Professional Documents

Culture Documents

MIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3

Uploaded by

AmeerHamzaWarraichOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3

Uploaded by

AmeerHamzaWarraichCopyright:

Available Formats

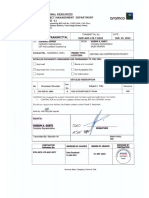

09 MAY 2021

Branch of Sinopec International Petroleum Services Corp.

MIP PKG 17 RAS TANURA AREA PIPELINE

CONTRACT No.: 6600044545 BI No.: BI-10-09004-0003

ENVIRONMENT MANAGEMENT PLAN - 2021

DOCUMENT No.: MIP17 – HSE – PP – 001 REVISION: 3

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

MIP PKG 17 RAS TANURA AREA PIPELINE

CONTRACT No.: 6600044545

BI-10-09004-0003

3 5/5/21 Resubmit after Incorporating the Comments Yu Tao An Faquan

HSSE

2 11/4/19 First Issue for Review & Approval HSSE Manager Project Manager

Department

Prepared Reviewed Approved

Rev. No Date Reason for Issue

By By By

Document Title:

ENVIRONMENT MANAGEMENT PLAN - 2021

Document No.: Rev. No.: Issue/Rev. Date:

MIP17–HSE–PP–001 3 5/5/21

Submitted by:

MIP17–HSE–PP–001 REV 3 Page 2 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

TABLE OF CONTENTS

1.0 FOREWORD ............................................................................................................................................................. 4

2.0 BRIEF SCOPE OF WORKS AND LOCATION MAP ........................................................................................... 5

3.0 COMPANY HSE POLICY,HSE STRATEGIC OBJECTIVES, HSE COMMITMENT..................................10

4.0 ORGNIZATION CHART .........................................................................................................................................11

5.0 ENVIRONMENTAL MANAGEMENT PLAN ........................................................................................................11

6.0 HANDLING TRANSPORTATION AND DISPOSAL OF HAZARDOUS MATERIAL (CLASS I) ...................21

7.0 CONTRACTOR ADDRESSES FOR ENVIRONMENTAL CONTRACTORS ................................................. 25

8.0 WASTE LOG – (NON HAZARDOUS WASTE ................................................................................................... 26

9.0 WASTE LOG-(HAZARDOUS WASTE) ............................................................................................................... 27

10. HAZARDOUS WASTE CONSIGNMENT NOTE ................................................................................................28

11. SINOPEC SERVICE SAUDI ARABIA/ SUBCONTRACTORS CAMP SANITATION AND SAFETY ..........29

12. DUST CONTROL ...................................................................................................................................................32

13. IONIZING RADIATION ........................................................................................................................................32

14. SICKNESS MANAGEMENT PLAN......................................................................................................................35

MIP17–HSE–PP–001 REV 3 Page 3 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

1.0 FOREWORD

The intent of this Environment Management Plan (EMP) is to specify our approach and principles of

all the environment requirements as applied to this project, both contractually in Schedule D and

requirements specified in the Saudi health and labor codes.

The objectives of this Environment Management Plan (EMP) is to:

Describes SINOPEC Service Saudi Arabia overall approach to preventing loss for the MIP

Package 17 Ras Tanura Area Pipeline Works, includes roles and responsibilities.

How compliance to the requirements of applicable standard will be achieved.

Ensure system is compatible to SAUDI ARAMCO requirements as relevant legislations and

other requirements.

This EMP covers the relevant EMP related function and process for this project. This EMP is to be

implemented from all stages of the construction project, from project planning through to project

completion and this EMP may not always get into specific detail on how HSE activities and process

are conducted, but mainly focuses on what SINOPEC Service Saudi Arabia provides assurance in

regards towards environment issues on site. This EMP also demonstrates the project management

team strong and steadfast commitment to provide suitable environment controls to meet SAUDI

ARAMCO requirements as the applicable, codes, standards and specifications to which apply to

this project.

Environment Management Plan is reviewed and updated as necessary by The SINOPEC Service

Saudi Arabia project management team upon consultation with relevant parties. Any document

changes are actively discussed during project meetings and interactive sessions with the client. A

member of management or staff, through document request change, can initiate request for

changes at any time. All document changes shall be indicated on the change history page and

approved by the Project HSE Manager and the Project Manager before becoming an official

requirement.

Sinopec International Petroleum Service Corporation (SINOPEC SERVICE) has established,

documented and implemented Health, Safety and Environment Management System (HSE MS)

that can be used internally as information and training to managers and employees, and externally

as information and reference to Regulatory Authorities, Partners, Media, and Public Interest Groups

etc. The HSE MS will be continuously developed and improved through regular audit and review.

MIP17–HSE–PP–001 REV 3 Page 4 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

All personnel working within SINOPEC SERVICE operations, staffs and contractors, are required to

comply with the requirements stipulated in the HSE MS.

2.0 BRIEF SCOPE OF WORKS AND LOCATION MAP

2.1 Project Description

The purpose of this project proposal is to provide the scope of work for the communication

services to be provided for the 11 new pipelines and associated scrapers to be constructed in

support of BI-10-09004 Marjan Downstream pipeline.

The following tables provide the pipeline data for the 11 new pipelines and the specific

pipeline associated with package #17:

MIP17–HSE–PP–001 REV 3 Page 5 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

This package involves two (2) downstream pipelines with total approx. length of 426 km

The subject scope of work dedicated for package # 17 (Ras-Tanura Pipelines) only, the

LSTK-Contractor shall be responsible for design, engineering, procurement, fabrication,

installation, construction, testing and Pre-Commissioning WORK of the pipelines and their

associated systems.

The detailed scope of work is attached to CSSP for review and further information in line to

schedule B of the contact.

2.2 SITE LOCATION MAP

MIP17–HSE–PP–001 REV 3 Page 6 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

2.3 General Provisions

2.3.1 Definitions

SAUDI ARABIAN OIL COMPANY (“SAUDI ARAMCO”), a company of limited liability

organized under the Laws of the Kingdom of Saudi Arabia.

SAUDI BRANCH OF SINOPEC INTERNATIONAL PETROLEUM SERVICE CORPORATION

P.O.Box:32159 Al-Khobar 31952 Kingdom of Saudi Arabia.

Sinopec Office Building, Euro village Compound, Al Khobar.

Tel:+966 13 8575801 Fax: +966 13 8575803

Email: Saudi.sips@sinopec.cm

Commercial Registration Number: 2051029892

Saudi Aramco Registration Number: 10032383

2.3.2 Compliance with safety, health and environmental requirements

SINOPEC Service Saudi Arabia and all their employees, agents and subcontractors shall

comply at all times with Saudi Aramco Mandatory Requirements. In case of conflicting

requirements, the most stringent requirement shall apply.

SINOPEC Service Saudi Arabia shall have available at the WORK site the most current

copy of the SAUDI ARAMCO Construction Safety Manual and all applicable SAUDI

ARAMCO G.I.s, Handbooks, and Engineering Standards. SINOPEC Service Saudi Arabia

may request, from the Company Representative, copies of those SAUDI ARAMCO

standards, rules and regulations which are applicable to this contract.

Additionally, SINOPEC Service Saudi Arabia shall comply with all applicable SAUDI

ARAMCO Operations or Refinery Instruction Manuals. For on shore/offshore WORK.

SINOPEC Service Saudi Arabia shall also take or cause to be taken any additional

measures under the direction of the Company Representative to prevent the injury or death

of any person, or any damage or loss of property, loss of process, or damage to the

environment during SINOPEC Service Saudi Arabia’s performance of the WORK.

SAUDI ARAMCO reserves the right to monitor and inspect any WORK Site, lay down yard,

fabrication yard, clinic, camp and dining facility (on or off SAUDI ARAMCO property) for

compliance with the above referenced Safety, Health and Environmental Requirements.

KSA National Environmental Standards Lists, PME Reference (Presidency of

Meteorology and Environment);

SA National Environmental Standards Lists, PME Reference (Presidency of

MIP17–HSE–PP–001 REV 3 Page 7 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Meteorology and Environment);

• Ambient Air Quality

• Ambient Water Quality

• Drinking Water Quality

• Environmental Noise

• Industrial - Municipal WW

• Mobile Source Emissions

• PME General Environmental Regulations

• Industrial - Municipal WW

• MEPA

• Law of Chemicals Import and Management

2.3.3 Deviation from Safety, Health and Environment Requirements

Any deviation by SINOPEC Service Saudi Arabia from SAUDI ARAMCO's (or other

applicable) safety, health and environmental requirements (or rules and regulations) shall

be approved, in advance, in writing by the Company Representative.

2.3.4 Failure to Comply

Should SINOPEC Service Saud Arabia fail to comply with any of the requirements of this

Schedule "D", SAUDI ARAMCO reserves the right to notify SINOPEC Service Saudi Arabia

of this situation. Upon receiving such notification, SINOPEC Service Saudi Arabia shall

immediately take all necessary corrective actions. Any corrective action shall, unless

provided otherwise in this Contract, be taken at SINOPEC Service Saudi Arabia’s expense.

If SINOPEC Service Arabia fails to take prompt corrective action, the Company

Representative may direct SINOPEC Service Saudi Arabia to suspend all or part of the

WORK pursuant to Schedule "A" until satisfactory corrective action has been taken. Costs

incurred by SINOPEC Service Saudi Arabia as a result of such WORK suspension shall be

solely SINOPEC Service Saudi Arabia’s responsibility, and any resultant SINOPEC Service

Saudi Arabia performance delays shall not be deemed excusable hereunder.

MIP17–HSE–PP–001 REV 3 Page 8 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

2.4 Saudi Aramco Assistance

SINOPEC Service Saudi Arabia may request assistance from SAUDI ARAMCO with respect

to the implementation of its Safety, Health and Environmental Requirements. The Company

Representative (or the Company Representative’s designated party or parties) may provide

assistance to the SINOPEC Service Saudi Arabia by explaining good safety and sound

environmental practices, pointing out unsafe conditions, and by applying experience and

judgment, to assist SINOPEC Service in improving safety and to safeguard the environment.

Such assistance by SAUDI ARAMCO shall in no way relieve SINOPEC Service Saudi Arabia

of its responsibilities as set forth in this Schedule "D".

MIP17–HSE–PP–001 REV 3 Page 9 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

3.0 COMPANY HSE POLICY,HSE STRATEGIC OBJECTIVES, HSE COMMITMENT

HSE Policy

HSE is one of the SINOPEC SERVICE’s core values. We integrate HSE in all business activities.

HSE Strategic Objectives

SINOPEC SERVICE shall conduct its business in safe and efficient manner, and strive continuously for

zero harm to people, zero damage to the environment, and zero loss to assets.

HSE Commitment

To achieve the company HSE Strategic Objectives, SINOPEC SERVICE commits to:

Ensure all our operations are carried out in accordance with the applicable laws and regulations.

Respect local customs and religions wherever we operate.

Provide resources including staffing, financial support, equipment, information, instruction and

training to the HSE management.

Focus on employee health and on improving the working environment.

Identify, assess and minimize risks involved in our operations to ALARP - As Low As Reasonably

Practicable.

Conduct our operations through efficient use of materials and energy, with minimum waste and

damage to the environment.

Develop, maintain and drill emergency response plan.

Apply line responsibility in HSE management. HSE performance is an indicator in the selection,

appraisal and reward of our staff.

Communicate HSE issues and performance internally and externally.

Monitor and audit compliance with this policy and its associated HSE management system to ensure

that they are effective.

Apply systematic approaches to continually improve our HSE performance.

Zhang Yongjie

President

February 2018

MIP17–HSE–PP–001 REV 3 Page 10 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

4.0 ORGNIZATION CHART

We shall provide responsible persons 24-hout contact lists prior to site mobilization.

5.0 ENVIRONMENTAL MANAGEMENT PLAN

5.1 General

This Environmental Management Plan comply with the provision of the: Saudi Arabian Laws

and Regulations Schedule “A” and “ D ” of the Contract No. 6600044545 and Saudi Aramco

mandatory requirements and the following standards as per Schedule “D”, Section II.

SINOPEC Service Saudi Arabia “HSE Management System. SINOPEC SERVICE SAUDI

MIP17–HSE–PP–001 REV 3 Page 11 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

ARABIA Environmental objective is to achieve “ZERO Environmental Releases”.

All the procedures and practices in Environmental Management Plan (EMP) document

shall be consistent to the EIA OF THE SAME BI.

The Environmental Management Plan (EMP) applies for topics covered by both SINOPEC

SERVICE SAUDI ARABIA and Saudi Aramco documents; in this case the description that is

more relevant to environmental control will be adopted.

Any deviation from Saudi Aramco Environment Requirements, Rules and Regulations, must

be approved, in advance and in writing, by the Saudi Aramco Representative through the

Environmental Protection Department.

SINOPEC SERVICE SAUDI ARABIA may request assistance from Saudi Aramco with respect

to the implementation of its ENVIRONMENT REQUIREMENTS according to the Schedule “D”

of the Contract.

5.2 Scope and Objective

The Environmental Management Plan for Construction (EMP) is designed to provide effective

methods for handling, recycling and disposal of wastes generated during the construction and

pre-commissioning/ commissioning phases.

The EMP is developed for adequate response to potential environmental impacts during the

construction operations led by SSSA related to the MIP PKG 17 Ras Tanura Area Pipelines.

The Environmental Management Program is designed as a Project reference in effective

waste handling and disposal and provides a set of guidelines for general Project use.

The target users are field personnel and technical staff involved in planning and implementing

Project environmental management facilities and practices.

The Environmental Management Plan is based on the following principals:

Assist SINOPEC Service Saudi Arabia personnel and their Subcontractors in managing

wastes effectively and within the requirements established by Saudi Aramco policies

and applicable waste regulations;

provide proper guidance for the handling of each waste generated during construction

operations to protect human health and to minimize the impact on the environment;

dispose of all waste in a safe manner and at Saudi Aramco approved disposal sites;

co-operate with Saudi Aramco and governmental agencies to limit impacts on local

waste disposal facilities;

form a basis for training, evaluation, monitoring and pollution prevention programs;

MIP17–HSE–PP–001 REV 3 Page 12 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

control the amount of waste generated by reducing waste at source through good

operating practices and implementing waste reduction principles;

recycle, re-use and recovery of waste wherever possible;

Be periodically reviewed and updated as new practices and options are discovered.

5.3 Applicable and Reference Saudi Aramco Documents

The contents of the EMP are in compliance with the main applicable laws, regulations,

guidelines and guidance documents on Environmental/waste management in Saudi Arabia,

In addition, the contents of the EMP also comply with the following Saudi Aramco

Corporate Policies:

(1) INT-5 Environmental Protection Policy.

(2) INT-11 Water Conservation Policy.

(3) Other missing applicable SAESs, SAEPs and regulations that are available

at:https://sharek.aramco.com.sa/orgs/30003644/Pages/IndustryPractice.aspx.

The reference basis of design for the assessment and management of wastes generated

during construction operations include:

Government Requirements: they provide appropriate bases for the evaluation and regulation

of industrial activities in the Kingdom; they provide requirements necessary to plan design

and operate facilities that will be established in a manner, which shall not cause undesired

health, safety and environmental effect:

Meteorology and Environmental Protection Administration (MEPA) “Environmental

Protection Standards”.

Saudi Aramco Standards : standards, that establish minimum requirements for the selection,

design, construction and maintenance of equipment and facilities ; they provide

environmental limitations, technical requirements and procedures to be applied for all new

plant located in Saudi Aramco facilities, or that are under Saudi Aramco operation and

maintenance:

SAES-A-102: Ambient Air Quality and Source Emission Standard

SAES-A-103: Discharges to the Marine Environment

SAES-A-104: Wastewater Treatment, Reuse and Disposal

SAES-A-007: Hydrostatic Testing Fluids and Laying Procedures

SAES-A-111: Borrow Pit Requirements

MIP17–HSE–PP–001 REV 3 Page 13 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

SAES-A-112: Meteorological and Seismic Design Data

SAES-S-007: Solid Waste Landfill Standard

SAES-S-010: Sanitary Sewers

SAES-S-020: Industrial Drainage and Sewers

SAES-S-030: Storm Water Drainage Systems

SAES-S-040: Saudi Aramco Water Systems

SAEP - 1661: Waste Minimization Opportunity Assessment

KSA National Environmental Standards Lists, PME Reference (Presidency of

Meteorology and Environment);

Ambient Air Quality

Ambient Water Quality

Drinking Water Quality

Environmental Noise

Industrial - Municipal WW

Mobile Source Emissions

PME General Environmental Regulations

Industrial - Municipal WW

MEPA

Law of Chemicals Import and Management

Saudi Aramco Engineering Procedures: they establish environmental limitations,

responsibilities and instructions to accomplish engineering activities according to the Saudi

Aramco management:

SAEP-327: Disposal of Wastewater from Cleaning, Flushing, and Hydrostatic Tests. Saudi

Aramco Sanitary Code: describes the public health requirements, limitations and procedures

which all organizations responsible for the construction, operation and maintenance of new

facilities shall comply with, in order to protect the public health, preserve resources and

prevent nuisance conditions: SACS: Saudi Aramco Sanitary Code.

Saudi Aramco General/Materials Instructions: they provide direction and guidance for

organizations of facilities development in in order to comply with the regulations of the

Kingdom of Saudi Arabia:

GI-002.714: Environmental Protection Policy Implementation

GI-140.001: Saudi Aramco Hazardous Waste Code

MIP17–HSE–PP–001 REV 3 Page 14 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

GI-150.001: Asbestos Hazard Management

GI-150.003: Ionization Radiation Protection

GI-151.006: Implementing the Saudi Aramco Environmental Health Code

GI-0002.717: Procedure and Guideline for Handling Polychlorinated Biphenyl’s (PCB’s)

GI-0006.021: Safety Requirements for Abrasive Blast Cleaning

GI-2.00: Work Permit System

5.4 Organization and Responsibility

SINOPEC Service Saudi Arabia and designated Subcontractors will be responsible for

management of wastes produced when performing their own activities. However SINOPEC

Service Saudi Arabia is wholly responsible for ensuring that its subcontractors follow

Environmental management programs.

The SINOPEC Service Saudi Arabia Site HSE Manager will be the responsible person to

monitor the proper waste management and the implementation of this Program. The main

duties are to ensure that:

A good housekeeping is maintained during day to day operations;

All of the waste streams that are generated in the project areas are identified, classified and

entered in the dedicated Waste Register;

An estimate of the quantity of waste generated is made;

All disposal sites used are designated and approved by Company;

All subcontractors in charge of waste management and disposal are licensed and approved;

All registered subcontractors are aware of the waste management procedures;

All environmental incidents (accidental spills or discharges) are properly managed and

documented.

Waste management activities will be carried out continuously during construction and pre

commissioning activities.

Waste Management Contractor and Transporter;

SEPCO INVIRONMENT

National Environment presentation Co (BEE’Ah)

During the construction period an average of 510 manpower will be at site, with a peak

of about 600 manpower (direct & indirect). The types of wastes and quantities of each

waste generated will be estimated prior to mobilization.

MIP17–HSE–PP–001 REV 3 Page 15 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

The waste list of each class and its physical status refer to 5.6 and will be updated prior

to mobilization.

5.5 Environmental Emergency

An emergency procedure specific for the Plant will be prepared and issued by proponent.

This will include a Pollution contingency Plan.

All spills and leaks eventually generated during the construction phase will be managed

according to specific instructions.

A “Pollution contingency Plan” shall be prepared and issued taking in to account the

applicable Saudi Aramco General instruction.

The Plan shall include:

Emergency actions;

Provisions for the notification to Saudi Aramco.

Schedule “D”, Section 6, Para 6.2/6.3.

Aside the emergency activity, SINOPEC Service Saudi Arabia/Subcontractors will lend any

reasonable assistance to Saudi Aramco in handling, controlling, or cleaning up any

discharge or escape of pollutions or contaminants.

INCIDENTS DETECTION, REPORTING, ANALYZING AND COORDINATING ACTIVITY.

5.5.1 Incident Detection

Environmental Incident: Undesired event giving rise to an uncontrolled dangerous

release (of fluids, solids, gases vapors, radiation, noise) into the environment.

Environmental “near miss”: Undesired event that under slightly different

circumstances can generate an accident.

All environmental incidents, including near misses, shall be detected and reported in

writing, to the attention of the SINOPEC Service Saudi Arabia Site Manager for the

relevant distribution and analysis.

5.5.2 Reporting: Damage Reports and Records

An immediate verbal report shall be done to SINOPEC Service Saudi Arabia Site

HSE Manager/Construction Manager and Saudi Aramco Representative for every

case involving major damage to property and fire.

For major damage to property, a written report shall be promptly submitted to Site

HSE Manager / Construction Manager and Saudi Aramco Representative.

MIP17–HSE–PP–001 REV 3 Page 16 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Subsequently, SINOPEC Service Saudi Arabia and Saudi Aramco shall perform an

investigation.

Damage is considered major when it exceeds 10,000 SR.

A summary of all records of environmental incidents shall be prepared and

maintained by the SSSA Site HSE Manager.

5.5.3 Incident Analysis

Analysis shall be performed according to the Saudi Aramco procedures. The analysis

shall lead to the definition of the necessary means to be applied to prevent the

recurrence of the accident. SINOPEC Service Arabia Site HSE Manager shall

implement the foreseen solution.

5.5.4 Coordination

Coordination activities include the involvement of external organization (if needed) in

the corrective actions, in particular the Head Offices SINOPEC Service Saudi Arabia

and Saudi Aramco.

This coordination shall be realized by means of a monthly report, normally include in

the Construction Monthly Progress Report. This report shall include:

Environment activity in the month (meetings, inspections, training and general

comments);

Inventory of wastes shipped from the site (in accordance with General Instruction

140.001 Waste Management).

5.6 Waste Management

This section covers the handling, treatment and disposal of liquid and solid wastes

generated in the course of the construction and pre-commissioning phases of the Project

and specifies the public health requirements, limitations and procedures pertain to collection,

storage, transportation, treatment and disposal of produced wastes.

The program shall comply with SAEHC-S-13 and SAES-S-007.

Everything shall be done to prevent and avoid pollution or contamination of the land, air or

water caused by construction activities.

The provisions of this chapter apply both to the construction sites and the camp area.

5.6.1 General Disposal Consideration

The first preference for the disposal of all solid wastes will be to recycle, by returning

MIP17–HSE–PP–001 REV 3 Page 17 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

the materials to a declaimer for commercial regeneration. In certain circumstances,

such as for wastes, which are not contaminated with hazardous chemicals, or for

some kinds of packaging, the material may be returned to the original vendor. Landfill

disposal wastes will be utilized for solid waste, suitably de-watered solid sludge and

generally for all materials which represent a hazard for the environment.

Disposal of wastes and hazardous materials will be performed by authorized

in-country contractors according with Saudi Aramco Engineering Standards and

Sanitary Code which provide guidelines and minimum requirements for waste disposal.

In particular: Solid Waste management shall be in accordance with SAEHC-S-13

“Solid Waste Management”.

Wastewater treatment plant and disposal of sanitary/industrial wastewater shall

comply with SAES-A-104 “Wastewater Treatment, Reuse and Disposal”, SAEHC-S-14

“Sanitary Wastewater and Sewerage Systems”, SAES-S-010 “Sanitary Sewers”

andSAES-A-007 “Hydrostatic Testing Fluids and Lay-up Procedures”.

5.6.2 Disposal of hazardous waste shall be transport with one of EPD-qualified waste

management contractors.

Saudi Aramco Approved Contractors:

SEPCO INVIRONMENT

National Environment presentation Co (BEE’Ah)

Chemicals and Lubricants Storage

All chemicals and lubricants will be stored properly to avoid free leakage in the soil. In

order to avoid free dispersion, the soil shall be compacted, paved and a wall installed to

contain any spillage and facilitate its collection. This kind of products will be protected

from direct sun.

5.6.3 Waste Water Management

During the construction period an average of 510 manpower will be at site, with a peak

of about 600 manpower (direct & indirect). About one third will be located at offices,

warehouses and workshops, one third at the grass root area and one third at live area.

All the sanitary waste water will be treated properly, STP unit shall be available

in field to treat sanitary wastewater as well as evaporation pond as final

disposal point. Disposal of wastewater used for hydro testing shall conform to

MIP17–HSE–PP–001 REV 3 Page 18 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Saudi Aramco Engineering Procedure 327.In addition, Method of treatment shall

be identified in accordance with SAEP 327.

Treatment of sanitary wastewater shall be in an adequate sewage treatment

plant that should be designed in accordance with SAES-A-104 Wastewater

Treatment, Reuse and Disposal and approved by EPD.

5.6.4 Provision for Landfill Disposal Site

SINOPEC Service Saudi Arabia will use the solid waste disposal landfill site approved

by Saudi Aramco.

The Landfill Disposal site shall only be used for Class II: Biodegradable or

Chemical Decomposable Waste, and Class III: Inert Waste.

Class I: Hazardous Waste shall not be disposed in/on the class II Landfill Disposal Site.

Only Environmental Protection Department approved contractors for Class I hazardous

wastes are acceptable.

All the Class II (Biodegradable or Chemical Decomposable Waste), and Class III (Inert

Waste) will be regularly (on a daily basis) collected and dumped in the Landfill Facility.

5.6.5 Classification of Landfill Disposal Site

If SINOPEC Service Saudi Arabia operates its own, or uses an existing solid waste

disposal site, SSSA shall dispose of waste in an area which will adequately contain it.

The following three landfill types and the material which may be disposed of in each:

• Class I Landfill Disposal Site – isolates solid wastes from surface water or groundwater.

The site shall have a stable foundation and two impermeable liners with leachate

collection and removal systems. Precipitation runoff from surrounding areas shall be

site must be used for the disposal of Class I hazardous wastes and may be used for

the disposal of Class II biodegradable and chemically decomposable wastes and

Class III inert wastes.

• Class II Landfill Disposal Site – shall be above the highest groundwater elevation to

prevent direct contact of the wastes with surface water or groundwater. The landfill site

shall be made for diversion of runoff. A Class II landfill disposal site must be used for

Class II wastes and may be used for Class III wastes.

• Class III Landfill Disposal Site – provides little or no protection from underlying

groundwater. Surface water adjacent to the disposal site may contact the waste

material. A Class III disposal site is for the disposal of Class III inert waste only.

MIP17–HSE–PP–001 REV 3 Page 19 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

5.6.6 Waste classification will be according to the following:

(a) Class I Hazardous Waste – Wastes which constitute a high degree of hazard to the

public health and the environment. These include materials which are flammable,

corrosive, reactive, toxic, radioactive, infectious, carcinogenic, and mutagenic or

teratogenicity.

(b) Class II Biodegradable or Chemically Decomposable Waste – Non-hazardous solid

wastes and sludge which are biologically or chemically decomposable in the natural

environment. Examples include paper, digested sewage, animal wastes, garbage

and other putrescible wastes and wood.

Class III Inert Wastes – Wastes which are not biologically or chemically active in the

natural environment. Examples include glass, most plastics, rubber products, and

construction debris.

5.6.7 Solid Waste Management (Class II and III)

Definition as per Saudi Aramco code: Class II (Biodegradable or Chemical

Decomposable Waste), and Class III (Inert Waste).

All biodegradable (rotting) waste shall be collected in dedicated closed containers

regularly cleaned.

The frequency is estimated as weekly and shall be verified according to the

prescriptions at point 5.7 - : Storage and collection”.

This temporary site storage shall be done in locations sufficiently isolate so not to

create health problems.

All the industrial scrap, both biodegradable and non-biodegradable waste will be

regularly (on a daily basis) collected and dumped in the Waste Handling Facility.

SINOPEC Service Saudi Arabia/ Subcontractors shall comply with operating

procedures for the landfill.

Unloading of solid waste shall be carried out in accordance with the landfill operators

‘instructions.

Provisions shall be made to assure that unauthorized material is not loaded for

disposal at the landfill site. The Waste Manifest (Form 9564) shall accompany all waste

leaving the site.

If advice on problematic wastes is needed, the Saudi Aramco representative, from

Environmental Protection Department should be identified as the authority.

MIP17–HSE–PP–001 REV 3 Page 20 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Incompatible wastes shall not be placed in common cells, tanks or containment areas.

Unloading of waste on the site shall be in accordance with the landfill operator

information.

6.0 HANDLING TRANSPORTATION AND DISPOSAL OF HAZARDOUS MATERIAL (CLASS I)

Hazardous waste examples:

Ignitable wastes, Toxic wastes, Solvent wastes, Acids/bases, Heavy metal wastes, Batteries,

Lubricating oil, Painting containers, Sealants, Additives.

Hazardous waste shall be collected separately, temporary stored and secured so that there will be no

damage to the containers, unforeseen free spillage on ground or improper disposal.

Hazardous waste shall not be disposed on site. SINOPEC Service Saudi Arabia shall engage a

specialized company for removal of hazardous waste from site, and disposal of in accordance with

GI.140.001 and Materials Supply CU-22.03.

Transportation of all hazardous waste from the generator to the final disposal /treatment facility shall be

tracked by Waste Manifest.

All Saudi Aramco hazardous waste must be manifested using forms generated by SAP EHSM Waste

manifest module.

6.1 Medical Waste Management

Clinic waste shall be stored separately in dedicated bags/containers. Their management shall

conform to the “Guide to the Management of Medical Wastes” by the General Directorate of

Health Affairs;

6.1.1 Radioactive sources

Storage and handling of the radioactive sources will be done with extreme care.

The storage location shall be done so to avoid security problems or radiation emissions

nearby.

Only specialized and authorized personnel shall have access to the radioactive sources.

At the end of the construction activities all the radioactive sources will be removed. Refer

to the applicable document GI 150.003 – “Ionizing Radiation”.

6.1.2 Hazardous Wastes from other sources

Only small amounts of Hazardous Material Waste (Class I) shall be produced during the

Construction phase; these include:

Batteries

MIP17–HSE–PP–001 REV 3 Page 21 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Lubricating oil

Painting containers

Sealants

Additives

All these materials shall be duly collected in dedicated containers and disposed at a

container location that previously been approved by Environmental Protection

Department.

All operations connected with changing/ refueling of oil, fuel and chemicals/solvents/

additives shall be done inside areas whose surface is prepared to avoid dispersion and

allow the cleaning of eventual spills.

Unused waste lubricating oil could be sent to recycle through Saudi Aramco

approved transportation vendor to lube oil refineries in KSA.

Hazardous wastes samples for recycling procedure: Batteries, Lubricating oil,

Paints, Chemical solvents.

Non-hazardous waste samples for recycling procedure: Plastics & PVC items,

Wood, papers, Electronic & Electrical wastes, Organic, Metals, Concrete wastes.

6.1.2 Storage and collection

Accumulating hazardous waste on site can pose a threat to human health and the

environment, so hazardous waste can keep only for a short time (90 Days) in

storage yard. Before transporting the waste for disposal or recycling, Sinopec is

responsible for its safe management, which includes safe storage, safe treatment

and preventing accidents.

Storage and collection of waste shall be conducted periodically (to be specified later)

and in a way that prevents:

Vermin breeding at harborage;

Conditions conducive to transmission of disease to man of animals;

Hazards to workers, users and the public;

Air, noise, and water pollution;

Objectionable odors, dust, unsightliness and nuisance conditions;

Corrosion or wear of storage containers and transfer devices and vehicle;

Accidental spillage or leakage during storage or transport.

MIP17–HSE–PP–001 REV 3 Page 22 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

6.2 Waste Trucks and transfer devices

All the vehicles used for the waste transportation shall be suitable and dedicated to the specific

class of waste so to avoid mixture of different type of waste.

In particular the vehicles must guarantee that no dispersion of product shall occur during the

transport.

All vehicles shall be provided with fire prevention equipment (if needed) and phone number to

contact in the event of an emergency.

The containment compartment of storage collection and transfer devices and vehicles shall be

made of durable, impervious materials and shall be designed to provide a watertight tank with

smooth and easily cleanable surfaces. The containment and appurtenances thereto shall be

cleaned at least once a week (more often if necessary) to prevent propagation of odors, insect,

rodents, of other nuisance conditions.

Storage, collection and transfer devices and vehicles shall be loaded and operated so as to

prevent dropping, leaking, and sifting, blowing or other escape of waste from the device or

immediate use.

Collection and transfer devices and vehicles carrying loads that are likely to blow from the

containment compartment shall have a cover which is either an integral part of the material with

fasteners designed to secure all sides of the cover to the device or vehicle. The cover shall be

used while in transit.

The handling of hazardous materials will be performed in accordance with current industry

practices.

The disposing of hazardous materials will comply with Saudi Arab Government Regulations

and Saudi Aramco relevant GIs. SINOPEC Service Saudi Arabia will provide SAUDI ARAMCO

proof that the hazardous wastes have been properly disposed of at a licensed hazardous

waste disposal facility.

SINOPEC SERVICE SAUDI ARABIA will provide SAUDI ARAMCO proof of an established land

treatment/disposable program which is designed to ensure that hazardous materials placed in

or on the treatment/disposal zone are degraded, transformed or immobilized within the treated

zone to prevent migration to ground and or surface wasters. SINOPEC SERVICE SAUDI

ARABIA will submit the program to SAUDI ARAMCO for approval prior to the disposal of any

hazardous material.

6.2.1 Material Safety Data Sheet (MSDS)

MIP17–HSE–PP–001 REV 3 Page 23 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Material Safety Data Sheet (MSDS) will be obtained from the manufacturer of all hazardous

materials. Normally the MSDS will be in English language. Prior to bringing the material to

the site, the Safety Engineer will receive the MSDS. The original will be kept in a

separate file for hazardous materials MSDS.

The Safety Engineer will educate selected worked in the handling the hazardous

material and regarding the personal protective equipment to be worn. The danger of the

material and all the details are in MSDS. All the workers will be kept away from any

chemical applied area for a period recommended by MSDS. The chemicals will be

stored in containers that are safe for transportation and use of the materials. Containers

will be labeled with appropriate hazardous label to indicate the actual contents.

MSDS log will be maintained properly. All chemicals shall be stored as per specific

storage recommendations for hazardous material. Saudi Aramco chemical hazard

bulletins and manufacturer provided MSDS shall be available to all persons. The Safety

Engineer will review hazardous of chemical storage and handling and advise safety

precautionary measures.

6.3 Training

All employees shall be instructed, during toolbox meetings, to avoid mixing of the various type

of waste.

Drivers shall be instructed by their Employer on how to store the waste on the vehicle, on the

risks connected with the hazardous waste, on what to do in case of emergency.

6.4 Air Pollution Mitigation

All vehicles will be properly maintained to minimize excessive exhaust emission. Dust control

shall be accomplished by properly wetting the work area prior to commencing the work

activities. Treated wastewater shall be considered a main source to be utilized for this

application.

Refer to Saudi Aramco SAES-A-102 “Ambient air quality and source emission standard”

6.5 Noise Control

All practicable methods will be used to reduce noise levels; where and when noise cannot be

avoided, it may be reduced or the effects minimized.

All vehicles shall have exhaust mufflers properly working.

6.6 Hazard

All reasonable precautions will be taken to prevent accidental ignition or spontaneous

MIP17–HSE–PP–001 REV 3 Page 24 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

combustion of waste on the waste landfill site.

7.0 CONTRACTOR ADDRESSES FOR ENVIRONMENTAL CONTRACTORS

A list of Environmental Contractors approved by Saudi Aramco EPD and Contracting Dept. is the

following:

AL KALTHOOMI GROUP

P. O. Box - 14058

Dammam 31424

Fax - +966-3-8148869

Tel - +966-13- 8415221

SEPCO INVIRONMENT

P.O. Box - 3394

Jed 21471

Fax - +966-12-2388224

National Environment presentation Co (BEE’Ah)

P .o. box – 10628

Jubail industrial city 31961

Fax- +966-13-3588584

Tel - +966-13-3588008

MIP17–HSE–PP–001 REV 3 Page 25 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

8.0 WASTE LOG – (NON HAZARDOUS WASTE

Area :

Waste Custodian Tel.

No.:

Subcontractor Tel. No.:

Origin of Waste

Qty. of

Name of Waste Waste Date Time Vehicle Disposal

Remarks

Stream Unit Dispatched Dispatched Number Point

(No./Kg)

AQUEOUS WASTE

• Sewage Effluent –

Untreated

• Hydro test Water

• Sewage Sludge

SOLID WASTE

• Domestic Refuse

• Industrial Refuse

GASEOUS WASTE

• Exhaust Stack

• Refrigerant

• Fire Fighting Agent

FUGITIVE GASES

• Any other Waste

MIP17–HSE–PP–001 REV 3 Page 26 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

9.0 WASTE LOG-(HAZARDOUS WASTE)

Area :

Waste Custodian Tel. No.:

Subcontractor Tel. No.:

Origin of Waste

Qty. of

Name of Waste Waste Date Time Vehicle Disposal

Remarks

Stream Unit Dispatched Dispatched Number Point

(No./Kg)

Waste Chemicals

Waste Lubricant

Oily Sand

Tank & Other

Sludge

Batteries

Tires

Oil Drums

Clinical Waste

MIP17–HSE–PP–001 REV 3 Page 27 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

10. HAZARDOUS WASTE CONSIGNMENT NOTE

Waste Details

Location : Name of waste stream :

Quality of waste :

Waste Originator

Name : Reference Indicator :

Date Dispatched : Time Dispatched :

Name of Disposal

Site : Location :

Signature :

Waste Transporter

Name : Company :

Vehicle Number : Date :

Time Start : Time Complete :

Signature :

Waste disposal

Facility

Site Name : Location :

Date Received : Time Received :

Name of Guard : Signature :

MIP17–HSE–PP–001 REV 3 Page 28 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

11. SINOPEC SERVICE SAUDI ARABIA/ SUBCONTRACTORS CAMP SANITATION AND SAFETY

The design and operation of any contractor camp (labor camp) shall be in accordance with the

requirements of GI298.010. Administration of Contractor Camps, which includes specific checklist

completion to be used for periodic self-assessment of site conditions to assure health, hygiene and

welfare conditions.

Prior to the commencement of any contractual activity at any site, SINOPEC Service Saudi Arabia

and Subcontractors shall obtain, through the Company Representative, the required Land Use

Permit (LUP) in accordance with G.I. 2.716, Land Use Permit Procedures; G.I. 2.718, Contractor

Sites Allotment Procedure; and SAUDI ARAMCO Form 8037. The LUP application shall include

drawings of proposed SINOPEC Service Saudi Arabia and Subcontractors camp facilities.

Additionally, a Letter of Undertaking for SINOPEC Service Saudi Arabia site allocation shall be

signed and all stipulated conditions stated therein shall be complied with by SINOPEC Service

Saudi Arabia.

SINOPEC Service Saudi Arabia and Subcontractors shall ensure that any SINOPEC Service

Saudi Arabia and Subcontractors camp facility provided for SSSA personnel and SAUDI ARAMCO

employees meets the provisions of Saudi Arabia's Labor and Workmen Law and SAUDI ARAMCO

Safety, Health and Environmental Requirements. (Also see section I-7, “Site Planning and

Housekeeping,” of the SAUDI ARAMCO Construction Safety Manual, the SAUDI ARAMCO

Sanitary Code, Section II of this Schedule “D”, and G.I. 151.006, Implementing the SAUDI

ARAMCO Sanitary Code). SAUDI ARAMCO reserves the right to inspect all SINOPEC Service

Saudi Arabia and Subcontractors camp facilities, on or off SAUDI ARAMCO property, to ensure

compliance with applicable laws and SAUDI ARAMCO standards.

Prior to occupancy and permanent connection of utilities, SINOPEC Service Saudi Arabia and

Subcontractor’s camp facilities shall be subject to inspection by SAUDI ARAMCO Company

Representative, Loss Prevention Department, Fire Protection Department, Environmental

MIP17–HSE–PP–001 REV 3 Page 29 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Protection Department, and the Medical Services Organization, and shall meet all applicable

safety, fire and health standards. Any additional concerns generated during the inspection shall be

brought to the attention of SINOPEC Service Saudi Arabia and Subcontractors for resolution or

action as needed (see G.I. 2.718, Contractor Sites Allotment Procedure).

SAUDI ARAMCO reserves the right to periodically re-inspect any camp facility to ensure that all

SAUDI ARAMCO safety, health and environmental requirements are being complied with.

SINOPEC Service Saudi Arabia will ensure that the sanitation and safety requirements for project

sites will be in compliance with SAUDI ARAMCO the contract requirement.

1) Adequate potable water and raw water supply.

2) Adequate garbage containers.

3) Daily garbage/refuse collection and disposal.

4) Housekeeping crew and maintenance personnel.

5) Pest control services.

6) Toilets, laundry and bathing facilities.

7) Sufficient lighting.

8) Sufficient fire extinguisher and fire protection.

9) Emergency telephone number posted.

10) First Aid facilities, nurse, and emergency vehicle.

11) Regular inspections

A vector management plan shall be implemented in accordance with the principles of

integrated Pest Management, include targeted species such as mosquitoes, rodents and

other pests. Sinopec Service will make a regular inspection of all sites and camps under

the contractor’s control, with route baiting, not just responding to complaints. The control

of beg bug infestations with worker accommodation is of significant importance.

Good housekeeping practices will be enforced. Sanitation facilities will be kept clean. Garbage will

MIP17–HSE–PP–001 REV 3 Page 30 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

not be allowed to accumulate outside of disposal bins. Medical waste will be disposed in

accordance with health regulation. Sewer will be collected on a daily basis.

11.1 General Conduct Regarding the Protection of the Environment

SINOPEC Service Saudi Arabia will make aware to all workers on site through the company

safety organization the need to respect the environment in the construction area. Educating

the worker to the awareness of the existing environment will be driven by the Safety

Orientation Program and will also be discussed during the weekly safety tool box meetings.

Purpose: The purpose of this plan is to provide an outline of procedures and guidelines to

establish and maintain a safe working environment at the construction site and surrounding

work locations to minimize pollution.

11.1.1 Prior to Mobilization

The following considerations must be established.

a. Severity and nature of pollution risk.

b. Plant safety requirements.

c. Training of personnel.

d. Anticipated volume of pollution hazard.

e. Quantity engine/power driven equipment including vehicles.

f. Waste disposal plan.

11.2 Temporary Site Office Building Facilities.

The facility shall be laid out and constructed such that, the following factors are taken into

account to minimize pollution.

a. Adequate garbage bin.

b. Complete toilet facilities.

c. Adequate water supply for washing and cleaning of toilet facilities.

d. Sufficient wash basin.

MIP17–HSE–PP–001 REV 3 Page 31 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

e. Regular disposal of garbage.

f. Eating facilities for workers at designated area.

12. DUST CONTROL

12.1 An adequate supply of N-95 rated mask will be provided and maintained and where required,

the supervisor will ensure affected site personnel wear them.

12.2 Wetting of open (unpaved) ground as in fabrication yards and site temporary facility will be

done as frequently as necessary to minimize dust.

12.3 Vehicle speed on open (unpaved) areas shall be as slow as possible to minimize dust

production and blowing.

12.4 Doors and windows of portable offices will be kept closed or sealed to minimize dust

accumulation in the indoor areas.

12.5 During sandstorm conditions, sandstorm (goggles) will be provided to and worn by site

employees.

13. IONIZING RADIATION

SINOPEC Service Saudi Arabia will ensure that any radioactive source used is in compliance

with the provisions of SAEP-1141, Industrial Radiation Safety; G.I. 150.003, Ionizing Radiation

Protection; and section IV-2, “Ionizing Radiation,” of the SAUDI ARAMCO Construction Safety

Manual. SINOPEC Service Saudi Arabia will implement safe working procedures for all

operations involving radioactive materials, ensure that all employees using this equipment

have a valid "Saudi Aramco Radiographer Permit" and are aware of the mandatory

precautions to be taken against ionizing radiation hazards. Radiation Safety Procedure(s) shall

be prepared by the SINOPEC Service Saudi Arabia and approved by the SAUDI ARAMCO

MIP17–HSE–PP–001 REV 3 Page 32 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Inspection Department Radiation Safety Officer (RSO) or his assistant.

These procedure(s) shall be consistent with SAUDI ARAMCO procedures and with King Abdul

Aziz City for Science and Technology (KACST) regulations. The Contractor shall have an RSO

who is licensed by KACST. The SINOPEC Service Saudi Arabia will notify the Inspection

Department Radiation Safety Officer and the Company Representative immediately in the

event of an incident involving radioactive materials or ionizing radiation producing equipment.

13.1 Scope

In the event SINOPEC Service Saudi Arabia encounters X-ray welding on site, a vendor

approved by the Saudi Aramco will be appointed. The approved vendor will submit all

details required by Saudi Aramco regarding ionizing radiation.

The below mentioned procedures are SINOPEC Service Saudi Arabia precautions that

will be taken only in the event X-ray welding is encountered through a subcontractors.

Proposed type of machine that may be used is a GAMA Camera ‘TECHOPS – USA’

Proposed Radioactive Isotope: IRIDIUM – 192

Proposed Manufacturer: AMYSCO Company (Local)

Proposed Manufacturer’s storage requirements: ISOTOPE CASE ‘OPL – 660’ 06.E of section 6,

Safety and Health Requirements Manual shall be consulted for authority and details.

13.2 Methods of Protecting Against Radiation

Distance is an effective method of protection because the intensity of Gamma and

x-radiation emitted by point source decreases with the increase of the distance. In other

words, dose rate at close distance can be extremely high, even for a small source.

Therefore, sealed source shall never be handled directly, but only by remote control.

Time is also a useful method of protection because high dose rates can be expected over

short period of time, provided that the cumulative doses remain low. The maximum

permissible doses are determined at time weighted measurements, that is mille rams per

MIP17–HSE–PP–001 REV 3 Page 33 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

hour.

Shielding reduces harmful radiation. Materials of high density such as lead, depleted

uranium or tungsten are used.

Planning procedure for radiography initially shall be formulated by the subcontractor and

submit to SINOPEC Service Saudi Arabia. All procedures shall be thoroughly discussed

by all related persons for familiarization.

All radiation equipment and radioactive materials of the Sub contractors shall be stored,

handled, transported or disposed off so that no person receives an unnecessary dose of

radiation.

Internationally recognized signs and posters shall be used.

13.3 Storage of Radioactive Isotopes (Current Manufacturer’s requirements)

Radioactive isotopes (IRIDIUM – 192) used for welding activities by the subcontractor shall

be stored separately from other materials or equipment. The storage place of radioactive

materials shall be 10 cm or above the ground and locked to prevent accident.

Radioactive isotopes shall be stored in a case made of lead of ample thickness with a lock

as per manufacturer’s recommendations. On the exterior surface of the case, the name of

company, description of material, quantity and danger sign shall be distinctly visible.

Labels and posters must indicate the description and quantity of the radioactivity materials,

name of responsible person and sign OFF LIMIT.

In case of trouble or accident the following provisions shall be applied.

When radioactive isotopes is in an abnormal stage due to mechanical fault in the radiation

apparatus, the position of the radioactive isotopes shall be checked with a meter and lead

plates installed to prevent radiation from dispersing. When radioactivity isotopes are

scattered from a broken capsule, the contaminated area shall be immediately be declared

as a restricted area.

MIP17–HSE–PP–001 REV 3 Page 34 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

13.4 Classification of Personnel

13.4.1 Competent supervisor - Radiography shall be performed under the direction of a

radiography competent supervisor of the subcontractors responsible for the work.

13.4.2 Radiography supervisor of the subcontractors should have extensive knowledge of the

work, such as radiation procedure, operation Apparatus and effect of radiation on the

body.

13.4.3 The area covered within a radius of 5 meter from the radiation working spot or location

and subject to a dose of radiation in any one hour in excess of 50 mille rams shall be

called the radiation area. Passing in

this area shall be strictly prohibited. Warning signs and barricades shall be provided to

prevent trespassing.

13.4.4 During radiation work display posters showing that radiation activity is taking place, no

entry is allowed and the danger sign shall be

displayed. Before starting the radiological work the restricted area shall be checked to

confirm that no unauthorized persons are working in this area.

13.4.5 Where possible radiation activities should be confined to “off hours” e.g. lunch breaks, etc.

Note: Detailed procedures will be submitted after approval of subcontractors for the

above works.

14. SICKNESS MANAGEMENT PLAN

For the sickness, Sinopec Service will treat with First-aid and if the sickness is severe

the patient will be sent to Hospital according to the MEDICAL EVACUATION PLAN.

FIRST-AID FACILITIES

14.1 SINOPEC Service Saudi Arabia will provide and maintain adequate first-aid facilities at the

project site in accordance with the most rigorous requirements of:

14.1.1 The Saudi Arab Labor Law as revised from time to time.

MIP17–HSE–PP–001 REV 3 Page 35 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

14.1.2 SAUDI ARAMCO Construction Safety Manual, Section I-9.2, “First Aid”

14.1.3 SAUDI ARAMCO GI 150.002, First Aid/CPR Training and First Aid Kits – Remote Areas

14.1.4 Minimum Standard Requirements and Recommendations for Contract Industrial Clinics

14.1.5 If SINOPEC Service Saudi Arabia employs 50 or more workmen at a WORK Site

(including all personnel at the WORK Site employed by Saudi Subcontractors and

involved in performance of the WORK):

14.1.6 SINOPEC Service Saudi Arabia will provide and maintain a full-time, dedicated

emergency vehicle (ambulance), properly marked and supplied (including stretcher), to

transport injured personnel to the nearest healthcare facility.

14.1.7 SINOPEC Service Saudi Arabia will provide one or more qualified and Saudi Arab Ministry

of Health-licensed nurse or nurses, each with a current Basic Life Support (BLS) and

First-Aid Certificate in accordance with Articles 134 & 135 of the Saudi Arabian Labor and

Workmen Law. The names, qualifications, and diplomas of the Saudi Arab Ministry of

Health-licensed nurse(s) shall be submitted to the Company Representative before

WORK begins at the WORK Site.

The minimum requirements that the first aid facility will contain and includes:

A desk, hot & cold water, wash basin, examining table, air conditioner, adequate lighting,

splints for bone fractures, bandages and sterile wash water in clinic and dust tight medical

supply cabinet.

First aid supplies will be kept available in a cabinet designed only for those supplies. The

cabinet will be placed under the charge of the qualified nurse, who will ensure the cabinet is

well stocked at all times.

A suitable type of stretcher shall be available on project site at all times.

The ambulance shall be equipped, as minimum with the following supplies:

Stretcher and blankets

MIP17–HSE–PP–001 REV 3 Page 36 of 38

LSTK CONTRACTOR:

COMPANY

Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project:

CONTRACT No# 6600044545

MIP PKG 17 RAS TANURA AREA PIPELINE

BI No. 10-09004-0003

Document title: ENVIRONMENT MANAGEMENT PLAN - 2021

Portable oxygen

Splints for bone fractures

Bandages

Sterile wash water

The following information will be permanently posted in the first aid clinic

The name of the designated qualified nurse who is in-charge of the first aid clinic

Name and location of hospital to which the injured that requires outside medical hospital

treatment is to be sent

MIP17–HSE–PP–001 REV 3 Page 37 of 38

You might also like

- Sinopec Work Permit SystemDocument22 pagesSinopec Work Permit SystemAmeerHamzaWarraichNo ratings yet

- Leak Test Procedure for Anchor SleevesDocument13 pagesLeak Test Procedure for Anchor SleevesAmeerHamzaWarraichNo ratings yet

- MIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)Document14 pagesMIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)AmeerHamzaWarraichNo ratings yet

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- Environment ProtectionDocument7 pagesEnvironment ProtectionPhilip YapNo ratings yet

- MIP17 - HSE - PP - 019 Security and Fencing Plans PKG 17 Rev. 0Document9 pagesMIP17 - HSE - PP - 019 Security and Fencing Plans PKG 17 Rev. 0AmeerHamzaWarraichNo ratings yet

- Surface Preparation SWMSDocument11 pagesSurface Preparation SWMSAmit SinghNo ratings yet

- Accident Report Cable Cutting Feb 03-2022Document2 pagesAccident Report Cable Cutting Feb 03-2022Charles DoriaNo ratings yet

- RA - 18 - For Concrete Topping On Hollow Core SlabDocument14 pagesRA - 18 - For Concrete Topping On Hollow Core SlabIbrahim EsmatNo ratings yet

- Bar Bending MachineDocument1 pageBar Bending Machinesaurav royNo ratings yet

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNo ratings yet

- Method Statement Excavation Civil WorksDocument9 pagesMethod Statement Excavation Civil WorksRanjith GabrielNo ratings yet

- Installation Method for Lift ProjectDocument22 pagesInstallation Method for Lift ProjectFarisNo ratings yet

- Method Statement of Cable Trench & Reinstatement WorksDocument11 pagesMethod Statement of Cable Trench & Reinstatement WorksarbazNo ratings yet

- JSA Pile Concrete Works OkDocument9 pagesJSA Pile Concrete Works OkMon Trang NguyễnNo ratings yet

- Method Statement For Construction Block PavingDocument11 pagesMethod Statement For Construction Block PavingMunaku TafadzwaNo ratings yet

- Logistics PlanDocument28 pagesLogistics PlanZiad HamatiNo ratings yet

- Installation of AMI/AMR CablesDocument9 pagesInstallation of AMI/AMR Cablessalman100% (1)

- Rams CCTV Inspection Survey l5 Qat 273aDocument30 pagesRams CCTV Inspection Survey l5 Qat 273arajaNo ratings yet

- 002-PDS-CON-010 Method Statement For Site Preparation WorksDocument15 pages002-PDS-CON-010 Method Statement For Site Preparation WorksMalik ZamanNo ratings yet

- Uzair CVDocument3 pagesUzair CVJilani ShaikNo ratings yet

- 3.2 Method - Statement - For - Construction - of - Civil - WorksDocument23 pages3.2 Method - Statement - For - Construction - of - Civil - WorksJoseph EgonaNo ratings yet

- Hazard Identification Plan for Tanajib Gas Plant ProjectDocument247 pagesHazard Identification Plan for Tanajib Gas Plant ProjectAbdul WasayNo ratings yet

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Document27 pages20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- RAMS For Modification of Phase 1 Existing Water TankDocument22 pagesRAMS For Modification of Phase 1 Existing Water TankAnandu AshokanNo ratings yet

- Construction Site Safety Program REV-02Document95 pagesConstruction Site Safety Program REV-0201095902062ahmedNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- TR 167-01-061 01 Contractors ES H Program PlanDocument138 pagesTR 167-01-061 01 Contractors ES H Program PlanErnesto SerranoNo ratings yet

- MS AND JSA SG6427-SY-CN0P-MTD-736-005 - Method Statement of Conduit Installation - RevbDocument25 pagesMS AND JSA SG6427-SY-CN0P-MTD-736-005 - Method Statement of Conduit Installation - Revbbrian sanchezNo ratings yet

- Piping Support Fabrication Safe Work Method StatementDocument8 pagesPiping Support Fabrication Safe Work Method StatementHichem BklNo ratings yet

- Excavation Safety ProceduresDocument7 pagesExcavation Safety ProceduresHasanuddin HAMIDNo ratings yet

- Work Method Statement Plumbing: Organisation DetailsDocument12 pagesWork Method Statement Plumbing: Organisation DetailsShrikant BudholiaNo ratings yet

- Method For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Document6 pagesMethod For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Subhash Chekka SEC 115KV ProjectNo ratings yet

- Fence ITP & ChecklistDocument27 pagesFence ITP & Checklistlike saddamNo ratings yet

- m1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningDocument27 pagesm1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningAnandu AshokanNo ratings yet

- HIRA 013 Working Over Water.Document2 pagesHIRA 013 Working Over Water.srinibas mohapatra100% (1)

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Method Statement For Installation of Temporary Plumbing, Drainage System and Electrical SupplyDocument48 pagesMethod Statement For Installation of Temporary Plumbing, Drainage System and Electrical SupplyAnandu AshokanNo ratings yet

- EN-099-PL-1804 - Rev B - HSE Accountability PlanDocument21 pagesEN-099-PL-1804 - Rev B - HSE Accountability PlanSkinhead TvNo ratings yet

- Abrasive Blasting Safety ChecklistDocument2 pagesAbrasive Blasting Safety ChecklistSaravanan JambunathanNo ratings yet

- Method Statement & Risk Assessment Hydrostatic Leak TestDocument7 pagesMethod Statement & Risk Assessment Hydrostatic Leak TestWalid AmdouniNo ratings yet

- Excavation Method Statement for Schools Improvement ProjectDocument19 pagesExcavation Method Statement for Schools Improvement ProjectIrfan AliNo ratings yet

- Dewa Phase Iii 800 MW PV Solar Power ProjectDocument14 pagesDewa Phase Iii 800 MW PV Solar Power ProjectPEMCO InspectionNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument30 pagesJSA For Scaffolding Erection Dismantling and Modification Workkmohamedkeita906No ratings yet

- Cable Trench and Bedding Quality Control and Inspection Report FormDocument1 pageCable Trench and Bedding Quality Control and Inspection Report FormHesham Helal100% (1)

- Method of Statment CONCRETEDocument7 pagesMethod of Statment CONCRETESyed AtherNo ratings yet