Professional Documents

Culture Documents

383-To-NPP-17-0059 MS, ITP and RA For Land Surveying Works

383-To-NPP-17-0059 MS, ITP and RA For Land Surveying Works

Uploaded by

721917114 470 ratings0% found this document useful (0 votes)

36 views30 pagesOriginal Title

383-To-NPP-17-0059 MS, ITP and RA for Land Surveying Works

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views30 pages383-To-NPP-17-0059 MS, ITP and RA For Land Surveying Works

383-To-NPP-17-0059 MS, ITP and RA For Land Surveying Works

Uploaded by

721917114 47Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 30

@ ALJABER

d@™ ENGINEERING

MD oiduaia

U383INPPISK/aa/17/0059 5 August 2017

Wis. New Port Project Steering Committee

P.O, Box: 28333,

Doha, Qatar

Tel: 4406 4444

Fax: 4406 4420

Attention : The Engineer

‘Mr. Maisar Jamil E-Qutami

Project Executive Director

New Port Project

Contract No. NPPI0085: Strategic Food Security Facilities

‘Subject: Control Traversing, Leveling and Topographic Survey

Dear Sir,

Project

The Contractor hereby submits the method statement forthe contol traversing, leveling and topographic

survey works, associated with the relevant inspection and testing plan (TP), risk assessment (RA), as well

as the cetiicates ofthe Contractor's survey machines, forthe Engineer's review and approval

Enclosures:

41. Method Statement forthe conto! Traversing and Leveling & Topogt

2. Inspection Testing Pian (TP)

3. Risk Assessment (RA)

$Date oft Survey Mactins, (_ CEFLY ray)

1 POBox ce f°)

F PiU Capa wwnjecas —- VELOS!

ew pon pRouect

‘Aljaber Engineering Company @ @ ALJABER

NP 8s: Sate Food Securty Method Statement ENGINEERING

Feclties

Method Statement for Control Traversing and Levelling & Topographic

Survey

Strategic Food Security Facility

NPPOO8S

Prepared ia

Rev| Date ‘Modifications Content "rarnenel | Designation

i ‘Survey

© | 2-August2017 First esue Ahmed Gemeiy | por,

1

2

3

Prepared by Reviewed by, Approved by,

lite ‘Ahmed Gemely Benedick Quiimit ‘Shadi Khashab

I ieee eee Project Mane

Designation ‘Survey Manager GA Manager oj —

Date 2-August-2097 2-August-2017 wgust 2017

ae

Signature A Geees

NEW PORT PROJECT

‘Aljaber Engineering Company af M@ ALJABER

held tine cate Fmd Serer Method Statement MMB ENGINEERING

v=

CONTENT

CONTENT...

4 INTRODUCTION .

4.4 SCOPE aND OBJECTIVES. 7

4.2. PROJECT SPECIFICATIONS & DRAWINGS.

2 RESPONSIBILITIES.

2.1 MAINCONTRACTOR....

2.1.1 Construction Manager

2.1.2. Senior Surveyor.

213° Safety Engineer.

2.14 Environment Engineer.

215 QA/QC Engineer.

3. DEFINITIONS / ABBREVIATION / REFERENCES.

3.1. ABBREVIATIONS

32 REFERENCES,

4 RESOURCES...

4.4 MANPOWER

4.2 SURVEY INSTRUMENTS AND SOFTWARE.

5 HEALTH/ SAFETY / ENVIRONMENTAL PROVISIONS:

5.1. HEALTHAND SAFETY...

5.2. EMERGENCY RESPONSE.

5.3. ENVIRONMENTAL ISSUES.

5.4 ASPECT AND IMPACT IDENTIFICATION.

5.5 EMERGENCY RESPONSE

6 SEQUENCE OF WORKS..

6.1__ SITE PLANNING AND PREPARATION.

6.1.1 Planning:

612 Setting up of GPS base on Government station:

6.13 Setting up of GPS rover on TBM...

6.14 Observation of Government point as chacking point:

6.1.5 Approvals.

lpowwcwccc oo © aVN VN Noo ® ooh ARRRRD bE OW

6.1.6 Signage...

61.7 Verification.

6.1.8 Coordination

6.1.9 Control m3 ee ed

6.2 PROCEDURE METHODOLOGY... in - ol

621 Benchmarks... 00m a eT)

6.2.2 Total Station oueraman 7 - eae 10

6.2.3 Observation .. - ne . 10

624 — Observation Detail... i ee a 40

6.3. DOWNLOADING AND PROCESSING THE OBSERVED DATA. sem 40

6.4 DELIVERABLES... Seis uM

7 APPENDICES.

an

NeW PORT PROJECT

Alabe Engineering Company @ @ ALJABER

Pe 08S Sate Feo Secny Method Statement ENGINEERING

v=

4_ INTRODUCTION

4.1 Scope and Objectives

‘The scope of survey work shall comprise all the activities and support services that are required and necessary to

gainfully perform and successfully complete the Survey works prior to commencing of the setting out of the works.

in compliance with the project requirements.

“The survey shall include the following

‘+ Establishment of Temporary Benchmarks at the project site.

+ Topographical survey

‘© Computation of field data

‘+ Preparation of Final survey report.

‘+ Preparation and submission of hard and soft copies of detailed survey data, survey report and drawings.

‘The Contractor reserves his right to adapt the methods of execution as contained in this document from time to

time, according to specific site conditions, in agreement with the Engineer.

Reference

1.2. Project specifications & Drawings

+ ICE Specification for Piling and Embedded Retaining Walls

+ BS 8110 ; 1997 Structural Use of Concrete

‘+ BS 8004 : 1986 Code of Practice for Foundation

‘+ Qatar Construction Specification (QSC) 2010/2014

ae

NeW PORT PROJECT

Aljaber Engineering Company ALJABER

pee ocaghe Roel acer Method Statement ENGINEERING

fd

2_ RESPONSIBILITIES ]

2.4 Main Contractor

2.1.1. Construction Manager

“The Construction Manager is the overall responsible forthe implementation ofthe Method Statement and ensures

that his team of Engineers are aware of this Method Statement. All resources to include personnel, required

material and necessary equipment are available in order to carry out the work as planned and without delay.

2.1.2. Senior Surveyor

‘The Senior Surveyor is responsible for carrying out of the work as per approved Method Statement and co-

ordinates with the Safely Engineer. He is also responsible to ensure that all necessary required equipment, tools.

‘and materials are in place prior to commencement of the works.

2.1.3 Safety Engineer

The Safety Engineer is responsible to ensure that all safety precautions are in place, all personnel have

ndergone any necessary induction training and that all Personnel are equipped with (PPE) Personal Protective

Equipment,

2.1.4 Environment Engineer

sible to ensure that all environmental precautions are in place, all personnel

The Environment Engineer is respons

duction training to ensure work are conducted in an environmentally

have undergone any necessary inc

responsible manner.

2.1.5 QA/QC Engineer

ris responsible 10 ensure work has been done as per the specification and approved Method

QNQC Engine

‘Statement and ITP- Appendix A

2.2 Sub Contractor

Team Personnel ____—_| Assigned Work.

; aa Site Supervisor ‘|ABOUELHAMD DANDARAWY

HASSAN

2 ‘Surveyor PRIMITIVO PALLANA VALLES

AR

3. Surveyor — ‘SHAILENDRA KUMAR SAH

SUD

4 Surveyor Assistant BIMALENDRA KUMAR PANDTT

5. Surveyor Assistant ‘| SAHID MANSURI

NEW PORT PROJECT

‘Aljber Engineering Company

NPP/0085: Strategic Food Security

Faclities

Method Statement

(40 ALJABER

d@™ ENGINEERING

ae

3 DEFINITIONS / ABBREVIATION / REFERENCES

3.1 Abbreviations:

‘Abbreviation Description

aM ‘Temporary Benchmark

os “Global Positioning System.

‘ang ‘atar National Grid

‘GNHD Qatae National Height Datum

eC Al jaber Engineering Company

3.2 References

pees Document tile

iT TNPPOOBS-JECTTP-000%

RA ‘NPPODBS.JEC-RA-0002

PMP {-383-NPP-SKARAT-003

‘awe 'NPPO08S:JEC POP 000%

SMP 383. NPP SK-AA-A7-0002

‘ceMP ‘NPPOOBS-JEC-CEMP-0001

sa

NeW PORT PROJECT

Aljaber Engineering Company 4 @ ALJABER

Ro ae aaa cake Method Statement in d@@ ENGINEERING

4 RESOURCES

4.1 Manpower

Site Supervisor no 1

‘Surveyor no 2

Surveyor Assistant no 2

4.2 Survey instruments and Software

The following equipment and software shall be used for the works:

Note:

Leica GPS $R530 - (To establish TBMs only)

Leica TS12 L 21000

Leica GEO Office Combined (for GPS data processing)

‘Trimble Geometrics Office (Total Station data processing)

Runner20 Automatic Level

Sprinter 160m Digital Level

‘Autodesk Land Desktop (for the topographical data processing, contouring)

‘AutoCAD (for final presentation of survey drawings)

Ms Word (for the survey report)

Mss Excel (for the survey report)

‘All equipment shall have accurate cerfficates for use, and shall be checked before starting works by trained

safety officer for good condition.

NeW PORT PROJECT

‘Aljaber Engineering Company @ MM ALJABER

ee Strategic Food Security Method Statement d@™ ENGINEERING

Lf

6 HEALTH / SAFETY / ENVIRONMENTAL PROVISIONS ]

5.1 Health and Safety

The health and safety activities are to be in accordance with the relevant Health, Safety and Environmental

requirements as described, but not limited to, within the guidelines for method statement.

Strict adherence to summer work hours shall be followed.

5.2 Emergency response

‘The activities for emergency responses are to be in accordance with the (insert reference of the Contractor's

Emergency response procedure) as described, but not limited to, within the guidelines for method statement.

5.3 Environmental issues

‘The activities for environmental preservation through mitigation are to be in accordance with the Qatari

Environmental Legistation, MoE permits, environmental contract conditions and CEMP.

‘Compliance to Qatari Environmental Legislation, MoE permits, environmental contract conditions and CEMP is to

be listed and ensured prior to commencing the works.

Specific environmental risks and mitigations related to the activities of the method statement are addressed

‘through the Aspect impact Assessment and Mitigation Measures table attached to this section.

JEC and their Sub-Contractor ensures that the preservation of the environment is achieved via no damage is

‘caused to the environment as a result of the execution of this method statement.

5.4 Aspect and Impact Identification

‘The aspects and impact relevant to the works described in the method statement are addressed through the

‘Aspect Identification and Mitigation Measures table attached in this section.

Aspect Identification and Mitigation measures.

Environmental | Source/Activity | Relevant pert Relevant control | Additional mitigation measures

aspect procedure

Soilcontamination | Fuel, oil or TEMP and Mot | Use drip rays during | Maintain appropriate spill kits on

hydraulic fluid from | Permit for ‘any maintenance, | siteot all times and training for,

equipment leak | Temporarysite | MOB/ DEMOB ‘emergency spill response

Office

‘Groundwater Fuel olor CEMP-and MoE | Use drip ways during | Maintain appropriate spil kts on

contamination hhydraulie fuid from | Permit for any maintenance, | site at all times and training for

equipment leak | Temporarysite | MOB/ DEMOB ‘emergency spill response

Office

Greahomegss | Operation offossi | CEMP and MoE | Ensure all equipment | Monitor equipment for any

‘emissions fuel combustion | Permit for has undergone ‘abnormal condition and

engines ‘Temporary site | inspection of replace/maintain equipment as

Office emissions within the | required

last 6 months

Littering Daly activities | CEMP and MoE | Promptiy collect all” Implement the principles of

Permit for rubbish and dispose | reduce, reuse and recycle to limit,

Temporary ite | in approved the amount of rubbish generated

office receptacle

WR

NEW PORT PROJECT

Aljaber Engineering Company @ @ ALJABER

'NPP/008S: Strategic Food Security Method Statement d@@ ENGINEERING

Facies v=

5.5 Emergency Response

‘All reasonably practicable precautions shall be taken to eliminate the potential for hydrocarbon or chemical

spills. All equipment (vehicles and plant including generators, excavator, compactor, etc.) will be maintained

according to manufacturer's specifications and delivered to the project site in a clean condition free of leaks,

drips, ete. A drip tray (or similarly suitable containment) and spill kit (approved by JEC) wil be accessible for

each piece of equipment (internal combustion engine) to be used in the event of a spill. The spill kit will contain

hydrocarbon absorbent, durable receptacle, PPE and Emergency Response instructions,

In the event of an environmental issue or incident, JEC Environment Manager and the PMC will be immediately

notified and it will be entered into the Info Exchange system.

wn

NEW PORT PROUECT

Aljaber Engineering Company 4 @ ALJABER

er eet Method Statement d@™ ENGINEERING

v-»>

6 SEQUENCE OF WORKS

6.1 Site Planning and Preparation

TBMs were established at the project site as per the project requirement. Coordinates and elevation of the

established TBMs were determined by GPS static observation methodology. GPS date collection producer

followed is mentioned hereunder.

6.1.1 Planning:

{As a first step of the GPS observation process, a drawing was prepared showing available Government Control

Station and the location of the new TBMs to be established at the project site. GPS observation sessions, total

number of the TBMs to be included in each session and Government control station to be used in GPS

‘observation session etc. planned accordingly.

6.1.2. Setting up of GPS base on Government station:

Based on the planning of GPS observation, GPS base unit was set up on the Goverment control station,

powered and programmed to start the observation. Details of control station, stating of the observation, height

between the control station and GPS unit etc. were noted in the survey field book

6.1.3. Setting up of GPS rover on TBM:

Based on planning of GPS observation, GPS rover unit was set up on the newly established TBMs, powered and

programmed to start the observation. Details such as description of TEM, starting time of the observation, height

between the TBM and GPS unit were noted in the survey field book. After 15-20 minutes of observation, the GPS

rover moved to next TEMS to be observed as per the plan sequence and continued the process until complete the

plan session.

6.1.4. Observation of Government point as checking point:

‘At the end of the each GPS observation session, a known Government control point was also observed using the

same methodology which was followed to observe the TBMs in the session.

6.1.5 Approvals

For this particular work no permits shall be required from government bodies, municipalites andlor authorities,

6.1.6 Signage

Proper sign board and barriers wil be placed as per HSE procedure & as required on site

6.1.7 Verification

Verity site conditions prior to commence the works,

6.1.8 Coordination

Co-ordinate withthe PMC if there are any concems related to the work location

6.1.9 Control

‘The Control Traversing and Levelling Works shall be executed within eight hours working days in the line with the

programme. This is based on (6) day working weeks, between 7:30 to 17:30.

92

[NEW PORT PROJECT

‘Aljaber Engineering Company ALJABER

oe ET PE Method Statement MB ENGINEERING

v7

6.2 Procedure Methodoloay

6.2.1. Benchmarks

Establishing of Benchmark shall be installed on the area that should not be easily disturbed. It will be used as

reference point during the construction stage.

‘The approved Government Control Primary Bench Marks ~ Package NPP/O085 shall be used as the “Origin of

Survey’ and the survey datum,

6.2.2 Total Station

“The station shall be provided with stee! barrier only well-adjusted and calibrated Total Station shall be used for

the observation. General procedure is explained under for the topographic observation. All personnel must be

provided with personal protective equipment.

Fixing of the Total station instrument precisely on the TBM point with the help of Tribrach and built in optical

plummet. The surveyor shall take the vertical distance between the Instrument and occupied station point and

Confirm the following matters in this phase.

Station Details has correctly been entered into the instrument.

Instrument height has correctly been entered into the memory.

‘The details of back sight have correctly entered into the instrument.

Fixing of the Prism on the back sight with the help of Tribrach and optical plummet.

6.2.3 Observation

Observation of the back sight and recording the details into the instrument memory. Observation of the

topographic details, Prior starting of the observation the surveyor shall give necessary instruction the chainman to

‘aeoure the quality of the work, While observing and the details surveyor will also confirm the following.

‘The prism rod is vertically straight

Changes in the target height are being correctly entered into the instrument,

(Surveyor shall keep brief written notes of station details and target height ete. so that to verify those information

tare correct in the SDR file while post processing the observed data.)

Rough sketch of the observing area is being maintained for the comparison with survey data while post

processing of the data

‘The distance between the instrument station and the prism point not exceeding 350m.

6.2.4 Observation Details

In connection with the said project, spotievels shall be taken at 20m. Interval, When taking spot levels, make

ihe stadia rod fip must not come too close with live overhead cable wire on busbars. Spot levels shal! be

ton such way to reflec exact ground truth in the cigtal terrain model which is prepared from the observe

ete rione om the site All other visible above ground features and services at the project site shall also be

Sbeerved. Extreme care should be taken in order to avold any damage to existing facilties.

6.3 Downloading and Processing the observed data

‘The observed data shall be downloaded to the computer and data shall be processed using the software Trimble

Geometries Office. Brief procedure of processing of the survey data is following under.

‘+ Downloading of the data files into the computer

+ Verification of the Government Control Station

wo

NEW PORT PROJECT

‘Aljaber Engineering Company @ @ ALJABER

ae See end RY Method Statement MM ENGINEERING

+ Eciting ofthe data file to rectify wrong coding or any other input details etc.

+ Transferring of data file into the database

‘+ Categorizing of observed details wth particular codes and layers

+ Export coordinate lis (asc, csv..ete) format from Trimble Geometrics Office

«import coordinate list (.asc,csv...etc) format to Autodesk Land Desktop

‘© Contouring: Contour shall prepare from the observed spot levels ata

+ Vertical interval of 0.5m and the main contour shell be every 2.5m. being applied necessary break lines to

show exact

© Ground truth. Contour shall be prepared using the software Autodesk Land Desktop

= Topographical Survey drawing: shall be prepared as 1:500 drawing scale on standard A1 sheet and

1-100 if required

6.4 Deliverables

Upon the completion of the project, the following data shall be submitted.

= Hard Copy

‘© Detailed topographical Survey plan of crossing (1 set)

© Survey Report (1 set)

‘© Soft Copy (1.No.)

© Topographic survey plan of crossing in AutoCAD format

nye

NEW PORT PROJECT

‘later Engineering Compony @ M@ ALJABER

ryan Saag Fern sear Method Statement ENGINEERING

cities —_? i

[7_APPENDICES

ae a

| A |certicates& Equipment cabaton

ye

240 T8ed

ONASNIONA a

usevrly wo

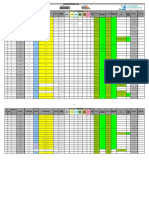

ue}d S81 UOIWadsu]

| erued st sjanay |

H H_|__H_|_ Sydomai yoano Bummas 04 01d Ageanooy | "8S OTOZ-S9D I | punoud / pus ayy Bunj2a4> 3

| ‘Aanung 21ydesBodo, ayy

| EL ued ‘tT 40) SueW Yyuag Aresodwa

H 4 H__|_S¥OM ayy Jo 3no Bupyas 04 JON Apeunaay | 9S _OTOZ-SID aL y3403no Sunaas | s |

| | ered ‘t asionedL

H H H_ | SYom ayy jo no Bupyas 0} old Aoeinaoy | “3985 0T0z-S90 ul | jonueg ayz jo ino Bunzas| oy

Aaning 21ydeuBodo »g asienesy ered ‘T

1 | Jo13U09 eauaUWOD 07 JOlid Aoeunaay | "3985 0T0z-S9D | D¥SD Me youag aouaiajoy | €

T

| soars Aud |

| sé Aq jana] punoad g pus |

| ‘slew ysuog Areiodwia, |

uonaadsuy ebued ‘T 4o suojeas joxqu0D |

1 1 2 40} JINd WUIgNs 03 JOG Ageanaoy | "385 OTOz-SID | DUS Paysiiqeys3 Jo Bupray> z

| Aaains 21ydesBodoy gepoD

| 7g assaned) josvoy | smeis aney erued st

t fe See 2ouawuos 0% Joug | 03 sweuin2og | 32a5 OL0z-s90 | IHS wuauners powew | 1

| ]

sowenuoy | Auta n€ | ‘syeAa) |

Hoa puesa| 19d se) ] ‘aoues9o, sapoa ay “on,

quawanjoauy pauinbay | Aguanbasy euaq ‘Spuepuers: ‘DYSD | qlod jo4UO2 Jo UORdISeg «PY

} aouerdar2y | suopesyjsads

(Aanang a1ydesZodo] »g 3ujjaA07 TODS SHSaTSemOAEN.

‘Ltor-Bnv-z

‘

BuIsIBAeJ] [O1JUOD 10} Ue]q }S84 pue UO!IadsSU}) 000-dii-Dar-se00adNn "nO 8 J8U dL

saquipes Ayunzag poos 218areN$ :sg00/ddN

917 09 Bujseausug Jager py

493f0ud 140d MAN

740 7 a8ed

ONINS3NIONS a

uazevrly we

aumyeusis

Loz-snany-z Lroz-snany-z Etoz-asnBny-z area

won essa

saeueyy 190f01d sa8euew vO. se8euey Aanins neusiseq

auleN [In

qeuseyy ipeus WIND y>IpauEB ‘Aawiey powuy ina

‘Aq panoiddy Aq pamainy Aq pasedasg

or

6

suom

hanuns s1ydeuBodo) »g assened, er ued ‘t

H H | jonuoy jo wonajdwos seyy | snsoy Aanuns | 3985 OTOe-sID | IYSI aouedaroy | 8

aiydesBodo1 »g asianeay | 149] aq pinoys orued‘t ‘syom kanins

1 ‘ 1 JonUOD Jo Uoa|duos sayy ysei3 ON | "3295 OTOZ-S20 | IuS> | seYe AWS aty jo BujweD!D gE

924 Aqyndas poog I1BareNS :S800/ddN

‘11°09 Buusaurdug sages ty

ry uejd say uoladsuy 1D3fOUd LYOd MAN

bebed zbozasnbny-z

gozas0ce 46 3SH Welald s9¥z9995|

jd S1aqunn yoeIuc0 AaveBsOUN

reuvosied 01 Antu fening 2us.

ayes oq vobauen oe sone anata 2

‘popinod 20}

1papoo snojeo pus paxou $100} ‘unl sued fpeq 104 / puett al

«| canaroe snonuans of anp fant aisha e]jauuosied

anveubis TeBevEVY YO = WIND YoIpeUER Aq paMONE Vr

ea) meus JeBeuEW fies -anewy uewry — ha apew yah

souaeou si ‘2¥S walold S800dN S00 Jo UOH!e907

— . RNS an,

Loooo-weO5r-sB00deN sOu019)94 YH yuevBodoy pue Buyarer pue Suisianes,

ONMSENIONS WBBYMIY

quaussassy ys1y Ajajes pue Yr/eaH 4039e43U0}

2402 ysnBny-Z

zebed

‘aunyBUBIS]

Troy] Zrbnve| TPB Z| ‘eG

JBBEUEN Paloig| TeBeUeH VO] TeBEUEW AareS| woneubiseq|

‘qeusEY PENS | WULIND WPSUEG| ‘aneuiy woul eurew jin3|

‘Aq ponouddy| Aq pomeinoy| Aq posedorg|

BudeayasnoH

quauissassy ysly Ayayes pue y3]e2H J0;9e4}U0)

- when ithas to be right Sica Authorised Service Center

Geosystems

Certificate

Product tes 15121 271000

Tota Station

Article no: 793653 ‘Accuracy:

‘Serial no: 1622146 ‘Standard to (ISO 17123-3) a) Angle Standard Deviation : 2°

Standerdto(IS0 1712-4). ) Distance measurement to prism

Inspection date: 25-Apr-2017 Display Resolution: or

Customer: (M/S. BEST ‘Spherical level: Bubble inside the circle

DOHA aATAR ‘Magnification: 30x

Master instrument: Universal Colimator Min, Target Distance: 15m

‘Serial No: (0010387 Compensator range: oe

Humidity 40 Temperature 240°C

: a Valuesbefore | ‘RewatAfter | Under

= view | Sater | Sea | Oo Ree

Horizontaly ofHorizontal Axis | <0030g00 002 gon | YES

forizonal Collimation = 0030gon, 009 go0 | ves]

‘Vertical Colimaton Sabiliy | ~<_0030gon 0003. gon | YES

(Titing Axis =. 0035g0n | YES

EDM Unit Functioning Funetoning YES |

| Sensitivity of Circular Level 62mm 6mm YES

Plumbing Accuracy 13mm 15mm YES: |

“Disp esol 1 i yes

z ‘Reference Distance ( SD) Difierence |

ca 5809 m ° YES

eee 253m ecco YES

t 3 16.380 m_ Imm+1.Sppm_ YES oor

~~ Certfcate: This is to certify thatthe above instrument has been tested and complied withthe specifications

and test report as stated ebove. The test equipment used traceable to international standard or

recognized procedure based on DIN 55350-18-42.2

Validity : Six months. However, this depends very much on the environment:n which the instrument is used.

‘Al Rafidein Co{RAFCO) ‘Next Calibration Due:

.0.Box 831,Dohe-atar 2-October-2017

Pratheesh Radhakrishnan Ss

‘SALES MANAGER ‘SERVICE ENGINEER

Rafeo, Doha-Gatar qualifies to be an Authorized Service Centor of Leica Geosystems AG.

The quelity and environmentel management system meets the relevant criterias ofa Leica Geosystems Service Centra

Cons7 zz8t9 age) when ithes tobe ight hica

Goosystoms

“We Service, We Repair... Always at your service.”

TUT. forage ghd daa = ATV ga = EEA VOWY / EEALEN AY: SU — LEWAEAA / EEANTAPY : 25h

Office : 44829831 /44178488, Fax : 44804102 / 44807577, P. O. Box: 831, DOHA - QATAR - C. R. No. 3230

| E-mail: leica @rafcoqatar.com / www.leica-geosystems.com

Vy

‘sos0n12008

‘aut Margarete

- when it has tobe right JSeica Authorised Service Center

Geosystems

Certificate

Product: Bebe TCRA 1205+ A400

Tota Station

Article no: 754312 ‘Accuracy:

Serial na: 261508, ‘Standard (ISO 171233) a) Angle Standard Deviation :3°

Standard 0 ISO 17123-4)_ 1) Distance measurement to prism

Inspection date: 17-June-2017 Display Resolution: = 0.1"

Customer: (WS. BEST Spherical level: Bubbio inside tha circle

‘DOHA QATAR Magnification: 0x

Master Instrument: Universal Colimator Min. Target Distance: 1.5m

Serial No: oorsa Compensetorrange: +4"

Humidity aor Temperature zo

Values before Result After | Under Acceptable

Description Calleaion Catraion ‘Tenet

Horizontally of Horizontal Axis ~ 0004 gon | 0003 gon YES |

Horizontal Col 0003 gon 0002 gon [Yes

‘Vertical Collimation Stability “0092 gon ‘0009 gon YES

Tilting Axis 0010 gon 0008 gon YES

EDM Unit Functioning | Funetioning YES

Sensitivity of Circular Level 62mm 72mm YES

15 mm 1S mam YES

= 1 = YES

Reference Distance (SD) | Measured Distance | Diflerenes

6.530 m 6530 0 YES

9.095 m 9.095 m 0 Yes

15.806 m 15.805 m + nm] Spm YES

Certificate: This is to certly thatthe above instrument has been tested and compliod withthe specifications

and test report as stated above. The test equipment used is traceable to international standard or

recognized procedure based on DIN 85350-10-4.2.2

Validity : Sixmonths. However, this depends very much on the environment in which the instrument is used.

‘Al Rafi Co,RAFCO) ‘Next Calibration Due:

.0.Box 831,Dohe-Qatar 16-Docember.2017

Prathoosh Redhskrishnan ‘Sunish Philip

‘SALES MANAGER ‘SERVICE ENGINEER

Rafeo, Doha-Qatar qualifies to be an Authorized Service Center of Leica Geosyatems AG.

The quality and environmental management system meets the relavant criterias of @ Lvica Geosystems Service Centre

ort 17 23300 age i)

“We Service, We Repair... Always arogrisrssere tint” Seica

: — - —_—_—— - Geosystems

TUF. ge ghd = degall — AVY ss a — EEALVOWV / EEA ENS : QiSld= ELAVAEAA / EEAYTATY SSL

Office : 44823831 44178488, Fax ; 44804102 / 44807577, P. O. Box: 831, DOHA- QATAR - C. R. No, 3230

E-mail: leica @rafcogatar.com / wwnw.leica-geosystems.com

"50001:708,

‘uty Manager Sten

= when it has to be right Seica Authorised Service Center

Geosystems

Certificate

Product: RUNNER20 AUTOMATIC LEVEL SPECIFICATIONS:

Article no: ‘727585: Accuracy: + 25 mm per km double run

Serial no: 011552, Spherical level: Bubble inside the circle

Inspection date: ‘14-June-2017 ‘Magnification: 20X

‘Customer: (WS. BEST ‘Shortest focusing distance: .8n

DOHA aATaR Telescopic image: Clear

Mester Instrument Universal Collimator Compensator working range range: + 15°

‘Serial No: (0011468 ‘Setting accuracy ( standard deviation): < 0.5"

Values before adjustment Yalues after adjusments Under acceptable tolerance

Compensator working range: +1 215" Yes

Hortzontality of the Line of Sight: 90° 00" 10° ‘99° 00" 00° Yes

Cireular Levet: Out ‘Checked And Adjusted Yes

‘Telescopic Image: Not clear Checked And Cl Yes

Eyepiece: Not clear ‘Checked - Functioning Yes

Focusing drive: Functioning, (Checked - Functioning Yes

Accuracy: 25mm 25mm Yes

Certificate: This is to certify thet the above instrument has been tested and complied with the specifications

‘and test report as stated above, The test equipment used i traceable to international standard or

recognized procedure based on DIN 55350-18-422.

Validity : Six months. However, this depends very much on the environment in which the instrument is used,

‘Al Rafidain Co,RAFCO) ‘Next Calibration Due:

.0.Box 831,Doha-atar 18-December-2017

Pratheesh Redhatrishnen Jt.

‘SALES MANAGER SERVICE ENGINEER

Rafco, Doha-Qatar qualifies to be an Authorized Service Center of Leica Geosystoms AG.

The quelity and environmental management system meets the relavant criterias ofa Leica Geosystams Service Contre

(cors7 25327 ago) = when thas to be sight Sica

Goosystoms

Always at your service

"We Service, We Repair

VV / $EALEN-Y 1 Sli — LEWAEAA / EEAYTATY : aS

le [9] YT. age = gh — dagill - ATVs ye = FRAY

FOV Y,| cinco daszansr erreeny, rox: 4480410 14807877, P.O, Box 891, OMA QATAR CF No 3280

nas gt E-mall: leica @rafeogatar.com / www-leica-geosystems.com

"go s017008

any Manager Ste

- when it has to be right Seica Authorised Service Center

Geosystems

Certificate

Product SPRINTER 150M DIGITAL LEVEL SPECIFICATIONS:

Article no: ‘762629 ‘Accuracy: + 1.5mm standard deviation (electronic)

‘Serial no: (2113757 ‘Spherical level: Bubble inside the circle

Inspection dete: (29-May-2017 Magnification: 24X

Customer: IWS. BEST ‘Shortest focusing distance: 5m

DOHA-QATAR Telescopic image: Clear

‘Master Instrument: ‘Universal Collimator Compensator working range range: + 10°

‘Serial No: (0010387 ‘Setting accuracy ( standard deviation): <0.8" max

Values before adjustment Valuesafferadjusments Under acceptable tolerance

CCompensator working range: 10 210" Yes

Horizoatality ofthe Line of Sight: 90°00" @S" 50° 00°00" Yes

Circalar Level Out Checked And Adjusted Ye

Tetescopie age: Not clear Checked And Cleaned Ye

Eyepiece Not ear Checked - Funetloning Ye

Focusing dive Fimetioning Checked - Functioning Ye

aecersey: ism ium Ye

Cortiicete: This is to certify thet the above instrument has been tested and complied with the specifications

‘and test report as statad above. The test equipment used is traceable to international standard or

racognized procedure besed on DIN 55350-18-422,

Velidty : Six months. However, this depends very much on the environment in which the instrument is used.

Al Rafidain Co(RAFCO} Next Calibration Due:

P.0.Box 831,Doha-Qatar (28-November-2017

iF

Pratheesh Radhakrishnan wyres ur.

‘SALES MANAGER HINEER

Rafeo, Doha-atar qualifies to be an Authorized Service Center of Leica Goosystems AG.

‘The quality and environmental management system meets tho relevant criterias ofa Leica Geosystems Service Centre

cont” 23104 age merttesotesg Leica.

Geosystems

“Qe Service, We Repair... Always at your service.”

] Were roue OAT taps gen HIANNGW / EANEVT gS EEWAEAA/ EEANYATY

y = J nll ATV ge / ’

(QV | a2.) tice: atceneds erro, Fox: ae0s%02 48807577, #0, Box 891, DOHA QATAR-C. RN. S20

[Sentes LSS} E-mall:leica @rafcoqatar.com / www.leice-geosystems.com

‘uation Sten

th soil, Matyi foc hie ner

(ged csneSiih patos Mic aicee @ALLTERRA

CALIBRATION CERTIFICATE Certificate No: ALT_R008

Date: February 23, 2017

CUSTOMER : BEST

Instrument Descrintion

-F

‘The above equipment has been examined and tested accordance with the

procedures, specifications and environmental conditions specified within the

manufacturer's Service and User Manual for the definition of the instruments.

functionabacc I.

has

rer's

The calibration was carried out using standards and equipment is subject to

verification and is traceable.

Calibrated & Checked by: Ravindra Sah

Calibration due date if the instrument sensitivity is not disturbed: August 22, 2017

For AllTerra Gulf

ira

Service Engineer

For any sales/ Product related inquiries

Sanju Mathew, Mobile: 66042060,

saniu@allterragulf.com

Nagendran 4, Mobile: 66931344, nagendran@allierragulf com

(MOHAMED ABDULRANMAN AL-BAHAR & SONS WLL_ pd oa gl g yma cy oe sane

POBox 2171, Doha, Qatar ay Saedediadh

gee

SE am

Se

ah nl

worwallterragulfcont sng

IE Bisceerncnanenter areca @ALLTERRA

CALIBRATION CERTIFICATE Certificate No: ALT_R0O9

Date: February 23, 2017

CUSTOMER : BEST

Instrument Description

Product : Trimble

Type GNSS Receiver

Model 1 R8 Model 4

Serial Number 18547443371

Calibration Procedure

The above equipment has been examined and tested accordance with the

procedures, specifications and environmental conditions ‘specified within the

manufacturer's Service and User Manual for the definition of the instruments.

functionaliaccuracy.

has

icturer’s.

Calibration Test Eauioment

The calibration was carried out using standards and equipment is subject to

Verification and is traceable.

Calibrated & Checked by —_: Ravindra Sah

Calibration due date if the instrument sensitivity is not disturbed: August 22, 2017

For AllTerra Guif

7 @ALLTERRA'E

h

Service Engineer

For any sales/ Product related inquiries, please contact:

Sanju Mathew, Mobile: 66042060,

saniu@allterragulf.com

Nagendran A, Mobile: 66931344, nagendran@allterragulf com

HONAMEDRBDULRANMAN ALBANAR Sows Wik 9-3 oa gI9 Jal Ganyjhaue sane

Poe 2171 ak Cate ferret acme

resent. wat Toa

A802 [Btrimble) wettest

Eni nogalermglcom Infoguiterrepsitcom aa

‘Web www alterag com ‘woewalterrogul cont casas

Wied (eb tos a Mee @ALLTERRA

CALIBRATION CERTIFICATE Certificate No: ALT_R002

Date: March 12, 2017

CUSTOMER : BEST

Instrument Descriotion

Product : Trimble =

1 : GNSS Receiver -

Model 18 Model 4

Serial Number 18550447879

Calibration Test Eauioment

The calibration was carried out using standards and ‘equipment is subject to

verification and is traceable.

Calibrated & Checked by —_: Ravindra Sah

Calibration due date if the instrument sensitivity is not disturbed: September 11, 2017

For AllTerga Gulf

ra

Service Engineer

For any sales/ Product related inquiries, please contact:

Sanju Mathew, Mobile: 66042060,

saniu@altterragulfcom

Nagendran A, Mobile: 66931344, nagendran@allterragulf com

VE UL ACA SN ayy TET es

PO e01217, oat alate daddy Soe

a aaae ey

Tats wpewmoes (Siiimtte) pac oa

Eat iegaheraglcom inogaeragit

‘ie wmalterrpal com ae

‘wwallterranif crn son

ppsOdYSb Lega a iisarce

tite sresninse rane soos SALLTERRA

CALIBRATION CERTIFICATE Certificate No: ALT_R003

Date: March 12, 2017

CUSTOMER : BEST

Instrument Descriotion

Product

Type

Model

Serial Number

Calibration Procedure

‘The above equipment has been examined and tested accordance with the

Procedures, specifications and environmental conditions specified within the

manufacturer's Service and User Manual for the definition of the instruments

shas

rer’s

{ealtration Test Eauioment

The calibration was carried out using standards and ‘equipment is subject to

verification and is traceable.

Calibrated & Checked by —_: Ravindra Sah

Calibration due date if the instrument sensitivity is not disturbed: September 11, 2017

For Al Guit

Sah

Service Engineer

For any sales/ Product related

‘Sanju Mathew, Mobile: 66042060,

Nagendran A, Mobile: 66931344, nagendran@allierragulfcom

‘MOvANED asbeLanna ALBARN a SONS WAL P3299 jaa Gama sane

(PO Bax 2171, Doha, Oster ite piers

ies Baas) a

Eee tam

Infooatrraguicom. ance

Web aera com vwwalteapucont conc

sodY3b MacIyctoslhicase

seat ianaace coms SALLTERRA

CALIBRATION CERTIFICATE Certificate No: ALT_R004

Date: March 42, 2017

CUSTOMER : BEST

Product

‘The above equipment has been examined and tested accordance with the

procedures, specifications and environmental conditions. ‘specified within the

manufacturer's Service and User Manual for the definition of the instruments

= le.

The calibration was carried out using standards and equipment is subject to

verification and is traceable.

Calibrated & Checked by —_: Ravindra Sah

Calibration due date if the instrument sensitivity is not disturbed: September 11, 2017

cs

: nak

enue

SS) ues!

please comact

sanju@allterragulf.com

For any sales/ Product related ing.

Sanju Mathew, Mobile: 66042060,

Nagendran A, Mobile: 66931344, nagendran@allterragulf com

(MOHAMED ABDULAANMAW AL-BANAR & SONS WAL

Saco

=e resets cme ee

Rp Scars

feo hore ta

Web . www aliterragulf.com ce

genset

ED ieecsecencranerterirers ®ALLTERRA

CALIBRATION CERTIFICATE Certificate No: ALT_R0OS

Date: March 12, 2017

CUSTOMER : BEST

Instrument Description

Product : Trimble

'| Calibration Procedure

‘The above equipment has been examined and tested accordance with the

Procedures, specifications and environmental conditions specified within the

manufacturer's Service and User Manual for the definition of the instruments

functior cours

irer's

[Catrason Te tpment

‘The calibration was carried out using standards and equipment is subject to

verification and is traceable,

Calibrated & Checked by —_: Ravindra Sah

Calibration due date if the instrument sensitivity is not disturbed: September 14, 2017

—_—S

Fa one 3

x

For any sales/ Product related inquiries,

‘Sanju Mathew, Mobile: 66042060,

Nagendran A, Mobile: 66931344, nagendran@allierragulf.com

(MOHAMED ABDULRAHMAN AL-BANAR & SONS WL post gl yaa Gam yuu sane

PO Box 2171, Daha, Qatar re ae BREW,

Ta 8744000410 feats oa

Fen + oneaeonmas seninees et

El nfopaterga om Infogalterasitcom se

Wabswonealtenap com wr alersgulicon’ cere

POVb Lalor isucie = ALLTERRA:

‘MOHAMED ABDULRAHMAN AL-BAHAR & SONS WLL.

CALIBRATION CERTIFICATE Certificate No: ALT_R0O6

Date: February 23, 2017

CUSTOMER . BEST

Instrument Description eo

Product : Trimble

Type : Data Collector

Model :T8¢3

‘Serial Number 1 ES6ND09245

Calibration Procedure

‘The above equipment has been examined and tested accordance with the

procedures, specifications and environmental conditions specified within the

manufacturer's Service and User Manual for the definition of the instruments

functionabac

' ; 4 le ore

ue it jirer hit rer’s

|| Calibration Test Equipment

The calibration was carried out using standards and equipment is subject to

verification and is traceable.

Calibrated & Checked by —_: Ravindra Sah

Calibration due date if the instrument sensitiv

For AllTerra Gulf

disturbed: August 22, 2017

y

ra

Service Engineer

For any sales/ Product related inquiries, please contact:

‘Sanju Mathew, Mobile: 66042060, saniu@allterragulf.com

Nagendran A, Mobile: 66931344, nagendran@allterragulfcom

—— SAT REET

PO Box 2171, Dohe, Ostar soe Pact AR

i sone ne

‘Web. vw leap comm ‘wor aitertapulfcont ase

ne SALLTERRA

CALIBRATION CERTIFICATE Certificate No: ALT_R0O7

Date: February 23, 2017

CUSTOMER : BEST

Instrument Description —

Product : Trimble

Type : Data Collector

Model :TSC3

Serial Number 1 ES61D06935

Calibration Procedure

‘The above equipment has been examined and tested accordance with the

procedures, specifications and environmental conditions specified within the

manufacturer's Service and User Manual for the definition of the instruments

functionalaccuracy.

has

rer’s,

The calibration was carried out using standards and equipment is subject to

verification and is traceable.

Calibrated & Checked by: Ravindra Sah

Calibration due date if the instrument is not disturbed: August 22, 2017

For Aliferra Gulf

@ALLTERRAT

Y

ra

Service Engineor

For any sales/ Product related inquiries, please contact:

‘Sanju Mathew, Mobile: 66042060,

saniu@allterragulfcom

Nagendran A, Mobile: 66931344, nagendran@allierragulf.com

(MOWAMED ABDULAANWAN ALAWAR & SONS WAL

ped ood gh g peal yaa ase aaa

ean ae

EE ae wot i

me

worw allterragul com aptaay

SALLTERRA

CALIBRATION CERTIFICATE Certificate No. ALT_NO3O

Date: April 8, 2017

CUSTOMER : BEST

Instrument Description ‘Waster Instrument (Collimator)

Product = Nikon Trimble bench Collimator

Tyee Auto Level Trimble Trunnion Collimator

TAS. Focal Length-300mm

Serial Number 2679501 sees a

Accuracy :+0.8 mm rim

Instrument Specifications ‘Standards. Before Calibration | After Calibration

Magnification 34x as found as found

Minimum focusing distance 1.0m as found «as found

Field of view (1° 30' ) +5% as found as found

Working range #12 as found as found

Setting Accuracy +03" as found as found

Resolving power 25" as found as found

Effective aperture of objective 45mm cas found as found

Sensitivity of circular level 1072 mm 1172 mm 1072 mm

‘Accuracy

Standard Deviation (1km. Double — run levelling) 40.8 mm +£0.8 mm +0.8 mm

The above instrument has been checked and calibrated with the standard collimator and procedures as

per the manufacture's specification and manual.

Calibrated & Checked by —_: Ravindra Sah

Calibration due date if the instrument sensitivity is not disturbed: October 8, 2017

For Allerra Gulf

Ravitdra Sa

Service Engineer

For any sales/ Product related inquiries, please contact

Sanju Mathew, Mobile: 66042060, sanju@allterragulficom

Nagendran A, Mobile: 66931344, nagendran@allierragulf.com

‘ib: Trimble.|

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Enc:osu :: Od: ReceivingDocument40 pagesEnc:osu :: Od: Receiving721917114 47No ratings yet

- Ra Eg C Oo Ecur' Yfachtties: Document Submitta!Document64 pagesRa Eg C Oo Ecur' Yfachtties: Document Submitta!721917114 47No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Regarding INR LogDocument51 pagesRegarding INR Log721917114 47No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- C823 3 Doc MST Mec 009Document24 pagesC823 3 Doc MST Mec 009721917114 47No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Reply From HPP0100-MS-0005 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0005 Method Statement Submittal721917114 47No ratings yet

- UntitledDocument33 pagesUntitled721917114 47No ratings yet

- Purchase Order For MemDocument3 pagesPurchase Order For Mem721917114 47No ratings yet

- UntitledDocument38 pagesUntitled721917114 47No ratings yet

- Responces To HPP Comments - Strategic Food Storage Facility - Al Jaber Engineering - 30 April 2018Document6 pagesResponces To HPP Comments - Strategic Food Storage Facility - Al Jaber Engineering - 30 April 2018721917114 47No ratings yet

- 383-NPP-0085-LT-0058 Reply From NPPDocument2 pages383-NPP-0085-LT-0058 Reply From NPP721917114 47No ratings yet

- 383-NPP-0085-LT-0108 Reply From NPPDocument3 pages383-NPP-0085-LT-0108 Reply From NPP721917114 47No ratings yet

- Reply From HPP0100-MS-0004 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0004 Method Statement Submittal721917114 47No ratings yet

- Reply From HPP0100-MS-0001 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0001 Method Statement Submittal721917114 47No ratings yet

- 383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation WorksDocument35 pages383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation Works721917114 47No ratings yet

- Qinph2 P08 Tes MST JTC Ele 00012 - R0Document34 pagesQinph2 P08 Tes MST JTC Ele 00012 - R0721917114 47No ratings yet

- 383-NPP-0085-LT-0016 - Rev - 0 Reply From NPPDocument3 pages383-NPP-0085-LT-0016 - Rev - 0 Reply From NPP721917114 47No ratings yet

- Installation ManualDocument7 pagesInstallation Manual721917114 47No ratings yet

- Iso ConfirmationDocument1 pageIso Confirmation721917114 47No ratings yet

- C823 3 Mtin Civ 042Document2 pagesC823 3 Mtin Civ 042721917114 47No ratings yet

- 1.internal Concrete Pour Register Updated On 25-01-2023Document9 pages1.internal Concrete Pour Register Updated On 25-01-2023721917114 47No ratings yet

- RFI Formrev 01Document1 pageRFI Formrev 01721917114 47No ratings yet

- New IndexDocument1 pageNew Index721917114 47No ratings yet

- Submittal Package No 3238.1Document1 pageSubmittal Package No 3238.1721917114 47No ratings yet

- New IndexDocument1 pageNew Index721917114 47No ratings yet

- Sequence of OperationDocument1 pageSequence of Operation721917114 47No ratings yet

- Ed G M G A GN 0002 00Document50 pagesEd G M G A GN 0002 00721917114 47No ratings yet

- Ed M M M A GN 0001 01Document39 pagesEd M M M A GN 0001 01721917114 47No ratings yet

- Installation Clean Agent SystemsDocument14 pagesInstallation Clean Agent Systems721917114 47No ratings yet

- Zeeman - Chamber of CommerceDocument2 pagesZeeman - Chamber of Commerce721917114 47No ratings yet

- RFIA Formrev00 (BP02B)Document2 pagesRFIA Formrev00 (BP02B)721917114 47No ratings yet