100% found this document useful (2 votes)

2K views4 pages11.method Statement - SS Railing With Glass-GFM

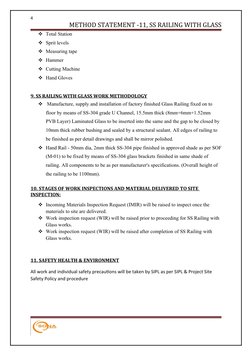

This method statement describes the process for installing stainless steel railings with glass for the Godrej Fund Management Building in Bangalore. It involves supplying and fixing laminated glass panels and stainless steel pipes. Quality control checks will be performed on delivered materials. Railings will be installed in sections and inspections will occur at key stages. Worker safety precautions will follow the project site's safety policy.

Uploaded by

Shyam SutharCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

2K views4 pages11.method Statement - SS Railing With Glass-GFM

This method statement describes the process for installing stainless steel railings with glass for the Godrej Fund Management Building in Bangalore. It involves supplying and fixing laminated glass panels and stainless steel pipes. Quality control checks will be performed on delivered materials. Railings will be installed in sections and inspections will occur at key stages. Worker safety precautions will follow the project site's safety policy.

Uploaded by

Shyam SutharCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd