Professional Documents

Culture Documents

Pump System Malfunction 125

Uploaded by

SERVICIOS ESPECIALIZADOS EN LUBRICACIÓN0 ratings0% found this document useful (0 votes)

2 views1 pageThe document lists various malfunctions that can occur in a pump system along with their potential causes and remedies. Some examples of malfunctions include a drop in pressure or delivery, noisy operation, rough or pulsating operation with pressure drop, and excessive leakage. Common causes are worn or damaged parts like packing seals, valves, belts, and hoses. Recommended remedies involve replacing or repairing worn parts, cleaning valves or strainers, checking for proper operation of unloaders, and addressing issues like restrictions in plumbing or cavitation in inlet lines.

Original Description:

Original Title

Pump-System-Malfunction-125

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document lists various malfunctions that can occur in a pump system along with their potential causes and remedies. Some examples of malfunctions include a drop in pressure or delivery, noisy operation, rough or pulsating operation with pressure drop, and excessive leakage. Common causes are worn or damaged parts like packing seals, valves, belts, and hoses. Recommended remedies involve replacing or repairing worn parts, cleaning valves or strainers, checking for proper operation of unloaders, and addressing issues like restrictions in plumbing or cavitation in inlet lines.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pagePump System Malfunction 125

Uploaded by

SERVICIOS ESPECIALIZADOS EN LUBRICACIÓNThe document lists various malfunctions that can occur in a pump system along with their potential causes and remedies. Some examples of malfunctions include a drop in pressure or delivery, noisy operation, rough or pulsating operation with pressure drop, and excessive leakage. Common causes are worn or damaged parts like packing seals, valves, belts, and hoses. Recommended remedies involve replacing or repairing worn parts, cleaning valves or strainers, checking for proper operation of unloaders, and addressing issues like restrictions in plumbing or cavitation in inlet lines.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

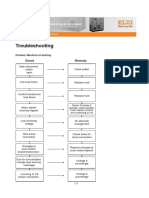

Pump System Malfunction

MALFUNCTION CAUSE REMEDY

The Pressure and/

Worn packing seals Replace packing seals

or the Delivery

Broken valve spring Replace spring

Drops

Belt slippage Tighten or Replace belt

Worn or Damaged nozzle Replace nozzle

Fouled discharge valve Clean valve assembly

Fouled inlet strainer Clean strainer

Worn or Damaged hose Repair/Replace hose

Worn or Plugged relief valve on pump Clean, Reset, and Replace worn

parts

Cavitation Check suction lines on inlet of

pump for restrictions

Unloader Check for proper operation

Water in crankcase High humidity Reduce oil change interval

Worn seals Replace seals

Noisy Operation Worn bearings Replace bearings, Refill crankcase

oil with recommended lubricant

Cavitation Check inlet lines for restrictions

and/or proper sizing

Rough/Pulsating Worn packing Replace packing

Operation with Inlet restriction Check system for stoppage, air

Pressure Drop leaks, correctly sized inlet

plumbing to pump

Accumulator pressure Recharge/Replace accumulator

Unloader Check for proper operation

Cavitation Check inlet lines for restrictions

and/or proper size

Pressure Drop Restricted discharge plumbing Re-size discharge plumbing to

at Gun flow rate of pump

Excessive Worn plungers Replace plungers

Leakage Worn packing/seals Adjust or Replace packing seals

Excessive vacuum Reduce suction vacuum

Cracked plungers Replace plungers

Inlet pressure too high Reduce inlet pressure

High Crankcase Wrong Grade of oil Giant oil is recommended

Temperature Improper amount of oil in crankcase Adjust oil level to proper amount

You might also like

- Jet Pump Troubleshooting Guide Rev 2 PDFDocument3 pagesJet Pump Troubleshooting Guide Rev 2 PDFMel FNo ratings yet

- Multi Stage Pump Troubleshooting Guide Rev 1Document2 pagesMulti Stage Pump Troubleshooting Guide Rev 1Edson França RodriguesNo ratings yet

- Troubleshooting For:: Premier Supplier of Pumps & PartsDocument6 pagesTroubleshooting For:: Premier Supplier of Pumps & Partsimam bukhoriNo ratings yet

- Gear Pump Troubleshooting GuideDocument3 pagesGear Pump Troubleshooting GuideRALPH JULES SARAUSNo ratings yet

- Gear Pump Troubleshooting Guide 2Document12 pagesGear Pump Troubleshooting Guide 2tepu msosaNo ratings yet

- Power Tongs Trouble ShootingDocument3 pagesPower Tongs Trouble ShootingAzlan RafiqueNo ratings yet

- Chapter 10: Pumps For Water SupplyDocument29 pagesChapter 10: Pumps For Water SupplyJasleneDimarananNo ratings yet

- BBA Pumps North America - Troubleshooting BADocument2 pagesBBA Pumps North America - Troubleshooting BAMarcosNo ratings yet

- Troubleshooting Charts For Eight Categories of Hydraulic ProblemsDocument9 pagesTroubleshooting Charts For Eight Categories of Hydraulic ProblemsGrant KasekeNo ratings yet

- PUMPSDocument21 pagesPUMPSAngga dwi raffiNo ratings yet

- Air Brake System TroubleshootingDocument5 pagesAir Brake System Troubleshootingbhanuka2009No ratings yet

- Operating & Maintenance Instructions: Type of Damage Cause Response External Leakage From Gas ValveDocument2 pagesOperating & Maintenance Instructions: Type of Damage Cause Response External Leakage From Gas ValveBill MurrayNo ratings yet

- Presentation 1Document20 pagesPresentation 1mame seidNo ratings yet

- 4306 - RAC - Practical 5Document7 pages4306 - RAC - Practical 5Sahil BurchundeNo ratings yet

- Vertical Inline Centrifugal Pump Troubleshooting GuideDocument4 pagesVertical Inline Centrifugal Pump Troubleshooting Guideadepp8642No ratings yet

- 7.1 Alignment TroubleshootingDocument6 pages7.1 Alignment TroubleshootingabdalwhabNo ratings yet

- TOM Training Centrifugal Compressors: TroubleshootingDocument5 pagesTOM Training Centrifugal Compressors: TroubleshootingAhmedNo ratings yet

- Engine ServiceDocument18 pagesEngine ServiceDhanu MalarNo ratings yet

- Troubleshooting Sub PumpDocument3 pagesTroubleshooting Sub Pumpahsanul haqueNo ratings yet

- Compressor Trouble ShoutingDocument7 pagesCompressor Trouble ShoutingDhiraj ShrivastavNo ratings yet

- Content9732691 PDFDocument17 pagesContent9732691 PDFRaphael LemosNo ratings yet

- Hyundai D6GA Fuel System PDFDocument53 pagesHyundai D6GA Fuel System PDFTonny Nguyen100% (3)

- Fuel Oil Pump Set (Worm Screw Pumps) : DL 2/150 ... 2/1000, DS 1/150 ... 1/1000, DS 4/650 ... 4/4000Document2 pagesFuel Oil Pump Set (Worm Screw Pumps) : DL 2/150 ... 2/1000, DS 1/150 ... 1/1000, DS 4/650 ... 4/4000徐玉坤No ratings yet

- Diagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts HardDocument11 pagesDiagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts HardAlejandro HernandezNo ratings yet

- General Diesel Engine Diagnostic Guide PDFDocument3 pagesGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3No ratings yet

- Liste Des Defauts 38Document5 pagesListe Des Defauts 38MMF PLUSNo ratings yet

- Troubleshooting The Hydraulic CircuitDocument3 pagesTroubleshooting The Hydraulic CircuitalexanderNo ratings yet

- 1225-1226 Список диагностики неисправностей кондиционера с ручным управлениемDocument2 pages1225-1226 Список диагностики неисправностей кондиционера с ручным управлениемalieks.klim1611No ratings yet

- Pump Troubleshooting: Problem Probable Cause SolutionDocument2 pagesPump Troubleshooting: Problem Probable Cause SolutionKarim MamdouhNo ratings yet

- Troubleshooting Guide DeaeratorsDocument2 pagesTroubleshooting Guide DeaeratorsMas ZuhadNo ratings yet

- Centrifugal Pump Troubleshooting ChartDocument6 pagesCentrifugal Pump Troubleshooting ChartDharmvir SinghNo ratings yet

- Chiller Troubleshooting CheckListDocument2 pagesChiller Troubleshooting CheckListMac Gerrard93% (15)

- 4 JB 1Document60 pages4 JB 1Rex Palmitos100% (1)

- Fluid Power General TroubleshootingDocument3 pagesFluid Power General Troubleshootinga7510378No ratings yet

- 50 General Maintenance Sept 2015Document3 pages50 General Maintenance Sept 2015Gerencia Rigar Colombia SASNo ratings yet

- Maintenance Schedule Surface MinerDocument8 pagesMaintenance Schedule Surface MinerSUBHASHNo ratings yet

- 75 Ts GuideDocument3 pages75 Ts GuideasursNo ratings yet

- Power Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky MovementsDocument1 pagePower Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky Movementsbetabet GeorgeNo ratings yet

- Book 1Document2 pagesBook 1Hasibullah MirzadNo ratings yet

- Troubleshooting - Air CompressorsDocument21 pagesTroubleshooting - Air CompressorsNikhil SonarbagkerNo ratings yet

- Troubleshooting Flow ChartsDocument16 pagesTroubleshooting Flow ChartsEzedin OsmanNo ratings yet

- TM and Repair of Centrifugal PumpsDocument29 pagesTM and Repair of Centrifugal PumpsPotter A. VijayNo ratings yet

- Manual Tecnico Motor TDIDocument146 pagesManual Tecnico Motor TDIMoysess OliverNo ratings yet

- Deaerator Troubleshooting Symptom Possible Causes Comments or Possible SolutionsDocument2 pagesDeaerator Troubleshooting Symptom Possible Causes Comments or Possible SolutionsRizki DarmawanNo ratings yet

- UntitledDocument1 pageUntitledanilNo ratings yet

- Microproject Report HPCDocument7 pagesMicroproject Report HPCkadamnavadeep5863No ratings yet

- Optimizacion de Sistemas de DistribucionDocument2 pagesOptimizacion de Sistemas de DistribucionJesus RodriguezNo ratings yet

- 47 Dosing Device Specification For Outer Circulating WaterDocument8 pages47 Dosing Device Specification For Outer Circulating WaterRiyal MorshadNo ratings yet

- Troubeshootings 8 Wheeler DHTC Detc-1Document27 pagesTroubeshootings 8 Wheeler DHTC Detc-1khan11k100% (1)

- Extruder MaintenanceDocument5 pagesExtruder MaintenanceRen Joseph LogronioNo ratings yet

- Centrifugal Pumps Problem SolvingDocument1 pageCentrifugal Pumps Problem SolvingKamal UddinNo ratings yet

- Hyundai HD 78Document19 pagesHyundai HD 78manuelmanriqueNo ratings yet

- Troubleshooting - MaceratorsDocument11 pagesTroubleshooting - MaceratorsBeni SaputraNo ratings yet

- Name: Abdul Nafe SEAT NUMBER: B1333001 Subject: Maintanence and SafetyDocument7 pagesName: Abdul Nafe SEAT NUMBER: B1333001 Subject: Maintanence and SafetyABDulNafeNo ratings yet

- Troubleshooting: No Liquid DeliveryDocument4 pagesTroubleshooting: No Liquid DeliveryFakhreddine ZahiNo ratings yet

- BBA Pumps North America - TroubleshootingDocument2 pagesBBA Pumps North America - TroubleshootingMarcosNo ratings yet

- Pump, Troubleshooting: Service InformationDocument1 pagePump, Troubleshooting: Service InformationPreett Rajin MenabungNo ratings yet

- Pump Head CalculationDocument2 pagesPump Head CalculationssarangNo ratings yet

- RED SUN Self-Charging Thermal - Electrical Platform For Developments & Transport - Water-Power-HVAC & Ice & Energy Arbitrage - DR, Colombia & PanamaDocument56 pagesRED SUN Self-Charging Thermal - Electrical Platform For Developments & Transport - Water-Power-HVAC & Ice & Energy Arbitrage - DR, Colombia & PanamaJay DubinskyNo ratings yet

- Mingyung Solar Power System DatasheetDocument19 pagesMingyung Solar Power System DatasheetPieter FourieNo ratings yet

- SM 11Document64 pagesSM 11Mohamed AdelNo ratings yet

- New Technical Folder For The YELLOW Brochure - TheRMAL OIL HEATERSDocument23 pagesNew Technical Folder For The YELLOW Brochure - TheRMAL OIL HEATERSOSAMANo ratings yet

- Brochure Steam AccumulatorDocument2 pagesBrochure Steam AccumulatorFrank HuNo ratings yet

- Basic Fire Fighting TrainingDocument63 pagesBasic Fire Fighting TrainingPravin Bodkhe100% (4)

- Well Stimulation Job ProgramDocument36 pagesWell Stimulation Job Programmuhammad anasNo ratings yet

- Siemens AG: Circuit Diagram Energy Management - Medium Voltage & SystemsDocument170 pagesSiemens AG: Circuit Diagram Energy Management - Medium Voltage & SystemsEdciel EbuenNo ratings yet

- Full Blasting Licence SyllabusDocument1 pageFull Blasting Licence Syllabustmadzi0% (1)

- NEMA SM-23 - Steam Turbine For Mechanical Drive SystemDocument62 pagesNEMA SM-23 - Steam Turbine For Mechanical Drive SystemkhorzooNo ratings yet

- Restructuring of Spares Planning Group As Per Category Codes Wef 03/10/17Document1 pageRestructuring of Spares Planning Group As Per Category Codes Wef 03/10/17yokelomeNo ratings yet

- CH 20 ExercisesDocument1 pageCH 20 ExercisesPaul BryanNo ratings yet

- ME/MTECH ELECTRICAL Project ListDocument7 pagesME/MTECH ELECTRICAL Project ListBUDDHA ELECTRICAL SMART TECHNOLOGIESNo ratings yet

- s540 Flue Gas Analyser Maxilyzer NG PlusDocument2 pagess540 Flue Gas Analyser Maxilyzer NG Plusisraelnogueira3No ratings yet

- Cargo Pumps Oper - ManualDocument19 pagesCargo Pumps Oper - ManualankitNo ratings yet

- FA2020 - ENE505 - L7 - The Power GridDocument48 pagesFA2020 - ENE505 - L7 - The Power GridTommy TrojanNo ratings yet

- Deaerators: 2-Aug-13 1 © 2012 Larsen & Toubro Limited: All Rights ReservedDocument36 pagesDeaerators: 2-Aug-13 1 © 2012 Larsen & Toubro Limited: All Rights ReservedPuspaanjaliNo ratings yet

- Cryocooler Technical Instruction, RDK-205DDocument12 pagesCryocooler Technical Instruction, RDK-205DluwerNo ratings yet

- Accepted Manuscript: Renewable EnergyDocument38 pagesAccepted Manuscript: Renewable EnergyPrivateNo ratings yet

- Stratified TES Tank ReportDocument8 pagesStratified TES Tank ReportSomnath RangrejNo ratings yet

- PV Carport Net-MeteringDocument2 pagesPV Carport Net-MeteringMohammad Al-RfoohNo ratings yet

- Turbine ACSDocument1 pageTurbine ACSpowerplant profNo ratings yet

- Wilo-Actun ZETOS: Design TypekeyDocument2 pagesWilo-Actun ZETOS: Design Typekeyshohan pteNo ratings yet

- Ecotec Pro Combi Boiler 1786926Document2 pagesEcotec Pro Combi Boiler 1786926Mohsin KhanNo ratings yet

- X2090allegatoDEPLIANT1-2X Suhr 08-21 enDocument4 pagesX2090allegatoDEPLIANT1-2X Suhr 08-21 enAntonioNo ratings yet

- Maglev Vertical Axis Wind Turbine (VAWT) Horizontal Axis Wind Turbine (HAWT)Document59 pagesMaglev Vertical Axis Wind Turbine (VAWT) Horizontal Axis Wind Turbine (HAWT)Mr. K.S. Raghul Asst Prof MECHNo ratings yet

- Failure Report: Toromont CompressorDocument11 pagesFailure Report: Toromont CompressorudbarryNo ratings yet

- E3 13 08ggDocument9 pagesE3 13 08ggAgent 47No ratings yet

- 00 Perhitungan Alat Besar 1-DeSKTOP-NJGKKH8Document359 pages00 Perhitungan Alat Besar 1-DeSKTOP-NJGKKH8Muhammad FakhrizalNo ratings yet