Professional Documents

Culture Documents

Strength of Material 2

Strength of Material 2

Uploaded by

willard sitholeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strength of Material 2

Strength of Material 2

Uploaded by

willard sitholeCopyright:

Available Formats

Strength of Material

Corrosion

Definition and Elements

● Corrosion is a natural process that converts a refined metal into a more chemically stable

form such as oxide, hydroxide, or sulfide.

● It is the gradual destruction of materials (usually a metal) by chemical and/or electrochemical

reaction with their environment

● In the most common use of the word, this means electrochemical oxidation of metal in

reaction with an oxidant such as oxygen or sulfates.

● Rusting, the formation of iron oxides, is a well-known example of electrochemical corrosion.

This type of damage typically produces oxide(s) or salt(s) of the original metal and results in

a distinctive orange colouration.

● Corrosion can also occur in materials other than metals, such as ceramics .

● Corrosion degrades the useful properties of materials and structures including strength,

appearance and permeability to liquids and gases.

Galvanising

● Galvanising is the process of applying a coating of zinc to steel, in order to protect it

against corrosion.

● The most common method used for the majority of sizes of steel members or

fabrications is hot dip galvanising

● This involves the entire immersion of the steel product into a bath of molten zinc.

● This process is used to stop the formation of rust through oxidation, hydroxidaton and

sulfidation

● It is an extremely versatile and easy means of providing corrosion protection for

construction materials exposed to atmospheric conditions.

Metal Beams

● I-beam

● H-Beam

● U or Channel-beam

● Square tube-beam

● Lintel

I-beam and H-Beam

● Most common beam used in construction and frame structures

● Used for spanning gaps and is referred to as beam because it is placed horizontally.

● Uses both compression and tensile force

● Rigid, strong, cost effective and is flexible and bendable

● Loses no structural ability because of its shape

● H-Beam is I-Beam turned 90 degrees does not function as well as I beam when used in same

circumstances and manner

U-Beam

● Shaped in a standard U shape, also referred to as a C beam when it is turned on its side

● Used as a means of joining member to one another by simple means of fitting and securing. This

allows for little to no drilling or other forms of connection

● U-Beams are cost effective and allow for frame structures to be joined

● Are not used often for support or absorbing weights, loads and forces

Square Tube Beam

● Square tubes are formed from coils of steel and run through a process converting them

into hollow quadrated beams.

● They are welded from the inside to form their shape.

● Square tubes are generally used for maintenance and structural purposes.

● Some examples of applications would be building construction, railings, and signposts.

Mass and Density

The difference between the two

You might also like

- BS 1449-1 - 1983Document39 pagesBS 1449-1 - 1983عمر عمر100% (7)

- Manufacture of Soda AshDocument46 pagesManufacture of Soda AshDinesh Dinnu100% (1)

- HT ProcedureDocument34 pagesHT ProcedureBHAKTAVATSALAM K.K.CNo ratings yet

- Structural Steel PresentationDocument91 pagesStructural Steel PresentationP SHANKAR BABU75% (4)

- Light Gauge Steel FramingDocument14 pagesLight Gauge Steel Framingremon100% (4)

- Project Report On Upvc and CPVC Pipe PlantDocument5 pagesProject Report On Upvc and CPVC Pipe PlantEIRI Board of Consultants and Publishers100% (1)

- Metals Steel Frame Const - GRP5 1Document47 pagesMetals Steel Frame Const - GRP5 1Audrey MargalloNo ratings yet

- Chapter 1 Introduction To Steel DesignDocument33 pagesChapter 1 Introduction To Steel DesignRami Demachki100% (1)

- Metals 18-19Document35 pagesMetals 18-19ZACHARIE TUYUBAHENo ratings yet

- Steel Member: Types and UsesDocument8 pagesSteel Member: Types and Usesgunjan kandariNo ratings yet

- Advantages and Disadvantages of Structural Steel StructuresDocument13 pagesAdvantages and Disadvantages of Structural Steel StructuresMangoTangoNo ratings yet

- Lec11 - Ce151p - 2Q - 1819 - Structural SteelDocument20 pagesLec11 - Ce151p - 2Q - 1819 - Structural SteelRachelle AndradeNo ratings yet

- Unit 2steel AlloyDocument29 pagesUnit 2steel AlloyLn VedanayagamNo ratings yet

- Unit 1Document11 pagesUnit 1Himal AryalNo ratings yet

- Steel Trusses PDFDocument73 pagesSteel Trusses PDFmayuresh barbarwar100% (1)

- Forms of Steel Used For Building Construction: Submitted By, Varsha Das 38 s3Document13 pagesForms of Steel Used For Building Construction: Submitted By, Varsha Das 38 s3Varsha DasNo ratings yet

- Chapter One - Introduction To Steel StructuresDocument8 pagesChapter One - Introduction To Steel StructuresJohn Philip Molina NuñezNo ratings yet

- CMT - Module 7 (STEEL)Document7 pagesCMT - Module 7 (STEEL)John Fred Marzan CativoNo ratings yet

- Bhemba Re SteelDocument26 pagesBhemba Re SteelAshley ChikodziNo ratings yet

- Basic Steel Structure - LatestDocument25 pagesBasic Steel Structure - LatestJun Crisostomo100% (1)

- DSR Unit 1Document69 pagesDSR Unit 1hujefaNo ratings yet

- Steel StructureDocument6 pagesSteel StructureONG VNo ratings yet

- Topic 1 Introduction To Steel DesignDocument6 pagesTopic 1 Introduction To Steel DesignAlzon SamboNo ratings yet

- Topic 1 - Introduction To Steel DesignDocument48 pagesTopic 1 - Introduction To Steel DesignAce De GuzmanNo ratings yet

- UB Powerpoint TemplateDocument54 pagesUB Powerpoint TemplateEloiza Lajara RamosNo ratings yet

- Tensile Strength of SteelDocument20 pagesTensile Strength of SteelChelsiemea VargasNo ratings yet

- Structural SteelDocument5 pagesStructural Steelnazlie1707No ratings yet

- Steeltrusses 170323101523Document22 pagesSteeltrusses 170323101523Mohan SaragadamNo ratings yet

- ME Assignment 2Document12 pagesME Assignment 2hecavodNo ratings yet

- Building Construction and Material - VDocument20 pagesBuilding Construction and Material - Vkushagra agrawalNo ratings yet

- BEC6Document6 pagesBEC6angelolagfNo ratings yet

- Steel Bridge: Prepared By: Christian J. EjocDocument13 pagesSteel Bridge: Prepared By: Christian J. EjocAlfredo VillanuevaNo ratings yet

- Urdaneta City University: Principle of Structural Steel DesignDocument10 pagesUrdaneta City University: Principle of Structural Steel DesignYZRAJAEL CELZONo ratings yet

- Structural SteelworkDocument15 pagesStructural SteelworkkgatoNo ratings yet

- Metal: Ferrous and Mild SteelDocument74 pagesMetal: Ferrous and Mild SteelRoshan MauryaNo ratings yet

- Lecture 01 - Introduction To Steel StructuresDocument20 pagesLecture 01 - Introduction To Steel StructuresVai re Vai100% (2)

- Steel Frame ConstructionDocument47 pagesSteel Frame Constructionapi-386384775No ratings yet

- Module 1 - Intro To Design of Steel StructuresDocument10 pagesModule 1 - Intro To Design of Steel StructuresJuan Paulo DiazNo ratings yet

- Classification of Steel SectionsDocument9 pagesClassification of Steel SectionsKavish Singh100% (2)

- Steel As A Building MaterialDocument11 pagesSteel As A Building MaterialPriyank Soni100% (1)

- What Is Steel?: Steel Is An Alloy in Which Iron Is Mixed With Carbon and Other ElementsDocument20 pagesWhat Is Steel?: Steel Is An Alloy in Which Iron Is Mixed With Carbon and Other ElementswwwNo ratings yet

- Topic 7 Steel and Non-Steel MaterialsDocument33 pagesTopic 7 Steel and Non-Steel MaterialsF2012 syifahumairahNo ratings yet

- Section 7 Structural Elements of Low-Rise Buildings Material and FunctionDocument33 pagesSection 7 Structural Elements of Low-Rise Buildings Material and Functionمحمد العلي100% (1)

- Steel and Steel Making: Fact: Carbon Steels Make Up About 90% of All Steel ProductionDocument6 pagesSteel and Steel Making: Fact: Carbon Steels Make Up About 90% of All Steel ProductionSAMANTHA SARAH PURBANo ratings yet

- Summary Iintroction To Structural Steel DesgnDocument5 pagesSummary Iintroction To Structural Steel Desgnbrayan guevaraNo ratings yet

- Materials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CDocument25 pagesMaterials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CNidhi MehtaNo ratings yet

- Structural SteelDocument26 pagesStructural Steeldiya.nithanya.barch22No ratings yet

- STEELDocument4 pagesSTEELAirah SaysonNo ratings yet

- Types of Steel Used in ConstructionDocument12 pagesTypes of Steel Used in ConstructionMary FelisminoNo ratings yet

- Structural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaDocument10 pagesStructural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaAnonymous nABFA4lNo ratings yet

- Structural Steel WorksDocument85 pagesStructural Steel Workscricket reviewNo ratings yet

- BJTC 2023 Construction Technology: Chapter 5 - Steel and Other MetalsDocument50 pagesBJTC 2023 Construction Technology: Chapter 5 - Steel and Other MetalsHermioneNo ratings yet

- Es Structural SteelDocument6 pagesEs Structural SteelMARUCOT ALEXIS P.No ratings yet

- Steel + Wood StructuresDocument129 pagesSteel + Wood StructuresYigezu YehombaworkNo ratings yet

- 20 - Patil Riya Reportno.01 - Introduction To SteelDocument18 pages20 - Patil Riya Reportno.01 - Introduction To Steel22Patil RiyaNo ratings yet

- 4thsembc 160317160307Document48 pages4thsembc 160317160307raviciviltNo ratings yet

- Steel in ArchitectureDocument21 pagesSteel in Architectureakarsh100% (1)

- Avani and RitijaDocument17 pagesAvani and RitijaDevyaniAgrawalNo ratings yet

- Steel Properties: Engr: Muhammad Yasir Samoo BE Civil MUET JamshoroDocument10 pagesSteel Properties: Engr: Muhammad Yasir Samoo BE Civil MUET JamshoroalibuxjatoiNo ratings yet

- MetalsDocument8 pagesMetalsAnna KateurinaNo ratings yet

- Steel Materials WikipediaDocument12 pagesSteel Materials WikipediaSam AlaxNo ratings yet

- L3-Structural SteelDocument58 pagesL3-Structural SteelTjia Tjie100% (1)

- Introduction To Structural Steel and Design To Ec3Document38 pagesIntroduction To Structural Steel and Design To Ec3Amsyar RazziNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- GRD 12 - Fundamental Skills WS - MEMODocument42 pagesGRD 12 - Fundamental Skills WS - MEMOwillard sitholeNo ratings yet

- Circuits in Electrical System-MatshikaDocument17 pagesCircuits in Electrical System-Matshikawillard sitholeNo ratings yet

- Grade 8 Technology Activity BookDocument61 pagesGrade 8 Technology Activity Bookwillard sitholeNo ratings yet

- ForcesDocument3 pagesForceswillard sitholeNo ratings yet

- Piping SolutionDocument41 pagesPiping SolutionSiddhi MhatreNo ratings yet

- Summative Test in SMAW 8: Luray II Barangay High School Luray II, Toledo CityDocument3 pagesSummative Test in SMAW 8: Luray II Barangay High School Luray II, Toledo CityKrizzie Jade CailingNo ratings yet

- Amendment No. 1 December 2016 TO Is 15820: 2009 General Requirements For Competence of Assaying and Hallmarking CentresDocument5 pagesAmendment No. 1 December 2016 TO Is 15820: 2009 General Requirements For Competence of Assaying and Hallmarking Centresnarendar.1No ratings yet

- QuizDocument2 pagesQuizAnas TubailNo ratings yet

- Henan Dafang Crane CatalogueDocument23 pagesHenan Dafang Crane CatalogueKhurshid AnwarNo ratings yet

- Schieber EN2008 PDFDocument144 pagesSchieber EN2008 PDFperfilma2013No ratings yet

- Landing Gear Weekly Change Reports Dated 02-21-2021 NSRDocument1,492 pagesLanding Gear Weekly Change Reports Dated 02-21-2021 NSRRangaNo ratings yet

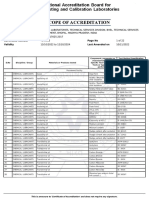

- NABL TestsDocument22 pagesNABL TestsSandeep YadavNo ratings yet

- SECTION 03200 Concrete ReinforcementDocument8 pagesSECTION 03200 Concrete ReinforcementSuranga ManuNo ratings yet

- How To Fix Ender 3 S1 and S1 Pro ABL Issues (2) .Docx - Documentos GoogleDocument5 pagesHow To Fix Ender 3 S1 and S1 Pro ABL Issues (2) .Docx - Documentos GoogleJeffson S. NobreNo ratings yet

- "Superalloy",: Is The Most Effective and Futuristic Alloy System of Modern TimesDocument24 pages"Superalloy",: Is The Most Effective and Futuristic Alloy System of Modern TimesKASHFI UDDINNo ratings yet

- Macerator Pump: Complete ManualDocument11 pagesMacerator Pump: Complete ManualHan HanNo ratings yet

- Ultrasonic CleanersDocument2 pagesUltrasonic CleanersPhan Cao An TruongNo ratings yet

- MyPDF PDFDocument4 pagesMyPDF PDFBill LindoNo ratings yet

- Lysaght Select Seam SeriesDocument12 pagesLysaght Select Seam SeriesFar AwayNo ratings yet

- GMCO FOR INDUSTRIAL SERVICES - Welding Procedure SpecificationsDocument2 pagesGMCO FOR INDUSTRIAL SERVICES - Welding Procedure SpecificationsMohamedNo ratings yet

- Awwa C510Document18 pagesAwwa C510Jacques BlueqNo ratings yet

- Lathe, Lathe Tools and WorksDocument5 pagesLathe, Lathe Tools and WorksHafsah M. MohammadaliNo ratings yet

- PY - The - M.kekkonen L.holapp - 2000 - Comparison of Different Coal Based Direct Reduction ProcessesDocument47 pagesPY - The - M.kekkonen L.holapp - 2000 - Comparison of Different Coal Based Direct Reduction ProcessesEduardo CandelaNo ratings yet

- BOQ and Specification For Adigrat BHA 4 Project.Document42 pagesBOQ and Specification For Adigrat BHA 4 Project.Tesfaye GirmaNo ratings yet

- Engineering Material Specification: Approval From The Sheet Metal Tech ClubDocument8 pagesEngineering Material Specification: Approval From The Sheet Metal Tech ClubaldairlopesNo ratings yet

- H-E Parts Data Sheet PT-95S CeramicDocument1 pageH-E Parts Data Sheet PT-95S CeramicJorge VillalobosNo ratings yet

- Ambia-Line & Orga-Line: Adjustable Organization Systems Designed For Legrabox, Movento, Tandem and TandemboxDocument32 pagesAmbia-Line & Orga-Line: Adjustable Organization Systems Designed For Legrabox, Movento, Tandem and Tandemboxarhi arhiNo ratings yet

- Angel Chacon: Qualified WelderDocument3 pagesAngel Chacon: Qualified Welderangel chaconNo ratings yet

- Glass ContainerDocument1 pageGlass Containerjes pristoNo ratings yet

- Welding Practice PDFDocument119 pagesWelding Practice PDFradugorj100% (1)