Professional Documents

Culture Documents

Anchor

Uploaded by

manish318Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchor

Uploaded by

manish318Copyright:

Available Formats

Doc. No.

- Rev : 0

Tank No : U-FA 103 Tank Anchorage Design

API 650, 12th Ed,March-2013,Add.2 Jan-2016

Design of Anchor bolts per 5.12

P Design pressure 0.00 kPa

Pt Test Pressure 0.00 kPa

DLR Nominal weight of roof plate plus any attached structural 12120 N

Pf Failure pressure per F.6 = 1.6*P -0.000746*DLR/D² 0.00 kPa

D Tank Diameter 3.20 m

H2 Tank height 4.00 m

th Roof Plate thickness 8.00 mm

Material of Anchor Bolt A 307 GrB

Anchor Bolt size M30

[Min bolt dia = 1 inch plus any specified corrosion allowance]

Nb Number of anchors (a minimum of 4 is required) 8

Ab Anchor bolt Root area 503.0 mm²

Bs Max.Bolt spacing per 5.12.3 3000.00 mm

Bsp Provided bolt spacing = π *Db/Nb 1315.5 mm

W1 Corr. Dead load of shell + Any other Corr. dead load excl.roof plates 22456 N

W2 Corr. Dead load of shell + Any other Corr. dead load incl. roof plates 20672 N

W3 UnCorr.Dead load of shell+Any other UnCorr. dead load incl. roof pl. 36802 N

Fy Min.Yeild Stregth of Anchor Bolts (Max. 250 Mpa) 240 MPa

Fty Minimum yield strength of the bottom shell course 205.0 MPa

Design uplift load due to product pressure per unit circ. Length =

wint 0 N/m

( π/4 * D^2 * P*1000 / π * D )

wt Tank and roof weight acting base of shell = [(Ws+Wr)/(π*D)] 3661 N/m

Pwr Wind uplift pressure on roof 1.88 kPa

Pws Wind pressure on shell 1.10 kPa

Mws Wind moment acting on shell from wind Analysis 41316.00 N-m

Mrw Ringwall seismic Moment from Siesmic Analysis 32448.00 N-m

Av Vertical earthquake acceleration coefficient 0.03

M Yield Strength Reduction Factors as per Appendix-M 0.894

Yes No

Uplilf Loads & Induced bolt stress calculation as per Table 5.21a

Induced bolt

stress Allow. Condtition

Uplift load case Net Uplift formula,U (N)

Sbi =U/(N*Ab) stress (Mpa) satisfied?

Mpa

1 Design pressure [ P*D2*785 ]- W1 = -22456 -5.6 89 Yes

-36802

2 Test Pressure [ Pt*D2*785 ] - W3 = -9.1 119 Yes

3 Wind Load Pwr *D²*785+ (4*Mws/D)-W2 = 46085 11.5 172 Yes

4 Seismic Load (4*Mrw/D)-W2*(1-0.4*Av) = 20136 5.0 172 Yes

5 Des.P + Wind [(0.4*(P+Pwr)*D²*785]+(4*Mws/D)-W1 = 35234 8.8 119 Yes

6 Des.P + Seismic [0.4*P*D²*785]+(4*Mrw/D)-W1(1-0.4Av) = 18373 4.6 172 Yes

7 Frangibility Pressure [(3*Pf * D² * 785)]-W3 = N/A N/A 215 N/A

U= Max.Uplif load ( Wind Load) 46085 N

4699.7 kg

Doc. No. - Rev : 0

Tank No : U-FA 103 Tank Anchorage Design

API 650, 12th Ed,March-2013,Add.2 Jan-2016

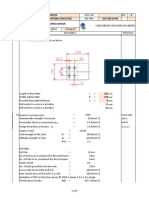

Check for Anchor Bolt Chairs As per AISI E-1, Volume II, part-VII

Dimensions of Anchor Bolt chair

a = 150 mm

b = 130 mm d e =70 mm t = 5 mm

f

c = 8 mm

Top Plate

k tp = 0.0 mm

h = 250 mm

E = 10 mm

g = 90 mm j = 8 mm

a Top plate width along the shell 150 mm 5.9 inch

b Top plate width in radial direction 130 mm 5.1 inch

c Top plate thickness 8 mm 0.3 inch

d Anchor bolt diameter 30 mm 1.2 inch

e Anchor bolt eccentricity 70 mm 2.8 inch

hmax Max. recommended chair height = 3*a 450 mm 17.7 inch

hmin Min. recommended chair height = 12 inch 305 mm 12.0 inch

hp Provided Chair height 250 mm 9.9 inch

g Dist. Between vertical plates 90 mm 3.6 inch

Jmin Required Min.Gusset plate thickness = Min(12.7 ,0.04*(h-c))

= Min(12.7,0.04*(250-8))=Min(12.7,9.68) 10 mm 0.4 inch

j Provided Gusset plate thickness 8 mm 0.3 inch

emin Anchor bolt efficiency = 0.886d+0.572

fmin d/2+1/8 18.29 mm 0.72 inch

f Provided top plate hole edge distance 45 mm 1.8 inch

k Vertical plate width :(h-c)/2 121 mm 4.8 inch

(average width for tapered plates)

E Bottom plate thickness 10 mm

Db Bolt circle diameter = D*1000+2*(e+t+tp) 3350 mm

L Tank length 4.00 m 157.5 inch

m Corroded Bottom or base plate thickness 7 mm 0.3 inch

R Nom. shell radius 1600 mm 63.0 inch

t Shell thickness 2.0 mm 0.080 inch

tp Reinforcment Pad thickness 0.0 mm 0.0 inch

w Weld size(leg dimension) 6 mm 0.2 inch

Doc. No. - Rev : 0

Tank No : U-FA 103 Tank Anchorage Design

API 650, 12th Ed,March-2013,Add.2 Jan-2016

Check for stress in Top plate:

Critical stress in the top plate occurs between the hole and the free edge of the plate

For convenience we can consider this portion of the top plate vas a beam with partially fixed

ends, with a portion of the total anchor bolt load distributed along part of the span,

P Max Bolt uplift load =U/Nb 5761 N 1.30 kips

S Allowable stress 137 MPa 19.8 ksi

c [P/f*S (0.375g-0.22d)]½ = 0.20 inch

= 5.04 mm

Provided Top Plate thickness 8.00 mm

Provided Top Plate Thickness is sufficient

Check for Induced stress in shell at attachment for provided skirt height

Maximum stress at the top of the chairs in vertical direction is a combination of bending plus

direct stress, based on Bjilaard formulas

P Bolt uplift load in design condition 2807.00 N 0.64 kips

S Bending stress + direct stress at top of chair as per 7-3 ( Induced stress in shell due to attachment)

=( P*e/(t+tp)² )*[ {(1.32*Z)/((1.43 a*h^2/( R*(t+tp)))+(4*a*h²)^0.333 )}+ {0.031/(R*(t+tp))^½} ]

=( P*e/(t+tp)²) * [ { A } + { B }]

= (0.64*2.76/(0.08+0)²) * [ {0.003} + { 0.014 } ] 4.609 ksi

A =(1.32*Z)/((1.43 a*h^2/( R*t))+(4*a*h²)^0.333 )

=(1.32*0.385)/((1.43*5.91*9.85²/(63*0.08))+(4*5.91*9.85²)^0.333) 0.0030

B =0.031/(R*(t+tp))^½

=0.031/(63*(0.08+0)^½}] 0.014

Z Reduction factor as per 7-4

= 1.0/[( ( ( 0.177 a*m) / (R*(t+tp))^½ ) * (m /( t+tp))² ) +1.0]

= 1/[( ( ( 0.177*5.91*0.28 ) / (63*0.08)^½ )*(0.28/0.08)² )+1] 0.385

Sa Allowable shell stress for design condition=2/3*Fty= 137 MPa 19.8 ksi

As Sa < S,Provided Chair Height is sufficient

Summary of check for Induced shell stress at anchor chair attachement as per Table 5.21a

Induced bolt uplift Induced shell stress due

Allowable stress at shell attachment Condtition

Uplift load case P =Sbi*Ab to P

satisfied?

N kips ksi Mpa Mpa

1 Design pressure 2807 0.64 4.61 31.8 2/3*Fty *M= 122 Yes

2 Test Pressure 4600 1.04 7.49 51.6 5/6*Fty*M= 153 Yes

3 Wind Load 5761 1.3 9.36 64.6 5/6*Fty*M= 153 Yes

4 Seismic Load 2517 0.57 4.10 28.3 5/6*Fty*M= 153 Yes

5 Des.P + Wind 4404 1 7.20 49.7 5/6*Fty*M= 153 Yes

6 Des.P + Seismic 2297 0.52 3.74 25.8 5/6*Fty*M= 153 Yes

7 Frangibility Pressure N/A N/A N/A N/A Fty*M= 183 N/A

Doc. No. - Rev : 0

Tank No : U-FA 103 Tank Anchorage Design

API 650, 12th Ed,March-2013,Add.2 Jan-2016

Gusset Plate thickness

jreq Min. required gusset palte thickness = P/(25*K) = 1.3 / ( 25*4.77) 0.011 inch

0.28 mm

j Provided gusset plate thickness 8 mm

Provided gusset plate thk is acceptable

Weld design of Anchor chair

WV WV: Total load on weld = P/(a+2h) 0.220 kips per lin. Inch of weld

WH WH: Horizontal load = Pe/(ah+0.667h^2) 0.063 kips per lin. Inch of weld

W SQRT(WV²+WH²) 0.229 kips per lin. Inch of weld

Wa Allowable fillet weld stress =9.6*w 2.304 kips per lin. Inch of weld

As Wa > W,the design Anchor chair is Safe

Check for Shear

Check for anchor bolts in shear

Sw Wind shear 20658 N

Ss Siesmic shear 15157 N

Su Sliding shear force due to wind 986.67 kg

9676 N

P Design shear =Max[ Sw,Ss,Su] 20658 N

Sa Allowable shear stress for anchor bolts in shear=0.4*Fy*M 86 MPa

Si Induced bolt stress per bolt = P/(Ab*N) 5 MPa

Provided anchorage is sufficient for shear

You might also like

- Ladder Calculation 9april2018Document2 pagesLadder Calculation 9april2018Diosdado Mingi Jr.No ratings yet

- Everything About Warstilla EngineDocument212 pagesEverything About Warstilla Enginesoldatosa100% (10)

- Daewoo Matiz Check Engine Error CodesDocument2 pagesDaewoo Matiz Check Engine Error Codesmisterredman93% (15)

- Project Name DOC. No.: Tank Name Rev No.: Item No.Document4 pagesProject Name DOC. No.: Tank Name Rev No.: Item No.AnggaNo ratings yet

- Upheval Bukling CalculationDocument2 pagesUpheval Bukling Calculationbaghelrohit100% (7)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- CE 2253 Applied Hydraulic Engineering QUESTION BANKDocument14 pagesCE 2253 Applied Hydraulic Engineering QUESTION BANKDhivya RamachandranNo ratings yet

- Din 471-2011-04 EngDocument24 pagesDin 471-2011-04 EngCristianCuleaNo ratings yet

- Assignment Shaft DesignDocument4 pagesAssignment Shaft DesignHasham Mehmood100% (1)

- Aw60 40le Zip in PDFDocument10 pagesAw60 40le Zip in PDFJosé Monteiro100% (2)

- AnchorageDocument5 pagesAnchoragemanish318No ratings yet

- Anchor Bolt Calculation 21-2231Document2 pagesAnchor Bolt Calculation 21-2231Huu Nguyen100% (1)

- Uplift Loads TableDocument1 pageUplift Loads TableNeeraj DubeyNo ratings yet

- TK-ALCOZAP-2020-01-06-Rev. DDocument65 pagesTK-ALCOZAP-2020-01-06-Rev. DDaniel Gómez100% (1)

- 7.253 M3 Tank Anchorage Calc.: MW Pws (S.Total Surface) (H/2) + PWR (R.total Surface) (D/2), N.MDocument1 page7.253 M3 Tank Anchorage Calc.: MW Pws (S.Total Surface) (H/2) + PWR (R.total Surface) (D/2), N.MMehmet ÖZCANNo ratings yet

- Input EchoDocument6 pagesInput EchohgagNo ratings yet

- 27Document3 pages27Fazri CMENo ratings yet

- Foundation LoadingsDocument1 pageFoundation Loadingsmanish318No ratings yet

- DPT Kolam Retensi H 3.8m (No Water)Document6 pagesDPT Kolam Retensi H 3.8m (No Water)chriscivil12No ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- Design. Ref - Decuments: API 650, 11TH - ED M09Document31 pagesDesign. Ref - Decuments: API 650, 11TH - ED M09hgagNo ratings yet

- Basering calculations and weld sizes for operating caseDocument6 pagesBasering calculations and weld sizes for operating caseevrim77No ratings yet

- Davit Cal 2251B Davit Arm CalculationDocument4 pagesDavit Cal 2251B Davit Arm CalculationKarina RoquelNo ratings yet

- PRL Design Study Of NMA Chemical Storage TankDocument56 pagesPRL Design Study Of NMA Chemical Storage TankShayan Hasan KhanNo ratings yet

- DAVIT CALCULATIONDocument13 pagesDAVIT CALCULATIONNiraj PandyaNo ratings yet

- KNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectDocument32 pagesKNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectrichardchiamNo ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- 107D Iv Feg 05a 00012Document68 pages107D Iv Feg 05a 00012vinayak jadhavNo ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- Gudang BUDocument16 pagesGudang BUedn_mj1645No ratings yet

- Wind Load CalculationDocument8 pagesWind Load CalculationAbdulsamad RacmanNo ratings yet

- Design Calculation TankDocument28 pagesDesign Calculation TankAsongwe HansNo ratings yet

- Lifting Lug CalculatorDocument4 pagesLifting Lug CalculatoralisobohNo ratings yet

- AMETANK REPORT: Roof design calculationsDocument41 pagesAMETANK REPORT: Roof design calculationsHasan arif KısaalioğluNo ratings yet

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- Post Footing 1Document3 pagesPost Footing 1John SmithNo ratings yet

- Lifting Lug CalculatorDocument3 pagesLifting Lug CalculatoranufabdesignsNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationmih1No ratings yet

- Design Data and Calculations for Rectangular Storage TankDocument31 pagesDesign Data and Calculations for Rectangular Storage Tanknamasral100% (9)

- Potable Water Tank Calculation PDFDocument37 pagesPotable Water Tank Calculation PDFboysitumeangNo ratings yet

- Input Rev. NO: L + (c1 + c2) TWDocument6 pagesInput Rev. NO: L + (c1 + c2) TWMudasir MughalNo ratings yet

- Tugas Perancangan TankiDocument47 pagesTugas Perancangan Tankimuh irchamNo ratings yet

- FIRE WATER TANK-API-650-Calculation-Report - RVDDocument42 pagesFIRE WATER TANK-API-650-Calculation-Report - RVDahmed aboyosefNo ratings yet

- Saddle CalcDocument26 pagesSaddle CalcVamsi S100% (2)

- MB4 (Rafter To Corner Column)Document63 pagesMB4 (Rafter To Corner Column)Crystal JaneNo ratings yet

- Analyzing stresses on new lifting lugDocument4 pagesAnalyzing stresses on new lifting lugdharwinNo ratings yet

- 1 Input Data: Anchor Type and Size: Hsl-3 M12 or EquivalentDocument4 pages1 Input Data: Anchor Type and Size: Hsl-3 M12 or EquivalentNp PwNo ratings yet

- Leg Support Calculation PDFDocument2 pagesLeg Support Calculation PDFSanjay MoreNo ratings yet

- Lug Calculation 1Document2 pagesLug Calculation 1Sachin5586No ratings yet

- Compress Spring Component Generator 2Document3 pagesCompress Spring Component Generator 2ra5tr@No ratings yet

- Left blind flange stress analysis and designDocument6 pagesLeft blind flange stress analysis and designkamardheen majithNo ratings yet

- Connection Surge Bin Supp Beam1Document5 pagesConnection Surge Bin Supp Beam1Venkatesh HebbarNo ratings yet

- Note de Calcul Ancrage Rev3Document3 pagesNote de Calcul Ancrage Rev3Bilel MahjoubNo ratings yet

- Base Plate Dan Anchor Bolt Calculation: Connection DesignDocument21 pagesBase Plate Dan Anchor Bolt Calculation: Connection DesignSurya FahmiNo ratings yet

- HDD Installation CalculationsDocument4 pagesHDD Installation Calculationslive4sankar100% (1)

- ANCHOR FLANGE CALCULATION STRESS ANALYSISDocument1 pageANCHOR FLANGE CALCULATION STRESS ANALYSISandi suntoroNo ratings yet

- Design of Boiler Foundation Anchor RodsDocument370 pagesDesign of Boiler Foundation Anchor RodsharsharanmannNo ratings yet

- Anchor bolt sizing checkDocument2 pagesAnchor bolt sizing checkmih150% (2)

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- SADDLE STRESS ANALYSISDocument19 pagesSADDLE STRESS ANALYSISSiva baalanNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Cast Iron: Physical and Engineering PropertiesFrom EverandCast Iron: Physical and Engineering PropertiesRating: 5 out of 5 stars5/5 (1)

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- WoodTech Wood Stains Exterior PDFDocument2 pagesWoodTech Wood Stains Exterior PDFsanjay guhaNo ratings yet

- TicketDocument3 pagesTicketsandeep uttaralaNo ratings yet

- A Guide To Storage Tank Repair Based On API 653 StandardDocument7 pagesA Guide To Storage Tank Repair Based On API 653 Standardmanish318No ratings yet

- Nozzle Load Calculation - U-FA 201Document32 pagesNozzle Load Calculation - U-FA 201manish318No ratings yet

- M-056 - Data SheetR1Document1 pageM-056 - Data SheetR1manish318No ratings yet

- WeightDocument3 pagesWeightmanish318No ratings yet

- M-056 - Data SheetR1Document1 pageM-056 - Data SheetR1manish318No ratings yet

- Design of Storage Tanks For Internal PressureDocument7 pagesDesign of Storage Tanks For Internal Pressuremanish318No ratings yet

- Print of Xi - An Hyatt RegencyDocument1 pagePrint of Xi - An Hyatt Regencymanish318No ratings yet

- SizingDocument1 pageSizingmanish318No ratings yet

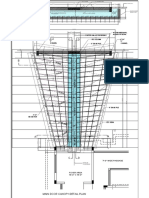

- Main Door Canopy Section-DDocument1 pageMain Door Canopy Section-Dmanish318No ratings yet

- IndexDocument1 pageIndexmanish318No ratings yet

- Heating Coil Design CalculationDocument3 pagesHeating Coil Design Calculationmanish318No ratings yet

- WindDocument5 pagesWindmanish318No ratings yet

- Foundation LoadingsDocument1 pageFoundation Loadingsmanish318No ratings yet

- Max Rafter SpacingDocument1 pageMax Rafter Spacingmanish318No ratings yet

- Age Calculator Etc (1) .Document2 pagesAge Calculator Etc (1) .manish318No ratings yet

- Capcity CalcuDocument1 pageCapcity Calcumanish318No ratings yet

- IndexDocument1 pageIndexmanish318No ratings yet

- A Glimpse of Our Life TodayDocument3 pagesA Glimpse of Our Life Todaymanish318No ratings yet

- Main Door Canopy PlanDocument1 pageMain Door Canopy Planmanish318No ratings yet

- Dealing With Organisational Change Can Emotional Intelligence Enhance Organisational LearningDocument16 pagesDealing With Organisational Change Can Emotional Intelligence Enhance Organisational LearningSabiqNadzimNo ratings yet

- Int PressDocument8 pagesInt Pressmanish318No ratings yet

- Main Door Canopy Section-CDocument1 pageMain Door Canopy Section-Cmanish318No ratings yet

- Crude Oil Stroage Tanks SpecsDocument48 pagesCrude Oil Stroage Tanks Specsmanish318No ratings yet

- Eng 2015Document103 pagesEng 2015manish318No ratings yet

- EngDocument13 pagesEngmanish318No ratings yet

- Corrugated rainwater channel section detailsDocument1 pageCorrugated rainwater channel section detailsmanish318No ratings yet

- Blademodeler: Ansys, Inc. Proprietary © 2009 Ansys, Inc. All Rights Reserved. April 30, 2009 Inventory #002693Document19 pagesBlademodeler: Ansys, Inc. Proprietary © 2009 Ansys, Inc. All Rights Reserved. April 30, 2009 Inventory #002693Ssheshan PugazhendhiNo ratings yet

- API 510 Section 8 QuizDocument17 pagesAPI 510 Section 8 Quizamalhaj2013No ratings yet

- WEISS Produktkatalog en WebDocument220 pagesWEISS Produktkatalog en WebBurak KoyuncuogluNo ratings yet

- FSTD Slim Ec Flex PDFDocument73 pagesFSTD Slim Ec Flex PDFJavier GarridoNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- FE Exam Chemical SpecsDocument3 pagesFE Exam Chemical SpecsChirack Singhtony SNo ratings yet

- HSPTA Malappuram Physics Question Bank Ch 1&2-Physical World, Units & Measurement (1)Document10 pagesHSPTA Malappuram Physics Question Bank Ch 1&2-Physical World, Units & Measurement (1)arunkrishna1120No ratings yet

- Selection of Gas CompressorsDocument5 pagesSelection of Gas CompressorsstreamtNo ratings yet

- 160145-Denso Poster Alternator 594x420 OnlineDocument1 page160145-Denso Poster Alternator 594x420 Onlinesupljina100% (1)

- Dana T2000 6 Speeds Long Drop Service ManualDocument209 pagesDana T2000 6 Speeds Long Drop Service Manualjccla100% (7)

- EQUIVALENT PRODUCT COMPARISON PERTAMINA, SHELL AND MOBILDocument2 pagesEQUIVALENT PRODUCT COMPARISON PERTAMINA, SHELL AND MOBILTheo AnggaraNo ratings yet

- Fluid Mechanics - Physics 122Document6 pagesFluid Mechanics - Physics 122Brian KimNo ratings yet

- 1-Ideal Gas LectureDocument60 pages1-Ideal Gas LecturemahmoudNo ratings yet

- Forces in Truss Members with Different Load PositionsDocument8 pagesForces in Truss Members with Different Load PositionswahtoiNo ratings yet

- As 1988.1-2006 Welding of Ferrous Castings Steel CastingsDocument8 pagesAs 1988.1-2006 Welding of Ferrous Castings Steel CastingsSAI Global - APACNo ratings yet

- Drifter MontabertDocument8 pagesDrifter Montabertramoncalderon100% (2)

- ZDR FFR GBDocument26 pagesZDR FFR GBPetru Stefan100% (2)

- EXTRAC TEC HPC 15 Specifications PDFDocument4 pagesEXTRAC TEC HPC 15 Specifications PDFAlejandro VillanuevaNo ratings yet

- Compressible Aerodynamics Linearized EquationDocument40 pagesCompressible Aerodynamics Linearized EquationJared ThamNo ratings yet

- Ix Ecsdc3 BlockdiagramDocument48 pagesIx Ecsdc3 BlockdiagramBranko Andric100% (1)

- Neuson 8002 RDDocument103 pagesNeuson 8002 RDPierpaolo GustinNo ratings yet

- A320LEAP1A-B12-0008.5 Cont&Ind R1 220517Document78 pagesA320LEAP1A-B12-0008.5 Cont&Ind R1 220517simsimsomNo ratings yet

- UK Datasheet (Lug)Document18 pagesUK Datasheet (Lug)Ahmer AliNo ratings yet

- Bernoulli's Equation SeatworkDocument2 pagesBernoulli's Equation SeatworkJojimar JulianNo ratings yet