Professional Documents

Culture Documents

Risk Assessment Installation of MDB SMDB DB MCC

Uploaded by

aaktgt MepOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment Installation of MDB SMDB DB MCC

Uploaded by

aaktgt MepCopyright:

Available Formats

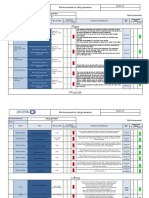

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 1 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

· TBT/DSTI to be conducted by the

foreman/ safety officer prior to work

commencement Low

· Unauthorized, · Cuts

1. Prepare work area 2 A L · Task specific safety training to be provided (ALARP)

untrained · Abrasions

workers · Authorized personnel to undertake the job

· Daily safety inspection should be carried and

eliminate the hazard.

· Any lifting tasks shall be carried out

by persons physically capable to do so

• No employee should be asked to carry loads

· Incorrect lifting of loads · Back Injuries above his capacity and in any case no load

shall exceed 30kg per man.

2. Manual Handling · Sharp edges. · Cut to finger Low

• Mass of the load is more then to be equally

· Placing the object · Strain 3 C M shared (ALARP)

while fingers underneath. • Musculoskeletal · Deploy enough number of personnel for

• Slip/trip/fall ( same level ) Injuries lifting shall be appointed to the task depending

• Unsafe posture upon the type of load to be lifted.

· Use easy mode of transport like trolley etc.

• Load not to be lifted above your

shoulder Height

• Keep your fingers away from pinch point

While placing the load

• Area to be illuminated with adequate lighting.

•Do not use pedestrian access for shifting

materials, tools by hand. It should be used

by through mechanical aids only.

· Proper personal protective equipments to

be used while manual handling of materials

and loads.

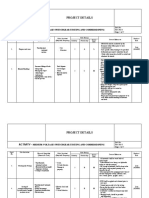

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 2 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• Prior to start obtain all relevant approval

from traffic department in connection to the

• Collision with vehicles • Fatality use of road.

Traffic and road • Poor identification • Property damage 4 B M • PTW to be approved Low

3. management • Unauthorized/ untrained • Fracture from Consultant/Contractor (ALARP)

Operator/ driver, banks prior to start the activity.

men • Trained and experienced operator/ driver and

• Poor access for vehicle banks men to be appointed for the activity.

• Public movement • Restricted to unauthorized and public to enter

the area.

• Public vehicles and transport to be restricted to

enter the work area and proper alternative way

to be provided.

• Warning sign boards to be placed and area to

be well barricaded.

• High visibility vest to be provided to flagman

to increase visibility.

• Flagman to be positioned to the areas wherever

required.

• Close supervision to be done at all times.

• Unauthorized, Untrained • Ensure the crane and forklift engaged is

Workers tested and havingvalid license and the operator

• Failure of lifting tools & has valid license and approved 3rd party

tackles. certificate.

• Failure of lifting • Fatality • Engage trained and certified banks man &

Unloading and shifting equipments. • Fractures rigger.

panels and accessories • Swinging of material • Property damage 4 C H • Barrication and warning signs in to the M

4. with using crane and • Damaged sling/wire rope or • Injury to personal area where lifting operation is carried out (ALARP)

forklift a chain sling • Sprain and strain and restrict the entry.

• Poor maintenance of vehicle • Check list should be carried out to their

• Speedy operation vehicles by the operator prior to start any

• Over turn work

• Over load • Use tagline for control of swing and alignment.

• The crane must be stopped when the

wind speed exceeds 38km/hr.

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 3 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• SWL should be clearly marked on the

crane and should be check that is

functioning.

• The crane and trucks shall be periodically

maintained and a periodical check has

been

done by the maintenance team.

· Vehicle not to be left unattended at site (ie,to be

switched off mode if required and keys

removed)

• SWL shall not be exceeded.

• Load should be secured properly with the

equipment.

• Operators and rigger must wear high level

of reflecting vest and adequate PPE ( Shoe,

helmet, leather gloves, goggles, over all )

· All materials shall be stored below 2

· Unauthorized, • Crush meter height.

untrained workers · Cut and abrasion ·If the material is too heavy, use hydraulic

5. Stacking and Storing 3 B M Low

· Material fall from height · Damage to trolley to shift the material.

(ALARP)

• Improper stacking property • No storage of materials to be done in the

• Collapse of materials work place, only required quantity to be taken

for the job.

• Personnel protective equipment must worn at

all time during the activity. (Helmet, shoe,

vest, overall, gloves, goggles, mask.)

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 4 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• Defective tools should not be issued or

• Slip, trip and fall used to perform the task, to be checked by

6. Working with Hand • Damaged warn out hand • Fatigue store keeper

tools. tools • Trigger finger 3 C M • Don’t extend the spanner by using a pipe Low

• Flying objects • Cuts and abrasions as an extension bar. (ALARP)

• Never use a file as a lever

• Never use a screw driver as a chisel

•Don’t work with oily or greased hands

• Use eye/ face protection when there is flying

materials hazard, wear gloves while required

to protect the hands

• Use right tools for the job

• PTW to be applied and obtained prior to

start, If spark producing activity is

performed

· Defective tools should not be issued or used

Defective equipment to perform a task.

Electricity Hearing losses • Monthly inspection should be carried out by the

Improper use of Eye injury electrician and record to be kept at the store

Working with power equipment Crushing · All portable power tools should be fitted M

7. tools (Grinder, Drill Poor maintenance Back injury 3 C M with adequate fuse protection either in the tool (ALARP)

machine ) Untrained workers Burns body or in its electrical plug.

Flying object Electrocution ·The weight, size and type of tool should

Noise and vibration Ringing in the be selected to suit the job being carried out.

Fire ear / Deafness • Don’t lay the cables around the access way, it

Dust should be proper routing

• Industrial distribution board and socket only

to be used at site

• No joints shall be made in electrical cable.

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 5 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• Trained and training card holding person

only to operate suitable power tools.

• Cable hangers shall be used to avoid the

direct contact of power tools cable with

the scaffolding members.

• Electrical connection shall be routed through

ELCB only.

• Correct rate of ELCB should be used (

Ex:- 30ma only acceptable)

· Only those persons who have been

adequately trained and experienced in the use

of the tool should be allowed to use the same.

Power tools shall have inspection sticker.

· Tools should be stored and maintained in

good working condition.

· Appropriate PPE Should use ( Goggles,

Mask, Ear plug, Gloves, Shoe, Helmet, Overall,

Vest )

• The ladder should extend minimum one

meter from the top for safe movement

• Heavy materials should not be carried

• Do not erect in slippery, uneven surface

• Should be set up with a 4 vertical to

• Person/ material falling • Sprain and strain 1 horizontal slope( 4:1 ) Low

from ladder • Fracture 3 C M • Inspection and maintenance to be registered (ALARP)

8. Working with ladder • Over reaching • Injury to the and recorded by the store keeper

• Over loading person • Step ladder must fully open and lock and the

• Obstructions overhead/ devices to be as per manufacturer

adjacent to work • Defective ladder should not be used and

location report it immediately

• Slippery or uneven surface • Do not work from the top of two rungs

• Remember the 3 point contact

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 6 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

•Do not work in front of the door. If work is

carried then lockedthe door or blocked off

• Ladder to be used for short duration works

only limited to 15 min.

• Colour coded system to be implemented

· Beware of overhead protrusions while

climbing up the ladder.

• Do not stack materials on to the scaffold

• Visual inspection should carry before use

• Out rigger fitted and breaks are locked on

• Only trained scaffolders shall be involved

• Uneven surface • Sprain and strain in erection & dismantling activities.

• Overhead structure and cable • Fracture • No person to be on the scaffold while it Low

• Materials and worker fall • Spinal cord damage 3 C M is being moved (ALARP)

Working on mobile from height • Musculoskeletal • Scaffold only use in on level and surface area

9. scaffold • Untrained, Injury • Safety harness to be used above 2mtr height

unauthorized Workers • Fatality and anchored in above shoulder height at all

• Collapse of scaffold time

• Tagging system to be implemented ( i.e., all

safe scaffolds shall be provided with green

tags and unsafe scaffolds with red tag )

• Keep walkways free of obstacles, tools

and Equipment

• Never stand and sit on the hand rails

• Mobile scaffold height should be restricted to

3.5 to 4 times the shortest base width, If height

of scaffold exceeds raker support or it should be

tied to the structure properly.

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 7 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

• PTW to be applied and obtained prior

to start work

• Authorized person to do the job.

· Rigidbarrication and toe board to be provided

· Material/equipment · Fatality

10. Working in near floor to all external edges and where a fallcan Low

openings fall from height · PropertyDamage 4 B M (ALARP)

occur.

· Slip/trip/fall • Fracture • Warning signboards to be provided in those

areas.

· PPE to be used at all times ( Helmet,

Shoes, Vest, Overall, Harness )

· Authorized personnel to undertake the job

• Work location shall be inspected

• Untrained, unauthorized • Cut and abrasion by concerned supervisor / foreman.

Installation of panels, Workers • Back Injuries • Close supervision to be done at all times Low

11. glanding, termination • Material Fall • Fatigue 3 C M • Materials should not be kept in walkways (ALARP)

• Sharp edges • Musculoskeletal and edge of the opening.

• Unsafe posture Injuries • Proper communication to be

• Slip, trip and fall maintained between the workers while

doing the installation.

• Maintain a good housekeeping policy

to prevent from slip, trip, fall hazards.

• PPE to be worn at all times( Gloves, goggles,

mask, helmet, shoe, vest, overall)

• Emergency procedure to be briefed to all

personnel prior to start the activity.

• Emergency evacuation plan shall be readily

available according to site condition and briefed

to the workforce prior to start.

• Trained first aider, fire warden and emergency

vehicle to be available at the site during the

activity.

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 8 of 9

Serial Sub-Activities Risk Rating

No. Hazards Identified Risks Involved Residual

Initial Control Measures

(Generic & Task) (People & Property) Severity Probability Risk

Risk

· Dehydration · Drink plenty of water Low

12. Working in hot · Heat Stress · Sunburn 2 B M · Employees shall be trained about (ALARP)

weather · Skin Cancer heat stress symptoms & first aid

measures.

· Avoid highly physical tasks during the hottest

part of the day

· Isotonic drinks to be provided

· Proper illumination to be provided

· Poor illumination · Fatality · light post to be secured from fall Low

13. While working at night · Slip/trip/fall • Cuts 3 B M · Proper cable management system to (ALARP)

shift

be Followed

· All materials to be staged in proper manner

without obstacles

· General housekeeping, Remove all

· Poor housekeeping surface, unwanted waste materials from the Low

14. Work Completion · Slip/trip/fall · Fire 2 A L building (ALARP)

· All necessary precautions will be adopted to

prevent fire

PROJECT DETAILS

Ref No:

ACTIVITY– Installation of MDB, SMDB, DB, MCC& CB Rev.No:0

Page 9 of 9

CONSULTANT RISK MATRIX

Probability

A B C D E

Improbable 1 in 100,000 Remote 1 in 10,000 Occasional 1 in 1000

Years Years years

Severity People Assets Environment Reputation Probable Frequent

1 in 100 years 1 in 10 years

Multiple fatalities or permanent total disabilities

Extensive damage International impact

5-Catatrophic Massive effect

Single fatalities or permanent total disabilities High Risk

Major damage

4-Severe Major effect National impact

Major injury or health effects Medium Risk (ALARP)

3-critical Local damage Localised effect Considerable impact

Minor injury or

health effects

2-Marginal Minor damage Minor effect Minor impact

Slight injury or health

Slight

effects

Damage Low Risk

1-Negligble Slight effect Slight impact

3-E

HIGH 4- C,D,E

5- B,C,D,E

1- D,E

2- B,C,D,E

3- A,B,C,D

MEDIUM 4- A,B

5-A

LOW 1-A,B,C

2A

You might also like

- For CABLE TRAY AssessmentDocument10 pagesFor CABLE TRAY AssessmentIliyanPetrovNo ratings yet

- HIRA - MS Staircase ErectionDocument7 pagesHIRA - MS Staircase ErectionRamNo ratings yet

- Risk Assessment Backfilling Around Foul Sewer and Storm Warter ManholesDocument8 pagesRisk Assessment Backfilling Around Foul Sewer and Storm Warter ManholesMidhunRameshThuvasseryNo ratings yet

- JSA #32 Manual HandlingDocument1 pageJSA #32 Manual HandlingSubham Sohal100% (2)

- JSA For SRP Instolation and DismentlingDocument17 pagesJSA For SRP Instolation and DismentlingShekh BabulNo ratings yet

- Tower CarneDocument2 pagesTower CarnenabeelNo ratings yet

- Crane Lift RAMsDocument18 pagesCrane Lift RAMsKaren Olivier100% (1)

- Jha - Working at HeightDocument11 pagesJha - Working at HeightAliff Apam100% (1)

- 07 Manual Excavations & Exposing of Underground FacilitiesDocument6 pages07 Manual Excavations & Exposing of Underground FacilitiesPangky Abasolo100% (1)

- ROO-HSE-PRO-0052 REV 12 - Lifting Operations - Eng - CompressedDocument157 pagesROO-HSE-PRO-0052 REV 12 - Lifting Operations - Eng - CompressedMohamad sharul nizam RusliNo ratings yet

- JSA For ExcavationsDocument3 pagesJSA For ExcavationsHSE fahadNo ratings yet

- 11 Construction of Kill LineDocument9 pages11 Construction of Kill LinePangky AbasoloNo ratings yet

- IndexDocument107 pagesIndexAina RazafimandimbyNo ratings yet

- Hazards and Risks: How To Identify and Rate ThemDocument28 pagesHazards and Risks: How To Identify and Rate ThemPhillip LNo ratings yet

- Environment PlanDocument13 pagesEnvironment Planhariom singh chaudhary100% (1)

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- Plant 6 3: Risk Assessment For Lifting OperationsDocument4 pagesPlant 6 3: Risk Assessment For Lifting OperationsIdris AdeniranNo ratings yet

- Emediong U. - Risk Assessment Matrix 1 WorkingDocument20 pagesEmediong U. - Risk Assessment Matrix 1 WorkingsterlingNo ratings yet

- RA For Installation of Fuel SystemDocument7 pagesRA For Installation of Fuel SystemAdel MorsyNo ratings yet

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- Rmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)Document1 pageRmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)myn maliQueNo ratings yet

- Roof Sheeting JSADocument6 pagesRoof Sheeting JSAJogendra BeharaNo ratings yet

- Precast Erection JSWDocument6 pagesPrecast Erection JSWPrabhakaran GurunathanNo ratings yet

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetYounis KhanNo ratings yet

- 2.4 Attachments - Risk Assessment and Method StatementDocument10 pages2.4 Attachments - Risk Assessment and Method StatementFahad MaqsoodNo ratings yet

- JHA CoatingDocument9 pagesJHA Coatingبسام كريم100% (1)

- J S A Extract Fan InstallationDocument3 pagesJ S A Extract Fan InstallationASLAM MULANINo ratings yet

- JSA - De-ShutteringDocument10 pagesJSA - De-ShutteringRaju0% (1)

- 14 Construction of Optf LineDocument9 pages14 Construction of Optf LinePangky AbasoloNo ratings yet

- 001 - SWMS - Crane Operations - FrannaDocument11 pages001 - SWMS - Crane Operations - FrannaNathan StokerNo ratings yet

- Hard Land Scape Risk AssessmentDocument4 pagesHard Land Scape Risk AssessmentvivekanandhanNo ratings yet

- Work at Height ChecklistDocument4 pagesWork at Height ChecklistSanil KuriakoseNo ratings yet

- Tele HandlerDocument30 pagesTele HandlerArturNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (06) Template SettingDocument13 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (06) Template Settingmohammed tofiqNo ratings yet

- Risk Assessment Work at Height ExpertiseDocument8 pagesRisk Assessment Work at Height ExpertiseyasirNo ratings yet

- SEM 655D T2 Operation Maintenance Manual-V1-20190729 - EN - 20220304082530173 - 1679222018Document89 pagesSEM 655D T2 Operation Maintenance Manual-V1-20190729 - EN - 20220304082530173 - 1679222018Deni Moch IchsanNo ratings yet

- Sample Project DASHBOARD REPORT - 03th October 2022 Construction WEEK No. 26Document1 pageSample Project DASHBOARD REPORT - 03th October 2022 Construction WEEK No. 26moes83No ratings yet

- 13 Construction of Blower LineDocument7 pages13 Construction of Blower LinePangky AbasoloNo ratings yet

- Drilling Rig ChecklistDocument33 pagesDrilling Rig Checklistmr_heera75% (4)

- RCDSO Infection ControlDocument56 pagesRCDSO Infection ControlsnaniraqNo ratings yet

- HSE Documents-Fit-Out Work-Ris AssessmentDocument3 pagesHSE Documents-Fit-Out Work-Ris AssessmentTom BobanNo ratings yet

- Lifting Plan Mobie Crane Unloading RebarDocument3 pagesLifting Plan Mobie Crane Unloading Rebarlutfi100% (1)

- 022 - Bored Cast in Place Concrete Piles - Night WorksDocument15 pages022 - Bored Cast in Place Concrete Piles - Night WorksMohammed Adnan100% (1)

- Lift Plan - Method Statement - Risk Assessment - SafetyCultureDocument21 pagesLift Plan - Method Statement - Risk Assessment - SafetyCulturebalachander100% (1)

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- Binder Spine Indexing SlipsDocument4 pagesBinder Spine Indexing Slipspundir_vineetNo ratings yet

- 2.LOAD CHART AT-22 T133750C (Color) PDFDocument21 pages2.LOAD CHART AT-22 T133750C (Color) PDFRoy Ferdy MassoloNo ratings yet

- JSA of Materila Handling ApproviedDocument2 pagesJSA of Materila Handling Approviedsakthi venkatNo ratings yet

- Method of Statement For Installation of Gi Boxes Yas AcresDocument12 pagesMethod of Statement For Installation of Gi Boxes Yas AcresGufran TariqNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- Risk Assessment Switchgear Testing CommissioningDocument7 pagesRisk Assessment Switchgear Testing Commissioningaaktgt Mep100% (1)

- Risk Assessment Switchgear Testing CommissioningDocument7 pagesRisk Assessment Switchgear Testing Commissioningaaktgt Mep100% (1)

- Risk Assessment Fire Hydrant Installation Testing CommissioningDocument11 pagesRisk Assessment Fire Hydrant Installation Testing CommissioningAmie GTunedNo ratings yet

- Metod of Staitment CDP (Pasha Construction)Document7 pagesMetod of Staitment CDP (Pasha Construction)GurbanNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- CBLM MasonryDocument188 pagesCBLM MasonryDanilo Bersaba100% (4)

- Nfpa 70e Tutorial Rev 10 With MTM and Aramco PDFDocument212 pagesNfpa 70e Tutorial Rev 10 With MTM and Aramco PDFMohamed rasheedNo ratings yet

- Risk Assessment Fire Hydrant Installation Testing CommissioningDocument11 pagesRisk Assessment Fire Hydrant Installation Testing CommissioningTorre 11 Departamento 1808No ratings yet

- En Allround Delekatalog 2017Document68 pagesEn Allround Delekatalog 2017Hanafiah RozaliNo ratings yet

- SS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Document5 pagesSS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Farhat SetharNo ratings yet

- Risk Assessments - Offloading-Transportation& Lifting Operation - ADFI-GFTS-CESDocument7 pagesRisk Assessments - Offloading-Transportation& Lifting Operation - ADFI-GFTS-CESIbrahim EsmatNo ratings yet

- Fabrication Work Risk AssessmentDocument7 pagesFabrication Work Risk Assessmentrahul jadhavNo ratings yet

- 38 Through Installation Job Safe Practice Ladder and Rack InstallationDocument1 page38 Through Installation Job Safe Practice Ladder and Rack InstallationsalmanNo ratings yet

- Risk Assessment / Method Statement Form: (Please)Document5 pagesRisk Assessment / Method Statement Form: (Please)Sham AranNo ratings yet

- General Consideration For Stacking and StorageDocument4 pagesGeneral Consideration For Stacking and StorageSiddhantShrivastavNo ratings yet

- PEMA IP14 Crane Operator Health SafetyDocument8 pagesPEMA IP14 Crane Operator Health SafetyCasopis SafetyNo ratings yet

- SWP Working Safely at Height Version 2.01Document7 pagesSWP Working Safely at Height Version 2.01marvinNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Attachment 2A Driver Safety GuideDocument22 pagesAttachment 2A Driver Safety GuideNoor Aimi Ayunie Mohd AzmiNo ratings yet

- DevicorebbtDocument1 pageDevicorebbtDaviss Pauca Morón100% (1)

- Ramp Stats Batha Land Port 20-07-2023-FinalDocument15 pagesRamp Stats Batha Land Port 20-07-2023-Finalaaktgt MepNo ratings yet

- Fiber Duct Progress-Albatha Landport-27!05!2023Document9 pagesFiber Duct Progress-Albatha Landport-27!05!2023aaktgt MepNo ratings yet

- Fans 3 PDFDocument1 pageFans 3 PDFaaktgt MepNo ratings yet

- Fans 1 PDFDocument1 pageFans 1 PDFaaktgt MepNo ratings yet

- Fans 2 PDFDocument2 pagesFans 2 PDFaaktgt MepNo ratings yet

- QS Dept. Roles and ResponsibilitiesDocument6 pagesQS Dept. Roles and Responsibilitiesaaktgt MepNo ratings yet

- IMS 467-QTR - Lighting Illumination Level Test Record Sheet Rev01Document1 pageIMS 467-QTR - Lighting Illumination Level Test Record Sheet Rev01aaktgt MepNo ratings yet

- ASW0401Document1 pageASW0401aaktgt MepNo ratings yet

- 31-Miroled (3) 2Document2 pages31-Miroled (3) 2aaktgt MepNo ratings yet

- 04 CAnyaeche Project Progress Template NIIErev 226 TH April 2012Document13 pages04 CAnyaeche Project Progress Template NIIErev 226 TH April 2012aaktgt MepNo ratings yet

- Health and Safety FileDocument3 pagesHealth and Safety Fileaaktgt MepNo ratings yet

- Method Statement For Split AC Manufacturers Installation DetailsDocument77 pagesMethod Statement For Split AC Manufacturers Installation Detailsaaktgt MepNo ratings yet

- SWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Document8 pagesSWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Md Shahbaz AlamNo ratings yet

- Electric Shock Can Kill YouDocument6 pagesElectric Shock Can Kill YoutemterNo ratings yet

- HIRA-Shaft Cable Tray N Cable InstallationDocument2 pagesHIRA-Shaft Cable Tray N Cable InstallationDivakar DhandeNo ratings yet

- Chromium Propionate 0.4% SDSDocument7 pagesChromium Propionate 0.4% SDSratatrampa25No ratings yet

- MSDS - TDS Vitamin ComplexDocument3 pagesMSDS - TDS Vitamin ComplexDominique WNo ratings yet

- MSDS Op62Document4 pagesMSDS Op62K QuispeNo ratings yet

- TVL CSS G11-Q1-M10-No CoverDocument10 pagesTVL CSS G11-Q1-M10-No CoverSergio B. Goco Jr.No ratings yet

- Nitrogen (Refrigerated) : Safety Data SheetDocument10 pagesNitrogen (Refrigerated) : Safety Data SheetiAnodisedNo ratings yet

- Process Engineering - Capstone Project Deliverable 2Document14 pagesProcess Engineering - Capstone Project Deliverable 2Harsh Sujit Kondkar ch18b109No ratings yet

- C122S2NL - 2 - USANSI C Flex 45 RedDocument11 pagesC122S2NL - 2 - USANSI C Flex 45 RedblpovedaNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- MDC COVID-19 Mandatory Health - Safety Protocols Upon Work Resumption - V4 20200507Document14 pagesMDC COVID-19 Mandatory Health - Safety Protocols Upon Work Resumption - V4 20200507Russell RaferNo ratings yet

- Lawson Products, Inc - Non-Flammable Penetrating OilDocument4 pagesLawson Products, Inc - Non-Flammable Penetrating Oiljaredf@jfelectric.comNo ratings yet

- Nitric AcidDocument6 pagesNitric Acidyayax_619No ratings yet

- Tle 7 - 8 Curriculum MapDocument11 pagesTle 7 - 8 Curriculum MapKristianTubagaNo ratings yet

- Pine Data SheetDocument6 pagesPine Data Sheetabdoamer.2553No ratings yet

- Ppe'S Daily Safety Inspection Form: Shibh Al Jazira Contracting Company Qhse DepartmentDocument2 pagesPpe'S Daily Safety Inspection Form: Shibh Al Jazira Contracting Company Qhse DepartmentJojit PalomenoNo ratings yet

- Personal Protective Equipment: Health Safety and Environment Training CourseDocument97 pagesPersonal Protective Equipment: Health Safety and Environment Training CourseBecha MouradNo ratings yet

- Diethylene GlycolDocument5 pagesDiethylene Glycolsatnam1979No ratings yet

- Vanillin MSDSDocument1 pageVanillin MSDSSkathir VelNo ratings yet

- Health and Safety in Cement Industry: June 2022Document7 pagesHealth and Safety in Cement Industry: June 2022shibanand.pandaNo ratings yet