Professional Documents

Culture Documents

RCC Pre Pour

Uploaded by

manish2603200 ratings0% found this document useful (0 votes)

20 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views1 pageRCC Pre Pour

Uploaded by

manish260320Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

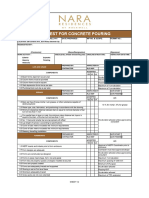

QC CARD

LODHA UPPER THANE

R C C PRE POUR

INSPECTION Request No-

Building Name : Structure:

Level: Date of Casting :

Location : Grade :

Source : Qty:

Sr. Contractor Execution QA Department

Perticulars Tolerances Remarks

No Observation Observation Observation

A SHUTTERING CHECKS - CONVENTIONAL

1 Props in plum & located at exactly end of the spans ± 10 %

2 Shuttering, supports and bracings as per formwork design/ approved ±5%

3 Horizontal wallers in full contect with vertical runners (Column) ±5%

4 Battens in full contect with spans / channels/ I beam (Slab) ±5%

5 Packing to stirrup head / channel / I beam given if used ±5%

6 Opening of stirrup head not more than 60 % Zero

7 Pin of Props used Min-12mm Dia Zero

±5 / 5 / 5

8 Centre, alignment and orientation of member checked

mm

9 Gaps sealing and cleaning of member done Zero

10 Approved shuttering Oil/ releasing agent has been applied Nil

11 Kandas / Cover block provided as required Zero

B SHUTTERING CHECKS - MIVAN

a. Pre Erection Checks.

1 Slab cleaned and marking of layout done Nil

2 Check for reinforcementsas per drawing Nil

3 check for electrical boxes & service lines if any Nil

4 all formwork coated with approved releasing agent Nil

a. Post Erection Checks.

1 Formwork erected as per sequence / Numbering Nil

2 Wall ties installed correctly with PVC sleeve Nil

3 All pins and wedges fixed and tightened Nil

4 All shutters checked for plumb, right angle & alignment ±2 mm

Wexternal working platforms fastened securely to the concrete

5 Nil

structure

6 Spaces between the rocker and floor levelhave been sealed ±2 %

Plumb and alignment of openings, internal walls, external walls & level

7 ± 5 mm

of beam and slab soffits checked

C REINFORCEMENT CHECKS

1 As per drawing with correct spacing and Diameter Nil

2 No crowing bars Zero

3 Lap length & hook bent @ 135 O as per drawing 15mm

4 Chairs provided as specified / required Zero

5 Cover block - Size / Strength / spacing checked Zero

6 Joggling done in (1 in 6) with extra stirrups Zero

7 Master ring provided in column to ensure spacing of main bar Nil

D ELECTRICAL CONDUCTING

1 Done as per the Drawing Nil

2 Drop position not in cover zone checked Zero

3 Space between Conduits maintained checked ±5%

4 Consultant's Approvel form filled Nil

QC BY (Contractor) QC BY (Project Execution) QE BY (Quality Dept.)

Name : Name : Name :

Signature: Signature: Signature:

Date & time: Date & time: Date & time:

Format No-LUT/QA/QF-002 R0 Dt-10-2-18

You might also like

- Checklist by Girish MishraDocument30 pagesChecklist by Girish MishraDeepak Kaushik100% (1)

- Concrete Work Check List-30-06-2022Document6 pagesConcrete Work Check List-30-06-2022Mobin100% (1)

- Concrete Placement Inspection ChecklistDocument4 pagesConcrete Placement Inspection Checklistzelda1022No ratings yet

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- Internal Plastering 16Document1 pageInternal Plastering 16manish260320No ratings yet

- CONTRACT NO.20705 Bitumen Storage Facility AT Port Khalid SharjahDocument17 pagesCONTRACT NO.20705 Bitumen Storage Facility AT Port Khalid SharjahFaruk OcalNo ratings yet

- Plastering Checklist PDFDocument1 pagePlastering Checklist PDFabdelmjidNo ratings yet

- Plastering ChecklistDocument1 pagePlastering Checklistmanish83% (6)

- Shuttering Check-List For TWDDocument2 pagesShuttering Check-List For TWDMohammed Shabbir LunawadiNo ratings yet

- Total Quality Management Assignment NO 5Document6 pagesTotal Quality Management Assignment NO 5Ramashankar YadavNo ratings yet

- Adobe Scan 23-Aug-2023Document2 pagesAdobe Scan 23-Aug-2023projectNo ratings yet

- 5.Rcc ConcreteDocument1 page5.Rcc ConcreteMuthu Kumar palaniNo ratings yet

- Plastering CHK ListDocument2 pagesPlastering CHK Listhafis0% (1)

- Checklist For Sleeves & Puddle Flang InstallationDocument1 pageChecklist For Sleeves & Puddle Flang InstallationBelal AlrwadiehNo ratings yet

- Inspection and Testing PlanDocument41 pagesInspection and Testing PlanRami KhedroNo ratings yet

- Cable GlandingDocument5 pagesCable GlandingSourav RanaNo ratings yet

- Checklist For Installation of Underground Checmical Waste TanksDocument1 pageChecklist For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNo ratings yet

- SSE QC CIV 402 Rev0 PDFDocument2 pagesSSE QC CIV 402 Rev0 PDFBhalsingh JangraNo ratings yet

- 4.pour Card For RCC WorkDocument1 page4.pour Card For RCC WorkMuthu Kumar palaniNo ratings yet

- Inspection Release Note: ChevronDocument3 pagesInspection Release Note: ChevronHassan M. OsmanNo ratings yet

- Plastering Work ChecklistDocument1 pagePlastering Work ChecklistNadira PervinNo ratings yet

- Plastering Work ChecklistDocument1 pagePlastering Work ChecklistAlphaNo ratings yet

- Checklist (Underground Pipe Laying Report) : Mr. Aden LiuDocument36 pagesChecklist (Underground Pipe Laying Report) : Mr. Aden LiuADEN LIU100% (1)

- Fabrication & Erection of Steel Works ChecklistDocument1 pageFabrication & Erection of Steel Works ChecklisttaghlubNo ratings yet

- Weil-qe&I-cl-002 Cable Glanding and TerminationDocument1 pageWeil-qe&I-cl-002 Cable Glanding and TerminationSayed AhammadNo ratings yet

- IGCC-OPM-QUA-FMT-0091 Rev.0 - CABLE TRENCH AND DUCT BANK INSPECTION BEFORE CABLE PULLINGDocument1 pageIGCC-OPM-QUA-FMT-0091 Rev.0 - CABLE TRENCH AND DUCT BANK INSPECTION BEFORE CABLE PULLINGAhmedNo ratings yet

- Concrete Preplacement ChecklistDocument5 pagesConcrete Preplacement ChecklistAr Hitesh ParmarNo ratings yet

- 3 Formwork Check List - Beams & SlabsDocument1 page3 Formwork Check List - Beams & Slabsgopi.bcimNo ratings yet

- I2114-OPR-ITP-CHK-007A (01) Pour Inspection Checklist - RCCDocument3 pagesI2114-OPR-ITP-CHK-007A (01) Pour Inspection Checklist - RCCPrasant Kumar SahooNo ratings yet

- 3 Reinforcement Check List - Beam Capital & Slab Grade SlabDocument2 pages3 Reinforcement Check List - Beam Capital & Slab Grade Slabgopi.bcimNo ratings yet

- Cable Tray Inspection ListDocument1 pageCable Tray Inspection ListTreesa Archnana100% (1)

- INSPECTION SHEET (Rebar)Document3 pagesINSPECTION SHEET (Rebar)Ye YintNo ratings yet

- Final Checklist-SLABDocument2 pagesFinal Checklist-SLABAh Rashed100% (1)

- 1A-Check List - CI Pipes - InstallationDocument1 page1A-Check List - CI Pipes - InstallationRajput AmitNo ratings yet

- Qap PDFDocument3 pagesQap PDFRavi BhadaniNo ratings yet

- S.No Description Format No Rev RemarksDocument23 pagesS.No Description Format No Rev RemarksGulam Mujtaba KhanNo ratings yet

- HPS QA ChecklistsDocument24 pagesHPS QA ChecklistsparthNo ratings yet

- Masonry - Block Joint Mortar 15bDocument1 pageMasonry - Block Joint Mortar 15bmanish260320No ratings yet

- Block Work CHK ListDocument1 pageBlock Work CHK Listhafis100% (1)

- ITD-GEN-000-CIV-CHK-0005 - 0 - Building Civil ITPsDocument16 pagesITD-GEN-000-CIV-CHK-0005 - 0 - Building Civil ITPsBerry UmpolaNo ratings yet

- Weil Qe&i CL 003 Installtion of CablesDocument1 pageWeil Qe&i CL 003 Installtion of CablesSayed AhammadNo ratings yet

- Block - Brick MasonryDocument1 pageBlock - Brick MasonryGabriel GabeNo ratings yet

- SECL-CV210-A4 Pre-Pouring InspectionDocument1 pageSECL-CV210-A4 Pre-Pouring InspectionhadefNo ratings yet

- Mod 1 FuDocument2 pagesMod 1 FuJacky BaculiNo ratings yet

- CONCRETE POURING CHECKLISTDocument2 pagesCONCRETE POURING CHECKLISTjohainaNo ratings yet

- Checklist For Under Ground Water Piping InstallationDocument1 pageChecklist For Under Ground Water Piping InstallationBelal Alrwadieh100% (1)

- ALL Checklist - FinalDocument33 pagesALL Checklist - FinalKaran KumarNo ratings yet

- PVC ChecklistDocument1 pagePVC Checklistchakravarthi kanugulaNo ratings yet

- 3.5 Network CabinetDocument1 page3.5 Network CabinetBoualem AisNo ratings yet

- 4.reinforcement For Concrete WorkDocument1 page4.reinforcement For Concrete WorkAshrafulAlomNo ratings yet

- Plastering ChecklistDocument3 pagesPlastering ChecklistayushNo ratings yet

- CONCRETE TOPPINGDocument1 pageCONCRETE TOPPINGjohainaNo ratings yet

- Post Pour Inspection ChecklistDocument2 pagesPost Pour Inspection Checklistwalidtkh78No ratings yet

- ENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - ADocument9 pagesENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AyoeyNo ratings yet

- Cro DC 01Document22 pagesCro DC 01فايز الحارثيNo ratings yet

- Aluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and MarkingDocument4 pagesAluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and Markinganbunilavan50% (2)

- Checklist For RCCDocument1 pageChecklist For RCCChirag TanavalaNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Low Speed Aerodynamics: by Jackie BerryDocument12 pagesLow Speed Aerodynamics: by Jackie Berrymkashkooli_scribdNo ratings yet

- Construction of Multi-Purpose Building (Barangay Hall) at Brgy Balansay, Mamburao, Occidental MindoroDocument15 pagesConstruction of Multi-Purpose Building (Barangay Hall) at Brgy Balansay, Mamburao, Occidental MindoroAJ RAVALNo ratings yet

- Analysis and Design of Singly Reinforced BeamDocument2 pagesAnalysis and Design of Singly Reinforced BeamLouise DiazNo ratings yet

- Nukiyama & Tanasawa Correlation: Liquid Mean Droplet Size or Sauter Mean DiameterDocument2 pagesNukiyama & Tanasawa Correlation: Liquid Mean Droplet Size or Sauter Mean Diametersreekanth reddyNo ratings yet

- Diploma Dce PROJECTDocument91 pagesDiploma Dce PROJECTSuthir SuthiNo ratings yet

- Layher Bracing Within Temporary Works StructuresDocument45 pagesLayher Bracing Within Temporary Works Structuresfazlullah fazilNo ratings yet

- TECH SPECS. Two Storey Residential House With Roof Deck VIRAY 042617Document27 pagesTECH SPECS. Two Storey Residential House With Roof Deck VIRAY 042617April Rose SantosNo ratings yet

- Piercap Strut and TieDocument55 pagesPiercap Strut and TieTamizhan_KNo ratings yet

- Installation Manual: Starken AAC Block WallDocument40 pagesInstallation Manual: Starken AAC Block WallEvans Corp100% (2)

- TCC31 One-Way SlabsDocument43 pagesTCC31 One-Way SlabsMuscadin MakensonNo ratings yet

- Review Iftekher 2013Document11 pagesReview Iftekher 2013RezaNo ratings yet

- Design of ConcreteDocument146 pagesDesign of ConcreteMhariecriszReazo100% (1)

- Specification For Testing of Bored PileDocument22 pagesSpecification For Testing of Bored PileAlly KhooNo ratings yet

- Shafeeq 123Document136 pagesShafeeq 123Maaz Uddin SiddiquiNo ratings yet

- PCI Hollow Core Manual 2nd EdDocument142 pagesPCI Hollow Core Manual 2nd EdRosalio AcostaNo ratings yet

- Design of Shear Reinforcement in RCC Structures: Intended Learning Outcomes (ILO)Document16 pagesDesign of Shear Reinforcement in RCC Structures: Intended Learning Outcomes (ILO)anirbanpwd76No ratings yet

- Overview Part 2Document59 pagesOverview Part 2Kim NamjoonNo ratings yet

- UPVC DOORS & WINDOW NewDocument14 pagesUPVC DOORS & WINDOW NewRUSHALI SRIVASTAVANo ratings yet

- Examination Procedure For Runway Beam InspectionDocument6 pagesExamination Procedure For Runway Beam InspectionTrust EmmaNo ratings yet

- Floor Truss Span TablesDocument2 pagesFloor Truss Span TablesTucker KellyNo ratings yet

- 19 - Heating and Ventilating Systems - HVACDocument6 pages19 - Heating and Ventilating Systems - HVACJoshua EvansNo ratings yet

- 970 Taken by Surprise 0tDocument10 pages970 Taken by Surprise 0ttwinkle00033% (6)

- Components of Road Structure and Method of ConstructionDocument14 pagesComponents of Road Structure and Method of ConstructionM iqbal100% (1)

- GEOWEB Load Support Contruction PackageDocument31 pagesGEOWEB Load Support Contruction PackageJohnEMERYNo ratings yet

- Stringing ChartDocument4 pagesStringing ChartHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Mechanisms of Cracking and Debonding in Asphalt and Composite PavementsDocument256 pagesMechanisms of Cracking and Debonding in Asphalt and Composite PavementsSk Sartaz AhmedNo ratings yet

- Geon™ Vinyl Fittings M1000: Polyone CorporationDocument3 pagesGeon™ Vinyl Fittings M1000: Polyone CorporationJames FaunceNo ratings yet

- 5 Over 2 Podium Design WoodWorks Part 2Document4 pages5 Over 2 Podium Design WoodWorks Part 2albertoxinaNo ratings yet

- Assignment 2 - New PDFDocument2 pagesAssignment 2 - New PDFprasadNo ratings yet