Professional Documents

Culture Documents

Process Flow of PRODUCTION

Process Flow of PRODUCTION

Uploaded by

Shadab AhmadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Flow of PRODUCTION

Process Flow of PRODUCTION

Uploaded by

Shadab AhmadCopyright:

Available Formats

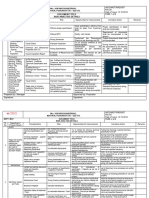

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. UF221PCHSG030 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- BUTTON PCB HOUSING NEO M2

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

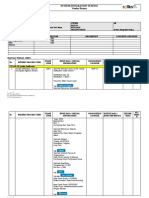

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. UF220PCTPG010 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- TOUCH PIN GUIDE NEO M2

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. UF220PCLEC360 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

TOUCH CUSHION GUIDE-NEO Core Team:Deepak Bharti,

Part Name- M2 Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. UF221PCHSG010 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- KNOB PCB HOUSING NEO M2

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. UF210PCKGB030 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- KNOB GUIDE BASE-WDR

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. UF221PCHSG020 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- PCB SUPPORT NEO M3

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. UF220PCWFU010 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- WIFI HOUSINNG UPPER LCWD

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. UF220PCWFL010 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- WIFI HOUSING LOWER LCWD

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. TL220MNPCH090 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

PCB CONTROLLER HSNG (TL Core Team:Deepak Bharti,

Part Name- ECO) Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. TL220MNPCH100 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- PB HSNG (TL ECO)

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. TL220MNLEC250 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- LED COVER TYPE1 (TL ECO)

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. TL220MNLEC260 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- LED COVER TYPE2(TL ECO)

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. TL220MNPCH110 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- PCB CONTROLLER HSNG-REAR

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. TL220MNLEC240 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- LED COVER TYPE2 (COMP)

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. TL220MNLEC270 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- LED COVER TYPE3 (COMP)

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

SHARAD ELECTRONICS

Plot No.- 96,Sec - 6,Faridabad,HARYANA

PROCESS FLOW CHART

Process Responsibility:

Control No.:-SE/F/QA-21 Process Identification:PRODUCTION

QA, Prod.

Prepared By

Part No. TL220MNLEC280 MODEL: CHANDRA Rev. No.: "00"

SHEKHAR

Core Team:Deepak Bharti,

Part Name- LED COVER TYPE4 (COMP)

Ram lala,Vinamra

Date Original: Date Revised:

Customer : IFB INDUSTRIES PVT. LTD. Key Date: 19/08/23 19/08/23

Process Operation No.

Source Of Variation Process Flow Diagram Product Characteristics Process Characteristics

Flow No. Brief Description

Receipt Inspection of Raw Variation in material As per Inspection As per Incoming

10 10

Material from supplier Standard/ PO Inspection Plan

Stacking & Stacking & As per define material

20 Storage of raw material. 20

Identification mark Identification mark location

Issue of Raw-Material to Exact description & Exact description &

30 30 ----

Inj. Molding. proper qty. proper qty.

No Moisture in

As per Process

Pre-heating of Raw Less & More 40 granules.

40 Standard sheet

Material temperature, Time No abnormal color

variation.

Raw Material, free from Shrinkage, Barrel Temperature, cooling

50 warpage & Other Moulding time, injection time, injection

50 Injection Molding Operator, Time & defects, Dimensions As per pressure, injection speed,

Temperature Drawing cycle time

free from gate, No over

60 Degating Operator's skill 60 cutting/No under Hand pressure

cutting

free from Shrinkage, As per Finishing &

Inspector skill & warpage & Other Moulding

70 Final Inspection 70 packaging Work

awareness of defects defects, Dimensions As per

Drawing Instruction

No mix up parts/No

Operator skill, packing As per packing

80 Packaging excess parts/No less

standard 80 standard

parts

90 Dispatch to customer Qty/material/Invoice Correct labeling ----

Legends:

Inspection Storage Operation & Inspection Operation Movement

Prepared by:- Sushil Approved by:- Mr.Vinamra mohata

You might also like

- WoodwardDocument104 pagesWoodwardwachuwachuNo ratings yet

- FRP ItpDocument2 pagesFRP ItpHrishikesan100% (2)

- Control Plan & FmeaDocument9 pagesControl Plan & FmeaManu SharmaNo ratings yet

- AI - Inspection Report - BagsDocument37 pagesAI - Inspection Report - Bagssiva6751No ratings yet

- Date Account Titles and Explanation P.R. Debit CreditDocument13 pagesDate Account Titles and Explanation P.R. Debit CreditNguyễn GiangNo ratings yet

- Forex Trading For BeginnersDocument13 pagesForex Trading For BeginnersChiedozie Onuegbu100% (2)

- Boston-Consulting-Group-Template-Corporate (2) (Autosaved)Document23 pagesBoston-Consulting-Group-Template-Corporate (2) (Autosaved)Tour De BandarbanNo ratings yet

- 02 Manufacturing Process Design InputsDocument3 pages02 Manufacturing Process Design InputsRaja DuraiNo ratings yet

- Control Plan - 608 2RS C3Document28 pagesControl Plan - 608 2RS C3trandangbkNo ratings yet

- Ppap - GP055291 - R2Document19 pagesPpap - GP055291 - R2Swapnil KupaleNo ratings yet

- FMEA, PFD and PFCDocument11 pagesFMEA, PFD and PFCrohit mathankerNo ratings yet

- PFD - Fmea - CPDocument5 pagesPFD - Fmea - CPNagarajanNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Spacer PFDDocument1 pageSpacer PFDShoaib AkhtarNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- 03 Pillar - 120Document1 page03 Pillar - 120Mohsin AkhterNo ratings yet

- F-PD-01 Process Flow DiagramDocument1 pageF-PD-01 Process Flow DiagramTrivesh SharmaNo ratings yet

- Ih Setup 38tDocument1 pageIh Setup 38tmuthuselvanNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Process Flow Chart (Pre-Launch / Production)Document1 pageProcess Flow Chart (Pre-Launch / Production)kumar0% (1)

- Ge Sill PFD PDFDocument1 pageGe Sill PFD PDFRavikumar BojjaNo ratings yet

- PFD Rear Link Maching (Y Section)Document2 pagesPFD Rear Link Maching (Y Section)Devam EngineeringNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- 17 - Risk Analysis Rev-1Document5 pages17 - Risk Analysis Rev-1vinuNo ratings yet

- PP-FR-03 Route CardDocument1 pagePP-FR-03 Route Cardchandra100% (1)

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDocument4 pagesControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationDocument13 pagesVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDNo ratings yet

- PFD FinsDocument3 pagesPFD FinsenggNo ratings yet

- Process Flow Diagram: Avon Tubetech Pvt. Limited, FaridabadDocument4 pagesProcess Flow Diagram: Avon Tubetech Pvt. Limited, FaridabadHimanshu GaurNo ratings yet

- Route Card FormatDocument1 pageRoute Card Formatsri Venkateshwara gear wheelsNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Process Audit Check SheetDocument5 pagesProcess Audit Check SheetaliNo ratings yet

- Control Plan-StampingDocument2 pagesControl Plan-StampingVipin Jangra100% (1)

- FM - MKT - 02 Quality Control Process ChartDocument4 pagesFM - MKT - 02 Quality Control Process Chartbarja subarjaNo ratings yet

- Control Plan: Cervantes Chavez, Sanchez Hernandez, Espinoza Rodriguez, Torres MuñizDocument8 pagesControl Plan: Cervantes Chavez, Sanchez Hernandez, Espinoza Rodriguez, Torres MuñizLuis Guillermo Cervantes ChávezNo ratings yet

- JCB21-SIT05-Vendor Return v0.1Document17 pagesJCB21-SIT05-Vendor Return v0.1mikeNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanQuality VenusNo ratings yet

- Control Plan-06Document2 pagesControl Plan-06PARI VALLALNo ratings yet

- QCPC Pmi FanDocument14 pagesQCPC Pmi FanMaelEdwardAritonangNo ratings yet

- 3 PFDDocument1 page3 PFDaslamNo ratings yet

- PT 001 PDFDocument1 pagePT 001 PDFDang sonNo ratings yet

- Shutter Mag WiDocument1 pageShutter Mag Wikiran vkNo ratings yet

- Job Router: Customer: JIF Respon: Description: PO #: Job No: Quote No: Date Arrived: Date RequiredDocument1 pageJob Router: Customer: JIF Respon: Description: PO #: Job No: Quote No: Date Arrived: Date RequiredJaydenNo ratings yet

- Sop For ShearingDocument4 pagesSop For ShearingsandipmhetreNo ratings yet

- Caliper Result ReportDocument2 pagesCaliper Result ReportAice LuzadaNo ratings yet

- 05) - Process Flow Diagram For 11190722 - DDocument2 pages05) - Process Flow Diagram For 11190722 - DMONISHRAJNo ratings yet

- Maharashtra Polymer Products: Control PlanDocument3 pagesMaharashtra Polymer Products: Control PlanHitarth_dhamsaniaNo ratings yet

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- Datasheet Vacuum Gauge: Project Project Number Purchase Order RequisitionDocument5 pagesDatasheet Vacuum Gauge: Project Project Number Purchase Order RequisitionManodipPatilNo ratings yet

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 pagesWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerNo ratings yet

- DSQR - RaltechDocument10 pagesDSQR - RaltechHimanshu MishraNo ratings yet

- Six Sigma Project ReportDocument39 pagesSix Sigma Project Reportsumeetsaini88No ratings yet

- M 6.340 LPDC Functional Validation of Equipment at SupplierDocument69 pagesM 6.340 LPDC Functional Validation of Equipment at SupplierJesus ValdezNo ratings yet

- Pt. Prestasi Inti Rubber: Control PlanDocument1 pagePt. Prestasi Inti Rubber: Control PlanHardjonoNo ratings yet

- Quality Plan Dyeing FinishingDocument3 pagesQuality Plan Dyeing FinishingITOPS TeamNo ratings yet

- Datasheet For RTD and ThermowellDocument1 pageDatasheet For RTD and ThermowellJeshinNo ratings yet

- CP-SS BLK-01Document5 pagesCP-SS BLK-01yogesh WakchaureNo ratings yet

- Plan de Surveillance ExempleDocument2 pagesPlan de Surveillance ExempleAudrey GavaletNo ratings yet

- Page 1 of 1: Control PlanDocument1 pagePage 1 of 1: Control PlannormalNo ratings yet

- SMT Generic Control PlanDocument3 pagesSMT Generic Control Plantuan mai vanNo ratings yet

- Coach Ticket EUMAF424Document1 pageCoach Ticket EUMAF424Abhilash SreekumarNo ratings yet

- Magnite OTT Is For EveryoneDocument17 pagesMagnite OTT Is For EveryoneTomeziy StrivesNo ratings yet

- Chapter 11 TugasDocument7 pagesChapter 11 TugasMichael HarveyNo ratings yet

- SM Ch-1Document89 pagesSM Ch-1Pavlo Andre AbiyNo ratings yet

- Chapters 4&5-Continued Growth For Zara and Inditex PDFDocument3 pagesChapters 4&5-Continued Growth For Zara and Inditex PDF溱洧No ratings yet

- SPL Updated Syllabus - 2020 PDFDocument6 pagesSPL Updated Syllabus - 2020 PDFCiara De LeonNo ratings yet

- Quirino Second State of The Nation Address 1950Document6 pagesQuirino Second State of The Nation Address 1950malacanangmuseumNo ratings yet

- Trademark EssayDocument2 pagesTrademark Essayz7wm9csbz5No ratings yet

- Quiroga v. Parsons Hardware Co.Document1 pageQuiroga v. Parsons Hardware Co.Elle MichNo ratings yet

- Chapter 1 - The Role of Accounting in BusinessDocument10 pagesChapter 1 - The Role of Accounting in BusinessHa Phuoc Hau100% (1)

- CSC 371 Lecture NoteDocument68 pagesCSC 371 Lecture NoteCharlesNo ratings yet

- Theory X and yDocument208 pagesTheory X and yhamiduabdulhakeem99No ratings yet

- Digital Marketing MCQsDocument4 pagesDigital Marketing MCQschanchalNo ratings yet

- Wedding - Consultant - Business - COMPUTER PROJECTDocument15 pagesWedding - Consultant - Business - COMPUTER PROJECTGoodangel BlessingNo ratings yet

- SBL BPP Kit-2019 Copy 454Document1 pageSBL BPP Kit-2019 Copy 454Reever RiverNo ratings yet

- Ocampo Vs NLRC PDFDocument2 pagesOcampo Vs NLRC PDFKristine NebresNo ratings yet

- AccountStatement 13 OCT 2023 To 12 NOV 2023Document7 pagesAccountStatement 13 OCT 2023 To 12 NOV 2023shainalom038No ratings yet

- Lecturenote - 1966059717advanced Fianacial Accounting - DraftDocument211 pagesLecturenote - 1966059717advanced Fianacial Accounting - DraftBetelehem Zenaw100% (1)

- Sme Covid-19 Seminar 2Document39 pagesSme Covid-19 Seminar 2api-581961377No ratings yet

- Sample Problems On Economy StudiesDocument17 pagesSample Problems On Economy StudiespotatookunNo ratings yet

- AE-036411-001 INDEX For Drawing and EquipmentDocument1 pageAE-036411-001 INDEX For Drawing and Equipmentnarutothunderjet216No ratings yet

- Taco Bell LawsuitDocument18 pagesTaco Bell LawsuitKBTXNo ratings yet

- Brexit ResearchDocument8 pagesBrexit ResearchShreya RaoNo ratings yet

- Green WorldDocument16 pagesGreen WorldThet Nwe OhnNo ratings yet

- Salesforce PKB Implementation GuideDocument30 pagesSalesforce PKB Implementation Guidehariharank12No ratings yet

- Making Globalization Work: Joseph E. StiglitzDocument26 pagesMaking Globalization Work: Joseph E. StiglitzsaraaqilNo ratings yet

- Basic Restaurant Management CourseDocument3 pagesBasic Restaurant Management CourseGoldriche ConsultsNo ratings yet