Professional Documents

Culture Documents

Zero Breakdown March

Uploaded by

ZarkKhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zero Breakdown March

Uploaded by

ZarkKhanCopyright:

Available Formats

Electricial Inspection Plan to Ensure Zero Un-planned Breakown - March

March

Area Item Inspect/Monitor content Frequency SBU Remark

W1 W2 W3 W4

1 General inspection of exterior of equipment. 1 1 1 1

2 Check panel lights for operation, burned out or missing bulbs LED's and covers. 1 1 1 1

3 Inspect insulation, stand-off insulators, and bus separators for damage or clearance Daily 1 1 1 1

4 Check control knobs and switches for freedom of movement and contact condition. 1 1 1 1

5 Inspect for broken instrument, relay cover glass and damaged phase indicator lights 1 1 1 1

6 Inspect breaker and cell primary and secondary contacts and alignment 1 1 1 1

All Ok. Inspection & maintenance

HT 7 Inspect for proper grounding of equipment insulation resistance to ground and neutral bus Weekly Mr Mukhtar 1 1 1 1

done as per plan

8 Verify proper operation of cell interlocks and auxiliary contact assemblies. 1 1 1 1

9 Perform relay calibration and settings. ; Test annunciator, alarm and/or target operation. 1

Monthly

10 Lubricate draw out assembly parts as required. 1

11 Inspect main line Up -coming WAPDA free from enviroment constraints

12 Perform Mositore test for transformer Yearly

13 Inspect and perform Continuty grounding test

1 Reading of MOG (Magnetic Oil Gauge) of main tank and conservator tank of transforme & 1 1 1 1

2 Checking of Contactor in NO/NC Point; Thimble Tightness Daily 1 1 1 1

3 Checking of auxiliary contacts continuity proper change overs ; No rust, corrosion, or 1 1 1 1

4 Checking of MCB & RCCB Terminals ; Inspect main bonding jumper, GEC 1 1 1 1

All Ok. Inspection & maintenance

5 Checking condition and alignment of jaw Contact Weekly Mr Mukhtar 1 1 1 1

done as per plan

LT 6 Checking and proper tightening of hardwares ; nsulation Resistance test, withstand 1 1 1 1

7 Checking motor operation in case of EDO. 1

8 Checking of auxiliary contacts continuity proper change overs Monthly 1

9 Checking presence of all circlips

10 Perform Mositore test for transformer

Yearly

11 Continuty grounding test for all LT

1 Check cleanliness in DB box 1 1 1 1

2 Check dressing of cables Daily 1 1 1 1

3 Check protection equipment must not be burnt 1 1 1 1 All Ok. Inspection & maintenance

Mr Akbar

4 Checking warth of DB 1 1 1 1 done as per plan

DB

5 Check fault inductor light working or not ; Proper labeling of parts inside the DB Weekly 1 1 1 1

6 Ground test for the DB 1 1 1 1

7 Check instantenous value of Protect system Fuse, Breaker 1

Monthly

8 Check cabeling connection and must ensure no leakage current 1

Score 100.00%

You might also like

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- ACMV Maintenance Check ListDocument7 pagesACMV Maintenance Check ListHtet Linn Aung100% (2)

- LY38 Ops Manual PDFDocument36 pagesLY38 Ops Manual PDForlando chullo llave100% (1)

- Nor30p Serv ManDocument187 pagesNor30p Serv Manjason_meyer_14100% (2)

- Daihatsu Sirion Model m300 Series Service Manual No9890 EngineDocument32 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 EngineJakub TarasinNo ratings yet

- Svsprasad Engineer (Design), Switchgear Products Division, Vijai Electricals LimitedDocument52 pagesSvsprasad Engineer (Design), Switchgear Products Division, Vijai Electricals Limitedkrmrps0% (1)

- Bartec Hazardous Class PosterDocument1 pageBartec Hazardous Class PosterDen Andri Nchu100% (2)

- TR231 or TR241 - E4 - 8112W00078 PDFDocument1 pageTR231 or TR241 - E4 - 8112W00078 PDFDave ChaudhuryNo ratings yet

- GX13Document537 pagesGX13Richard GodoyNo ratings yet

- Scope of Work For MaintenanceDocument4 pagesScope of Work For Maintenancepirates kingNo ratings yet

- Street Light MarchDocument1 pageStreet Light MarchZarkKhanNo ratings yet

- Mainteance SOP - Rev 06Document25 pagesMainteance SOP - Rev 06Kushal SinghNo ratings yet

- MCP DetailsDocument2 pagesMCP DetailsMohammad YaseeenNo ratings yet

- FM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectionDocument2 pagesFM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectiondavidburkepsNo ratings yet

- Distribution Panel Board Testing ChecklistDocument2 pagesDistribution Panel Board Testing ChecklistSumit SaurabhNo ratings yet

- HV Substation Testing Maintenance Practise IEM Seminar 18th November 202...Document51 pagesHV Substation Testing Maintenance Practise IEM Seminar 18th November 202...Pujayantha KumarNo ratings yet

- UPSDocument8 pagesUPSMohammed Sayeeduddin100% (1)

- Date Done: Customer: Address: Reference No.: 22157 January 13, 2024Document2 pagesDate Done: Customer: Address: Reference No.: 22157 January 13, 2024Karlo X CorpuzNo ratings yet

- G 2711 NDocument23 pagesG 2711 NValerică HizanuNo ratings yet

- PM Report at Purefoods Hormel Powerplant 1Document2 pagesPM Report at Purefoods Hormel Powerplant 1Karlo X CorpuzNo ratings yet

- Maintenance Checklist Fore Ot Crane 142708Document1 pageMaintenance Checklist Fore Ot Crane 142708Sumeet TrivediNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- Best Practice For Inspection of Weld EquipmentDocument11 pagesBest Practice For Inspection of Weld EquipmentmehdiNo ratings yet

- Maintenance Checklist Shekar AugerDocument1 pageMaintenance Checklist Shekar Augershamsheer ikramNo ratings yet

- EN-RAC-04 - Power Substation MaintenanceDocument30 pagesEN-RAC-04 - Power Substation Maintenancemd_khudNo ratings yet

- IMEE-6 Maintenance PDFDocument8 pagesIMEE-6 Maintenance PDFHirakNo ratings yet

- MPM 311 03 01Document1 pageMPM 311 03 01Mousa PetrolNo ratings yet

- Job Description Remarks: Single Phase Preventer and Y/ Timer) Decoloursation, BurnsDocument2 pagesJob Description Remarks: Single Phase Preventer and Y/ Timer) Decoloursation, Burnssanjeev267No ratings yet

- Maintenance Checklist Feed AugerDocument2 pagesMaintenance Checklist Feed Augershamsheer ikramNo ratings yet

- D-07A-H Maintenance and Inspection of Fire Protection System, LSA and Appliances-EnglishDocument20 pagesD-07A-H Maintenance and Inspection of Fire Protection System, LSA and Appliances-Englishjajangsuryadilaga76No ratings yet

- A-2.2-21-17-04 - Batching PlantDocument1 pageA-2.2-21-17-04 - Batching PlantNisanth ThulasidasNo ratings yet

- MCC and Panels Maintenance ProcedureDocument15 pagesMCC and Panels Maintenance ProcedureEldhose PaulNo ratings yet

- Frequent Inspection: CautionDocument1 pageFrequent Inspection: CautionMuhammed ShamseerNo ratings yet

- Crane Inspection PDFDocument234 pagesCrane Inspection PDFBudi Santony100% (1)

- Weekly Maintenance Schedule and Checklist AgitatorDocument2 pagesWeekly Maintenance Schedule and Checklist AgitatorNaqqash Sajid100% (1)

- Toyota Reach Truck PM Check SheetDocument2 pagesToyota Reach Truck PM Check Sheetharshavardhan100% (1)

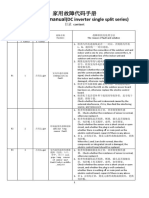

- Failure Code Manual: (DC Inverter Single Split Series)Document5 pagesFailure Code Manual: (DC Inverter Single Split Series)cristian osornoNo ratings yet

- Ims-Om-Cl-001-R00 AcdbDocument1 pageIms-Om-Cl-001-R00 AcdbVeerendra YduvanshiNo ratings yet

- Top Drive Maintenance Plan20210925Document4 pagesTop Drive Maintenance Plan20210925Franklin Silva100% (1)

- PMS Report at The Grove Tower CDDocument2 pagesPMS Report at The Grove Tower CDKarlo X CorpuzNo ratings yet

- Fault, Protection and Failure Indications in PSE Soft StarterDocument5 pagesFault, Protection and Failure Indications in PSE Soft StartermichaelNo ratings yet

- 8-Maintenance and InspectionDocument10 pages8-Maintenance and InspectionmominzadahNo ratings yet

- Ikedc Ie Care PresentationDocument11 pagesIkedc Ie Care PresentationAhamdi AbarikwuNo ratings yet

- Planned Preventive Maintenance Rsi Sultan Agung SemarangDocument2 pagesPlanned Preventive Maintenance Rsi Sultan Agung SemarangNainggolan TaruliNo ratings yet

- Verificare Bujii IncandescenteDocument1 pageVerificare Bujii IncandescentemihaimartonNo ratings yet

- Ngome ReportDocument4 pagesNgome ReportmrlaeluNo ratings yet

- Gh17ls Es LCD Monitor SMDocument36 pagesGh17ls Es LCD Monitor SMmimelendezaNo ratings yet

- 1PPM Maintenance Package UnitDocument24 pages1PPM Maintenance Package UnitAhmad AlmhimidNo ratings yet

- MW 1150 WaDocument23 pagesMW 1150 WaKbs SinghNo ratings yet

- Maintenance and RepairsDocument6 pagesMaintenance and RepairsMakinde TosinNo ratings yet

- Transformer: Power/TractionDocument9 pagesTransformer: Power/Tractionappy sagarNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- CD-Ruby Preventive Maintenance ChecklistDocument6 pagesCD-Ruby Preventive Maintenance ChecklistLuis Felipe Fuentes LNo ratings yet

- Scope of WorkDocument3 pagesScope of WorkShah Aizat RazaliNo ratings yet

- Qc-Qcr-Ele-24 Power CircuitDocument1 pageQc-Qcr-Ele-24 Power CircuitRoderick HipolNo ratings yet

- Samsung TV LCD Ltm1525xDocument100 pagesSamsung TV LCD Ltm1525xJuan SanchezNo ratings yet

- Samsung Gd17as Gd17n Gd17aDocument64 pagesSamsung Gd17as Gd17n Gd17aluis francisco heras parragaNo ratings yet

- Samsung TV Service Manual PDFDocument98 pagesSamsung TV Service Manual PDFali83No ratings yet

- Test Report For Tripping Relay: 9,10 (86) 41.0 Hand ResetDocument2 pagesTest Report For Tripping Relay: 9,10 (86) 41.0 Hand ResetSubramaniam NPNo ratings yet

- RCG Electrical Equip Maint Guides 913 Bre PDFDocument4 pagesRCG Electrical Equip Maint Guides 913 Bre PDFBarney ParadoxNo ratings yet

- Medium-Voltage Circuit Breaker Maintenance: Special FeatureDocument2 pagesMedium-Voltage Circuit Breaker Maintenance: Special FeatureSing Yew LamNo ratings yet

- Planned Preventive Maintenance: Check List 1 2 3Document2 pagesPlanned Preventive Maintenance: Check List 1 2 3LaluAlwanNo ratings yet

- Microlok II System Maintenance Check List Rev 2 (1) .0 (3) - Merged PDFDocument7 pagesMicrolok II System Maintenance Check List Rev 2 (1) .0 (3) - Merged PDFSûmìt KúmãrNo ratings yet

- Task Assigned by HOD: Targets Deptt SBU 2nd SBU (If Any) Target Date Actual Score Status RemarksDocument1 pageTask Assigned by HOD: Targets Deptt SBU 2nd SBU (If Any) Target Date Actual Score Status RemarksZarkKhanNo ratings yet

- 1.0-Introduction: Technical Proposal R.O. SystemDocument13 pages1.0-Introduction: Technical Proposal R.O. SystemZarkKhanNo ratings yet

- Water Line DiagramDocument1 pageWater Line DiagramZarkKhanNo ratings yet

- Die & Mold MNT - MarDocument1 pageDie & Mold MNT - MarZarkKhanNo ratings yet

- Unit Population Popoulation Male Population Transgender Karachi Thatta HUB Hydrabad Jamshoro Female PopulationDocument2 pagesUnit Population Popoulation Male Population Transgender Karachi Thatta HUB Hydrabad Jamshoro Female PopulationZarkKhanNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum VitaeZarkKhanNo ratings yet

- China's Exports To Saudi ArabiaDocument20 pagesChina's Exports To Saudi ArabiaZarkKhanNo ratings yet

- Daily KWH ConsumDocument1 pageDaily KWH ConsumZarkKhanNo ratings yet

- Paint Workshop-3: Braced Bay Braced BayDocument1 pagePaint Workshop-3: Braced Bay Braced BayZarkKhanNo ratings yet

- Project PM Quality Control - Mar - SignedDocument1 pageProject PM Quality Control - Mar - SignedZarkKhanNo ratings yet

- Thin Film Solar Cell EfficiencyDocument9 pagesThin Film Solar Cell EfficiencyZarkKhanNo ratings yet

- Security Incident Report TemplateDocument3 pagesSecurity Incident Report TemplateZarkKhanNo ratings yet

- Cirp Journal of Manufacturing Science and Technology: Prakash Rao, Michael R. Muller, Garan GunnDocument8 pagesCirp Journal of Manufacturing Science and Technology: Prakash Rao, Michael R. Muller, Garan GunnZarkKhanNo ratings yet

- Factories Internal Project - MarchDocument1 pageFactories Internal Project - MarchZarkKhanNo ratings yet

- Power Sector - PACRA Research - Jan'21 - 1611329371Document36 pagesPower Sector - PACRA Research - Jan'21 - 1611329371ZarkKhanNo ratings yet

- 2016 Annual ReportDocument238 pages2016 Annual ReportZarkKhanNo ratings yet

- Embedded Systems Design: Andling Hybrid Task SetsDocument16 pagesEmbedded Systems Design: Andling Hybrid Task SetsZarkKhanNo ratings yet

- Plastic Button Manufacturing Rs. 16.03 Million Dec - 2020Document20 pagesPlastic Button Manufacturing Rs. 16.03 Million Dec - 2020ZarkKhanNo ratings yet

- TGL Annual 2017Document72 pagesTGL Annual 2017ZarkKhanNo ratings yet

- Pakistan Gas Pipeline NetworkDocument2 pagesPakistan Gas Pipeline NetworkZarkKhanNo ratings yet

- AC Drive Technology: An Overview For The Converting IndustryDocument12 pagesAC Drive Technology: An Overview For The Converting IndustrykatriNo ratings yet

- Cat 6a Futp Patch CordsDocument2 pagesCat 6a Futp Patch CordsMANUEL CASTRONo ratings yet

- Mx341 Avr Newage StamfordDocument4 pagesMx341 Avr Newage Stamfordabuzer1981No ratings yet

- KIA278R15PIDocument7 pagesKIA278R15PIIdrissa NikiemaNo ratings yet

- RLO CableDocument1 pageRLO CableLeiden O'SullivanNo ratings yet

- Geo Metri Ay To Polo GiaDocument4 pagesGeo Metri Ay To Polo GiaChaile Saint SebastianNo ratings yet

- Mercury Vapor Lamp PDFDocument7 pagesMercury Vapor Lamp PDFaryaNo ratings yet

- Multi Range, Double Time Adjusted Flasher Relay: FUNCTION (Operation Mode)Document1 pageMulti Range, Double Time Adjusted Flasher Relay: FUNCTION (Operation Mode)dhaferNo ratings yet

- Altivar 11 - ATV11HU18M2EDocument4 pagesAltivar 11 - ATV11HU18M2EPaulNo ratings yet

- Section - 16445 - Feeder PillarDocument3 pagesSection - 16445 - Feeder Pillarahmadove1100% (1)

- Analog Adjustable 2-Wire Transmitters: Apaq-HDocument1 pageAnalog Adjustable 2-Wire Transmitters: Apaq-HDariusNo ratings yet

- Unpacking and InstallationDocument17 pagesUnpacking and InstallationTran Thanh HungNo ratings yet

- EOCR Relay CatalogDocument4 pagesEOCR Relay CatalogSomnathNo ratings yet

- ET601 - Chapter 1Document25 pagesET601 - Chapter 1Thanaletchumy RamesamyNo ratings yet

- 25219145Document7 pages25219145Ammar SafwtNo ratings yet

- Automatic Voltage Stabilizer - Syed Tahmid MahbubDocument21 pagesAutomatic Voltage Stabilizer - Syed Tahmid Mahbubjewel768100% (2)

- EE 09 605 Electrical Engineering Drawing APR 2015Document2 pagesEE 09 605 Electrical Engineering Drawing APR 2015علي عائشةNo ratings yet

- Control Gear Price ListDocument15 pagesControl Gear Price ListShubham GuptaNo ratings yet

- Dual Power Source 1scc011008k0201Document2 pagesDual Power Source 1scc011008k0201Edison EstrellaNo ratings yet

- P - Chapter 7Document17 pagesP - Chapter 7usa2017lapNo ratings yet

- 8N70 UtcDocument9 pages8N70 UtcMike GhanemNo ratings yet

- EEC ImpDocument71 pagesEEC Imp166CMYashvardhan ShindeNo ratings yet

- Assignmentsolutionselected 150208132823 Conversion Gate02Document30 pagesAssignmentsolutionselected 150208132823 Conversion Gate02apelokayaNo ratings yet

- 2017 Winter Model Answer PaperDocument30 pages2017 Winter Model Answer PaperVaibhav ChaudharyNo ratings yet

- Bldutl2 - Building Utilities 2 Electrical, Electronic and Mechanical SystemsDocument10 pagesBldutl2 - Building Utilities 2 Electrical, Electronic and Mechanical Systemsgimel tenorioNo ratings yet