Professional Documents

Culture Documents

09 Pid

Uploaded by

Viren Parmar0 ratings0% found this document useful (0 votes)

39 views8 pagesOriginal Title

09-PID

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views8 pages09 Pid

Uploaded by

Viren ParmarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

P&ID

ChemKlub India PDEC-P&ID

PIPING & INSTRUMENT DIAGRAM (P&ID)

A P&ID is a pictorial representation of the piping of the process flow together with the installed

equipment (tanks, vessels, pumps, compressors, etc.) and the instrumentation (flow, pressure,

temperature, level, etc.) required to control and operate the process. Preliminary P&IDs are

prepared during FEED and are further updated during Detail Design (DD). P&IDs are normally issued

in 3 to 4 revisions during DD wherein information such as vendor data, Design Review, HAZOP

changes and As-Built changes are incorporated.

For processing facilities, it is a pictorial representation of:

• Key piping and instrument details

• Control and shutdown schemes

• Safety and regulatory requirements

• Basic startup and operational information

The Institute of Instrumentation and Control defines a P&ID as follows:

“A diagram which shows the interconnection of process equipment and the instrumentation used

to control the process. In the process industry, a standard set of symbols is used to prepare drawings

of processes. The instrument symbols used in these drawings are generally based on International

Society of Automation (ISA) Standard S5.1”.

• CAD system is employed for developing the P&IDs and is not vendor, hardware or software

specific.

• It is intended to provide a balance between the desire to show all data on P&IDs with the need

to make P&IDs legible and easy to read. Most details that are available from other types of

documentation (e.g., instrument loop diagrams, vessel data sheets) are not recommended for

inclusion on P&IDs.

• P&ID shows equipment with simple outline representation.

• Equipment’s are not drawn to scale, however equipment relative to one another both in size

and general orientation has to be maintained.

• P&ID shows nozzles on equipment, including spares, as single lines.

• P&ID indicates nozzle sizes unless the size is implied by piping connections.

• P&ID indicates equipment Item Number and Title/Service as a minimum.

• P&ID indicates internals for equipment as dashed lines. Details of internals that have no

significant bearing on the piping design and layout or equipment operation are omitted.

• P&ID does not indicate equipment elevations unless they are necessary to specify process

requirements for associated equipment location or orientation relative to one another.

• P&ID indicates associated trim (e.g., vent and drain valves, instrument bridles) for equipment.

• P&ID indicates auxiliary system requirements for individual pieces of equipment (e.g., lube oil

systems, seal flush systems, turbine gland leak-off piping, sample systems) on auxiliary P&IDs.

• P&ID indicates jacketing requirements for equipment and jacketing / tracing requirements for

piping.

• P&ID indicates the type of insulation (e.g., personnel protection, heat conservation) for

equipment as part of the equipment data.

• P&ID indicates insulation thickness where applicable.

• P&ID indicates piping serial number and piping class

ChemKlub India PDEC-P&ID

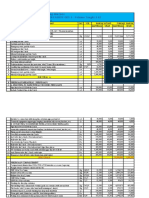

FLOW CHART FOR PREPARATION OF PIPING & INSTRUMENT DIAGRAM

ChemKlub India PDEC-P&ID

ChemKlub India PDEC-P&ID

A typical P&ID is shown:

ChemKlub India PDEC-P&ID

ChemKlub India PDEC-P&ID

ChemKlub India PDEC-P&ID

ChemKlub India PDEC-P&ID

You might also like

- Aerodynamics in CarsDocument20 pagesAerodynamics in CarsSagar KnNo ratings yet

- HAZOP Study Guide for Process SafetyDocument61 pagesHAZOP Study Guide for Process SafetyAmritRoshniKaurNo ratings yet

- Plant Design P&ID GuideDocument15 pagesPlant Design P&ID Guideplanet123No ratings yet

- Introduction To P&Id: Types of Chemical Process DiagramsDocument21 pagesIntroduction To P&Id: Types of Chemical Process DiagramsAldrick Lance HernandezNo ratings yet

- BE-WI-203-08-F01 Technical Checklist Instrumentation - Instrument Index and I-O ListDocument1 pageBE-WI-203-08-F01 Technical Checklist Instrumentation - Instrument Index and I-O Listmika cabelloNo ratings yet

- Process & Instrumentation Diagram (P&ID)Document66 pagesProcess & Instrumentation Diagram (P&ID)Syed HameedNo ratings yet

- P&ID Symbol Diagram Basics - Part 2: International StandardsDocument14 pagesP&ID Symbol Diagram Basics - Part 2: International Standardschris110100% (1)

- Progress Piping GCC CaCo3Document66 pagesProgress Piping GCC CaCo3Alif Rahmat FebriantoNo ratings yet

- Piping External Visual Inspection ProcedureDocument3 pagesPiping External Visual Inspection Procedurecamasa2011100% (1)

- P&ID drawing symbology guideDocument36 pagesP&ID drawing symbology guideSterling GordianNo ratings yet

- Unibell Handbook - Chapter 2 Raw Materials PDFDocument9 pagesUnibell Handbook - Chapter 2 Raw Materials PDFDAVID GREGORIO FRANCO ANDRADENo ratings yet

- ICM-SU-5140-C.1 - FlowDocument37 pagesICM-SU-5140-C.1 - FlowShivani DubeyNo ratings yet

- Process AuxillariesDocument58 pagesProcess AuxillariesHarsh ParmarNo ratings yet

- P&ID Basics: Understanding Piping and Instrumentation DiagramsDocument9 pagesP&ID Basics: Understanding Piping and Instrumentation DiagramsUps YamNo ratings yet

- Piping & Instrumentation Diagrams Guide - LucidchartDocument12 pagesPiping & Instrumentation Diagrams Guide - LucidchartEnrique ArmandoNo ratings yet

- PPT 02Document52 pagesPPT 02Dickson LeongNo ratings yet

- My Resume 01.dec.2009 - USDocument6 pagesMy Resume 01.dec.2009 - USDanny Obrien100% (1)

- Air Coolers Versus Shell-And-tube Water CoolersDocument8 pagesAir Coolers Versus Shell-And-tube Water CoolersDefenceDog67% (3)

- Cameron Wellhead CCU PanelDocument4 pagesCameron Wellhead CCU PanelLaw100% (3)

- Process P ID Training 1705304683Document130 pagesProcess P ID Training 1705304683rajesh_sgNo ratings yet

- ICM-DU-5080-D.1 Temperatute - 1Document27 pagesICM-DU-5080-D.1 Temperatute - 1Shivani DubeyNo ratings yet

- Piping & Instrumentation DiagramDocument20 pagesPiping & Instrumentation DiagramOladayo Siyanbola100% (2)

- 8 14 344 TX HD Pipeline Feed ProposalDocument27 pages8 14 344 TX HD Pipeline Feed ProposalELPIDIO LUCERONo ratings yet

- Check List For Piping LayoutsDocument3 pagesCheck List For Piping LayoutskarunaNo ratings yet

- P&ID Diagram Basics - Part 1 Purpose, Owner & ContentsDocument15 pagesP&ID Diagram Basics - Part 1 Purpose, Owner & Contentschris110100% (1)

- Sandvik Cths660: Spare Parts CatalogDocument36 pagesSandvik Cths660: Spare Parts CatalogWalter Barradas100% (1)

- 10a - Pressure Relief SystemsDocument3 pages10a - Pressure Relief SystemsIslam SolimanNo ratings yet

- Basic Knowledge About P&IDDocument6 pagesBasic Knowledge About P&IDDaveyNNo ratings yet

- Process Industry Practices Piping: PIP PNE00003 Process Unit and Offsites Layout GuideDocument15 pagesProcess Industry Practices Piping: PIP PNE00003 Process Unit and Offsites Layout GuideSilambarasan PalanisamyNo ratings yet

- Process Design Engineering Manual - Part 3Document74 pagesProcess Design Engineering Manual - Part 3Mahathir Che ApNo ratings yet

- ICM-SU-5102-C.3 - Control ValvesDocument67 pagesICM-SU-5102-C.3 - Control ValvesShivani DubeyNo ratings yet

- Ips e in 100Document87 pagesIps e in 100charleselitb92No ratings yet

- ICM-DU-5076-E Pressure CriteriaDocument14 pagesICM-DU-5076-E Pressure CriteriaShivani DubeyNo ratings yet

- Table of Contents and Design BasisDocument17 pagesTable of Contents and Design BasisEbby OnyekweNo ratings yet

- ICM-PU-5316.2 CV Quality Assurance Inspec TestDocument52 pagesICM-PU-5316.2 CV Quality Assurance Inspec TestShivani DubeyNo ratings yet

- KROHNe Principles of Electromagnetic Flow MeasurementDocument200 pagesKROHNe Principles of Electromagnetic Flow MeasurementIntano Sidharta100% (1)

- Process Skid TrainingDocument5 pagesProcess Skid TrainingrutujaNo ratings yet

- Process and Instrumentation Diagram Development for Water and Waste Water TreatmentDocument14 pagesProcess and Instrumentation Diagram Development for Water and Waste Water TreatmentATUL SONAWANENo ratings yet

- 07 PumpDocument23 pages07 PumpViren ParmarNo ratings yet

- 50B10 Standard Assembly LibraryDocument78 pages50B10 Standard Assembly Libraryishu vohraNo ratings yet

- Multi Pump Test Rig Positive Displacement Plunger PumpDocument9 pagesMulti Pump Test Rig Positive Displacement Plunger PumpDaniel IsmailNo ratings yet

- Spacing Between EquipmentsDocument3 pagesSpacing Between Equipmentsdhananjay84100% (2)

- 8474l 000 JSD 1300 006 0 (Specifications For Equipment Spacing)Document38 pages8474l 000 JSD 1300 006 0 (Specifications For Equipment Spacing)Muhammad AhsanNo ratings yet

- Att594 0 PFD P IDDocument432 pagesAtt594 0 PFD P IDZizoGamed0% (1)

- Chemical Process Control - Stephanopoulos PDFDocument376 pagesChemical Process Control - Stephanopoulos PDFjosenivans83% (53)

- Separator Design GuideDocument37 pagesSeparator Design GuideSanjay ParmarNo ratings yet

- PIP PCCCV002-2018 Pressure Regulators Selection CriteriaDocument7 pagesPIP PCCCV002-2018 Pressure Regulators Selection Criteria刘旭No ratings yet

- Valve ActuatorsDocument4 pagesValve ActuatorsMargaret DaughertyNo ratings yet

- How Orifice Meters Measure Flow RatesDocument4 pagesHow Orifice Meters Measure Flow Rateszubi13No ratings yet

- P&ID Check List For EM-PEDocument14 pagesP&ID Check List For EM-PEsajjadyasin100% (1)

- 2.3 Process Flow Diagram (PFD) 2.4 Process and Instrumentation Diagram (P&ID)Document34 pages2.3 Process Flow Diagram (PFD) 2.4 Process and Instrumentation Diagram (P&ID)Sofea Izyan100% (1)

- P&id SeminarDocument30 pagesP&id SeminaryasirvazhikkadavuNo ratings yet

- Good P&IDDocument3 pagesGood P&IDsmithworkNo ratings yet

- Hypersonic Air Intake Design For High Performance and StartingDocument40 pagesHypersonic Air Intake Design For High Performance and StartingRavi ShankarNo ratings yet

- Engineering Sequence PresentationDocument22 pagesEngineering Sequence PresentationpapathsheilaNo ratings yet

- Process Safeguarding - PSE02Document2 pagesProcess Safeguarding - PSE02Sarfraz AliNo ratings yet

- Equipment SizingDocument5 pagesEquipment SizingPandu RockingNo ratings yet

- Shutdown ValvesDocument2 pagesShutdown Valvesnazury2kNo ratings yet

- Process Safety Check List 2Document2 pagesProcess Safety Check List 2renjithv_4No ratings yet

- Piping and Instrumentation Diagrams (P&IDs)Document40 pagesPiping and Instrumentation Diagrams (P&IDs)Mohamed SakrNo ratings yet

- Peggen03 PDFDocument5 pagesPeggen03 PDFMohamedNo ratings yet

- Chemical Engineering DiagramsDocument1 pageChemical Engineering DiagramsAngela Te SabordoNo ratings yet

- Typical Instrument SignalsDocument8 pagesTypical Instrument SignalsSharjeel AbidNo ratings yet

- Pumps Final TeDocument48 pagesPumps Final Tegharsallah mounaNo ratings yet

- Process and Instrument Diagram SymbolsDocument24 pagesProcess and Instrument Diagram SymbolsBabak Hosseini100% (1)

- IPS Standards Manager ListDocument12 pagesIPS Standards Manager Listdeyanshu7No ratings yet

- Typical Process Datasheet For Restriction OrificeDocument7 pagesTypical Process Datasheet For Restriction Orificemartin.rubenNo ratings yet

- Engineering Standard: IPS-E-PR-340Document22 pagesEngineering Standard: IPS-E-PR-340Sadegh AhmadiNo ratings yet

- Ethanol Plant Commissioning Startup and ShutdownDocument5 pagesEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083No ratings yet

- Hospital Wastewater and Its TreatmentDocument8 pagesHospital Wastewater and Its TreatmentDjHanna OlShopsNo ratings yet

- Overview Part 1 PDFDocument65 pagesOverview Part 1 PDFKim NamjoonNo ratings yet

- Lc370wud Sab1 LG PDFDocument34 pagesLc370wud Sab1 LG PDFARTMehr Eng. GroupNo ratings yet

- PROJECT STANDARDS and SPECIFICATIONS Offshore Piping and Instrumentation Diagrams Rev01Document7 pagesPROJECT STANDARDS and SPECIFICATIONS Offshore Piping and Instrumentation Diagrams Rev01totongopNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- 01material Energy BalanceDocument23 pages01material Energy BalanceViren ParmarNo ratings yet

- 08 PDSDocument8 pages08 PDSViren ParmarNo ratings yet

- Types of Valve and SupportDocument22 pagesTypes of Valve and SupportViren ParmarNo ratings yet

- Reynolds Experiment: Laminar Turbulen TDocument12 pagesReynolds Experiment: Laminar Turbulen TViren ParmarNo ratings yet

- Reynolds Experiment: Laminar Turbulen TDocument12 pagesReynolds Experiment: Laminar Turbulen TViren ParmarNo ratings yet

- CPI-II (Chemical Process industries-II) : Discuss About Vinyl Sulphone and Chrome Blue BlackDocument8 pagesCPI-II (Chemical Process industries-II) : Discuss About Vinyl Sulphone and Chrome Blue BlackViren ParmarNo ratings yet

- Volumetric Properties of Pure FluidsDocument38 pagesVolumetric Properties of Pure FluidsViren ParmarNo ratings yet

- Lesson Plan GDJPDocument2 pagesLesson Plan GDJPSundar Mahalingam100% (1)

- Bernuili EquationDocument15 pagesBernuili EquationHaitham AliNo ratings yet

- Perencanaan Pengadaan Barang Dan Jasa Pekerjaan Pengadaan Unit Pertashop Gen 4 - Volume Tangki 3 KL Pt. Radia Denta NusantaraDocument4 pagesPerencanaan Pengadaan Barang Dan Jasa Pekerjaan Pengadaan Unit Pertashop Gen 4 - Volume Tangki 3 KL Pt. Radia Denta NusantarayuwonoNo ratings yet

- Reguladores RECADocument12 pagesReguladores RECADanny FabricioNo ratings yet

- R300LC 9S (H)Document2 pagesR300LC 9S (H)AimHighNo ratings yet

- Operating Instruction Manual Of: Big Notch and Weir APPARATUSDocument9 pagesOperating Instruction Manual Of: Big Notch and Weir APPARATUSRavi ParikhNo ratings yet

- Oliemans Et Al (1986) - Liquid EntraintmentDocument15 pagesOliemans Et Al (1986) - Liquid EntraintmentTiago LimaNo ratings yet

- BD520 Aif129092Document40 pagesBD520 Aif129092Nikolay VelchevNo ratings yet

- NS Equation Class 6Document17 pagesNS Equation Class 6Ashish RanjanNo ratings yet

- Analysis of Supercavitating and Surface-Piercing Propeller Flows Via BEMDocument12 pagesAnalysis of Supercavitating and Surface-Piercing Propeller Flows Via BEMraul19rsNo ratings yet

- Piping System BookbindDocument19 pagesPiping System BookbindCharles Amiel DionisioNo ratings yet

- 07 Panel MethodsDocument45 pages07 Panel MethodsPramudita Dinar100% (1)

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)AliZenatiNo ratings yet

- 2018 - DEVICES - Victaulic Catalog Cu Piese PDFDocument39 pages2018 - DEVICES - Victaulic Catalog Cu Piese PDFNicolae BoaruNo ratings yet

- Chromaster - Spare Parts Catalogue 2013Document40 pagesChromaster - Spare Parts Catalogue 2013JonathanCubillosSerratoNo ratings yet

- Pneu-Hydro Valve CatalogDocument39 pagesPneu-Hydro Valve CatalogMoises Alejandro Ordoñez GuerraNo ratings yet

- PumpsDocument106 pagesPumpscarloNo ratings yet

- Answers (Open-Channel Flow Examples) AUTUMN 2020Document85 pagesAnswers (Open-Channel Flow Examples) AUTUMN 2020خالد عبدالجبار يحيىNo ratings yet

- Chemical Engineering Journal: Somasekhara Goud Sontti, Arnab AttaDocument17 pagesChemical Engineering Journal: Somasekhara Goud Sontti, Arnab AttaSomaSekhar GoudNo ratings yet