Professional Documents

Culture Documents

Anchoring Operation Check List-Page1

Uploaded by

Jim JimiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchoring Operation Check List-Page1

Uploaded by

Jim JimiCopyright:

Available Formats

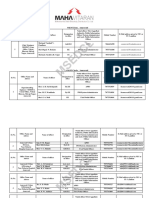

Anchoring operation check list

Yes No

:A-PRE-operation maintenance

1-After each letting go or longer standstills period basic setting of brake adjustment,

Readjusted if necessary.

2-Has the windlass been tested within last 30 days if no extra care to be taken.

Easy going of spindle band brake should be checked at regular interval (once -3

A month )

4- Has maintenance been done as per makers instruction book if not following

To be done:

a) Ensure the brake lining is 9mm or more and in no case to be less than the

brake lining thickness table given in the makers manual.

b) Ensure the brake drum is smooth , with no build up of rust or resin , use

frequently ,or use needle gun plus pneumatic wire brush )

c) Ensure ALL bearing and joint are FULL of grease ,with no grit or rust in ,

avoid in excess of grease entering under brake lining .

d) Ensure that hydraulic oil is at correct level and working pressure .

e) Ensure hydraulic filters are clean with no metal particles in ( metal particles

are an indication of past overload )

f) Ensure the brake lead screw and nut are clean and greased.

5- Both company procedure manual and maker instruction to be comply with.

6-Are the brake adjustments in the middle of the range not near permissible limit

7- Anchoring operation has been considered as critical operation and guillotines,

Are made to withstand 80 % of anchor chain proof load and make sure seat

Properly with anchor in housed otherwise seek for rectifying it before vessel

Departure .

8- Cable lifter brake designed to take 45% anchor chain proof load, note

Proof load are 86% (UTS) ultimate tensile strength.

9- During operation listen to transmission of abnormal gear wheel noise ,bearings,

Motors And check for overheating.

10- All windlass maintenance back ground such as weekly, monthly , yearly

Checking and overhauling of the machinery has done & recorded properly.

11- Equal number of use for both port and starboard anchor has been

considered that not any anchor being over worked than the other one.

12-Hydraulic system and performance of both winch and windlass has been

Checked by the chief engineer.

13- Chief officer to be familiar with equipment and has read the maker manual

And to make sure boson and crew are familiar to work with winch/windlass.

14- When replacing the brake lining change both upper and lower liners and

Re-adjust simultaneously.

15 –Overall condition of anchor flukes ,crown, crown pin ,retaining pins, shank

To be checked before being use.

16- Check mating surface of brake lining and new liners should be bedded in

Before use.

17- cable stopper should be able to carry approximately twice the proof load of

Anchor chain, check no sign of crack or weakness and gaps > 25mm.

18- windlass brake holding power is approximately half breaking strength of

The anchor chain , check if properly maintained thickness and adjusted.

(1 of 5)

You might also like

- Bendix Brake BoosterDocument6 pagesBendix Brake BoosterDarshan MakwanaNo ratings yet

- INTRO TO ICTs PDFDocument472 pagesINTRO TO ICTs PDFReigning Terror100% (2)

- JCB 3DX Maintenance ManualDocument12 pagesJCB 3DX Maintenance ManualDavid Palash100% (2)

- Free File StorageDocument9 pagesFree File Storageapi-3721188100% (1)

- 6.4. Tulsa Service ManualDocument33 pages6.4. Tulsa Service Manualdandisy100% (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Crane InspectionDocument234 pagesCrane InspectionAyman64100% (11)

- Braden BG8A BG8B Installation Mainenance and Service ManualDocument31 pagesBraden BG8A BG8B Installation Mainenance and Service ManualAnibal Jose Cruz Larez100% (2)

- Crane ProceduresDocument67 pagesCrane ProceduresKen RanggaNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- The Platform of Choice: Stevenson, Manufacturer of The FMTV A1, Is Proud To Support The UnitedDocument4 pagesThe Platform of Choice: Stevenson, Manufacturer of The FMTV A1, Is Proud To Support The UnitedppNo ratings yet

- Operation and Maintenance DamperDocument4 pagesOperation and Maintenance DamperBharatsinh ChauhanNo ratings yet

- Cat d8tDocument8 pagesCat d8tAlex I FBNo ratings yet

- Conveyor Belt ProjectDocument7 pagesConveyor Belt ProjectSameh TelebNo ratings yet

- Installation, Maintenaince and Service Braden PD15B, PD12C, PD17ADocument39 pagesInstallation, Maintenaince and Service Braden PD15B, PD12C, PD17ALázaro ConcepcionNo ratings yet

- Maintenance Management 30Document8 pagesMaintenance Management 30Hemant SharmaNo ratings yet

- Kalmar Reachstacker Park Brake Failure AnalysisDocument15 pagesKalmar Reachstacker Park Brake Failure AnalysisElgrego Wayne Swartz100% (1)

- Lathe Machine Safety OperatingDocument4 pagesLathe Machine Safety Operatingebad100% (1)

- Hydraulics: Safe Practice GuideDocument76 pagesHydraulics: Safe Practice GuideNadeem Nadeem100% (1)

- Big Data Module 2Document31 pagesBig Data Module 2Mahmoud ElnahasNo ratings yet

- CHAPTER 13 Design Criteria - Drafting Guidelines Rev 0Document139 pagesCHAPTER 13 Design Criteria - Drafting Guidelines Rev 0jahanzebafzal100% (1)

- AlstomDocument82 pagesAlstomaqsa63967% (3)

- Tle-Epas: Preparing and Interpreting Technical Drawings (PITD)Document26 pagesTle-Epas: Preparing and Interpreting Technical Drawings (PITD)RhodaCastilloNo ratings yet

- Modbus Communication For RTU SlavesDocument15 pagesModbus Communication For RTU SlavesZishan TyagiNo ratings yet

- Outside Vehicle: General MaintenanceDocument9 pagesOutside Vehicle: General Maintenanceapi-3833108No ratings yet

- Commissioning Procedure (Diesel Prime Mover)Document4 pagesCommissioning Procedure (Diesel Prime Mover)Foros IscNo ratings yet

- 8 Tips Memastikan Mooring Winch & Anchor Windlass Berfungsi Dengan SempurnaDocument3 pages8 Tips Memastikan Mooring Winch & Anchor Windlass Berfungsi Dengan SempurnaOctavian YudhaNo ratings yet

- 302 Cat Service ScheduleDocument3 pages302 Cat Service ScheduleNathan PittsNo ratings yet

- Lembar Inspeksi Bell 412 600 FH 12 MonthDocument6 pagesLembar Inspeksi Bell 412 600 FH 12 MonthReza Setyo PermadiNo ratings yet

- December 2009 Edition AnglaiseDocument247 pagesDecember 2009 Edition Anglaisedfry wsertstsxNo ratings yet

- Outside Vehicle: General MaintenanceDocument9 pagesOutside Vehicle: General MaintenanceCharly CastroNo ratings yet

- Manual de Instalación y Mantenimiento - Transmisiones Con Correas SKFDocument24 pagesManual de Instalación y Mantenimiento - Transmisiones Con Correas SKFeder pariapaza justoNo ratings yet

- MotorDocument4 pagesMotorjoaofelippejsaNo ratings yet

- Installation Operation and Maintenance GuideDocument21 pagesInstallation Operation and Maintenance GuideAscencio RubenNo ratings yet

- OSHA ChecklistDocument2 pagesOSHA ChecklistCésar Augusto Quiroga MontenegroNo ratings yet

- Warning: Inspection, Testing, Preventive Maintenance and Special Operating Instructions For Planetary HoistsDocument8 pagesWarning: Inspection, Testing, Preventive Maintenance and Special Operating Instructions For Planetary HoistsPedro RiveraNo ratings yet

- Boilers: 9-1. Minimum Maintenance Activities For BoilersDocument12 pagesBoilers: 9-1. Minimum Maintenance Activities For BoilersLacshay ShekharNo ratings yet

- Axial Split Volute Case PumpsDocument21 pagesAxial Split Volute Case Pumpshardik sakariya100% (1)

- Observe and ObeyDocument3 pagesObserve and ObeyMalaravan RamNo ratings yet

- Royal Enfield Bullet 1995 Owners ManualDocument109 pagesRoyal Enfield Bullet 1995 Owners ManualAndrea De SantisNo ratings yet

- Re 07900Document2 pagesRe 07900muhammadNo ratings yet

- Outside Vehicle: General MaintenanceDocument10 pagesOutside Vehicle: General Maintenancekywheat3306No ratings yet

- Section 8 Maintenance and Repair: Safety Storing ComponentsDocument22 pagesSection 8 Maintenance and Repair: Safety Storing ComponentsJonathanDavidDeLosSantosAdornoNo ratings yet

- Irector General Border Roads General Maintenance Instruction No. 241 On Operation and Maintenance of Concrete Mixer Gamzen 750 RDDocument8 pagesIrector General Border Roads General Maintenance Instruction No. 241 On Operation and Maintenance of Concrete Mixer Gamzen 750 RDBrajnandan AryaNo ratings yet

- AMWDocument14 pagesAMWSudeesh BabuNo ratings yet

- V Belt Replacement Work Instructions - ENDocument24 pagesV Belt Replacement Work Instructions - ENfendy_wu100% (1)

- Outside Vehicle: General MaintenanceDocument8 pagesOutside Vehicle: General MaintenanceDean BNo ratings yet

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- Outside Vehicle: General MaintenanceDocument8 pagesOutside Vehicle: General MaintenanceTung NguyenNo ratings yet

- MaintenanceInformation 6CylVeradoDocument25 pagesMaintenanceInformation 6CylVeradocombaheeNo ratings yet

- Discuss The Pre-Operative Check-Up of Tools, Implements and Equipment - October 17, 2023Document21 pagesDiscuss The Pre-Operative Check-Up of Tools, Implements and Equipment - October 17, 2023peterNo ratings yet

- Mercury 115 Manual 1bDocument13 pagesMercury 115 Manual 1bMomed MdNo ratings yet

- Top Drive Drilling Equipment: HSE ManualDocument17 pagesTop Drive Drilling Equipment: HSE ManualAlejandro HernadezNo ratings yet

- Inspection and Maintenance of Mechanical Power Presses: National Safety Council Data Sheet 603 Rev. July 2004Document9 pagesInspection and Maintenance of Mechanical Power Presses: National Safety Council Data Sheet 603 Rev. July 2004Emrah AkcayNo ratings yet

- MaintenanceInformation 4CylVeradoDocument27 pagesMaintenanceInformation 4CylVeradocombaheeNo ratings yet

- Sam Industries PumpDocument52 pagesSam Industries PumpHunney KotiyaNo ratings yet

- Customer & Dealer Responsibilities For Cat Extra LVL 3Document2 pagesCustomer & Dealer Responsibilities For Cat Extra LVL 3purwa cuteNo ratings yet

- dp7490 Pump ManualDocument16 pagesdp7490 Pump Manualvipequi50No ratings yet

- Royal Enfield Bullet Workshop Manual PDFDocument110 pagesRoyal Enfield Bullet Workshop Manual PDFdyna1450hotmail.frNo ratings yet

- Vmax Owner Period Maint1Document12 pagesVmax Owner Period Maint1bobbyr456No ratings yet

- Chapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1Document75 pagesChapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1carmen solanoNo ratings yet

- Installation, Operation and Maintenance Manual: CRANE® Cast Steel ValvesDocument44 pagesInstallation, Operation and Maintenance Manual: CRANE® Cast Steel ValveszumrottNo ratings yet

- 9852 1398 01a Maintenance Instructions COP 1532Document18 pages9852 1398 01a Maintenance Instructions COP 1532Helver Mauricio Valbuena FarfanNo ratings yet

- Braden CH330A ServiceDocument35 pagesBraden CH330A ServiceHarry Leonardy SihiteNo ratings yet

- Posted Swamp Buggy SpecsDocument11 pagesPosted Swamp Buggy SpecsdakidofdaboomNo ratings yet

- Braden Winch PD15B PDFDocument40 pagesBraden Winch PD15B PDFAlex BravoNo ratings yet

- Manual For Hand Portable Halon 1211 ExtinguishersDocument8 pagesManual For Hand Portable Halon 1211 ExtinguishersSerge aswadNo ratings yet

- Braden - Service BulletinDocument5 pagesBraden - Service BulletinRafael MonteiroNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Candidate's Name: Ports and Maritime Organization Seafarer's Examination and Certification DirectorateDocument1 pageCandidate's Name: Ports and Maritime Organization Seafarer's Examination and Certification DirectorateJim JimiNo ratings yet

- Voyagepl Anni NG: Solas Chapt Er5, Annexes24&25Document7 pagesVoyagepl Anni NG: Solas Chapt Er5, Annexes24&25Jim JimiNo ratings yet

- Celestial EaxmDocument6 pagesCelestial EaxmJim JimiNo ratings yet

- Anchoring Operation Check List-Page - 3Document1 pageAnchoring Operation Check List-Page - 3Jim JimiNo ratings yet

- 4 5778432790831826446Document1 page4 5778432790831826446Jim JimiNo ratings yet

- As An Officer in Charge of Cargo Watch On An RO-RO Ship Gives Important Points You Would Consider During Discharging Cars?Document1 pageAs An Officer in Charge of Cargo Watch On An RO-RO Ship Gives Important Points You Would Consider During Discharging Cars?Jim JimiNo ratings yet

- Anchoring Operation Check List-Page 2Document1 pageAnchoring Operation Check List-Page 2Jim JimiNo ratings yet

- Emergency and Contingency ManualDocument83 pagesEmergency and Contingency ManualJim JimiNo ratings yet

- Air Mass Properties: - Tropical, Polar, Arctic - Maritime, ContinentalDocument10 pagesAir Mass Properties: - Tropical, Polar, Arctic - Maritime, ContinentalJim JimiNo ratings yet

- Ports and Maritime Organization Seafarers' Examination and Certification DirectorateDocument1 pagePorts and Maritime Organization Seafarers' Examination and Certification DirectorateJim JimiNo ratings yet

- Candidate's NameDocument1 pageCandidate's NameJim JimiNo ratings yet

- Briefly Describe Following : Seafarers' Examination and Documents DirectorateDocument1 pageBriefly Describe Following : Seafarers' Examination and Documents DirectorateJim JimiNo ratings yet

- نﻮﻣزآ مﺎﻧ: ﻲﺘﺸﻛ نﺎﻤﺘﺧﺎﺳ و لدﺎﻌﺗ ﺦﻳرﺎﺗ: 1392.03.08 ﻪﺟرد: زاﺮﺘﻤﻛ هﺪﻧﺎﻣﺮﻓ 3000 - ﻞﺣﺎﺳ ﻪﺑ ﻚﻳدﺰﻧ يﺎﻫﺮﻔﺳ نﺎﻣز: 5 / 2 ﺖﻋﺎﺳ (Pass mark: 55)Document1 pageنﻮﻣزآ مﺎﻧ: ﻲﺘﺸﻛ نﺎﻤﺘﺧﺎﺳ و لدﺎﻌﺗ ﺦﻳرﺎﺗ: 1392.03.08 ﻪﺟرد: زاﺮﺘﻤﻛ هﺪﻧﺎﻣﺮﻓ 3000 - ﻞﺣﺎﺳ ﻪﺑ ﻚﻳدﺰﻧ يﺎﻫﺮﻔﺳ نﺎﻣز: 5 / 2 ﺖﻋﺎﺳ (Pass mark: 55)Jim JimiNo ratings yet

- Ports and Maritime Organization Seafarers' Examination and Certification DirectorateDocument1 pagePorts and Maritime Organization Seafarers' Examination and Certification DirectorateJim JimiNo ratings yet

- Ports and Maritime Organization Seafarers' Examination and Documents DirectorateDocument2 pagesPorts and Maritime Organization Seafarers' Examination and Documents DirectorateJim JimiNo ratings yet

- Ports and Maritime Organization Seafarers' Examination and Certification DirectorateDocument1 pagePorts and Maritime Organization Seafarers' Examination and Certification DirectorateJim JimiNo ratings yet

- Candidate's Name: Ports and Maritime Organization Seafarer's Examination and Certification DirectorateDocument1 pageCandidate's Name: Ports and Maritime Organization Seafarer's Examination and Certification DirectorateJim JimiNo ratings yet

- 1393.09.11 Exam Code: SMCN - 936: Ports and Maritime Organization Seafarers' Examination and Documents DirectorateDocument1 page1393.09.11 Exam Code: SMCN - 936: Ports and Maritime Organization Seafarers' Examination and Documents DirectorateJim JimiNo ratings yet

- Candidate's Name: Ports and Maritime Organization Seafarer's Examination and Certification DirectorateDocument1 pageCandidate's Name: Ports and Maritime Organization Seafarer's Examination and Certification DirectorateJim JimiNo ratings yet

- Seafarers' Examination and Certification DirectorateDocument1 pageSeafarers' Examination and Certification DirectorateJim JimiNo ratings yet

- Seafarers' Examination and Certification DirectorateDocument2 pagesSeafarers' Examination and Certification DirectorateJim JimiNo ratings yet

- Seafarers' Examination and Documents Directorate: Candidate's Name: Ports and Maritime OrganizationDocument1 pageSeafarers' Examination and Documents Directorate: Candidate's Name: Ports and Maritime OrganizationJim JimiNo ratings yet

- Candidate's Name:: Exams CycleDocument4 pagesCandidate's Name:: Exams CycleJim JimiNo ratings yet

- Candidate's Name: Ports and Maritime Organization Seaferar's Examination and Certification DirectorateDocument1 pageCandidate's Name: Ports and Maritime Organization Seaferar's Examination and Certification DirectorateJim JimiNo ratings yet

- Exams CycleDocument4 pagesExams CycleJim JimiNo ratings yet

- Exams CycleDocument4 pagesExams CycleJim JimiNo ratings yet

- Candidate's Name: Ports and Maritime Organization (AA) Seafarer's Examination and Certification DirectorateDocument1 pageCandidate's Name: Ports and Maritime Organization (AA) Seafarer's Examination and Certification DirectorateJim JimiNo ratings yet

- Q.1) Explain Safe Handling, Stowage, Securing and Transporting of A Heavy Lift CargoDocument2 pagesQ.1) Explain Safe Handling, Stowage, Securing and Transporting of A Heavy Lift CargoJim JimiNo ratings yet

- Candidate's NameDocument2 pagesCandidate's NameJim JimiNo ratings yet

- Candidate's Name:: Subject: Celestial Navigation Date: Rank: Second Officer (GT 500) Time Allowed: 2.5 HrsDocument3 pagesCandidate's Name:: Subject: Celestial Navigation Date: Rank: Second Officer (GT 500) Time Allowed: 2.5 HrsJim JimiNo ratings yet

- Swe Mid Term - ExampleDocument4 pagesSwe Mid Term - Exampleanas mazenNo ratings yet

- CAD CAM 2 Group AssignmentDocument3 pagesCAD CAM 2 Group AssignmentAnonymous XybLZfNo ratings yet

- Mind Mapping Introduction Speller 2008Document32 pagesMind Mapping Introduction Speller 2008shaileshvc100% (1)

- Price List 2021 - R9Document53 pagesPrice List 2021 - R9WinSajeewaNo ratings yet

- Compiler Optimizations For The PowerPCDocument30 pagesCompiler Optimizations For The PowerPCaNo ratings yet

- Lab-07-Tuning RMAN Backup PerformanceDocument4 pagesLab-07-Tuning RMAN Backup PerformanceArif AhmadNo ratings yet

- (Junos) How To Mount A USB Drive On The EX - SRXDocument3 pages(Junos) How To Mount A USB Drive On The EX - SRXLi KangNo ratings yet

- 005 Spring63Document63 pages005 Spring63JPNo ratings yet

- Clint Cha k726p 36012p Brochure 0325 enDocument2 pagesClint Cha k726p 36012p Brochure 0325 enDorin100% (1)

- Software Development Life Cycle (SDLC) : Asma SajidDocument20 pagesSoftware Development Life Cycle (SDLC) : Asma SajidIsrar ulhaqNo ratings yet

- Using Roaming SIM Cards With The MRD Series RoutersDocument10 pagesUsing Roaming SIM Cards With The MRD Series RoutershussamNo ratings yet

- Emergency Stop Relays, Safety Gate Monitors PNOZ - X9P - GBDocument4 pagesEmergency Stop Relays, Safety Gate Monitors PNOZ - X9P - GBmanuel99a2kNo ratings yet

- Tesla MegapackDocument2 pagesTesla MegapackSicong MaNo ratings yet

- Display Picture and Menu With ViewsDocument32 pagesDisplay Picture and Menu With ViewsNorazlina AbdullahNo ratings yet

- Unit 3 Inside The SystemDocument5 pagesUnit 3 Inside The SystemElfito GansitoNo ratings yet

- Msedcl: O&M Zone, AmravatiDocument17 pagesMsedcl: O&M Zone, AmravatiPrathamesh BanginwarNo ratings yet

- Q2 - (05+05 Marks) Write The Code For - A) Suppose Y...Document2 pagesQ2 - (05+05 Marks) Write The Code For - A) Suppose Y...Unlimited EchoNo ratings yet

- RD48 Model 7194-0 External Fill Tank Spec Sheet 10000032700Document5 pagesRD48 Model 7194-0 External Fill Tank Spec Sheet 10000032700Noame Pauline SimbajonNo ratings yet

- Is.12032.7.1987 Graphical Symbols For Diagrams in The Field of Electrotechnology, Part 7 Switchgear, Controlgear and Protective Devices PDFDocument43 pagesIs.12032.7.1987 Graphical Symbols For Diagrams in The Field of Electrotechnology, Part 7 Switchgear, Controlgear and Protective Devices PDFMukesh Kumar100% (1)

- Apl Process GuideDocument37 pagesApl Process Guidekevinzhang2022No ratings yet