Professional Documents

Culture Documents

ASTM A779-10 Standard Specification For Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-Relieved For Prestressed Concrete

Uploaded by

benedick barquinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM A779-10 Standard Specification For Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-Relieved For Prestressed Concrete

Uploaded by

benedick barquinCopyright:

Available Formats

Designation: A779/A779M – 10

Standard Specification for

Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-

Relieved for Prestressed Concrete 1

This standard is issued under the fixed designation A779/A779M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* uniform pitch of not less than 14 and not more than 18 times

1.1 This specification describes three grades of compacted, the nominal diameter of the strand.

seven-wire, uncoated, stress-relieved strand for use in pre-

4. Classification

tensioned and post-tensioned prestressed concrete construc-

tion. 4.1 Grade 1700 (245) —Nominal diameter of 18.0 mm (0.7

1.2 Supplement I describes low-relaxation strand and low- in.) with tensile failure stress of 1705 MPa (247 ksi) based on

relaxation testing. nominal area of the strand.

1.3 The values stated in either inch-pound or SI units are to 4.2 Grade 1800 (260) —Nominal diameter of 15.2 mm (0.6

be regarded as standard. Within the text, the inch-pound units in.) with tensile failure stress of 1815 MPa (263 ksi) based on

are shown in parentheses. The values stated in each system are nominal area of the strand.

not exact equivalents; therefore, each system shall be used 4.3 Grade 1860 (270) —Nominal diameter of 12.7 mm (0.5

independently of the other, without combining values in any in.) with tensile failure stress of 1860 MPa (270 ksi) based on

way. nominal area of the strand.

2. Referenced Documents 5. Ordering Information

2.1 ASTM Standards: 2 5.1 It shall be the responsibility of the purchaser to specify

A751 Test Methods, Practices, and Terminology for Chemi- all requirements that are necessary for material ordered to this

cal Analysis of Steel Products specification. Such requirements shall include, but are not

A1061/A1061M Test Methods for Testing Multi-Wire Steel limited to, the following:

Strand 5.1.1 Quantity (meters (feet)),

5.1.2 Grade of strand (Section 4), -

-

-

3. Terminology 5.1.3 Special inspection requirements, if desired (see Sec-

`

,

,

`

,

`

,

3.1 Definitions of Terms Specific to This Standard: tion 13), ,

`

,

,

`

-

3.1.1 compacted strand—strand that has been compacted by 5.1.4 Packaging, `

-

`

,

`

`

5.1.5 ASTM designation and date of issue, and

,

`

drawing through a die or a similar compacting process and ,

`

`

`

`

subsequently stress-relieved prior to winding into coils or 5.1.6 Special requirements, if any. ,

,

,

`

,

,

,

`

reelless packs. NOTE 1—A typical ordering description is as follows: 100 000 m Grade

`

`

,

,

,

`

3.1.2 lot—all of the compacted strand of the same grade and 260 compacted low-relaxation strand in approximately 3700 m reelless

`

`

`

,

`

-

package size produced on the same production equipment and

-

packs to ASTM A779/A779M (328 000 ft Grade 1800 compacted

submitted for inspection at the same time. low-relaxation strand in approximately 12 000 ft-reelless packs to ASTM

A779/A779M.)

3.1.3 strand—a group of wires having a center wire en-

closed tightly by six helically placed outer wires with a 6. Materials and Manufacture

6.1 The steel shall be of such quality that, when processed,

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, the finished wire shall be free of detrimental flaws and undue

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee segregation.

A01.05 on Steel Reinforcement.

Current edition approved April 1, 2010. Published July 2010. Originally

6.2 Wire from which the strand is to be fabricated shall be

approved in 1980. Last previous edition approved in 2005 as A779/A779M – 05. in the cold-drawn condition and have a common dry-drawn

DOI: 10.1520/A0779_A0779M-10. finish.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.3 After stranding and compacting, all strand shall be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on subjected to a stress-relieving continuous thermal treatment to

the ASTM website. produce the desired mechanical properties. Temper colors

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

Provided by IHS under license with ASTM

1

Licensee=Academic Consortium Orta Dogu Tecknik Universites/5969111001

No reproduction or networking permitted without license from IHS Not for Resale, 09/18/2010 00:18:37 MDT

A779/A779M – 10

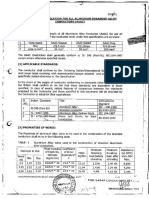

TABLE 1 Breaking Strength Requirements

Nominal Diameter of Strand Specified Minimum Nominal Steel Area of Strand Nominal Mass (Weight) of

Breaking Strength Strands kg/1000 m (lb/1000 ft)

2 2

mm (in.) of Strand, kN (lbf) mm (in.)

Grade 1860 (270)

12.7 (0.5) 209 (47 000) 112 (0.174) 890 (600)

Grade 1800 (260)

15.2 (0.6) 300 (67 440) 165 (0.256) 1295 (873)

Grade 1700 (245)

18.0 (0.7) 380 (85 430) 223 (0.346) 1750 (1176)

TABLE 2 Yield Strength Requirements

which result from the stress-relieving operation are considered

Nominal Strand Diameter Initial Load, Specified Minimum

normal for the finished appearance of this strand. kN (lbf) Load at 1 %

mm (in.) Extension, kN (lbf)

7. Chemical Requirements Grade 1860 (270)

12.7 (0.5) 20.9 (4700) 182 (40 900)

7.1 The chemical analysis of each heat shall be determined Grade 1800 (260)

in accordance with Test Methods, Practices, and Definitions 15.2 (0.6) 30.0 (6740) 261 (58 700)

A751. Grade 1700 (245)

18.0 (0.7) 38.0 (8540) 330 (74 300)

7.2 Variations in production processes and equipment ne-

cessitates the individual selection of an appropriate chemical

composition at the discretion of the producer.

10. Workmanship

7.3 Phosphorus and sulfur values shall not exceed the

following: 10.1 Joints:

Phosphorus 0.040 % max 10.1.1 There shall be no strand joints or strand splices in any

Sulfur 0.050 % max length of the completed strand.

10.1.2 During the process of manufacture of individual

8. Mechanical Properties wires for stranding, welding shall be permitted only prior to the

start of wire drawing.

8.1 Tests for mechanical properties shall be conducted in

10.2 The finished compacted strand shall be uniform in

accordance with Test Methods A1061/A1061M.

diameter and shall be free of imperfections not consistent with

8.2 Breaking Strength—The breaking strength of the fin-

good commercial drawing and stranding practice.

ished strand shall conform to the values specified in Table 1.

10.3 When the strand is cut without seizings, the wires shall

8.3 Load at 1 % Extension—The minimum load at 1 %

not fly out of position. If a wire or wires flies out of position

extension shall conform to the specified values shown in Table

and can be replaced by hand, the strand will be considered

2

satisfactory.

8.4 Elongation—The total elongation of the strand under

-

-

` 10.4 The strand shall not be oiled or greased. Slight rusting,

maximum load shall not be less than 3.5 % measured in a gage

,

`

`

`

`

,

,

provided it is not sufficient to cause pits visible to the unaided

length of not less than 600 mm (24 in.).

,

`

eye, shall not be cause for rejection.

`

`

,

,

8.4.1 Strand specimens that break outside of the extensom-

,

`

,

,

,

10.5 Curvature of the finished compact strand shall be not

`

eter or in the testing machine grips and meet the minimum

`

`

`

,

`

,

`

more than 75 mm (3 in.) in a length of 1 m (3 ft) when lying

specified value, shall be considered as meeting the elongation

`

,

on a flat surface.

`

-

`

-

requirements of this specification.

`

,

,

`

,

,

`

8.5 If any strand specimen breaking within the grips of the

,

`

,

,

`

11. Sampling

-

testing machine results in test values below those specified,

-

-

11.1 One specimen for test shall be taken from each 18 Mg

those results shall be considered invalid and retesting shall be (20 ton) or fraction thereof from the lot of compacted strand.

required. The test specimen shall be cut from the outside ends of reels or

either end of coils or reelless packs.

9. Dimensions and Permissible Variations

9.1 The size of the finished strand shall be expressed as the 12. Test Methods

nominal diameter of the strand in fractions or decimal fractions 12.1 Test specimens obtained in 11.1 shall be tested for

of an inch. dimensions (Section 9), breaking strength (8.2), load at 1 %

9.2 Prior to compacting, the diameter of the center wire of extension (8.3), elongation (8.4), and workmanship (Section

any strand shall be larger than the diameter of any outer wire 10).

by a minimum of 2 %. 12.2 Typical load-elongation curves, based on accumulated

9.3 After compacting, the strand shall conform to a size data, shall be delivered to the purchaser on each lot shipped.

tolerance of plus 0.4 mm (0.016 in.) or minus 0.2 mm (0.008 12.2.1 When specified in the purchase order or contract, a

in.) from the nominal diameter when measured across the load-elongation curve shall be made from one test specimen

crowns of the wire. representing the lot.

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Academic Consortium Orta Dogu Tecknik Universites/5969111001

No reproduction or networking permitted without license from IHS Not for Resale, 09/18/2010 00:18:37 MDT

A779/A779M – 10

13. Inspection an electronic data interchange (EDI) transmission shall be

13.1 Inspection of the material shall be agreed upon by the regarded as having the same validity as a counterpart printed in

purchaser and the supplier as part of the purchase contract. the certifier’s facility. The content of the EDI transmitted

13.2 If purchaser inspection is required, the supplier shall document must meet the requirements of the invoked ASTM

afford the inspector representing the purchaser all reasonable standard(s) and conform to any existing EDI agreement be-

facilities so that the inspector is satisfied that the material being tween the purchaser and the supplier. Notwithstanding the

furnished is in accordance with this specification. All tests and absence of a signature, the organization submitting the EDI

inspections shall be made at the place of manufacture prior to transmission is responsible for the content of the report.

shipment and shall be conducted as not to interfere unneces- NOTE 2—The industry definition as invoked here is: EDI is the

sarily with the operation of the works. computer-to-computer exchange of business information in a standard

format such as ANSI ASC X12.

14. Rejection and Rehearing

14.1 Material that fails to conform to the requirements of 16. Packaging and Marking

this specification shall be subject to rejection. Rejection shall 16.1 The strand shall be furnished on reels, reelless packs,

be reported to the producer or supplier promptly and in writing. or in coils having a minimum inside diameter of 910 mm (36

In case of dissatisfaction with the test results, the producer or in.). Each package shall be protected from mechanical damage

supplier shall have the right to make claim for a rehearing. during shipment. A strong tag securely attached to each

package shall show the grade, length, reel or lot number,

15. Certification ASTM A779/A779M, special requirements, if any, and name

15.1 If inspection by the purchaser is waived, a manufac- or mark of the manufacturer. Special packaging, protection, or

turer’s certification that the material has been tested in accor- tagging shall be agreed upon between the purchaser and

dance with, and meets the requirements of this specification, supplier at the time of purchase.

shall be the basis of acceptance of the material. The certifica- 16.2 Low-relaxation compacted strand meeting the require-

tion shall include the specification number, year-date of issue, ment of Supplement I shall be specifically identified.

and revision letter, if any.

15.2 A material test report, certificate of inspection, or 17. Keywords

similar document printed from or used in electronic form from 17.1 compacted strand (tendon); prestressed concrete

SUPPLEMENTARY REQUIREMENTS

I. LOW-RELAXATION COMPACTED STRAND

S1. Scope S5. Load at 1 % Extension

S1.1 This supplement details those special properties that S5.1 The load at 1 % extension of compacted strand with

are applicable to low-relaxation compacted strand which are in low relaxation properties shall be not less than 90 % of the

addition to the properties prescribed in this specification. specified minimum breaking strength as described in 8.2.

S1.2 Relaxation testing methods as applicable to compacted

strand are also prescribed. S6. Conditions of Relaxation Test

S6.1 The temperature of the test specimen and testing

S2. Applicable Documents equipment shall be maintained at 20 6 2°C (68 6 3.5°F).

S6.2 The test specimen shall not be subjected to loading

S2.1 ASTM Standards:

prior to the relaxation test.

A1061/A1061M Test Methods for Testing Multi-Wire Steel

S6.3 The initial load shall be applied uniformly over a

Strand

period of not less than 3 min and not more than 5 min, and the

gage length shall be maintained constant; load relaxation

S3. Sampling

readings shall begin 1 min after application of total load.

S3.1 Test specimens shall be selected from those obtained in S6.3.1 The initial load shall be 70 % of the actual breaking

Section 11, representative of the process. The number of load of a test specimen obtained adjacent to the specimen being

samples to be tested shall be agreed upon between the tested.

purchaser and producer. S6.4 Over-stressing of the test specimen during the loading

operation shall not be permitted.

S4. Test Methods S6.5 Duration of the test shall be 1000 h or a shorter

S4.1 Compacted strand shall be tested for relaxation prop- computed period extrapolated to 1000 h which can be shown

erties in accordance with Test Methods A1061/A1061M. by test data to provide similar relaxation values.

--`,````,,,```,,,`,,,````,`,``,`-`-`,,`,,`,`,,`---

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Academic Consortium Orta Dogu Tecknik Universites/5969111001

No reproduction or networking permitted without license from IHS Not for Resale, 09/18/2010 00:18:37 MDT

A779/A779M – 10

S6.6 The test gage length shall be at least 60 times the specification with the added requirement that the relaxation

nominal diameter of the strand. If this gage length exceeds the loss after 1000 h under conditions of Section S 6 shall be not

capacity of the extensometer or testing machine, then it is more than 2.5 %.

permitted to substitute a gage length of 40 times the nominal

diameter of the strand.

S7. Relaxation Properties

S7.1 Low-relaxation, compacted strand shall meet the di-

mensional, breaking load, and elongation requirements of this

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this standard since the last issue

(A779/A779M – 05) that may impact the use of this standard. (Approved April 1, 2010.)

(1) Revised Sections 2 and 8 and Sections S2 and S4 in mechanical properties and deleted Test Methods E328 because

Supplementary Requirements to replace Test Methods A370 Test Methods A1061/A1061M includes testing for relaxation

with Test Methods A1061/A1061M as the testing standard for properties.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

--`,````,,,```,,,`,,,````,`,``,`-`-`,,`,,`,`,,`---

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Academic Consortium Orta Dogu Tecknik Universites/5969111001

No reproduction or networking permitted without license from IHS Not for Resale, 09/18/2010 00:18:37 MDT

You might also like

- Baldosas y Luminarias - CCM1Document5 pagesBaldosas y Luminarias - CCM1mvalenzuelatNo ratings yet

- Technical Supply Conditions For Steel Wire Ropes and StrandsDocument17 pagesTechnical Supply Conditions For Steel Wire Ropes and StrandsAbinashBeheraNo ratings yet

- Astm e 1417pdfDocument12 pagesAstm e 1417pdfShabbir aliNo ratings yet

- AAAC ConductorsDocument14 pagesAAAC ConductorsDipanku GoswamiNo ratings yet

- Jis G 3505 LC W RodsDocument1 pageJis G 3505 LC W RodsRamesh DattaNo ratings yet

- Extended Data: A1 P Rose S Jones1 Bgiww Bgigb - Eng Part Drawing ReleasedDocument2 pagesExtended Data: A1 P Rose S Jones1 Bgiww Bgigb - Eng Part Drawing ReleasedSarita ForgingNo ratings yet

- Katalog Flexible Joint King FlexDocument1 pageKatalog Flexible Joint King FlexMuhammad IzzuddinNo ratings yet

- Is 8376Document8 pagesIs 8376PRABHJOT SINGHNo ratings yet

- Temperature of Freshly Mixed Hydraulic-Cement ConcreteDocument3 pagesTemperature of Freshly Mixed Hydraulic-Cement ConcreteHasan al MahmudNo ratings yet

- ND BRG GuideDocument32 pagesND BRG Guidemohammed barghothiNo ratings yet

- thyssenkrupp Project No. 66-6699-700 Piping List O & UDocument2 pagesthyssenkrupp Project No. 66-6699-700 Piping List O & URajeev KumarNo ratings yet

- Jis D0203 PDFDocument6 pagesJis D0203 PDFsabaris ksNo ratings yet

- Yei%-P7: Bitumen-Mastic For Flooring - Specification (Third Revision)Document14 pagesYei%-P7: Bitumen-Mastic For Flooring - Specification (Third Revision)Amanulla KhanNo ratings yet

- Din 267-3 - 08.83Document2 pagesDin 267-3 - 08.83gkhnNo ratings yet

- Astm 139Document6 pagesAstm 139Kenny WongNo ratings yet

- 01 25284124-8230-26-104-0001 REV.02 Piping List CT1Document1 page01 25284124-8230-26-104-0001 REV.02 Piping List CT1Rajeev KumarNo ratings yet

- Astm A420-A420m 2010Document6 pagesAstm A420-A420m 2010Lucas IglesiasNo ratings yet

- Conectores Multiconductores Serie TCDocument2 pagesConectores Multiconductores Serie TCING_MBMNo ratings yet

- Technical Supply Conditions FOR Threaded Steel Fasteners: Indian StandardDocument5 pagesTechnical Supply Conditions FOR Threaded Steel Fasteners: Indian Standardsonnu151No ratings yet

- ASTM C 1396-2017 - Placas de YesoDocument8 pagesASTM C 1396-2017 - Placas de YesoMaria GomezNo ratings yet

- Time Delay Sensitivity Housing Cable Entry: Production 712906Document2 pagesTime Delay Sensitivity Housing Cable Entry: Production 712906Arjun BharambeNo ratings yet

- Clasificacion API Engine Oil 2010Document8 pagesClasificacion API Engine Oil 2010anica moldovanNo ratings yet

- Steel Wire, Hard-Drawn For Prestressed Concrete TanksDocument3 pagesSteel Wire, Hard-Drawn For Prestressed Concrete TanksDarwin DarmawanNo ratings yet

- Motor Lincoln 286 TSCDocument5 pagesMotor Lincoln 286 TSCJose BarreroNo ratings yet

- An Overview of API 579-1/ASME FFS-1 Fitness-For-Service Assessment Standard With Applications To Case StudiesDocument57 pagesAn Overview of API 579-1/ASME FFS-1 Fitness-For-Service Assessment Standard With Applications To Case StudiesLeonardo PestanaNo ratings yet

- 4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsDocument1 page4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsIbrahim shaikNo ratings yet

- 1264 1997 Reff2021Document7 pages1264 1997 Reff2021ocsspectroNo ratings yet

- Astm C 936 - CompressDocument3 pagesAstm C 936 - CompressabrskpNo ratings yet

- Metric (MM 2) Standard (AWG) Metric (MM 2) Standard (AWG) : TolerancesDocument8 pagesMetric (MM 2) Standard (AWG) Metric (MM 2) Standard (AWG) : TolerancesGonzalo GalvezNo ratings yet

- TECO Air Conditioning Variable Refrigerant Flow (VRF), VRF System 5-150 TRDocument6 pagesTECO Air Conditioning Variable Refrigerant Flow (VRF), VRF System 5-150 TRirtedyNo ratings yet

- Snap Tite 75sDocument4 pagesSnap Tite 75sDavid RossNo ratings yet

- 01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKDocument2 pages01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKRajeev KumarNo ratings yet

- Astm A 779 A779m-12Document4 pagesAstm A 779 A779m-12Mohammed AliNo ratings yet

- SPE IADC FC Dull Bit GradingDocument5 pagesSPE IADC FC Dull Bit GradingJonathanNo ratings yet

- LEAD SCREW - p1 - 785Document1 pageLEAD SCREW - p1 - 785wawandev7No ratings yet

- Mechenical Foam ExtinguisherDocument20 pagesMechenical Foam Extinguisheraman singhNo ratings yet

- Is 6594Document17 pagesIs 6594rajmarathiNo ratings yet

- Conveyor Belts - Fire Resistant Conveyor Belting For Underground Mines and Such Other Hazardous Applications - SpecificationDocument27 pagesConveyor Belts - Fire Resistant Conveyor Belting For Underground Mines and Such Other Hazardous Applications - SpecificationARAVINDRAJ V RNo ratings yet

- Diaphragm CouplingDocument36 pagesDiaphragm CouplingnguyennhatbaoNo ratings yet

- Weatherford McMurry GLM - Gas Lift MandrelDocument25 pagesWeatherford McMurry GLM - Gas Lift MandrelYovaraj KarunakaranNo ratings yet

- Iso 6361 2 1990 en PDFDocument8 pagesIso 6361 2 1990 en PDFganmoses0% (1)

- Innovance H2U Data SheetDocument2 pagesInnovance H2U Data SheetAmr samir ShahinNo ratings yet

- SPEC SHEET 005 AeroGlass LensDocument1 pageSPEC SHEET 005 AeroGlass LensMarco GalindoNo ratings yet

- SEIP For 080-AC-001: GeneralDocument5 pagesSEIP For 080-AC-001: GeneralThinh NguyenNo ratings yet

- Drawn Arc Welding of Panel Segments PV 1604: Klass.-Nr./Class No. 04 87 1 September 2003Document4 pagesDrawn Arc Welding of Panel Segments PV 1604: Klass.-Nr./Class No. 04 87 1 September 2003aldairlopesNo ratings yet

- Seamless and Welded Steel Pipe For Low-Temperature Service and Other Applications With Required Notch ToughnessDocument8 pagesSeamless and Welded Steel Pipe For Low-Temperature Service and Other Applications With Required Notch ToughnessTim SharpNo ratings yet

- 01 25284124-8230-26-000-0003 REV.02 Piping List EPCM6 PIPE RACKDocument1 page01 25284124-8230-26-000-0003 REV.02 Piping List EPCM6 PIPE RACKRajeev KumarNo ratings yet

- 1786 2012 New Ammendments PDFDocument23 pages1786 2012 New Ammendments PDFS RamakrishnaNo ratings yet

- Asme Section II A-2 Sa-662 Sa-662mDocument6 pagesAsme Section II A-2 Sa-662 Sa-662mAnonymous GhPzn1xNo ratings yet

- AKS 4100 - Inglês 2012Document3 pagesAKS 4100 - Inglês 2012Carlos CarreraNo ratings yet

- Astm A615mDocument8 pagesAstm A615mKelvin100% (1)

- Is 1285 PDFDocument11 pagesIs 1285 PDFswaroop87No ratings yet

- Collar 9.5X10Document1 pageCollar 9.5X10Preetam KumarNo ratings yet

- 01 - 25284124-8230-26-000-0010 - REV.01 - Line List - C4 ImportDocument1 page01 - 25284124-8230-26-000-0010 - REV.01 - Line List - C4 ImportRajeev KumarNo ratings yet

- SSFD NIMR - EARLY DEVELOPMENT FACILITY UNIT RATE SHEETDocument16 pagesSSFD NIMR - EARLY DEVELOPMENT FACILITY UNIT RATE SHEETSasi MesthiriNo ratings yet

- Reporte Icc Esr - 3517Document5 pagesReporte Icc Esr - 3517Fernando Castillo HerreraNo ratings yet

- FM700 / FM701 & FM700B: Butterfly ValvesDocument1 pageFM700 / FM701 & FM700B: Butterfly ValvesRonaldNo ratings yet

- ENGINEERING MATERIALS TEST REPORTDocument1 pageENGINEERING MATERIALS TEST REPORTMiftahul IslamNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Porosity in Metallic Coatings by Humid Sulfur Vapor ("Flowers-of-Sulfur")Document5 pagesPorosity in Metallic Coatings by Humid Sulfur Vapor ("Flowers-of-Sulfur")ROHITNo ratings yet

- Copper Alloy Permanent Mold Castings For General ApplicationsDocument3 pagesCopper Alloy Permanent Mold Castings For General ApplicationsJonicus-DextoreNo ratings yet

- B172Document4 pagesB172rohit kumar100% (4)

- Astm B805Document7 pagesAstm B805Jonicus-DextoreNo ratings yet

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDocument3 pagesHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For Weldingbenedick barquinNo ratings yet

- Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, For Electrical ConductorsDocument5 pagesRope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, For Electrical Conductorsbenedick barquinNo ratings yet

- Aluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification ForDocument4 pagesAluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification Forbenedick barquinNo ratings yet

- Astm B 161 - 03Document4 pagesAstm B 161 - 03Ahmad KhreisatNo ratings yet

- B154Document3 pagesB154rohit kumarNo ratings yet

- B 160 - 99 Qje2maDocument6 pagesB 160 - 99 Qje2mawahyudiNo ratings yet

- Subject Spec - Number Title Spec. NameDocument2 pagesSubject Spec - Number Title Spec. Namebenedick barquinNo ratings yet

- 9i-B 162 - 99 - QJE2MGDocument9 pages9i-B 162 - 99 - QJE2MGmarjan banooNo ratings yet

- B 167 - 01 - Qje2nwDocument8 pagesB 167 - 01 - Qje2nwIntegrity EngineerNo ratings yet

- ASTM C1017-13 Standard Specification For Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesASTM C1017-13 Standard Specification For Chemical Admixtures For Use in Producing Flowing Concretebenedick barquinNo ratings yet

- Breaking Load and Flexural Properties of Block-Type Thermal InsulationDocument7 pagesBreaking Load and Flexural Properties of Block-Type Thermal InsulationZed ZedNo ratings yet

- ASTM C1582-17 Standard Specification For Admixtures To Inhibit Chloride-Induced Corrosion of Reinforcing Steel in ConcreteDocument10 pagesASTM C1582-17 Standard Specification For Admixtures To Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concretebenedick barquinNo ratings yet

- ASTM C979-05 Standard Specification For Pigments For Integrally Colored ConcreteDocument5 pagesASTM C979-05 Standard Specification For Pigments For Integrally Colored Concretebenedick barquinNo ratings yet

- ASTM C1622-10 Standard Specification For Cold-Weather Admixture SystemsDocument8 pagesASTM C1622-10 Standard Specification For Cold-Weather Admixture Systemsbenedick barquinNo ratings yet

- ASTM D256-23 Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsDocument11 pagesASTM D256-23 Standard Test Methods For Determining The Izod Pendulum Impact Resistance of Plasticsbenedick barquinNo ratings yet

- ASTM D648-18 Standard Test Method For Deflection Temperature of Plastics Under Flexural Load in The Edgewise PositionDocument6 pagesASTM D648-18 Standard Test Method For Deflection Temperature of Plastics Under Flexural Load in The Edgewise Positionbenedick barquinNo ratings yet

- ASTM D4959-07 Standard Test Method For Determination of Water (Moisture) Content of Soil by Direct HeatingDocument3 pagesASTM D4959-07 Standard Test Method For Determination of Water (Moisture) Content of Soil by Direct Heatingbenedick barquinNo ratings yet

- PNS49 2020Document20 pagesPNS49 2020benedick barquin100% (2)

- 802 11 Qos OverviewDocument38 pages802 11 Qos Overviewswapnil tiwariNo ratings yet

- Content Analysis Research Paper ExampleDocument5 pagesContent Analysis Research Paper Examplefvfzfa5d100% (1)

- Cloze Test For The Upcoming SSC ExamsDocument9 pagesCloze Test For The Upcoming SSC ExamsAbhisek MishraNo ratings yet

- Aoc ts185 LCD MonitorDocument56 pagesAoc ts185 LCD MonitoraldinaenNo ratings yet

- Plan Test Strategy for Flight Search WebsiteDocument13 pagesPlan Test Strategy for Flight Search WebsiteНаталья ПримаNo ratings yet

- Benguet Management v. Keppel BankDocument3 pagesBenguet Management v. Keppel BankChester BryanNo ratings yet

- IH May-June 2022Document60 pagesIH May-June 2022Omkar R PujariNo ratings yet

- Activity#tachometer - MEC 0326.1-2Document4 pagesActivity#tachometer - MEC 0326.1-2MarkJude MorlaNo ratings yet

- Newspaper Layout DummyDocument1 pageNewspaper Layout Dummy1w2e3r4t5y100% (9)

- Swiss Ephemeris Table of Houses for Southern HemisphereDocument121 pagesSwiss Ephemeris Table of Houses for Southern HemisphereAnonymous 5S91GvOgNo ratings yet

- Modified Castigliano TheoremDocument10 pagesModified Castigliano Theoremmszlazak4179No ratings yet

- North American Free Trade Agreement: Prof. MakhmoorDocument15 pagesNorth American Free Trade Agreement: Prof. MakhmoorShikha ShuklaNo ratings yet

- Nameet Kumar Jain: Education ProjectsDocument1 pageNameet Kumar Jain: Education ProjectsNameet JainNo ratings yet

- LG AnalysisDocument4 pagesLG AnalysisAnkit MishraNo ratings yet

- Automotive Transmission-ShaftDocument7 pagesAutomotive Transmission-Shaftfileuse.fNo ratings yet

- Nano-technology for Post-Harvest Management of Fruits and VegetablesDocument3 pagesNano-technology for Post-Harvest Management of Fruits and VegetablesArin RujinNo ratings yet

- Melissa Wanstall March 2016Document2 pagesMelissa Wanstall March 2016api-215567355No ratings yet

- L27 - Optical Measuring InstrumentsDocument14 pagesL27 - Optical Measuring Instrumentschaitanyamohod2020No ratings yet

- The Threat Landscape Quiz ResultsDocument5 pagesThe Threat Landscape Quiz ResultsKaskusemail88 EmailNo ratings yet

- HyungJae Yang Sound Water EnvironmentDocument25 pagesHyungJae Yang Sound Water EnvironmentPepeNo ratings yet

- Philippines Customs Law and ProceduresDocument70 pagesPhilippines Customs Law and ProceduresRojusandino Acevedo Ylagan50% (2)

- Stolle Cupping Systems: ConnectingDocument2 pagesStolle Cupping Systems: ConnectingHieu NguyenNo ratings yet

- Mobile Scaffold Inspection ChecklistDocument3 pagesMobile Scaffold Inspection Checklistanthony murphyNo ratings yet

- Data Sheets Bulletin Yarway Wye Type Pipeline Strainers Yarway en en 2722064Document8 pagesData Sheets Bulletin Yarway Wye Type Pipeline Strainers Yarway en en 2722064gembulflow8153No ratings yet

- "Hybrid" Light Steel Panel and Modular Systems PDFDocument11 pages"Hybrid" Light Steel Panel and Modular Systems PDFTito MuñozNo ratings yet

- Haslinda Mohd Anuar Senior Lecturer School of Law ColgisDocument24 pagesHaslinda Mohd Anuar Senior Lecturer School of Law ColgisSHAHEERANo ratings yet

- Beam Loader Tributary ExcelDocument2 pagesBeam Loader Tributary ExcelHari Amudhan IlanchezhianNo ratings yet

- OSN 9800 U64, U32, U16, UPS Installation GuideDocument157 pagesOSN 9800 U64, U32, U16, UPS Installation GuidedonekeoNo ratings yet

- Solutions Manual For Introduction To Management Accounting 16Th Edition Horngren Sundem Schatzberg Burgstahler 0133058786 9780133058789 Full Chapter PDFDocument36 pagesSolutions Manual For Introduction To Management Accounting 16Th Edition Horngren Sundem Schatzberg Burgstahler 0133058786 9780133058789 Full Chapter PDFdavid.rex111100% (10)

- EIA For Maize & Wheat Milling Plant DEI PDFDocument110 pagesEIA For Maize & Wheat Milling Plant DEI PDFSasira Fionah100% (2)