Professional Documents

Culture Documents

Rams CCTV Inspection Survey l5 Qat 273a

Uploaded by

rajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rams CCTV Inspection Survey l5 Qat 273a

Uploaded by

rajaCopyright:

Available Formats

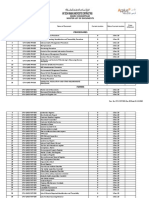

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

ENGINEER’S STAMP: CONTRACTOR’S STAMP:

PROJECT:

20-09-20

00 For Approval Velosi

REV. PREPARED CHECKED APPROVED DATE

ISSUED FOR

BY BY BY

Glennis Mark Thomas

Raja

Loughman

Krishnasamy

CLIENT:

CONTRACTOR VELOSI CERTIFICATION SERVICES LLC

DOCUMENT TITLE:

RISK ASSESSMENT FOR CCTV INSPECTION SURVEY

DOCUMENT NO.

Rev Page

AV-PLR-RA-00 0 1 of 22

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

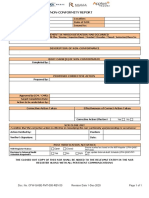

PRE-TASK CONSENTS TO Check (as applicable)

YES NO

1. Has the work activity been identified? X

Check that all foreseeable risks to health, safety and the environment have been assessed via a structured risk assessment procedure:

(a) Process been identified i.e. are all the specific hazards identified? X

2. (b) Are the persons who are at risk identified? X

(c) Have the risks been quantified i.e. High/Med/Low or 1, 2, 3 etc? X

(d) Have effective control measures been put into place? X

Check that adequate health, safety and environment arrangements have been specified in the Method Statement:

(a) Supervisor in charge of operations named? X

(b) Has a person(s) been appointed to take charge of SHE issues? X

3.

(c) Has communication with the Principal Contractor been established? X

(d) Has information, instruction and training been given due regard? X

(e) Are emergency arrangements detailed inc. rescue from height / confined space etc? X

Check that the Method Statement is compatible with the CPP & IEMP and addresses the following:

(a) Are emergency plans (including fire and environmental emergency) compatible? X

(b) Are measures for site security, storage and waste management as required? X

(c) Are Site SHE rules being given due consideration? X

(d) Has the scope/description of work been adequately identified? X

(e) Is the sequence of operations clearly detailed in logical steps? X

4.

(f) Do these steps have hold points for key requirements such as the issue of permits? X

(g) If Temporary Works are included, is there reference TW Process (Design, Approval& Permits?) X

(h) Do these steps cover all the activity from start to finish? X

(i) Is plant and equipment needed for the activity clearly detailed? X

(j) If lifting operations are included, is reference made to the Lifting Plan & Permit To Lift? N/A

(k) Is interface & coordination with other activities / operations covered? X

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

Check that the Method Statement is compatible with the work of other contractors:

5. Are there any specific hazards required e.g. requirements for noise, COSHH, manual handling, welfare

(a) X

etc.

If there are specific hazards such as COSHH, manual handling, noise, vibration etc. Are there separate

(b) X

and suitable assessments?

Check that all Permits below have been identified as hold points stating that the permits must be in place before that activity can

commence

(a) Permit to Dig N/A

(b) Confined Space Permit X

6. (c) Temporary Works Permit to Load / Proceed

(d) Hot work Permit N/A

(e) Permit to Work Adjacent or Under H/V Overhead Cables X

(f) Permit to work on Electrical Equipment X

(g) Other permits (e.g. access permit from client) X

PPE

TYPE

PVC Rubber

Face Visor Muff Dry / Safety Jacket Fuel / Oil – Nitrile Safety

REF

Hard Hat waterproof or Coverall Shoes

General Handling

Carbon First Aid Cones & Signs

Dioxide Spill Kit Escape Mask

for type of road

On van

AFFF Foam

Gas Monitor, Tripod, Winch &

Confined Space Harness, Waders, 10-minute on vehicle. welfare unit

Welfare:

Entry: Escape Set, Head Lamps

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

1 Poor hygiene Leptospirosis / weils 4 4 16 Good hygiene standards – wash hands 4 1 4

disease prior to eating/ drinking etc avoid

contact with face/mouth during works.

Food and drink only to be consumed in

designated welfare areas.

Smoking only permitted in designated

areas.

Waste food to be disposed of in

designated bins. Pest control to carry

out regular inspections.

All Cuts/abrasions open wounds to be

covered with water resistant plasters

before entry

2 Site Plant & Exhaust Fumes from 5 4 20 No plant vehicles to be left switched on 5 1 5

Vehicles Plant & Vehicles near entry hole.

adjacent to Inspection

Chamber

3 Materials & Falls of Materials 4 4 16 Ensure all plant and materials are kept 4 1 4

Plant away from edge of shaft

4 Manhole Cover Manual Handling 3 3 9 Frames and covers to be lifted using 3 1 3

Removal mechanical aids or lifting keys

The seal between the cover and the

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

surround will be broken by inserting

the point of a crowbar and moving it, if

need be using a rubber mallet.

If a small manhole joint lifting by two

operatives will be carried out using the

long handled ‘keys’ and the manhole

moved aside.

If a large manhole the lifting will be

done using the wheeled manhole lifter

device after the keys have engaged on

the cover.

Replacement of the cover should be

the reverse of above

5 Working with Exposure to infection 4 4 16 All staff have waterproof clothing, 4 1 4

sewerage from Leptospirosis / industrial gloves, face mask and

Weils Disease, Tetanus, disposable breathing masks.

Typhoid, Hepatitis B, Operatives change out of

Hepatitis C or other contaminated clothing at end of work.

Bacterium exposure. Work is carried out to avoid

contamination of clothing or skin as far

as possible and equipment and

clothing is washed down after use.

All exposed wounds or grazes are

cleaned and covered by a waterproof

plaster.

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

Operatives wash exposed skin before

eating

Hand cleanser supplied in trucks to be

used.

A safe area will be designated for all

PPE worn in the sewer

(decontamination area).

6. Environmental Contamination of 3 3 9 Tanker trucks carrying oils, fuels or 3 1 3 Public Statements

Spillage – watercourses; sewage will have the following basic Any public

Sewerage / Oil / contamination of land / emergency equipment: statements or

Resins drainage; slipping Mobile phone for summoning aid. media interviews

hazards on roads PPE including rubber boots, WP regarding a spill

trousers, chemical resistant gloves, involving a

visibility clothing and eye protection company vehicle

goggles. or depot will be

Bag of oil absorbent granules made by the

Spill cover for drains Managing Director

Suitable shovel and liquid scraper. or in his absence

Suitable hand wash gels and wipes one of the other

directors with his

approval. The

In the event of a spill incident the truck

Managing Director

driver will contact his Project Manager

or Director may

who will arrange suitable emergency

consult the

response.

company legal or

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

H&S/PR

The driver will attempt to prevent the consultants for

spill reaching the public drains or advice and

waterways using the basic emergency assistance before

equipment and any sand or soil to making any

hand. If the vehicle is a suction tanker statement.

the vacuum pump will be used to lift

the spill. The Jet Vac equipment can

be used to hose down the road

The driver has the equipment and

training to deal with small spills

Sand for blocking run away

Spill covers for gutter drains and

manholes

Shovels and liquid scraper

Suitable PPE including rubber boots,

WP trousers, chemical resistant

gloves, visibility clothing and eye

protection goggles.

Suitable handwash gels and wipes.

A suction tanker/Jet Vac unit will be

despatched if liquid or semi-solids

have to be lifted and hose down the

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

road in the event of sewage

contamination. Suitable BS

environmentally approved disinfectants

will be used to decontaminate the road

or site and any PPE.

7. CCTV Survey Manual handling Injuries 3 3 9 CCTV Survey operators to be fully 3 1 3

from lowering camera trained in Pipe Sewer Condition

into sewer. Classification.

Cameras vary in weight with size and

Injury from plant and are lowered and raised using an

equipment electric winch on the rear of the CCTV

van.

Care is taken not to snag the winch

cable on the manhole side or

protrusions as it could release from the

hook and fall suddenly.

All Plant and Equipment operated is

subject to a Planned Preventative

Maintenance regime. All Plant and

Equipment is subject to pre-use

inspection. Defect Reporting

Procedures exist for Reporting

Defects.

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

8. Use of Carbon Monoxide 3 4 12 In one of the vans, Generator is fitted 3 1 3 Supervisor to ensure

generators in Poisoning with a Quick Lift device which enables that generator is to be

the van it to be lifted out of the van and set lifted out of van when

away from the works area. in use. (if possible)

Generator is to be fitted with a long

hose which will take all fumes away

from the works area.

Gas monitor to be used in the works

area to ensure carbon monoxide

fumes are at a minimum.

In the other vans, generator is built in

to van and fumes are filtered out

through hose connected to vehicle

exhaust.

For the vans with the generator built in,

carbon monoxide monitors are fitted to

each van. Additionally all built in

generators will be ventilated with

exhaust fumes directed outside the

van.

Battery Invertors to be used where

possible to eliminate the use of

generators .

Injuries re Manual 3 2 6 Generator is only to be lifted by two 3 1 3 Supervisor to ensure

handling persons – proper manual handling that generator is lifted

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

techniques to be used. by two operatives.

All operatives have manual handling

training.

Failure of generator due 3 2 6 Generator to be regularly serviced 3 1 3 Daily checks to be

to wear, tear, damage, carried out on

etc. generator by

operatives. All defects

to be reported to

supervisor

immediately.

9. High Pressure Impact with displaced 4 3 12 All Jetting Operatives wear protective 4 1 4

Water Jetting articles face visors, when operating HPW

Works All Water Jetting activities will be

Impact injuries to other controlled and will be carried out

persons signed and guarded and all personnel

will be trained in the procedures for

Injury from unauthorised Operation Stop.

use of HPWJ Only suitably qualified and

equipment. experienced persons will be authorised

to carry out High Pressure Water

Injury from plant and Jetting Operations. All Plant and

equipment equipment will be secured when not in

use, and monitored when in use.

All Plant and Equipment operated is

subject to a Planned Preventative

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

Maintenance regime. All Plant and

Equipment is subject to pre-use

inspection. Defect Reporting

Procedures exist for Reporting

Defects.

10 Working in Presence of Toxic 5 4 20 Permit to Enter System to be in 5 1 5 Defined situations

Confined Space /Flammable or place requiring immediate

asphyxiating gases All Operatives entering inspection vacation of the

chamber to be confined space sewer:

trained

Inspection Chamber to be vented If the Gas monitors

for at least 20-minute, Atmosphere indicate a

to be monitored before entry for at dangerous

least 5 minutes and continually atmosphere;

whist in chamber If the Topman says

Gas monitors as a minimum to be that the Breathing

3 in 1 (H2S, Co2 &O2) Apparatus Tank

Harness to be worn by operative has indicated that

and attached to winch on Tripod at it is time for the

all times (6 monthly testing is entrant to leave

carried out of Tripod and Winch, the sewer or

which should be ensured is within manhole;

date). Top man to be present at all If any member of

times. No inflammable materials the team feels

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

including matches or lighters to be unwell;

used on site. All Torches or If depth or velocity

Lamps, Gas Detectors or other of flow increases

electrical devices to be in significantly;

accordance with approved QCS There will always

Regulations for the Zones of entry be a competent

undertaken. and responsible

Other necessary surveying person in the

equipment such as cameras or team; this will be

electronic surveying instruments the site supervisor.

will only be used during periods of He will be able to

continuous atmosphere monitoring take full control in

where no adverse conditions are the event of an

indicated. emergency. He

should not ever be

in a position where

he could be out of

action. He should

not generally enter

the confined

space, but if he

does he must first

pass responsibility

to another

competent person

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

on site.

Site Specific Self -

Rescue Procedures

If a hazard

arises within

the manhole or

sewer,

personnel in

both will

immediately

exit and

contact the

Site

Supervisor.

The Site

Supervisor will

re-evaluate the

space to

determine the

appropriate

course of

action.

If the alarm

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

from the

entrant in the

sewer is

activated, the

sewer entrant

will

immediately

exit the sewer

and the

manhole

If the alarm

from the

worker in the

manhole (if

only manhole

work is being

carried out) is

activated the

manhole

entrant will

immediately

exit the

manhole

If the alarm

from the

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

Bottom man (if

there is an

entrant in the

sewer) is

activated the

manhole

entrant will

immediately

exit the

manhole. The

sewer entrant

will be

informed by

the Topman

that the alarm

of the Bottom

Man has been

activated and

the sewer

entrant will be

informed to

evacuate the

sewer also.

If at any time

there is any

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

questionable

action or non-

movement by

any of the

Authorized

Entrants, the

Top Man will

make a verbal

check. If there

is no response

or a

questionable

response, the

worker in the

space will be

ordered to

evacuate the

space

immediately.

If possible,

Authorized

Entrants will

initiate self-

rescue by

climbing out of

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

the space

Site Specific Rescue

Procedures using

Rescue Team

(Manhole Worker or

Bottom Man)

If self-rescue is

not possible

for the

Manhole

Worker or the

Bottom Man,

one of the

rescue team

will don Full

Breathing

Apparatus,

enter the

manhole and

attempt to

retrieve the

entrant via

connecting the

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

retrieval line to

his harness.

The entrant

will then be

winched to

ground level

by the

Topman.

Site Specific Rescue

Procedures using

Rescue Team (Sewer

Worker)

If self-rescue is

not possible

for the entrant

to the sewer,

both bottom

men will enter

the sewer at

both the upper

and lower

manholes

(they are

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

already in the

manholes at

this stage) to

investigate

what the

problem is;

If the entrant

for any reason

is unable to

initiate self-

rescue, if they

are able to

retrieve the

sewer entrant

via the

retrieval line,

he will be

connected to it

and winched to

safety by the

Topman.

If the Bottom

men are

unable to

retrieve the

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

sewer entrant

via the

retrieval line,

another 2 men

will enter the

sewer via both

the upstream

and

downstream

manholes,

again wearing

full BA Kits

and being

lowered by the

Topmen (if

lowering via

the winch is

applicable)

The two men

(one of who

will have a

stretcher) will

enter the

sewer to the

point that the

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

original sewer

entrant is.

He will be lifted

and strapped

to the stretcher

with the four

men (space

permitting)

lifting / pushing

him to the

closest

manhole.

Once in the

manhole, he

will be

connected to

the retrieval

line and

winched to

ground by the

Topman.

Emergency

services will

have already

been called by

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

the Site

Supervisor

when the

Topman lost

communication

with the sewer

entrant.

If any of the

entrants are

disabled due

to falling or

impact, he will

not be

removed from

the confined

space unless

there is

immediate

danger to his

life.

In this case,

Emergency

services are

used to

recover injured

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

man – the Site

Supervisor will

give details of

sewer layout,

position of

injured man

and other use

of specialized

equipment if

required

11. Working in Injuries caused by 3 3 9 Insure lighting is used when 3 1 3

Shaft falling materials, or due required.

to poor lighting The Top Man will take all

conditions measures necessary to ensure

tools, objects or loose materials

are kept clear of the open manhole

or access and that the manhole is

protected by a barrier to prevent

members of the public or other

workers from standing too close to

the shaft and accidentally knocking

items onto the person or persons

below. All tools required will be

lowered in to chamber before

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

operatives enter and after

operatives leave.

12. 110V electric Electrocution 5 3 15 All portable electrical plant and 5 1 5

portable tools tools to be used by trained and

and plant competent operatives. Portable

electrical equipment to be tested

with identification tag attached. No

damaged tools / equipment to be

used.

13. Night Working Exceeding consented 3 3 9 Portable task lighting shall be 3 1 3

noise requirements. provided. If work progresses into the

Sprains. Crushing evening

injuries. Trips and falls. Operatives shall ensure that the task

lighting is pointed away from sensitive

receptors.

Ensure that there is a supply of spare

bulbs.

Each gang shall have a torch with

batteries in case of light failure.

14. Lowering and Injuring lower back 3 2 6 Cameras vary in weight and size. 3 1 3

raising of Operatives to take care when

camera units lowering the camera and if it

into and from releases and falls not to catch the

manholes co axel cable to stop it as the

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

resulting jolt may injure the back. A

full and specific manual handling

assessment will be carried out on

site prior to works commencement.

15. All site works Slips. Trips & Falls 3 3 9 Good housekeeping and suitable 3 1 3

lighting

16. All site works Manual Handling 4 4 16 Mechanical lifting aids to be used where 4 2 8

possible. Maximum weight for single

person lift to be 25kg. Items heavier than

this or longer than 2m to be carried by at

least 2 operatives. Operatives to be trained

in manual handling

17. Working at Fall from Heights, Strike 5 3 15 Secure Barriered and Signed Exclusion 5 1 5

Height by falling object Zone: Placed around the base of the

access equipment to prevent unauthorised

entry into the area below the work site.

Areas Beneath Work Areas: Where

equipment or materials could fall barriers,

nets or other equipment to protect persons

underneath or prevent persons accessing

hazardous areas will be used. Access:

shall be made in reference to the

applicable Safe System of Work. Where

work is undertaken within 2 metres of

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

edges: edge protection in the form of a

guard rail of height not less than 950mm

shall be installed where reasonably

practicable Fall Arrest: Where edge

protection is not provided then fall arrest

devices or other suitable protection must

be provided and used by persons working

within 2 metres of such areas.

18. Environmental Contamination of 3 3 9 All Applus tanker trucks carrying oils, 3 1 3

Spillage – watercourses; fuels or sewage will have the following

Sewerage / Oil / contamination of land / basic emergency equipment:

Resins drainage; slipping Mobile phone for summoning aid.

hazards on roads PPE including rubber boots, WP

trousers, chemical resistant gloves,

visibility clothing and eye protection

goggles.

Bag of oil absorbent granules

Spill cover for drains

Suitable shovel and liquid scraper.

Suitable hand wash gels and wipes

In the event of a spill incident the truck

driver will contact his Divisional

Manager who will arrange suitable

emergency response.

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

The driver will attempt to prevent the

spill reaching the public drains or

waterways using the basic emergency

equipment and any sand or soil to

hand. If the vehicle is a suction tanker

the vacuum pump will be used to lift

the spill. The Jet Vac equipment can

be used to hose down the road

The driver has the equipment and

training to deal with small spills

Absorbent granules in bags

Sand for blocking run away

Spill covers for gutter drains and

manholes

Shovels and liquid scraper

Suitable PPE including rubber boots,

WP trousers, chemical resistant

gloves, visibility clothing and eye

protection goggles.

Suitable handwash gels and wipes.

19 Plant Collision with workers or 4 3 12 All operators are to be competent and 4 1 4

Operations other plant. Roll over

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

causing serious injury. trained.

Unauthorised use All moving plant is to have a

leading to serious injury recognisable flashing light when in

or damage. operation.

Seat belts are to be worn when

operating the plant.

Pedestrian routes around the site are

to be clearly defined.

Keys are to be removed from plant and

equipment when left unattended.

20 Use of lifting Failure of lifting 3 3 9 All lifting accessories are to be certified 3 1 3

accessories accessories with the correct documentation.

All lifting equipment is to be inspected

prior to use by site supervisor and

inspections recorded.

21 Material/Spoil Excavation collapse 4 2 8 All materials/spoil is to be stored away 4 1 4

Storage from excavation to avoid

backfill/collapse/fall.

22 Lifting Insufficient length of 4 2 8 Dummy lifts with no load attached will 4 1 4

operations hoist rope/chain leading be carried out as the trench extends

below ground to load being dropped or deeper underground

level becoming unbalanced

23 Storage and Illness or disease 3 3 9 All COSHH items are to be stored in 3 2 6

use of materials caused by exposure to accordance with COSHH data sheets,

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

L5-QAT-273C

RISK ASSESSMENT

CCTV INSPECTION SURVEY H&S Department

Rev.00

Date: 20 Sept. 2020

No Hazard Risk Description Inherent Controls Residual Notes

Risk Risk

S P S P

R R

harmful substances written assessments for all materials,

kept in COSHH files outlining the

correct use, exposure and PPE.

Never decant into unmarked

containers.

Emergency procedures to be briefed to

all site personnel and procedure to be

kept in site safety manual.

24 Materials Fire risk associated with 4 2 8 Minimise storage of flammable 4 1 4

storage storage of materials materials such as diesel and petrol

Prepared By: Reviewed By: Approved By:

Raja Krishnasamy GLENNIS Mark Thomas Loughman

Safety Manager Project Manager

Doc. No. L5-QAT-273C Rev 00 Date: 20.09.2020

You might also like

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- Monthly HSE Performance StatisticsDocument1 pageMonthly HSE Performance StatisticsRami KhedroNo ratings yet

- Method Statement For Construction Block PavingDocument11 pagesMethod Statement For Construction Block PavingMunaku TafadzwaNo ratings yet

- Fence ITP & ChecklistDocument27 pagesFence ITP & Checklistlike saddamNo ratings yet

- Corrective Action ReportDocument1 pageCorrective Action ReportTito GarciaNo ratings yet

- Incident Investigation ReportDocument4 pagesIncident Investigation ReportABGM SalemNo ratings yet

- F.hse.07 Work PermitDocument4 pagesF.hse.07 Work PermitMOJIBNo ratings yet

- HSE-RA-064 Control of Hazardous - Substances - Rev 0Document13 pagesHSE-RA-064 Control of Hazardous - Substances - Rev 0عمروNo ratings yet

- Logistics PlanDocument28 pagesLogistics PlanZiad HamatiNo ratings yet

- 08 Hirarc Form (r02)Document2 pages08 Hirarc Form (r02)Aizat Sera SuwandiNo ratings yet

- Demolition Work Audit Checklist: Los Angeles Community College DistrictDocument6 pagesDemolition Work Audit Checklist: Los Angeles Community College DistrictJaycee PagadorNo ratings yet

- 3.REG001 Training Attendance RegisterDocument81 pages3.REG001 Training Attendance RegisterWelma JohnsonNo ratings yet

- PR 01 EHS 007 EHS Compliance AuditDocument7 pagesPR 01 EHS 007 EHS Compliance AuditClarabelle Mae Dela RosaNo ratings yet

- QCS 2014 Training RequirementsDocument1 pageQCS 2014 Training RequirementsRehan hassan janjuaNo ratings yet

- XX - PTW 609066 Doc1Document17 pagesXX - PTW 609066 Doc1JeffersonDeGuiaNo ratings yet

- Drivers Safe InductionDocument1 pageDrivers Safe Inductionortega yawa100% (1)

- Safety Training PassportDocument2 pagesSafety Training PassportAbhaySnghNo ratings yet

- Competence, Training and AwarenessaaDocument4 pagesCompetence, Training and AwarenessaaRana DanishNo ratings yet

- Night Work Inspection ChecklistDocument1 pageNight Work Inspection ChecklistAdarsh sNo ratings yet

- FormsDocument134 pagesFormstaisiermed.safety100% (1)

- HEMP-005 Excavation Manual & Mechanical Rev.2Document9 pagesHEMP-005 Excavation Manual & Mechanical Rev.2saravana.bNo ratings yet

- HSE-RA-005 Working at Heights - Rev - 0Document8 pagesHSE-RA-005 Working at Heights - Rev - 0عمروNo ratings yet

- Method Statement - PilingDocument16 pagesMethod Statement - Pilinguebdennis100% (1)

- Blockwork and Plastering - HalulDocument14 pagesBlockwork and Plastering - HalulDindo QuintanNo ratings yet

- Risk Assesment For Shifting of MEP Services and Re-Installations 26-03-2022Document5 pagesRisk Assesment For Shifting of MEP Services and Re-Installations 26-03-2022Zameer Basha Navzath AliNo ratings yet

- SWP Fire PumpDocument6 pagesSWP Fire PumpbsynnottNo ratings yet

- RA - 18 - For Concrete Topping On Hollow Core SlabDocument14 pagesRA - 18 - For Concrete Topping On Hollow Core SlabIbrahim EsmatNo ratings yet

- Imb SH Hse 0009 01Document64 pagesImb SH Hse 0009 0101095902062ahmedNo ratings yet

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- Procurement Requisition: Form No. Version No. 5.1Document1 pageProcurement Requisition: Form No. Version No. 5.1loveson glariyansNo ratings yet

- MIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3Document40 pagesMIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3AmeerHamzaWarraichNo ratings yet

- Pouring PermitDocument1 pagePouring PermitHanz RodriguezNo ratings yet

- Method Statement & Risk Assessment Hydrostatic Leak TestDocument7 pagesMethod Statement & Risk Assessment Hydrostatic Leak TestWalid AmdouniNo ratings yet

- SEPR-IC-Q-111 Rev.1 Formwork StrippingDocument3 pagesSEPR-IC-Q-111 Rev.1 Formwork Strippingengr.s.a.malik6424No ratings yet

- Construction Procedure Concrete Form WorkDocument12 pagesConstruction Procedure Concrete Form WorkDimas DzununNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Fire Detection and Alarm System ChecklistDocument3 pagesFire Detection and Alarm System ChecklistSalim BakhshNo ratings yet

- COSHH Assessment - MasterGlenium Sky 8711Document2 pagesCOSHH Assessment - MasterGlenium Sky 8711Clifford100% (1)

- 13 Emergency Response: Project Employer Engineer ContractorDocument9 pages13 Emergency Response: Project Employer Engineer ContractorcenkunalNo ratings yet

- Method Statement for Hot WorkDocument5 pagesMethod Statement for Hot WorkJeffersonDeGuiaNo ratings yet

- Work Procedure For The Construction of CO2 Cylinder HouseDocument9 pagesWork Procedure For The Construction of CO2 Cylinder HouseJoyce GordonioNo ratings yet

- Method Statement for Portland Cement PlasterDocument18 pagesMethod Statement for Portland Cement Plasterlinga2014No ratings yet

- Section 03 Site Clearance N Demolition PDFDocument11 pagesSection 03 Site Clearance N Demolition PDFlakmalperera1986100% (1)

- Hazard Identification & Risk Assessment: Main ActivityDocument3 pagesHazard Identification & Risk Assessment: Main ActivityAnsari Shakeel100% (1)

- Risk Assessment for EarthworksDocument1 pageRisk Assessment for EarthworkskumarNo ratings yet

- 42 AS-F-HSE 042 - Inspection Checklist For Construction EquipmentDocument3 pages42 AS-F-HSE 042 - Inspection Checklist For Construction EquipmentJHUPEL ABARIALNo ratings yet

- Abrasive Blasting Safety ChecklistDocument2 pagesAbrasive Blasting Safety ChecklistSaravanan JambunathanNo ratings yet

- RAMS Review for Telehandler WorksDocument30 pagesRAMS Review for Telehandler WorksArturNo ratings yet

- Masterprotect 1855 TdsDocument2 pagesMasterprotect 1855 TdsShahsoor Shah Majeed100% (1)

- IEE Report for Pakistan Power Distribution ProjectDocument62 pagesIEE Report for Pakistan Power Distribution ProjectMunir HussainNo ratings yet

- ALDAR Projects Health and Safety Alert Electrical SafetyDocument1 pageALDAR Projects Health and Safety Alert Electrical SafetyerwinNo ratings yet

- Emergency PLANDocument20 pagesEmergency PLANShariq AhmedNo ratings yet

- HSE Plan SubconDocument27 pagesHSE Plan SubconTaufan Arif Zulkarnain100% (1)

- Accidents / Incidents / Near Miss RecordDocument1 pageAccidents / Incidents / Near Miss RecordArul EdwinNo ratings yet

- HSE Auditing ProceduresDocument20 pagesHSE Auditing ProceduresMuhammad AbdullahNo ratings yet

- 3.3.4 Monthly Suction Septic Tank LogDocument2 pages3.3.4 Monthly Suction Septic Tank LogSubzone ThreeNo ratings yet

- Ma'Aden SpecificationDocument14 pagesMa'Aden Specificationahmed elesawyNo ratings yet

- HSE KPI Dashboard-NewDocument4 pagesHSE KPI Dashboard-NewChandan Kumar SinghNo ratings yet

- Construction Incident Report PDFDocument1 pageConstruction Incident Report PDFalfieNo ratings yet

- RAMS Water Jet Cleaning L5 QAT 273DDocument25 pagesRAMS Water Jet Cleaning L5 QAT 273DrajaNo ratings yet

- CFW QHSE FMT 008 Customer Satisfaction SurveyDocument1 pageCFW QHSE FMT 008 Customer Satisfaction SurveyrajaNo ratings yet

- CFW Qhse FMT 007 Document TransmittalDocument1 pageCFW Qhse FMT 007 Document TransmittalrajaNo ratings yet

- CFW QHSE FMT 001 CFW Master List of DocumentsDocument6 pagesCFW QHSE FMT 001 CFW Master List of DocumentsrajaNo ratings yet

- CFW QHSE FMT 004 Calibration RegisterDocument1 pageCFW QHSE FMT 004 Calibration RegisterrajaNo ratings yet

- CFW QHSE FMT 005 Non Conformity Report (NCR)Document1 pageCFW QHSE FMT 005 Non Conformity Report (NCR)rajaNo ratings yet

- RAMS Water Jet Cleaning L5 QAT 273DDocument25 pagesRAMS Water Jet Cleaning L5 QAT 273DrajaNo ratings yet

- Method for LED Pipe LiningDocument11 pagesMethod for LED Pipe LiningrajaNo ratings yet

- Rams CCTV, Cleaning, Cipp Uv Lining l5 Qat 273bDocument29 pagesRams CCTV, Cleaning, Cipp Uv Lining l5 Qat 273brajaNo ratings yet

- CFW QHSE FMT 006 Customer Feedback RegisterDocument2 pagesCFW QHSE FMT 006 Customer Feedback RegisterrajaNo ratings yet

- Rams Robotic Cutting l5 Qat 273cDocument25 pagesRams Robotic Cutting l5 Qat 273crajaNo ratings yet

- L4-QAT-087C Method Statement For Patch Repair WorkDocument10 pagesL4-QAT-087C Method Statement For Patch Repair WorkrajaNo ratings yet

- RAMS CCTV, Cleanning, Patch Repair L5 QAT 273CDocument26 pagesRAMS CCTV, Cleanning, Patch Repair L5 QAT 273CrajaNo ratings yet

- L4-QAT-087B Method Statement For CIPP - UV Lining WorkDocument9 pagesL4-QAT-087B Method Statement For CIPP - UV Lining WorkrajaNo ratings yet

- Risk Assessment for LED Cure Lining WorkDocument25 pagesRisk Assessment for LED Cure Lining WorkrajaNo ratings yet

- L4-QAT-087 Method Statement For CCTV & Deflection SurveyDocument10 pagesL4-QAT-087 Method Statement For CCTV & Deflection SurveyrajaNo ratings yet

- MIC Construct Workers' Accommodation and Welfare PlanDocument60 pagesMIC Construct Workers' Accommodation and Welfare PlanrajaNo ratings yet

- Why I Love My Career in Occupational and Environmental Health and SafetyDocument16 pagesWhy I Love My Career in Occupational and Environmental Health and SafetyrajaNo ratings yet

- Incident Accident Emergency Response Plan Rev. 01Document57 pagesIncident Accident Emergency Response Plan Rev. 01rajaNo ratings yet

- Stakeholder Management StrategyDocument9 pagesStakeholder Management StrategyrajaNo ratings yet

- HSE Management Plan Rev. 08Document61 pagesHSE Management Plan Rev. 08rajaNo ratings yet

- Incident, Accident & Emergency Response Plan Rev. 03Document46 pagesIncident, Accident & Emergency Response Plan Rev. 03rajaNo ratings yet

- Bowen Exam Prep Timeline WebDocument1 pageBowen Exam Prep Timeline WebrajaNo ratings yet

- The Design and Synthesis of Novel BarbituratesDocument333 pagesThe Design and Synthesis of Novel BarbituratesLucas Timmer100% (1)

- Path-SARS-CoV-2 Winterplex IFU Issue 11.02Document36 pagesPath-SARS-CoV-2 Winterplex IFU Issue 11.02nazmiNo ratings yet

- Word ScoutDocument104 pagesWord ScoutMobina RadNo ratings yet

- AFMC PrimerDocument523 pagesAFMC PrimerFajar Nurrachman100% (1)

- Effectiveness of Coma Stimulation Therapy On Traumatic Brain InjurypatientsDocument5 pagesEffectiveness of Coma Stimulation Therapy On Traumatic Brain InjurypatientsZoroNo ratings yet

- Ceramic Veneers DR Jason WangDocument13 pagesCeramic Veneers DR Jason Wangyovita meliaNo ratings yet

- Drug StudyDocument2 pagesDrug StudymatthewchadNo ratings yet

- Renal Disease PresentationDocument17 pagesRenal Disease Presentationapi-292524690No ratings yet

- Healthy Homes Barometer 2019 examines impact of buildings on children's healthDocument16 pagesHealthy Homes Barometer 2019 examines impact of buildings on children's healthMihai TomaNo ratings yet

- Gate Ee FinalDocument171 pagesGate Ee FinalAnonymous LXHlHv2RWNo ratings yet

- Duty Report Muzaini UAPDocument29 pagesDuty Report Muzaini UAPAinil MardiahNo ratings yet

- PSORIASISDocument9 pagesPSORIASISDianne BernardoNo ratings yet

- Exam 2017 Questions and AnswersDocument10 pagesExam 2017 Questions and AnswersKen LeeNo ratings yet

- College of Nursing: Pharmacology Drug StudyDocument2 pagesCollege of Nursing: Pharmacology Drug StudyChristine Pialan SalimbagatNo ratings yet

- Ujian Semester Gasal Kelas Xi IpaDocument38 pagesUjian Semester Gasal Kelas Xi IpaRichard sutantoNo ratings yet

- 1307 Ascot Bpla (Sever)Document8 pages1307 Ascot Bpla (Sever)Fernando CamargoNo ratings yet

- Nutrients and Their Functions in Maintaining HealthDocument6 pagesNutrients and Their Functions in Maintaining Healthuma crespoNo ratings yet

- Case Study Pneumonia)Document20 pagesCase Study Pneumonia)Jai - Ho83% (6)

- Advia 2120i Hematology SystemDocument8 pagesAdvia 2120i Hematology SystemDwitaRiadiniNo ratings yet

- Techno - Obstetric miniOSCEDocument153 pagesTechno - Obstetric miniOSCEIssa JbourNo ratings yet

- The Effects of STRESS On Your Body: Your Company Name/Logo HereDocument2 pagesThe Effects of STRESS On Your Body: Your Company Name/Logo HereIveta NikolovaNo ratings yet

- Pelvic Inflammatory DiseaseDocument20 pagesPelvic Inflammatory DiseaseDeniela Jamaicy Herbert100% (1)

- Sources of Nutrients and Deficiency Diseases PDFDocument3 pagesSources of Nutrients and Deficiency Diseases PDFmohammad sammeerNo ratings yet

- Bab 1 Normal KGBDocument14 pagesBab 1 Normal KGBukhtianitaNo ratings yet

- Anatomy of Hepatobiliary SystemDocument46 pagesAnatomy of Hepatobiliary SystemAyu Tiara FitriNo ratings yet

- Thesis 01Document14 pagesThesis 01Vladimere Censon Reyes100% (1)

- English Research EssayDocument10 pagesEnglish Research Essayapi-542021916No ratings yet

- 3 Steps To Reverse Aging 1Document3 pages3 Steps To Reverse Aging 1santosh MaliNo ratings yet

- Respiratory Effects of Amyotrophic Lateral Sclerosis, Problems and SolutionsDocument14 pagesRespiratory Effects of Amyotrophic Lateral Sclerosis, Problems and SolutionsMarcelaNo ratings yet

- List of Hazard IdentifiedDocument47 pagesList of Hazard IdentifiedNik Mohamad Zhafran100% (1)