radiography 10alla malikNo ratings yet

- RA For Site Fabrication Work - 05Document10 pagesRA For Site Fabrication Work - 05alla malikNo ratings yet

- RA - 11 (K2 Paste.Document4 pagesRA - 11 (K2 Paste.alla malikNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Methods of Irrigation PDFDocument80 pagesMethods of Irrigation PDFJagpreet SinghNo ratings yet

- Janapriya Journal of Interdisciplinary Studies - Vol - 6Document186 pagesJanapriya Journal of Interdisciplinary Studies - Vol - 6abiskarNo ratings yet

- Earth DayDocument12 pagesEarth DayAnto Roldan OliveraNo ratings yet

- VYR Agriculture Irrigation 2Document6 pagesVYR Agriculture Irrigation 2Ahmed HussienNo ratings yet

- Our Mother Earth Is CryingDocument26 pagesOur Mother Earth Is CryingMark Erwin SalduaNo ratings yet

- Polar Bear Facts: Distribution, Ecology and BehaviorDocument4 pagesPolar Bear Facts: Distribution, Ecology and BehaviorOussama MezriguiNo ratings yet

- Proposed Muchami Hotel Plumbing DrainageDocument4 pagesProposed Muchami Hotel Plumbing DrainagefebousNo ratings yet

- Course 4 GroundwaterBudget-rev2Document12 pagesCourse 4 GroundwaterBudget-rev2evonNo ratings yet

- Folk Tales of North-2077Document3 pagesFolk Tales of North-2077Subodh ShrivNo ratings yet

- The Political Environment of International BusinessDocument22 pagesThe Political Environment of International BusinessdinescNo ratings yet

- Workshop Group 9-1-1Document16 pagesWorkshop Group 9-1-1kathy oseiNo ratings yet

- Ahmed Moayad Jameel, (Hydrolic Structure 1)Document18 pagesAhmed Moayad Jameel, (Hydrolic Structure 1)Ahmed AmediNo ratings yet

- Fs Reaction Paper Ep 1-6Document8 pagesFs Reaction Paper Ep 1-6Shiela Marie NazaretNo ratings yet

- Unit 4Document28 pagesUnit 4Vaishali JoshiNo ratings yet

- Test BankDocument9 pagesTest BankmslaurielooNo ratings yet

- CVSyed HassanDocument4 pagesCVSyed HassanAliya HussainNo ratings yet

- C: C E - C: 5411 L Ade S:S 2023 Assignment No 1Document19 pagesC: C E - C: 5411 L Ade S:S 2023 Assignment No 1israrNo ratings yet

- ACTION PLAN 30 AGUSTUS 2021.revisiDocument92 pagesACTION PLAN 30 AGUSTUS 2021.revisiyudha erlanggaNo ratings yet

- GRI 3: Material Topics 2021: Universal StandardDocument30 pagesGRI 3: Material Topics 2021: Universal StandardMaría Belén MartínezNo ratings yet

- Risk of Arsenic in Jacobabad City Groundwater AssessedDocument8 pagesRisk of Arsenic in Jacobabad City Groundwater AssessedWajeeh khanNo ratings yet

- Practical Foundation EngineeringDocument1,152 pagesPractical Foundation EngineeringMark Anthony Olinares100% (1)

- 8 Soil Movement Due To Deep Excavations PDFDocument69 pages8 Soil Movement Due To Deep Excavations PDFHammad SalahuddinNo ratings yet

- Environmental Screening and Scoping Report for Road Project in MaharashtraDocument94 pagesEnvironmental Screening and Scoping Report for Road Project in MaharashtraRahul RanaNo ratings yet

- Triglyceride SL Reagent MsdsDocument5 pagesTriglyceride SL Reagent MsdsSuperZero 'SpZ'No ratings yet

- Chile, Environmental History Perspectives and Challenges - Alaniz 2019Document308 pagesChile, Environmental History Perspectives and Challenges - Alaniz 2019DANIEL MATIAS FLORIN GUTIERREZNo ratings yet

- Readingpracticetest1 v9 3220417Document18 pagesReadingpracticetest1 v9 3220417KritikaThakurNo ratings yet

- SOLAR PANEL: A COST-SAVING NECESSARY IN EVERY HOUSEHOLDDocument17 pagesSOLAR PANEL: A COST-SAVING NECESSARY IN EVERY HOUSEHOLDSuan , Troy Justine , R.No ratings yet

- SEQ Catchments Catching Up Newsletter Stanley Upper Brisbane April 2012Document2 pagesSEQ Catchments Catching Up Newsletter Stanley Upper Brisbane April 2012Healthy Land and WaterNo ratings yet

- Watertight Concrete FAQs - MasterLife WP 799 Admixture SolutionsDocument3 pagesWatertight Concrete FAQs - MasterLife WP 799 Admixture SolutionsgarcharvijayNo ratings yet

- USGA Recommendations For A Method of Putting Green ConstructionDocument11 pagesUSGA Recommendations For A Method of Putting Green ConstructionTheo VighNo ratings yet