Professional Documents

Culture Documents

6.0 DN Steel Deck-4 Design Calonzo Roof

Uploaded by

Farly VergelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6.0 DN Steel Deck-4 Design Calonzo Roof

Uploaded by

Farly VergelCopyright:

Available Formats

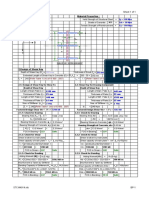

DNSTEEL DECK 4 DESIGN

PROJECT : CALONZO RESIDENCE TO : TYPE OF BEAM : 2

LOCATION : SAN JUAN REF. # : FDVERGEL 1. CONCRETE BEA

SLAB DESIGNATION : ROOF DATE : 2. STEEL BEAM O.K.

INPUT DATA : INPUT BEAM WIDTH = 150

length = total length of panel = 3300 mm RESULTS : ( mm )

nspan = number of continuous (permanent) spans = 1 span

nprop = number of intermediate temporary propping

ITEM FACTOR REMARKS

per span during concrete pouring = 1

span = slab permanent clear span = 3150 mm CONCRETE STRESS 0.23 SAFE

LL = specified uniform live load = 1.90 kN/m2 STEEL DECK STRESS 0.23 SAFE

f = factor for vibration = 1 STEEL BARS STRESS 0.25 SAFE

DL = super imposed dead load = 2.4 kN/m2 DEFLECTION DUE TO LL 0.21 SAFE

t = steeldeck thickness = 1 mm DEFLECTION DUE TO LL + DL 0.45 SAFE

Fysd = steeldeck yield stress = 550 Mpa

slab = slab thickness = 100 mm REINFORCEMENTS:

topping = concrete topping thickness = 0 mm

f'c = concrete compressive strength = 27.5 MPa REQ'D.

Fy = steel bar yield strength = 275 MPa ITEM DIA. SPACING SPACING

bot bar = bottom bar diameter = mm mm mm mm

Nbot = number of bottom bars per

one steel deck panel = bars NEGATIVE BARS 10 165 165

c = distance of bottom steel bar = 25 mm TEMPERATURE BARS 10 509 500

top bar = top bar diameter at near support = 10 mm

uw = unit weight of concrete = 23.56 kN/m3 SLAB TYPE : CONTINUOUS SLAB

coef = moment coefficient at support = 0.1

dww = diameter of distribution steel = 10 mm

CHECK DECKING DURING CONCRETE POURING : INTERACTION OF SHEAR & BENDING

1SPAN 2SPAN 3SPAN

ITEM LOAD CASE FACTOR REMARKS

FACTOR REMARKS FACTOR REMARKS FACTOR REMARKS

1. SHEAR 0.14 SAFE 0.13 SAFE 0.13 SAFE 1 SPAN 0.02 SAFE

2. WEB CRIPPLING 0.51 SAFE 0.48 SAFE 0.46 SAFE 2 SPAN 0.03 SAFE

3. BENDING 0.12 SAFE 0.16 SAFE 0.16 SAFE 3 SPAN 0.03 SAFE

4. DEFLECTION 0.20 SAFE 0.06 SAFE 0.07 SAFE

ACTUAL DEFLECTION 1.75 0.49 0.63

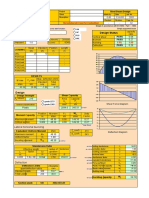

DNSTEEL DECK 4 DESIGN

PROJECT : CALONZO RESIDENCE TO:

LOCATION : SAN JUAN REF #.: FDVERGEL

SLAB DESIGNATION : ROOF DATE: December 30, 1899

CONTINUOUS SLAB Given loadings Steel beam

Assumed loadings Concrete beam

INPUT DATA :

lenght = total length of panel = 3300 mm

nspan = number of continuous (permanent) spans = 1 span

nprop = number of intermediate temporary propping

per span during concrete pouring = 1 span

span = slab permanent clear span = 3150 mm

Live Load:

LL = specified uniform load = 1.90 kN/m2

wll = uniform live load per meter strip of slab = 1.90 kN/m

f = factor for vibration = 1

Dead Load:

DL = super imposed dead load = 2.4 kN/m2

Trial Section :

t = steeldeck thickness = 1 mm

Fysd = steeldeck yield stress = 550 MPa

slab = slab thickness = 100 mm

topping = concrete topping thickness = 0 mm

f'c = concrete compressive strength = 27.5 MPa

Fy = steel bar yield strenght = 275 MPa

bot bar = bottom bar diameter = 0 mm

Nbot = number of bottom bars per

one steel deck panel = 0 bars

c= distance of bottom steel bar = 25 mm

top bar = top bar diameter at near support = 10 mm

d' = distance of top bar from the

bottom of slab( slab-20-btop/2) = 75 mm

uw = unit weight of concrete = 23.56 kN/m3

pi = pi constant = 3.14

coef = moment coefficient at support = 0.1

dww = diameter of distribution steel = 10 mm

Trial Section Calculated Data :

Asd = steel deck cross section area

per meter = 1276 mm2

Abb = bottom bar area per meter = 0 mm2

Aconc = concrete cross section

area per meter = 77225 mm2

Es = steel elastic modulus = 200000 MPa

Ec = concrete elastic modulus = 24647 MPa

n = modular ratio = 8

Isd = moment of inertia of steel deck per meter = 647797 mm4

page

1

Sn = section modulus at the top per meter = 23259 mm3

Sp = section modulus at the bottom per meter = 29247 mm3

Wsd = weight of steel deck per meter = 0.10 kN/m

Wconc= weight of concrete per meter = 1.82 kN/m

Ws.i.dl = total superimposed dead load per meter = 2.40 kN/m

Wcl = construction load per meter = 1.47 kN/m

W1= 1.6Wconc+1.2Wsd+1.4Wcl = 5.09 kN/m

Wp = 1.6Wll +1.2Wdl = 8.22 kN/m

spanprop = span of temporary support = 1575 mm

fip1 = initial stress at steel deck

using +M = 0.125 wl2 = 71 MPa

fip2 = initial stress at steel deck

using +M = 0.080 wl2

= 46 Mpa

fip = recommended initial stress = 46 Mpa

Check the Stress at Midspan :

ONE METER STRIP CRACKED SLAB SECTION FOR

POSITIVE BENDING

Ax = b/(2n) = 62

Bx = Asd + Abb = 1276

Cx = Asd (t-ycp)+Abb(t-c) = 99372

ac = (-Bx+(Bx2+AxCx)^.5/(2Ax) = 31 mm

Ic = cracked moment of inertia per meter = 4673300 mm4

Sc = cracked section modulus per meter = 67842 mm3

ONE METER STRIP UNCRACKED SLAB SECTION

FOR POSITIVE BENDING

Ax = (b-b2)/2n = 29

Bx = Asd + Abb +b2*h/n = 7857

Cx = Asd (h-ycp)+Abb(h-c)+b2*h2/(2n) = 428410

auc = (-Bx+(Bx2+4AxCx)^.5/(2Ax) = 47 mm

Iuc = cracked moment of inertia per meter = 8743755 mm4

Suc = cracked section modulus per meter = 394770 mm3

Iave = average of cracked & uncracked moment of

inertia = 6708528 mm4

Mp = actual moment at near support = 8.16 kN.m

Mp = actual moment at midspan = 6.53 kN.m

CONCRETE STRESS :

fc = actual stress at concrete(transformed) = 5.35 MPa

Mp*ac/(nIc)

Fc = .85f'c = 23.38 MPa

SAFE

ROOF page

2

3

STEEL DECK STRESS:

fsd = actual steel deck stress = 96.2 MPa

Mp(h-ac)/Ic

Fsd = remaining allowable steel deck stress = 421.79 MPa

( .85fy - fip )

SAFE

STEEL BARS STRESS :

fs = actual steel bar stress = 61.28 MPa

Mp(h-a-c)/Ic

Fs = allowable steel bar stress = 247.5 Mpa

0.9Fy

SAFE

CHECK DEFLECTION :

def ll = deflection due to live load = 1.81 mm

allodef ll = allowable deflection due to live load = 8.75 mm

SAFE

def tot = deflection due to live load plus dead load = 5.93 mm

allodeftot = allowable deflection due to live load = 13.13 mm

plus dead load

SAFE

DESIGN OF NEGATIVE REINFORCING :

As = total area of req'd. negative reinforcement = 474.83 mm2

Ax = 0.011764706

Bx = -75

Cx = 32959.7463

N = number of negative of bars per meter = 6 bars

Sneg = spacing of negative bars = 165 mm

Aww = minimum area for distribution = 154 mm2

Nww = number of distribution bar per meter = 2.0 bars

Sww = spacing of distribution bar = 509 mm

Recommended by:

Note : This design is subject for final

evaluation by the structural engineer

of the project.

ROOF

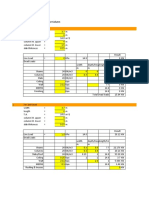

PROJECT : CALONZO RESIDENCE TO :

LOC ATION : SAN JUAN REF # : FDVERGEL

SLAB DESIGNATION : ROOF DATE: December 30, 1899

DESIGN CRITERIA :

f'c = concrete compressive strength = 27.5 MPa

Fy = steel bar yield strenght = 275 MPa

t = steeldeck thickness = 1 mm

Fysd = steeldeck yield stress = 550 MPa 3150 mm

span = total length of panel = 3150 mm 788 mm 788 mm

nprop = number of intermediate temporary

proping per span during concrete SHEAR STUDS 10mm dia. NEG. BARS @

pouring = 1 span BY OTHERS 165mm cut @ L/4

LOADING : 100 mm

LL = specified uniform load = 1.9 kN/m2 10mm dia. TEMP. BARS @

Dl = superimposed deadload = 2.40 kN/m2 500mm o. c. b. w.

Wsd = weight of steel deck per meter = 0.10 kN/m2 no bottom bars needed

Wconc = weight of concrete per meter = 1.82 kN/m2

Use 1 mm DNSD-4 (550 Mpa)

PROPERTIES :

Asd = steel deck cross section area = 1276 mm2

per meter

Es = steel elastic modulus = 200,000 MPa

Ec = concrete elastic modulus = 24647 MPa 8.22 KN/m

n = modular ratio = 8

Isd = moment of inertia of steel deck per meter = 647,797 mm4

Sn = section modulus at the top per meter = 23,259.38 mm3 12.9485 kN

Sp = section modulus at the bottom per meter = 29,247.23 mm3

Ic = cracked moment of inertia per meter = 4,673,300 mm4 V-D

Sc = cracked section modulus per meter = 67,842.27 mm3

Iave = average of cracked & uncracked -12.948 kN

moment of inertia = 6,708,527.79 mm4

Mp = actual moment at near support = 8.16 kN.m 6.53 KN-m

ITEM Actual Allowable Remarks M-D

1. Concrete Stress 5.35 23.38 passed

2. Steel Deck stress 96.19 421.79 passed 8.16 kN.m 8.16 kN.m

3. Steel Bar Stress 61.28 247.50 passed

4. Deflection Due To

Live Load 1.81 8.75 passed CONTINUOUS SLAB

5. Deflection Due To

Live Load + Dead Load 5.93 13.13 passed

Prepared by: Checked and Approved by:

METAL SYSTEMS, INC.

Trunck line: 9512289-91 FDVERGEL

Direct line: 455-9174 Design is subject for evaluation and approval

Fax No: 9311459 of the structural engineer concerned.

PROJECT : CALONZO RESIDENCE TO :

LOC ATION : SAN JUAN REF # : FDVERGEL

SLAB DESIGNATION : ROOF DATE : December 30, 1899

DESIGN CRITERIA :

f'c = concrete compressive strength = 27.5 MPa

Fy = steel bar yield strength = 275 MPa

t = steeldeck thickness = 1 mm 3150 mm

Fysd = steeldeck yield stress = 550 MPa 788 mm 788 mm

span = total length of panel = 3150 mm

nprop = number of intermediate temporary 10mm dia. NEG. BARS @

proping per span during concrete . 165mm cut @ L/4

pouring = 1 span

100 mm

LOADING :

10mm dia. TEMP. BARS @

LL = specified uniform load = 1.9 kN/m2 500mm o. c. b. w.

Dl = superimposed deadload = 2.40 kN/m2 no bottom bars needed

Wsd = weight of steel deck per meter = 0.10 kN/m2

Wconc = weight of concrete per meter = 1.82 kN/m2 Use 1 mm DNSD-4 (550 Mpa)

PROPERTIES :

Asd = steel deck cross section area = 1276 mm2

per meter

Es = steel elastic modulus = 200,000 MPa

Ec = concrete elastic modulus = 24647 MPa

n = modular ratio = 8

Isd = moment of inertia of steel deck per meter = 647,797 mm4 8.22 KN/m

Sn = section modulus at the top per meter = 23,259.38 mm3 3300 mm

Sp = section modulus at the bottom per meter = 29,247.23 mm3

Ic = cracked moment of inertia per meter = 4,673,300 mm4 12.9485 kN

Sc = cracked = 67,842.27 mm3

Iave = average of cracked & uncracked V-D

moment of inertia = 6,708,527.79 mm4

Mp = actual moment at near support = 8.16 kN.m -12.95 kN

ITEM Actual Allowable Remarks 6.53 KN-m

1. Concrete Stress 5.35 23.38 passed

2. Steel Deck stress 96.19 421.79 passed M-D

3. Steel Bar Stress 61.28 247.50 passed

4. Deflection Due To

Live Load 1.81 8.75 passed 8.16 kN.m 8.16 kN.m

5. Deflection Due To

Live Load + Dead Load 5.93 13.13 passed CONTINUOUS SLAB

Prepared by: Checked and Approved by:

METAL SYSTEMS, INC.

Trunck line: 9512289-91 FDVERGEL

Direct line: 455-9174 Design is subject for evaluation and approval

Fax No: 9311459 by the structural engineer concerned.

UNSHORED SPAN CALCULATION ( DNSD 4 )

PROJECT : CALONZO RESIDENCE TO:

LOCATION : SAN JUAN REF #.: FDVERGEL

SLAB DESIGNATION : RO ROOF DATE: December 30, 1899

SPECS OF DECKING :

Thickness = 1 mm

Fy = 550 MPa

E = 200000 MPa

I = 647797 mm4

Sp = 29247 mm3

Sn = 23259 mm3

wt. = 0.098 KPa

Rb = 16.995 kN/m

oV = 33.76 kN/m

LOADING :

Uniform concrete load , w1 = 1.82 KPa

Uniform construction load , w2 = 0.96 KPa

Concentrated man or equipment load , P = 2.193 KPa

Clear span , L = 1575 mm

1SPAN:

ucl = 2.729 KPa

CASE1: w = 1.6ucl + 1.4w2 +1.2wdeck = 5.829 KPa

R = 0.5wL = 4.59 KN SAFE

Mp = wL /8

2

= 1.807 KN.m

def. = 0.013(ucl + wdeck)L4/(EI) = 1.75 mm SAFE

CASE2: w = 1.4w2 = 1.344 KPa

P = 3.0702 KN

Mp = 0.25PL + wL2/8 = 1.626 KN.m

Mpmax = 1.807 SAFE

INTERACTION = 0.018

2SPAN:

CASE1: w = 1.6w1 + 1.4w2 +1.2wdeck = 4.373 KPa

R1=R3 = 0.375wL = 2.583 KN SAFE

R2 = 1.25wL = 8.609 KN SAFE

V = 0.625wL = 4.305 KN SAFE

Mp = 0.070 wL2 = 0.759 KN.m

Mn = 0.125 wL2 = 1.356 KN.m

def = 0.0054(w1 + wdeck)L4/(EI) = 0.492 mm SAFE

CASE2: w = 1.6w1 + 1.2wdeck = 6.186 KPa

P = 3.070 KN

Mp = 0.203PL + 0.096wL2 = 2.455 KN.m

Mn = 0.094PL + 0.063wL2 = 1.421 KN.m

Mpmax = 2.45 KN.m SAFE

Mnmax = 1.42 KN.m SAFE

INTERACTION = 0.030

3SPAN:

CASE1: w = 1.6w1 + 1.4w2 +1.2wdeck = 4.373 KPa

R1=R4 = 0.40wL = 2.755 KN SAFE

R2 = 1.10wL = 7.576 KN SAFE

V = 0.60wL = 4.133 KN SAFE

Mp = 0.08 wL2 = 0.868 KN.m

Mn = 0.10 wL 2

= 1.085 KN.m

def = 0.0069(w1 + wdeck)L4/(EI) = 0.628 mm SAFE

CASE2: R2 = 1.20wL = 8.265 KN SAFE

V = 0.60wL = 4.250 KN SAFE

Mp = 0.074 wL2 = 0.803 KN.m

Mn = 0.117 wL 2

= 1.269 KN.m

CASE3: w = 1.6w1 + 1.2wdeck = 6.186 KPa

Mp = 0.20PL + 0.094wL 2

= 2.410 KN.m

Mpmax = 2.410 KN.m SAFE

Mnmax = 1.269 KN.m SAFE

INTERACTION = 0.027

ALLOWABLE CAPACITY:

MOMENT: Mn = 0.95FySn = 12.15 KN.m

Mp = 0.95FySp = 15.28 KN.m

DEFLECTION def = L/180 = 8.750 mm <=18.75 mm)

INTR WEB CRIPPLING Ri = f .Rb = 17.84 kN

SHEAR oV = 33.76 kN

RECOMMENDED BY:

Checked and Approved by : Architecks Metal Systems, Inc.

Design is subject for evaluation & approval

of the Structural Engineer concerned

You might also like

- Top Slab of Sludge Collection Tank SilcharDocument3 pagesTop Slab of Sludge Collection Tank SilcharAditya KumarNo ratings yet

- Fix Base As Per Is Code - Seismic DetailingDocument1 pageFix Base As Per Is Code - Seismic DetailingrohitnrgNo ratings yet

- Input Unite Fcu Kg/cm2 D CM - A CM B CM Pul KG Col CaseDocument3 pagesInput Unite Fcu Kg/cm2 D CM - A CM B CM Pul KG Col CaseEng Abdulahi HajiNo ratings yet

- TSR NIRMAN Bow String Girder Launching Design Note-06.05.2022Document2 pagesTSR NIRMAN Bow String Girder Launching Design Note-06.05.2022sups madiNo ratings yet

- Truss Bridge Steel Members Design As Per IRS Code Steel Truss Bridge Design ExampleDocument96 pagesTruss Bridge Steel Members Design As Per IRS Code Steel Truss Bridge Design ExampleStructural SpreadsheetsNo ratings yet

- Free POT/PTFE BearingDocument25 pagesFree POT/PTFE BearingZakee MohamedNo ratings yet

- Code of Practice For Concrete Road Bridges IRC:112: Case Study 1 - Design of I GirderDocument15 pagesCode of Practice For Concrete Road Bridges IRC:112: Case Study 1 - Design of I GirderSony JsdNo ratings yet

- Comments Log: Rev. For MRVC/ IIT Comments) Designer Reply RemarkDocument6 pagesComments Log: Rev. For MRVC/ IIT Comments) Designer Reply RemarkAJAY SHINDENo ratings yet

- Bolted ConnectionsDocument1 pageBolted ConnectionsManju BirjeNo ratings yet

- 1.design ConditionDocument22 pages1.design Conditionakshay magarNo ratings yet

- ANNEXURE - A - BEARING LOAD DATA SHEET 30m BRIDGEDocument1 pageANNEXURE - A - BEARING LOAD DATA SHEET 30m BRIDGEShivendra KumarNo ratings yet

- Parapet (Containment Level L2) (SDMHR Table 32)Document7 pagesParapet (Containment Level L2) (SDMHR Table 32)Kwan Shing ChanNo ratings yet

- Abutment Program VarshneyDocument7 pagesAbutment Program VarshneyRaju Ranjan SinghNo ratings yet

- ULS ChecksDocument3 pagesULS ChecksVenkata MayurNo ratings yet

- ACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Document5 pagesACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Vietanh PhungNo ratings yet

- Bow String Girder Steel Members Design As Per IRC Code Bow-String Girder - DesignDocument967 pagesBow String Girder Steel Members Design As Per IRC Code Bow-String Girder - DesignStructural SpreadsheetsNo ratings yet

- Basic Data: Scour DepthDocument6 pagesBasic Data: Scour Depthvishal guptaNo ratings yet

- Cross Section Properties (All Dimensions Are in CMS)Document2 pagesCross Section Properties (All Dimensions Are in CMS)Hanamantrao KhasnisNo ratings yet

- Differences Between Indian and Chinese Codes and PractisesDocument4 pagesDifferences Between Indian and Chinese Codes and PractisesMuralidhar SivarajuNo ratings yet

- S.M. Consultants: An Iso 9001 Company Bhubaneswar / Balasore / Secunderabad / South Andaman Web: E-MailDocument1 pageS.M. Consultants: An Iso 9001 Company Bhubaneswar / Balasore / Secunderabad / South Andaman Web: E-MailShivendra KumarNo ratings yet

- Pier Sheet Hollow r0Document1 pagePier Sheet Hollow r0Varun VermaNo ratings yet

- Elastomeric Bearings: 6 (1) Design Load On BearingsDocument8 pagesElastomeric Bearings: 6 (1) Design Load On BearingsCivil MexNo ratings yet

- Design of Balanced Cantilever BridgeDocument37 pagesDesign of Balanced Cantilever BridgeArafat RahmanNo ratings yet

- Beam DesignDocument9 pagesBeam Designمحمد شاويNo ratings yet

- Jim CK Load - Calc 052611Document19 pagesJim CK Load - Calc 052611GSVNo ratings yet

- P-M Interaction CalculationDocument3 pagesP-M Interaction CalculationSyed Kaleem GilaniNo ratings yet

- Arch - BracingDocument3 pagesArch - BracingvibishnanNo ratings yet

- Aditya Joshi CVDocument23 pagesAditya Joshi CVAditya JoshiNo ratings yet

- X Y and Partners: Steel Beam DesignDocument35 pagesX Y and Partners: Steel Beam DesignAndré SantosNo ratings yet

- (2/3H of Backfill) : Resultant Location Within BaseDocument1 page(2/3H of Backfill) : Resultant Location Within Basemark ignacioNo ratings yet

- 60m Span DesignDocument131 pages60m Span DesignPhanindra NathNo ratings yet

- MNB AbutmentDocument145 pagesMNB AbutmentSUSHEEL KUMAR KANAUJIYANo ratings yet

- Box GirderDocument13 pagesBox GirderAlfiady fachry AkbarNo ratings yet

- Influencelines Lineas de InfluenciaDocument6 pagesInfluencelines Lineas de InfluenciaMarlon MartinezNo ratings yet

- Com ColumnDocument2 pagesCom ColumnHarjasa AdhiNo ratings yet

- Post-Tensioning Format For Pc-Girder General InformationDocument1 pagePost-Tensioning Format For Pc-Girder General InformationTirthajit RoyNo ratings yet

- Well SBCDocument5 pagesWell SBCVenkat PalliNo ratings yet

- LRFD Distribution Factors: TxdotDocument1 pageLRFD Distribution Factors: TxdotShaileshRastogiNo ratings yet

- Punch Typ C4Document10 pagesPunch Typ C4Suhail AhamedNo ratings yet

- Base Plate BiaxilDocument19 pagesBase Plate BiaxilGunjan KolarkarNo ratings yet

- Trial ExcelDocument15 pagesTrial ExcelCyndrille John BragatNo ratings yet

- SDCDSCDocument9 pagesSDCDSCAnish NeupaneNo ratings yet

- Corbel Design With Angle LimitDocument2 pagesCorbel Design With Angle LimitFrederick TanNo ratings yet

- LiquidRet IndianDocument13 pagesLiquidRet Indianchandra BandaraNo ratings yet

- Composite Beam-Stilt FloorDocument9 pagesComposite Beam-Stilt FloorjatinNo ratings yet

- Loads For Supporting Beams: LX Ly UDL On SlabDocument6 pagesLoads For Supporting Beams: LX Ly UDL On SlabAnonymous sfkedkymNo ratings yet

- Foundation Beam DesignDocument4 pagesFoundation Beam DesignPartha GangopadhyayNo ratings yet

- Stress Check With ValuesDocument83 pagesStress Check With ValuesruchitaNo ratings yet

- The World Bank: Uttarakhand Disaster Recovery ProjectDocument14 pagesThe World Bank: Uttarakhand Disaster Recovery Projectvicky rawatNo ratings yet

- Welded Gusset BaseDocument21 pagesWelded Gusset BaseFAHD ABDUL RAHMANNo ratings yet

- Mean Flange Thickness T Overall Depth DDocument3 pagesMean Flange Thickness T Overall Depth DAkhil BabuNo ratings yet

- Seismic ArrestorDocument8 pagesSeismic ArrestorankitNo ratings yet

- STUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and ThrustDocument9 pagesSTUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and Thrustraja mistryNo ratings yet

- Controlling Forces Wind FactorDocument3 pagesControlling Forces Wind FactorRajib MaharjanNo ratings yet

- 14 M Steel Bridge - Floor Plate Capacity CheckDocument2 pages14 M Steel Bridge - Floor Plate Capacity CheckvibishnanNo ratings yet

- Pile Design SpreadsheetDocument180 pagesPile Design SpreadsheetsubamanivelNo ratings yet

- Journal of The IRC Oct-Dec14Document18 pagesJournal of The IRC Oct-Dec14Sony JsdNo ratings yet

- 3 Slab Design CalculationsDocument4 pages3 Slab Design CalculationsNapoleon Carino100% (1)

- Element Location: Subject: Made by Design Code: Loading On Slab Value Units JamesDocument5 pagesElement Location: Subject: Made by Design Code: Loading On Slab Value Units JamesJames AswaNo ratings yet

- Two Way SlabDocument130 pagesTwo Way SlabMayank Rawat100% (1)

- 9.0 Retaining Wall McdoLDocument81 pages9.0 Retaining Wall McdoLFarly VergelNo ratings yet

- Reinforced Concrete Beam Design (LRFD)Document1 pageReinforced Concrete Beam Design (LRFD)Farly VergelNo ratings yet

- 1 Computation of Loading For ColumnDocument2 pages1 Computation of Loading For ColumnFarly VergelNo ratings yet

- Construction Methodology Site DemolitionDocument1 pageConstruction Methodology Site DemolitionFarly VergelNo ratings yet

- 5.0. Beam Design-Steel PlateDocument19 pages5.0. Beam Design-Steel PlateFarly VergelNo ratings yet

- Column Design Using Balance Loading C1 (Foundation To 2nd FLR LVL)Document8 pagesColumn Design Using Balance Loading C1 (Foundation To 2nd FLR LVL)Farly VergelNo ratings yet

- Reinforced Concrete Beam Design (LRFD)Document1 pageReinforced Concrete Beam Design (LRFD)Farly VergelNo ratings yet

- 3.0. Wind Analysis-DDocument2 pages3.0. Wind Analysis-DFarly VergelNo ratings yet

- Reinforced Concrete Beam Design (LRFD)Document1 pageReinforced Concrete Beam Design (LRFD)Farly VergelNo ratings yet

- Design Consideration & Load Criteria References & CodesDocument2 pagesDesign Consideration & Load Criteria References & CodesFarly VergelNo ratings yet

- 6.0 S-Portal Method Lateral LoadingDocument1 page6.0 S-Portal Method Lateral LoadingFarly VergelNo ratings yet

- 4.0 W-Portal Method Lateral Loading DDocument1 page4.0 W-Portal Method Lateral Loading DFarly VergelNo ratings yet

- Design Consideration: Seismic AnalysisDocument3 pagesDesign Consideration: Seismic AnalysisFarly VergelNo ratings yet

- Design of Purlins: The Greenway Market Days Maharlika Highway, Cauayan City Proper, Isabela Provice, CagayanDocument23 pagesDesign of Purlins: The Greenway Market Days Maharlika Highway, Cauayan City Proper, Isabela Provice, CagayanFarly VergelNo ratings yet

- Design of RafterDocument4 pagesDesign of RafterFarly VergelNo ratings yet

- Scan Apr 15, 2020Document4 pagesScan Apr 15, 2020Farly VergelNo ratings yet

- Hilti HIT-RE 500 V3 Mortar With Rebar (As Post-Installed Connection)Document17 pagesHilti HIT-RE 500 V3 Mortar With Rebar (As Post-Installed Connection)Farly VergelNo ratings yet

- Design of Base Plate Column 1Document2 pagesDesign of Base Plate Column 1Farly VergelNo ratings yet

- One Way SlabDocument4 pagesOne Way SlabFarly VergelNo ratings yet

- 8.0. Column Design-JP r1Document6 pages8.0. Column Design-JP r1Farly VergelNo ratings yet

- 9.0. Footing-UPDATED 21,2012xlsDocument12 pages9.0. Footing-UPDATED 21,2012xlsFarly VergelNo ratings yet

- Timber Column Design: Mark Diameter 200mmDocument4 pagesTimber Column Design: Mark Diameter 200mmFarly VergelNo ratings yet

- Project Execution Management (Pem) System: Business PlanDocument10 pagesProject Execution Management (Pem) System: Business PlanFarly VergelNo ratings yet

- 8.0. Column Design DDocument31 pages8.0. Column Design DFarly VergelNo ratings yet

- CertificationDocument1 pageCertificationFarly VergelNo ratings yet

- Adobo Pusit Sa GataDocument1 pageAdobo Pusit Sa GataFarly VergelNo ratings yet

- Application FormDocument99 pagesApplication FormFarly Vergel100% (1)

- 2.1. Design ParametersDocument2 pages2.1. Design ParametersFarly VergelNo ratings yet

- ASEP Application FormDocument4 pagesASEP Application FormJoseph Cloyd LamberteNo ratings yet

- Lateral Buckling of Above-Ground Piping CheckDocument4 pagesLateral Buckling of Above-Ground Piping CheckAnjani PrabhakarNo ratings yet

- A Study of The Weld Heat-Affected Zone Toughness of 9% Nickel SteelDocument7 pagesA Study of The Weld Heat-Affected Zone Toughness of 9% Nickel Steelmp87_ing100% (1)

- Settlement CalculationDocument3 pagesSettlement Calculationjibeesh cm100% (2)

- Question & Answer Set-7Document12 pagesQuestion & Answer Set-7eeng.ali651550% (2)

- Sample Questions - STRENGTHDocument4 pagesSample Questions - STRENGTHEvan Carniyan0% (1)

- hw2 (NEW)Document3 pageshw2 (NEW)Willie ChangNo ratings yet

- Dupont Vespel Scp-5000: Polyimide Isostatic ShapesDocument2 pagesDupont Vespel Scp-5000: Polyimide Isostatic ShapesGeoff LewisNo ratings yet

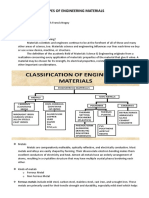

- Types of Engineering MaterialsDocument3 pagesTypes of Engineering MaterialsMark Francis Pangilinan Nogoy100% (3)

- Alumina-Mullite Ceramics For Structural Applications: Eugene MedvedovskiDocument7 pagesAlumina-Mullite Ceramics For Structural Applications: Eugene MedvedovskiPrasad KrishnamoorthiNo ratings yet

- Ce 6501 Sructural Analysis - I Question Bank - Kesavan Edition 2015Document24 pagesCe 6501 Sructural Analysis - I Question Bank - Kesavan Edition 2015senthurrNo ratings yet

- HardnessDocument2 pagesHardnessv_s_sethilkumarNo ratings yet

- Similarity Solutions For Boundary Layer Flows On A Moving Surface in Non-Newtonian Power-Law FluidsDocument10 pagesSimilarity Solutions For Boundary Layer Flows On A Moving Surface in Non-Newtonian Power-Law FluidsSalam AlbaradieNo ratings yet

- User's Manual: Study of Dielectric ConstantDocument10 pagesUser's Manual: Study of Dielectric ConstantJagjiwanNo ratings yet

- Aggregated Diamond Nanorods, or Adnrs (Also Called A Hyperdiamond), Are A Nanocrystalline Form of DiamondDocument6 pagesAggregated Diamond Nanorods, or Adnrs (Also Called A Hyperdiamond), Are A Nanocrystalline Form of DiamondguleriaaNo ratings yet

- Minfm42894 Jis g4314 Grade Sus304Document4 pagesMinfm42894 Jis g4314 Grade Sus304m natarajanNo ratings yet

- Sp6 - 6 Stral Hand BookDocument220 pagesSp6 - 6 Stral Hand BookproxywarNo ratings yet

- Boardwork - Closed SystemDocument12 pagesBoardwork - Closed SystemJannineNo ratings yet

- Cert-Vb172 - (1-2199) FF-1002-1Document23 pagesCert-Vb172 - (1-2199) FF-1002-1TarasNo ratings yet

- PSCDocument59 pagesPSCYaswanthGorantlaNo ratings yet

- Microfabrication For MEMS: Part III: Carol Livermore Massachusetts Institute of TechnologyDocument65 pagesMicrofabrication For MEMS: Part III: Carol Livermore Massachusetts Institute of Technologycat.zeNo ratings yet

- 6.2 Beam DesignDocument12 pages6.2 Beam DesignShamen Amarasekara100% (2)

- Plate Heat Exchanger Design in ExcelDocument6 pagesPlate Heat Exchanger Design in Excelamitkray67% (12)

- Convection and Radiation Heat TransferDocument14 pagesConvection and Radiation Heat TransferSalman ShalwaniNo ratings yet

- Growth of Passive Films On Valve Metals and Their AlloysDocument9 pagesGrowth of Passive Films On Valve Metals and Their AlloysDjedili AmelNo ratings yet

- Film DefectDocument3 pagesFilm Defectamitrameshwardayal100% (2)

- AMME 2301/9301: Mechanics of Solids - WK3: Axial LoadDocument35 pagesAMME 2301/9301: Mechanics of Solids - WK3: Axial LoadMatthew LinNo ratings yet

- ShearDocument16 pagesShearyadav04_abhishekNo ratings yet

- Unsteady State Heat TransferDocument14 pagesUnsteady State Heat TransferHassan AhmedNo ratings yet

- Is.3600.8.1985 0 PDFDocument6 pagesIs.3600.8.1985 0 PDFSukalpa ChowdhuryNo ratings yet

- Prezentare Grosan Marius Bogdan An 2 ADSCSDocument25 pagesPrezentare Grosan Marius Bogdan An 2 ADSCSGanea Marius BogdanNo ratings yet