Professional Documents

Culture Documents

WQM - CGL48-QA-WQM-010 Draft (1) - Removed

Uploaded by

Vijay Allimuthu AvathipalayamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WQM - CGL48-QA-WQM-010 Draft (1) - Removed

Uploaded by

Vijay Allimuthu AvathipalayamCopyright:

Available Formats

GEC - RECORD OF MEETING

(QA/QC MEETING)

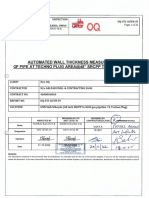

EPC Contract for Central48’’Rich and Lean Gas Pipeline Segregation

Project: Contract No: 4600006060

Project

Company: OQ S.A.O.C Meeting No.: GL48-GEC-QA-WQM-010

Contractor: GEC Date: 22-Aug-22

Subject: Weekly QA/QC Review meeting Previous Meeting Date: 15-Aug-22

Meeting location: MS teams prepared by Abdul Jaleel

Meeting Attendees

OQ GEC Next Meeting Schedule

1. MURALI Vadlapatla - CSR 1. Abdul Jaleel - Manager (QA/QC)

2. Muraleedharan S - QA/QC lead (site base) 2. Vipin MP -Manager (QA/QC) Not attended

3. Praveen - QC Engineer (Pipeline) 3. Istiaq Ahmed - Welding Engineer

4. Shajan K - Sr. Engineer (QA/QC) - Pipeline Not attended

29-August-2022, 10.00 AM

5. Rajeev Thomas-Sr. Engineer (QA/QC) – E&P

6. Dipin - Sr. Engineer (QA/QC) - Piping

Distribution

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

1 Quality Awareness session to be continued for project staff. QAQC Team Ongoing

EPC contractor to check for the Virtual training option for

this stage also and arrange to start conducting from coming

week. First offiline session on the Quality conducted on

Awareness of

1 Quality 29.06.2022.

OQ advised Contractor to conduct awareness session on the Contract Quality Plan to staff deployed at QA/QC

Requirement 2 Ongoing Second sesssion at GNH conducted on 27.07.2022.

Sur / GNH area Manager

Further session will be carried out during the site visit of

QA/QC Manager, if not, by QA/QC Engineer positioned at

site.Galfar ensured assured section to all dicipline staff by

frequently verifying new arrivals to site.

MOM for Weekly Progress/Quality Meeting SHEET 1 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

Project Management team has agreed to submit the DDM

Document & drawing distribution system has partially implemented at Sur. Document distribution system for OQ review on 03.07.2022. Initial draft issued for review.

is yet to be implemented at GNH area. Controlled copies of the documents required for the GNH area are DDM to be revised to include Engineering deliverable and

being issued from Sur / Head Office. the same shall be submitted to OQ for review by

3 Galfar Immediate

MDR has been prepared for the documents. DDM is under preparation to captured the distribution 02.08.2022. Draft version being discussed among site team

philosophy. at SUR. Finalized DDM to be submitted through EDMS. OQ

OQ asked Contractor to mention the planned date of DDM submission. comments ( Verbal) Should be incorporated on DDM and

joined review to be done distribution list.

Document /

2

Drawing Control

Dedicated Document Controller deployed to Sur.

Draft DDM prepared ad submitted for OQ review.

Request for EDMS to Document Controllers deployed at site

OQ advised Galfar to deploy a dedicated document controller to site. OQ enquired on individual is being taken up through the Project Manager. Discussed

reponsibility and the same was clarified by Galfar. OQ pointed out that with IM Lead of OQ for providing access. Password and user

4 (Galfar) Immediate

1. Requirement of DDM for having clarity in the distribution of document. name provided by OQ. Access to be provided by OQ.

2. Accessibility to the EDMS system to view the status of documents. Training to be provided to the Document Controller

deployed to site by the DC available at HO on receipt of

access. Access yet to be received. Galfar to send reminder to

OQ IM lead.

Only two documents remaining in Code B. The same will be

submitted for OQ approval by 11.08.2022. Other pending

OQ advised to resubmit the documents which are in Code B & Code.D (whichever applicable) and get procedures are under preparation and will be submitted to

Immediate

final approval ( Code A). OQ for approval. Following ITPs submitted last week

General Galfar

4 6 1. QCP for On-Plot (Code B)

Documents

OQ advised Contractor to check the status of procedure and ITP for Stoppaq Application submitted by 2. QCP for INstrumentation work (Code B)

the Subcontractor. Also advised the Contractor to ensure that the documents are approved on time. 3. QCP for Road Works

4. QCP for Pipe Bend on 21st August

ITP for painting work and OHL will be submitted by 25th Aug

MOM for Weekly Progress/Quality Meeting SHEET 2 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

OQ also advised Galfar to submit the tentative mobilization for QA/QC resource in the project.

Galfar informed that QA/QC resources will be deployed based on the work progress. Galfar Quality

team will coordinate with Planning function to obtain the tentative schedule for start of activities at

site and will plan the mobilization accordingly. Draft mobilization plan to be provided to OQ.

Currently - QA/QC Manager, QA/QC Superintendent, Sr.

Galfar to plan in advance if the approved personnel are to be mobilized from outside Oman and to QA/QC Engineer (On Plot), Welding Engineers (Manual &

consider the visa process time and readiness etc. Automatic), Sr. Engineer (E&P), QC Inspectors (Pipeline) (2

nos), QC Inspector (Piping) (1 No.), QC Inspectors (Civil) -2

OQ asked Contractor to mobilize QA/QC Superintendent to site on priority basis as Pipeline activities Nos. and QC Inspector (Coating) (3nos) are already

Key personnel are progresssing ( Survey to Pipe stringing) at this stage as Senior Quality personnel is required at site deployed.

5 7 Galfar 19.04.22

mobilization for the dedicated control and coordination. Contractor can arrange accommodation as other

constuction personnel are mobilized and accommodated. Also OQ asked to mention the date of QA/QC Superintendent mobilized to site on 03.07.2022

mobilization. Sr. QA/QC ENgineer (GNH) mobilzed to site on 30.06.2022

Sr. QA/QC Engineer (Sur) mobilized to site on 28.07.2022

OQ asked the plan for the mobilization of QA/QC Manager of EPC contractor at site. GEC QCI instrumentation to be made available at site for FOC Duct

mentioned that their QA/QC Manager will be stationed at HO to coordinate in Enginneering, receiving inspection.

procurement and construction activities ate both GNH and Sur areas.

OQ advised that GEC's QA/QC Manager to do frequent site visit to SUR & GNH locations at

this time and to be stated/deployed at site once major Engineering phase done.

GNH Areas

OQ representative informed the Contractor that the Soil Testing is a Hold Point for Galfar and Galfar QA/QC Manager (Civil) has witnessed the testing that was

approved representative need to witness the testing at Third Party Lab. conducted this week. His CV to be submitted for OQ Approval

on 23.06.2022. Still pending approval.

Contractor informed that the testing will be witnessed by the QA/QC Manager (Civil) based at Head

Office. His CV will be submitted to OQ for review and approval. Mr. Joby has witnessed the testing of the soil sampled

Soil Testing &

6 8 Galfar 15.06.22 borrow pit 11.

MAS Approval

Contractor also informed that the information captured in the Quality Control Plan is having

ambiguities and Contractor will be revising the QCP to provide more clarity for the sampling and soil OQ raised concern over the delay in MAS approval of sand

testing. dune utilized at Sur (Hot tapping Pits padding). Galfar

informed that MAS is submitted to OQ for approval by

OQ stated that, at this stage Contractor has to follow the approved documents requirements. 04.08.2022. Approved by OQ in Code A with minor comments

MOM for Weekly Progress/Quality Meeting SHEET 3 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

OQ stated to `Galfar to compile the complete RCA report for the higher rate FDT failures at GNH areas

filling. The RCA report to prepared in project format and submit with document numbering.

Final RCA report submitted to OQ by 28.06.2022 (CGL48-

GEC-006060-0000-QA-RPT-0003-00 dt 28.06.2022)

Galfar shared a compiled data in excel sheet for OQ review.

Contractot has agreed to review and revise the RCA.

OQ shared the comments and the points to be considered in RCA and advised EPC contractor to

Contractor will also review the possibiliy of revising the

compile the final report and close at the earliest. OQ advised Contractor to finalize the RCA and submit

High FDT Failure document numbering philosphy

7 10 it to OQ by 23.06.2022. Galfar 12.06.22

rate

RCA is being revised and final version of the RCA will be

OQ informed that the RCA has been reviewed and commented. Galfar need to revise and submit the

submitted for OQ by 15.08.2022.

RCA for final approval.

RCA approval received in Code A (18.08.2022)

OQ suggested hence forth RCA should be submitted at site

OQ also advised Contractor to provide the document as "RCA" rather that "RPT". Also mention the

level and document number should inclued RCA.

details of FDT failures in the RCA documents (like introduction, Location, activity performed, total

samples taken & failed % in tabular form etc..)

Najad Al Ahliya (Approved by OQ) Mix Designs formal

approval received through EDMS in Code A with minor

OQ informed that the Concrete Mix Design submitted for C35/45 by Contractor has been rejected as

comments. Re-submission will be done on 23rdAugust

the Supplier is not identified in the Company AVL. OQ advised Contractor to raise Deviation Request

8 Concrete 11 Galfar 12.06.22 C45 Trial Mix completed on 01.08.2022 and Lab testing in

with Supplier profile,PTR and other details of the concrete sourced by the Contractor from the

progress. Test results of 7 days and 14 days compressive

proposed Supplier for other Contracts executed.

strength meeting the requirement.Document type should be

RCA

MOM for Weekly Progress/Quality Meeting SHEET 4 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

Contractor has deployed Mr. Vijayakumar to Sur and Mr.

Gopukrishnan to GNH area to witness the activity

OQ advised Contractor to deploy approved Quality Personnel to site witness the coating removal and MMEs being arranged for close out of the Observation.

AUT activity being carried out at Sur and GNH areas immediately.

Chemical analysis for all analysis Hot Tap locations at GNH and Sur- Metal shaving will be carried out by AUT Report has been submitted to OQ for review and

the NDT Subcontractor. Location identification shall be available in the report. approval.

OQ advised EPC contractor to prepare and verify all the dimensions in Hot tap locations. Ovality, straightness and roundness check carried out at

Coating Removal

both Sur and GNH and report submitted to OQ. Results

9 Activity at Sur 12 Galfar 09.06.22

OQ mentioned as per the project requirements, Pipe straightness and roundness to be checked at the fowarded to Vendor; confirmation/accepatance

and GNH

Hot tap locations and the details to be shared to MEC as well as Hot Tap vendor for their review and awaited.

confirmation.

Carbon equivalent analysis report received from NDE

OQ again mentioned the Hot tap/Tie-ins locations pipe straightness and roundness is very important Subcontractor (related to advance tie-in)

for the revoiew and conformation/acceptability from related parties ( MEC/Vendors) and to ensure the

propoer installation of Split Tee and Smart Plug for complete sealing. CE analysis, report submitted by Subcontractor commented

and returned to Subcontractor. Revised report received,

without stamp and signature from the Lab. Returned to sub-

contractor

MOM for Weekly Progress/Quality Meeting SHEET 5 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

Galfar has reviewed the requirements and have

communicated the gaps to the PIMS Vendor.

Based on the Vendor response Galfar is coordinating the

review of formats with OQ site representative

OQ advised Contractor to ensure that format shared by the Vendor for PIMS covers complete

information for the Pipeline activity and details as required by various formats identified by the

Vendor is currently revising the finalized format to remove

Contractor are captured.

the duplication of the data captured in the format. The

same will be submitted for OQ review prior to finalizarion.

OQ advised to prepare a complete list `Forms and share to OQ also.

Civil formats finalized. OQ comments to be incorporated.

10 PIMS 14 Galfar 12.06.22

OQ raised concern over the current practice of updating

OQ reviewed and given the comments (by hand) to Contractor of forms shared by Contractor and to

progress in the PIMS. OQ advised Galfar to implement the

finalize at the earliest.

PIMS immediately in the project and also conduct the

related training for the OQ & GEC and team involved in the

OQ raised concern as PIMS not yet fully implemented at site as construction activities progressing ansd

implementation. Meeting ongoing

no any reports are generating and updating through PIMS.

Training on PIMS scheduled at site on 17.08.2022 and same

is recorded in the MOM.

OQ reminded that all quality records remaining for approval

from OQ and PIMS shall be taken up immediately.

Dossier Index to be finalized. OQ suggested to have a

consolidated Quality Dossier Index for both Off Plot and On

11 Quality Dossiers 15 Construction Quality Dossier Index to be prepared and submitted for OQ review and approval Galfar 26.06.22

plot works. Galfar has agreed to prepare and submit the

same. Dossier Index to be ready for site review by 24.08.2022

MOM for Weekly Progress/Quality Meeting SHEET 6 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

Discussed with MEC. Galfar has advised the Surveyor to

OQ informed that a mismatch is being noted in the Chainage identified in the AFC drawing issued and

determine the Chainage from Auto CAD drawing and mark

the chainage derived through GPS System. OQ advised Galfar to coordinate with MEC to obtain

the same at site. Revised drawing awaited from MEC. Mail

12 Chainage 16 solution for the issue noticed at site. Galfar 19.06.2022

communication sent to MEC. Contractor assured follow up

OQ advised Contractor to mark the AFC drawing the actual location (minor) of the Wadi's as Red Line

with MEC for resolution. Galfar to send another follow up

Markup. Major changes in the chainage in the chainage to be regularized through Site Technical Query.

OQ informed that the width of the trench obtained with trench operator is just adequate for the pipe Issue to be reviewed in coordination with Construction

to be lowered. This may have following adverse effect during the lowering operation: team.

- Pipes may hit against the trench wall during lowering - Can cause damage to coating

13 Trench Width 17 - Difficult to maintain the required gap between the pipe and trench wall. Galfar 22.06.2022 OQ advised Contractor to carryout a mock up lowering prior

to finalizing the process. Mock up carried out for the single

EPC contractor to ensure the required trench dimensions and smooth lowering of pipes ,pipeline pipe. OQ advised to keep this point open till completion of

section (s) without any damages to pipes as well as coatings. one section lowering successfully.

Galfar propose to carryout the IN log review on a fortnightly

basis.

Contractor to coordinate with Construction Manager for

carrying out the joint review.

OQ informed that many of the Inspection Notifications in the project are being approved with

14 IN Log 18 Galfar Immediate

comments. OQ advised Galfar to review these comments and close out the IN on a periodic basis.

Second seesion conducted at both Sur and GNH area.

Based on the comments in the RFI, site QA/QC Engineer and

team need to arrange fortnightly review, if required.

MOM for Weekly Progress/Quality Meeting SHEET 7 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

Contractor informed that the Lab will be established along

with the office facility at Sur and GNH. Contractor informed

that the Soil compaction and Concrete cube test will be

carried out inhouse. All other Civil lab testing are planned to

be conducted ISO 17025 certified external labs. OQ advised

to communicate till when they require the approval of the

OMC Lab for cocnrete testing. Same has been

OQ enquired on Contractor plan for carrying out the Concrete cube testing and Soil compaction test at communicated to OQ as below,

16 Civil Laboratory 20 Galfar

Sur and GNH area.

Project specific Site Lab at SUR: by September 2022 end.

Project specific Site Lab at GNH: by October 2022 end.

Temperorary approval given for Galfar OMC Lab.

Mr. Kashif, Lab Technician will be mobilzied to Sur with

available lab equipments. Remaining equipments are sourced

from other sites.

Noted. OQ advised Galfar to check whether

OQ mentioned EPC contractor to ensure the Pre-Requisites and follow as usual practise prior to

Reference/Calibration block sketch, technique sheet,

mobilize for the activities at site. Eg. Mobilized AUT crew without any basic preparations like

dimensional certificate, MTC, NDE contractor conformity

documents, calibration block, temperature scanner etc.. and delayed more than 3 days. EPC contractor

letter/certificate for the applicable SP 1195 (V3) compliance

AUT (Hot Tap/Tie- to take these lessons learnt and to ensure Pre-Requisites for activities in advance.

19 23 Galfar immediate on Reference/Calibration block etc. are submitted in the

ins Locations

AUT Report submitted to OQ. Reports available, however all

EPC contractor to compile the documents (Reference/Calibration block sketch, technique sheet,

of these are not attached along with submitted AUT Report

dimensional certificate, MTC, NDE cpontractor confority letter/certificate for the applicable SP 1195

received in Code B. While resubmitting all of the documents /

(V3) compliance on Reference/Calibration block etc.) to OQ for approval and to regularise.

reports will be submitted.

Contractor Quality representative will henceforth

OQ highlighted that the Construction team & Quality team are not aligned. Noticed communication participiate in the Daily Progress Meeting conducted at site

20 Communication 24 Galfar Immediate

gap at many instances, Quality team was found not aware on the start of the activity. and hence the gaps will be sorted out. Galfar ensured

compliance and monitord closely.

MOM for Weekly Progress/Quality Meeting SHEET 8 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

Contractor informed that the personnel will be provided

Activity-wise Training by Quality team prior to start of any

new activity.

OQ raised concern that personnel are being deployed

OQ highlighted the some crew deployed at site are not experienced with regard to the specific activity

25 Galfar Immediate without adeuqate training on the activity. Galfar confirmed

(Stringing etc..) and also not provided the training on the same prior to deployment.

that they have aligned with PM team and all personnel

deployed to site will be provided with Site Induction and

will also provided activity based training prior to

deployment / start of the activity.

MOM for Weekly Progress/Quality Meeting SHEET 9 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

Noted. Galfar pointed out that the DEP 31.40.30.30 is

specifically for Concrete Coating. If Contractor decides to

carry out concreting after lowering of pipes and same is

agreed by the Company, then the following will be carried

out:

1. Deviation for carrying out insitu concrete after lowering

OQ mentioned the following documents to be regularied regarding the Wadi Crossings Concrete of pipe section.

coating ( In-situ) proposal from EPC contractor. 2. Updation of Typical drawing related to wadi crossing and

their approval from OQ.

Wadi Crossing - 1). Deviation Request for applicable Specifications to be followed.As per Contract SP 1208 & DEP OQ CSR response /comments received in submitetd Method

21 26 Galfar Immediate

CWC 31.40.30.30 Gen, 2017 to be followed,but in submitted proposal & MST as per SP 1275, SP-1279 etc.. statement in this regard will be complied with

2). Engineering /OQ approvals on updated Typical drawings and related sketches/drawings proposals Deviation submitted for Plant Approval and Slump variation

of Wadi Crossings. as it is going to pumping. MAS for Mix Design submitted to

OQ. On approval of DVR and Mix Design, RFI for trial mix

will be raised. DVR for Plant approval obtained.GEC collected

the closed observaions from the plant (which were issued

during the last OQ audit on them). On approval of the DVR

pertaining to slump and MAS for Mix Design, new QC Plan

need to be prepared for the activity and submitted.

Contractor has confirmed that all resources except the

OQ asked EPC contractor to check and confirm the complete/sufficient resources (Equipment,

consumables for automatic welding repair are available.

27 Accessories, Spares, Instruments,Filler metals, consumables, manpower etc.) availability for starting Galfar Immediate

Consumables for repair of automatic welding has arrived at

Production Welding at site.

Nizwa Fab Shop

Automatic

22 Welding

(Production)

Galfar confirmed that the compressed air from paywelder will

OQ mentioned that, EPC contractor to ensure/update the arragements/methology for the effective be utilized for cleaning.

28 cleaning of entire bevelling metal chips/pieces & other debris from inside Line pipes ( after bevelling Galfar Immediate QC Inspector (Welding) will also ensure cleanliness prior to

and prior to fit up for welding) at site. fitup clearance. Point to be closed after demonstrating the

cleaning of pipes at site

MOM for Weekly Progress/Quality Meeting SHEET 10 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

Sl. Action required

Section Item Narrative

No Responsible Action Date Action

OQ highligthed that the Tie-In locations numbers identified in the drawings have changed. Initially the Galfar has written a mail to MEC on this regard for further

23 Hot Tap 29 Tie numbers were 16A & 16B and the Hot tap locations identified as 17A & 17B in Tie-in schedule Galfar Immediate clarifications and close. Clarification received, can be

document. OQ advised Contractor to obtain clarification the same removed

Galfar site team to check and inform the details of the

OQ informed to GEC that to update all the applicable drawings/documents to IFC category and make drawings required to be issued. Galfar has compiled the list

24 Drawings at site 30 Galfar Immediate

sure the controlled copies availability at site for references. of drawings, which require AFC status, and mailed for MEC to

verify and confirm.

OQ advised Contractor to avoid IN cancellations as after IN raising, then at site related arrangements (

25 IN Cancellation 31 Galfar Info Noted: being monitored and advised site team accordingly

water etc.) are not available at site for execution of the works.

Have advised the Materials team and also Project

Management on the cocnerns raised by OQ. Storekeeper

identified for Sur area.

Materials have started reaching site. OQ advised Contractor to deploy the storekeeper, Material

The concerns have been highlighted in the Project Review

Material receipt Controller site immediately and the Material receiving inspections to be regularised. It was also advised

26 32 Galfar Info meeting conducted on 14.08.2022

at site to establish the required material storage facility and share the RFT check list for the received

OQ advised Contractor to maintain separate RFI log for

materials for ensuring preservation as per manufacturer recommendation

material receiving Inspection.

And also advised to develop a pre-requisite check sheet for

establishing consumable storage at site

The concerns have been highlighted in the Project Review

OQ raised the concern (improper storage & preservation) noticed at SUR camp location stored the

meeting conducted on 14.08.2022. OQ also highlighted that

27 FOC Duct 33 HDPE Duct for FOC in open areas. GEC to take prompt actions and check/verify with Vendor Galfar Immediate

there are few FOC duct at Nizwa and advised Galfar to check

recommendations immediately and required corrections to be done.

and update OQ on the storage condition at Nizwa.

Internal Observation has been identified in the log. Action

OQ mentioned that, GEC has already issued their internal Onservation and the same not captured in

28 NCR/OBS Log 34 Galfar Immediate taken on observation and the same is closed out. Evidence

their NCR/OBS Log ans well as not in Weekly Quality Report.

shown to OQ. Can be removed

MOM for Weekly Progress/Quality Meeting SHEET 11 OF 12 Doc. No. CGL48-GEC-QA-WQM-009

You might also like

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- MRM - Jan-2015Document8 pagesMRM - Jan-2015RajVardhanNo ratings yet

- Itp Electrical CheweeDocument2 pagesItp Electrical CheweeRonnel Dean LimNo ratings yet

- Materials and Metallurgy Unit 1 IntroductionDocument31 pagesMaterials and Metallurgy Unit 1 IntroductionMuthu KumaranNo ratings yet

- Quality Requirements For Subcontractor: Project ProcedureDocument15 pagesQuality Requirements For Subcontractor: Project ProcedureDindo QuintanNo ratings yet

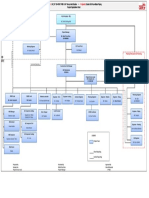

- QAQC Organization ChartDocument1 pageQAQC Organization Chartteto100% (1)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Checklist For Electrical Safety InspectionDocument1 pageChecklist For Electrical Safety InspectionSatya Naidu100% (2)

- VECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0Document10 pagesVECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0hymerchmidtNo ratings yet

- NRO QUALITY GUIDELINES - To CONTRACTOR & CONSULTANTSDocument49 pagesNRO QUALITY GUIDELINES - To CONTRACTOR & CONSULTANTSZulaika Laini100% (2)

- Quality Management Review Agenda and MinutesDocument4 pagesQuality Management Review Agenda and MinutesKannan MurugesanNo ratings yet

- Flow Process Chart For Stage InspectionDocument1 pageFlow Process Chart For Stage InspectionEngr Saeed AnwarNo ratings yet

- TWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodDocument11 pagesTWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodBangkit SamosirNo ratings yet

- QA-QC Bi-Weekly Report DT 1 Janto.15JanDocument11 pagesQA-QC Bi-Weekly Report DT 1 Janto.15JanTwin BullsNo ratings yet

- Audit Plan - ISO 9001 - ISO 14001 - 2015Document8 pagesAudit Plan - ISO 9001 - ISO 14001 - 2015Corrosion Factory100% (2)

- Audit Plan 审核计划: To be completed by theDocument3 pagesAudit Plan 审核计划: To be completed by thegeorge liuNo ratings yet

- Minutes of Meeting: Bekapai-3 Surface Facilities Modification and Dogleg Installation (Epcic)Document13 pagesMinutes of Meeting: Bekapai-3 Surface Facilities Modification and Dogleg Installation (Epcic)Arung IdNo ratings yet

- Tie in Procedure Rev. BDocument8 pagesTie in Procedure Rev. BgenjiNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Radiographic Examination Procedure B-QAC-PRO-210-39158Document24 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Radiographic Examination Procedure B-QAC-PRO-210-39158ZaidiNo ratings yet

- 66kv Monopole SpecificationsDocument3 pages66kv Monopole SpecificationsSIVA NAGA SUDHEER SIDDANI100% (2)

- Quality ManualDocument29 pagesQuality Manualgs_humboldtNo ratings yet

- Inspection and Test Plan For TRAFFIC SIGNSDIRECTIONAL SIGNS-RajDocument4 pagesInspection and Test Plan For TRAFFIC SIGNSDIRECTIONAL SIGNS-RajRajNo ratings yet

- 306-1 - Internal Quality AuditsDocument17 pages306-1 - Internal Quality AuditsYusufNo ratings yet

- Inspection Test & Plan: Pondasi Bangunan NOMOR: I-QAC-027/100.19Document21 pagesInspection Test & Plan: Pondasi Bangunan NOMOR: I-QAC-027/100.19pahrizan100% (2)

- Quality Procedure Doc No KQP 04 Rev.19 Date 30 Sept 2016 UNCONTROLLEDDocument104 pagesQuality Procedure Doc No KQP 04 Rev.19 Date 30 Sept 2016 UNCONTROLLEDudin cupuNo ratings yet

- A Guide To Energy Efficiency ComplianceDocument16 pagesA Guide To Energy Efficiency ComplianceOARIASCONo ratings yet

- Quick Reference Card - DTTL Audit Quality MilestonesDocument2 pagesQuick Reference Card - DTTL Audit Quality Milestonestorte1No ratings yet

- 00 Saip 13Document10 pages00 Saip 13Muhammad azeem AshrafNo ratings yet

- Final QAP of RBL AME RVNL PROJECTDocument84 pagesFinal QAP of RBL AME RVNL PROJECTPrasanta Parida100% (1)

- Critical Analysis RICS APCDocument17 pagesCritical Analysis RICS APCakg2004191% (11)

- Muthukkumaran Anbalazhan - CVDocument4 pagesMuthukkumaran Anbalazhan - CVSaqib AliNo ratings yet

- Procedure For Flushing and Hydrotesting (On-Plot)Document11 pagesProcedure For Flushing and Hydrotesting (On-Plot)Vijay Allimuthu Avathipalayam100% (3)

- Seaa2112 l2 CementDocument70 pagesSeaa2112 l2 Cementrawk hahihu100% (1)

- VT Procedure-Rev. 01Document9 pagesVT Procedure-Rev. 01Mohamed AttiaNo ratings yet

- Method Statement For Chamber Construction of TSE Line Ev ManagerDocument20 pagesMethod Statement For Chamber Construction of TSE Line Ev ManagerBleep News100% (1)

- Inspection and Test Personnel Qualification ProcedureDocument9 pagesInspection and Test Personnel Qualification ProcedureDindo QuintanNo ratings yet

- Agenda: Workgroup For Guideline On Development of Maintenance Procedure Manual For Building FacilitiesDocument2 pagesAgenda: Workgroup For Guideline On Development of Maintenance Procedure Manual For Building FacilitiesSon PhanNo ratings yet

- QAS Risk Oppotunity Register 2022Document5 pagesQAS Risk Oppotunity Register 2022Nathanniel Pogado GonzalesNo ratings yet

- Kaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Document7 pagesKaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Jonas PadillaNo ratings yet

- Panama Renewable Energy PVT LTD: Standard Operating ProcedureDocument3 pagesPanama Renewable Energy PVT LTD: Standard Operating ProcedureAradhya SinghNo ratings yet

- Vendor Approval For GFRC Rev.1Document16 pagesVendor Approval For GFRC Rev.1Ravi Shankar KolluruNo ratings yet

- AMC ReportDocument14 pagesAMC ReportAnimesh Narayan SinghNo ratings yet

- Dashboard - Aug 2021 For CoEACaP Division - FinalDocument11 pagesDashboard - Aug 2021 For CoEACaP Division - FinalTandin PenjorNo ratings yet

- 30-99-90-1615 Rev 1 Internal and External Audits ProcedureDocument10 pages30-99-90-1615 Rev 1 Internal and External Audits ProcedureEswar ReddyNo ratings yet

- P6012MAB.000.10.01.390 VO1 (QMP For Post Contract Review (MAB) )Document9 pagesP6012MAB.000.10.01.390 VO1 (QMP For Post Contract Review (MAB) )Vasilica BArbarasaNo ratings yet

- Action PlanDocument5 pagesAction PlansharanNo ratings yet

- Report Weekly Engine Project #2 (PMMO) 190612Document10 pagesReport Weekly Engine Project #2 (PMMO) 190612Kadir SamtaNo ratings yet

- Dashboard - January 2021 For CoEACaP DivisionDocument11 pagesDashboard - January 2021 For CoEACaP DivisionTandin PenjorNo ratings yet

- Manyane Elizabeth Mofokeng: Q.C Inspector - Welding & FabricationDocument3 pagesManyane Elizabeth Mofokeng: Q.C Inspector - Welding & Fabricationelizabeth MofokengNo ratings yet

- Orienetal Audit - QMSDocument10 pagesOrienetal Audit - QMSysraoNo ratings yet

- Production Part ApprovalDocument3 pagesProduction Part Approvalvidya410gmailcomNo ratings yet

- 2007 MR Facilities 10-16-2007Document6 pages2007 MR Facilities 10-16-2007api-26042912No ratings yet

- Qaqc MSM NCR FL3B CVL FR 01 PDFDocument1 pageQaqc MSM NCR FL3B CVL FR 01 PDFhafizd zullahNo ratings yet

- PBU PPVC MAS Flowchart New Application RenewalDocument1 pagePBU PPVC MAS Flowchart New Application RenewalNicky LimNo ratings yet

- PO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureDocument11 pagesPO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureKarthikNo ratings yet

- Sac Myp Qa Pro 0006 - 1Document6 pagesSac Myp Qa Pro 0006 - 1ziaNo ratings yet

- Quality Assurance - Quality Control: Afd/Gok Roads 2000 Central Phases 2 ProjectDocument23 pagesQuality Assurance - Quality Control: Afd/Gok Roads 2000 Central Phases 2 ProjectWambugu MaInaNo ratings yet

- AFR - Land Disposition With Survey ClaimantDocument2 pagesAFR - Land Disposition With Survey ClaimantGarry RocmaNo ratings yet

- Acl Qmip 01Document2 pagesAcl Qmip 01Mo ZeroNo ratings yet

- Quality Training ProcedureDocument9 pagesQuality Training ProcedureDindo QuintanNo ratings yet

- J910-DT03-P0ZEN-040005 SQCP-0104 (Risk Control) - Rev.1Document8 pagesJ910-DT03-P0ZEN-040005 SQCP-0104 (Risk Control) - Rev.1valent aviolandaNo ratings yet

- EEMC-PQP-PF-01-QAQC InductionDocument1 pageEEMC-PQP-PF-01-QAQC InductionAzeem SheikhNo ratings yet

- The Committee Quality Assurance Policy E&M Services: OF FOR FORDocument37 pagesThe Committee Quality Assurance Policy E&M Services: OF FOR FORAssistant Engineer VJCESD-2No ratings yet

- Dashboard - Nov 2021 For CoEACaP Division - Final v1.1Document11 pagesDashboard - Nov 2021 For CoEACaP Division - Final v1.1Tandin PenjorNo ratings yet

- Method Statement Procedure: Revision LogDocument20 pagesMethod Statement Procedure: Revision LogJoyce GordonioNo ratings yet

- SA-MAGE-PQP - Internal AuditsDocument21 pagesSA-MAGE-PQP - Internal Auditssajidazmi.amuNo ratings yet

- New Doc 2021-08-05 - 1Document1 pageNew Doc 2021-08-05 - 1Vijay Allimuthu AvathipalayamNo ratings yet

- NCR-08 ClosedDocument4 pagesNCR-08 ClosedVijay Allimuthu AvathipalayamNo ratings yet

- Code A Approved ITP BST-GEN-QAC-PLN-GEC-19037-10010-00 U-01 R1Document4 pagesCode A Approved ITP BST-GEN-QAC-PLN-GEC-19037-10010-00 U-01 R1Vijay Allimuthu AvathipalayamNo ratings yet

- Fab and Initial Test RecordsDocument11 pagesFab and Initial Test RecordsVijay Allimuthu AvathipalayamNo ratings yet

- Organization ChartDocument1 pageOrganization ChartVijay Allimuthu AvathipalayamNo ratings yet

- F65 Yoke Daily Calibration FormDocument1 pageF65 Yoke Daily Calibration FormVijay Allimuthu AvathipalayamNo ratings yet

- Site Audit Plan 2021Document1 pageSite Audit Plan 2021Vijay Allimuthu AvathipalayamNo ratings yet

- Hydrotest Header - Spread BDocument1 pageHydrotest Header - Spread BVijay Allimuthu AvathipalayamNo ratings yet

- BookingReceipt TPVWTGDocument3 pagesBookingReceipt TPVWTGVijay Allimuthu AvathipalayamNo ratings yet

- Abrasive Description and MSDS - Garnet - AustralianDocument6 pagesAbrasive Description and MSDS - Garnet - AustralianVijay Allimuthu AvathipalayamNo ratings yet

- Attachment 1 - USTS PO 6090414Document2 pagesAttachment 1 - USTS PO 6090414Vijay Allimuthu AvathipalayamNo ratings yet

- SNGP To Sgss Sketch FinalDocument1 pageSNGP To Sgss Sketch FinalVijay Allimuthu AvathipalayamNo ratings yet

- Painting & Coatinfg SpecDocument61 pagesPainting & Coatinfg SpecVijay Allimuthu AvathipalayamNo ratings yet

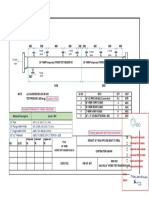

- KM264W17Document5 pagesKM264W17Vijay Allimuthu AvathipalayamNo ratings yet

- KM 286 W 30Document5 pagesKM 286 W 30Vijay Allimuthu AvathipalayamNo ratings yet

- Page 1 of 0Document1 pagePage 1 of 0Vijay Allimuthu AvathipalayamNo ratings yet

- Linearity Check AccutrackDocument1 pageLinearity Check AccutrackVijay Allimuthu AvathipalayamNo ratings yet

- DOC008 RemovedDocument1 pageDOC008 RemovedVijay Allimuthu AvathipalayamNo ratings yet

- KM 288 W 07 RDocument5 pagesKM 288 W 07 RVijay Allimuthu AvathipalayamNo ratings yet

- DOC008Document3 pagesDOC008Vijay Allimuthu AvathipalayamNo ratings yet

- 7a Techno PlugDocument27 pages7a Techno PlugVijay Allimuthu AvathipalayamNo ratings yet

- RLGP Val 001 RunDocument3 pagesRLGP Val 001 RunVijay Allimuthu AvathipalayamNo ratings yet

- Ilovepdf MergedDocument47 pagesIlovepdf MergedVijay Allimuthu AvathipalayamNo ratings yet

- W65RDocument5 pagesW65RVijay Allimuthu AvathipalayamNo ratings yet

- W19RDocument5 pagesW19RVijay Allimuthu AvathipalayamNo ratings yet

- Geosynthetics - Geocells - Specification: Indian StandardDocument20 pagesGeosynthetics - Geocells - Specification: Indian StandardAshish Walia100% (1)

- DBATU BTech Civil Syllabus 2017Document66 pagesDBATU BTech Civil Syllabus 2017Abhishek DhangarNo ratings yet

- Column Design Using Balance Loading C1 (Foundation To 2nd FLR LVL)Document8 pagesColumn Design Using Balance Loading C1 (Foundation To 2nd FLR LVL)Farly VergelNo ratings yet

- Construction Proxy PDFDocument2 pagesConstruction Proxy PDFAbinet MarsNo ratings yet

- Dr. C. Curnis Bronzetti Amberg Hydro2017 - AbstractDocument1 pageDr. C. Curnis Bronzetti Amberg Hydro2017 - AbstractClemente CurnisNo ratings yet

- Bearers and Floor JoistsDocument2 pagesBearers and Floor JoistsTuroyNo ratings yet

- Pipe & Conduit SystemsDocument24 pagesPipe & Conduit SystemsTrần Hồng NgọcNo ratings yet

- CPE Versus PVC Tech Bulletin 013Document1 pageCPE Versus PVC Tech Bulletin 013DhavalNo ratings yet

- Typical Section (X-X) : MP1 MP2 MP3 MP4 Mp8 Future MP3 Mp7 Future Mp6 Future Mp5 FutureDocument1 pageTypical Section (X-X) : MP1 MP2 MP3 MP4 Mp8 Future MP3 Mp7 Future Mp6 Future Mp5 FuturesartajNo ratings yet

- 18.solid HollowDocument19 pages18.solid HollowEmanuel MarquesNo ratings yet

- Flat Socket Head Cap ScrewsDocument8 pagesFlat Socket Head Cap Screwsvietross100% (1)

- I MC S M F: Timber Advantages and Disadvantages of Wood Bending Stress in BeamsDocument4 pagesI MC S M F: Timber Advantages and Disadvantages of Wood Bending Stress in Beamssenior highNo ratings yet

- PHB 2018 GBDocument196 pagesPHB 2018 GBDareyoss NegussieNo ratings yet

- 乳膠英文目錄Document8 pages乳膠英文目錄Kʜʌn SʜaʜzʌʌdNo ratings yet

- Variable Displacements Axial Piston Pumps: Edition: 07/03.2022 Replaces: MVP 06 T ADocument72 pagesVariable Displacements Axial Piston Pumps: Edition: 07/03.2022 Replaces: MVP 06 T ARidha AbbassiNo ratings yet

- Brochure Masterlife - SraDocument6 pagesBrochure Masterlife - SraДанило ГадайчукNo ratings yet

- Plumbing Fixture Flow Rate Tables (Non Residential)Document1 pagePlumbing Fixture Flow Rate Tables (Non Residential)DNo ratings yet

- 73127-Irelands-Stow-Park-Bungay-FINAL 2Document16 pages73127-Irelands-Stow-Park-Bungay-FINAL 2Jonathan HuntNo ratings yet

- Bolting - Selection Guide For Bolting MaterialDocument5 pagesBolting - Selection Guide For Bolting MaterialLatif RadwanNo ratings yet

- Quality-Assurance Guidelines: Tech TodayDocument1 pageQuality-Assurance Guidelines: Tech TodayjesoneliteNo ratings yet

- Contractor: M/S Haji Khan Rahim & Sons (PVT) LTD Concrete Compressive Strength (T-22)Document4 pagesContractor: M/S Haji Khan Rahim & Sons (PVT) LTD Concrete Compressive Strength (T-22)Muhammad AwaisNo ratings yet

- Data Sample HondaDocument183 pagesData Sample HondaBilal Khan BangashNo ratings yet

- Spe 77-162 - Valves and AccessoriesDocument9 pagesSpe 77-162 - Valves and Accessorieshisaj4uNo ratings yet

- APMC Punchlist AS Alabang Esperanza 3rd Floor - EE and AUX RoomDocument1 pageAPMC Punchlist AS Alabang Esperanza 3rd Floor - EE and AUX RoomKris TolentinoNo ratings yet