Professional Documents

Culture Documents

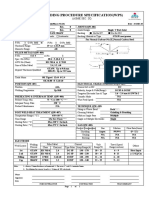

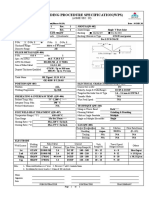

Welding Procedure Specification: PWPS No.: E 515 36

Welding Procedure Specification: PWPS No.: E 515 36

Uploaded by

rexOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification: PWPS No.: E 515 36

Welding Procedure Specification: PWPS No.: E 515 36

Uploaded by

rexCopyright:

Available Formats

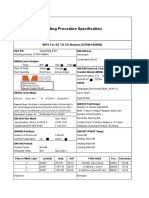

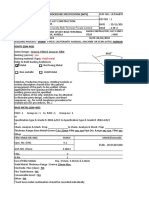

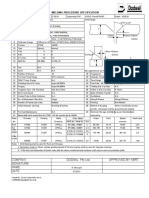

Welding Procedure Specification

Nenzing Sunderland Rostock pWPS No.: E 515 36

Parent metal 1 LH 355-60 Supporting W PA

Parent metal 2 Welding process SMAW (111)

Welding process SMAW (111) Shielding gas Flux None

Filler metal Standard: AWS A 5.1 Gas flow [l/min] Flux height None

Filler metal class E 7018 Number of electrodes Single

Filler metal manufacturer Boehler Number of passes Multiple

Filler metal brand FOX EV 50 Stick out [mm] n. a.

Re-baking 2 h / 300 °C Orifice diameter [mm] n. a.

Bevel preparation + cleaning Flame cutting + grinding Tungsten electr. diam. [mm] n. a.

Cleaning of beads and seam Grinding, LWVH, wire brush Bead type Stringer: PA, PC, PE; Weaver: PF

GROOVE DESIGN

Partial geometrical variation(s)

t1 [mm] = 5 - 24

t2 [mm] = n. a

a [grd] = n. a.

s [mm] = n. a.

x [mm] = n. a.

WELDING PARAMETERS

Position Run Process AC/DC Wire Max. width Amperage Voltage Travel Heat input

+/- diam. of bead [A] [V] speed [kJ/cm]

[mm] [mm] [cm/min]

PA R/T SMAW DC/+ 4,0 12 140 - 170 n. a. 15 - 23 7 15

PC R/T SMAW DC/+ 4,0 12 140 - 170 n. a. 15 - 23 7 15

PE R/T SMAW DC/+ 4,0 12 140 - 170 n. a. 15 - 23 7 15

PF R/T SMAW DC/+ 3,2 12 105 125 n. a. 9 - 15 8 - 18

Run: R Root, F Filler, B Back Weld T Top

Min. preheat temperature: 12mm: none; t>12mm: T=150°C

Max. interpass temperature: 220°C Back gouging: n. a.

Temperatures measured with: Thermoindicators Preheat temp./back gouging: n. a.

Width of preheat: 75 mm left and right of the bevel Width of preheat: n. a.

Post weld heat treatment: n. a. Carbon electrode s diameter: n. a.

Cleaning: n. a.

NDT after gouging: n. a.

01 First edition 29.07.04 Kogler Brunner

Revision Description Date Prepared Approved

1/1 LWN_WPS_1379_0307

You might also like

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- 3rd Quarter W4 LECTURE On Protein Synthesis in DNA and MutationDocument53 pages3rd Quarter W4 LECTURE On Protein Synthesis in DNA and MutationMorante GeraldineNo ratings yet

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Tissue Preparation For Light MicrosDocument4 pagesTissue Preparation For Light Microsscribdarnab75% (4)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Document1 pageWelding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Lipika GayenNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Whatvespprpstphys N16 P1 PDFDocument15 pagesWhatvespprpstphys N16 P1 PDFjszNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- WPS 141-121 P460QH To SameDocument2 pagesWPS 141-121 P460QH To SameakisdassasNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- Onex-Wps-100 - Single V - 27-Smaw-Vertical UpDocument1 pageOnex-Wps-100 - Single V - 27-Smaw-Vertical Upteopan PanNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Welding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Document1 pageWelding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Worldwide: Disc Bottom Outlet ValvesDocument6 pagesWorldwide: Disc Bottom Outlet ValvesmaygomezNo ratings yet

- (L4) - (JLD 4.0) - Solutions - 10th MayDocument28 pages(L4) - (JLD 4.0) - Solutions - 10th MayVidhan jainNo ratings yet

- 6.2ionic Bonding MS - 2Document10 pages6.2ionic Bonding MS - 2Mahir ShahriyarNo ratings yet

- X T K Q: Visit Us At: WWW - Nodia.co - inDocument1 pageX T K Q: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Common EtchantsDocument3 pagesCommon EtchantsValeria Reyes VilchezNo ratings yet

- Capitulo Membrana Celular PDFDocument13 pagesCapitulo Membrana Celular PDFAlejandra SofiaNo ratings yet

- General Pharmacology 1Document59 pagesGeneral Pharmacology 1Ramadi PrameelaNo ratings yet

- Emissivity Chart 139697ARTDocument3 pagesEmissivity Chart 139697ARTbelinda khuthiNo ratings yet

- Conditions For Producing LaserDocument15 pagesConditions For Producing LaserNishant SharmaNo ratings yet

- Final Exam F2 Sem 1Document18 pagesFinal Exam F2 Sem 1miss intNo ratings yet

- SDS Irganox 1076 Ex-BASF (Expiry 2024)Document14 pagesSDS Irganox 1076 Ex-BASF (Expiry 2024)Arista DianaNo ratings yet

- Din 2605 PDFDocument3 pagesDin 2605 PDFPedro Montes MarinNo ratings yet

- Convection Lab 2 Thermo 2 MEE30004 PDFDocument6 pagesConvection Lab 2 Thermo 2 MEE30004 PDFBoydo HilNo ratings yet

- GENERAL CATALOGUE VABW 2019 2020 EN RDDocument140 pagesGENERAL CATALOGUE VABW 2019 2020 EN RDdawit aregayNo ratings yet

- Aerowhip EZ Presentation Rev 1 (Dist)Document20 pagesAerowhip EZ Presentation Rev 1 (Dist)pedrazasNo ratings yet

- Civil Mech Process Electrical InstrumentDocument2 pagesCivil Mech Process Electrical InstrumentAbhishek JainNo ratings yet

- Mix Design FormatDocument3 pagesMix Design FormatAkshay MitraNo ratings yet

- 1-Criteria For Water Quality Monitoring - Water Quality-19!6!18Document72 pages1-Criteria For Water Quality Monitoring - Water Quality-19!6!18maruthi prasad KNo ratings yet

- Class 11th Ch-1 (Some Basic Concepts of Chemistry) 2023-2024Document3 pagesClass 11th Ch-1 (Some Basic Concepts of Chemistry) 2023-2024gauravNo ratings yet

- Plogarithm Edited Report 1 NowDocument44 pagesPlogarithm Edited Report 1 NowSrinivasa bnNo ratings yet

- Freitas2018 PDFDocument11 pagesFreitas2018 PDFVanesa CaroNo ratings yet

- A Sample of Aluminum Metal Absorbs 9Document13 pagesA Sample of Aluminum Metal Absorbs 9Abdullah AltwirqiNo ratings yet

- Liquefied Petroleum Gas (Lpgas) : Safety Data SheetDocument8 pagesLiquefied Petroleum Gas (Lpgas) : Safety Data Sheetnuke apriyaniNo ratings yet

- Química Plantilla PowerPointDocument38 pagesQuímica Plantilla PowerPointJosé Rafael GuillénNo ratings yet

- MSDS - Shell Spirax - Gear OilDocument7 pagesMSDS - Shell Spirax - Gear OilAnonymous LfeGI2hMNo ratings yet

- Non Metallic and PolymersDocument15 pagesNon Metallic and PolymersHemant PokhraNo ratings yet

- IS 8944.2005 Chlorpyrifos Emulsifiable Concentrates-SpecificationDocument4 pagesIS 8944.2005 Chlorpyrifos Emulsifiable Concentrates-Specificationsvivek463No ratings yet