Professional Documents

Culture Documents

Block - Brick Masonry

Uploaded by

Gabriel GabeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Block - Brick Masonry

Uploaded by

Gabriel GabeCopyright:

Available Formats

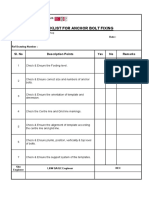

BLOCK / BRICK MASONRY Report No:

AS PER IS 2572:2005

CHECKLIST Date:

Customer : Project : Project Code:

Sub- Contractor : WO No & Amndt, If any.:

Manufacturer : PO No & Amndt, If any.:

Item Description: Identification No.

Location : Sub Location:

Package: Drg No & Rev No :

FQP No. & Rev No. RFIC No.

Qty: Grid No & Level:

Sl.No. Description of Check Points Checked Remarks

Yes No NA

A Pre Masonry Work

1 Approved drawing is available.

2 Make is approved by client

3 Method Statement is approved by client

Ensure cleaning done in all the areas of entire floor before starting the line-out of

3

masonry & cement slurry applied.

4 Ensure higher grade concrete or DPC course on RCC done & cured as specified.

Ensure hacking of RCC column surface is done / bonding agent applied as per

5

manufacturer's specification

6 Ensure green mortar dash coat is applied to RCC surface.

7 Ensure Blocks made wet by sprinkling water as before start of work

8 Ensure Bricks are immersed in water prior to use.

9 Ensure Metal / GI tray is available at work location for mixing of mortar

10 Ensure availability of measurement boxes for batching of sand.

Ensure all type of tools such as Mason's trowel, plumb bob, line thread, spirit

11

level, right angle, measuring tape, etc., are available with mason.

12 Ensure all measuring equipment/ tools are in good condition

13 Interface between Architectural, Structural & MEP works is checked.

B During Masonry Checks

Ensure dimensions and diagonals of room are checked after completion of first

14

layer.

15 Ensure mortar prepared is used within initial setting time

Ensure alignment & plumb of block work is within tolerance limit as per

16

specification

17 Horizontal/vertical joint thickness is uniformly maintained as per specification

18 Ensure raking and simultaneous brooming of joints is done

19 Ensure height of masonry constructed in a day is not more than 1m.

Ensure RCC band / Wire mesh is placed in masonry at 1m (applicable for 4”

20

thickness wall) as specified.

Ensure joint between RCC frame & masonry is kept 20 mm and filled with metal

21

packing as per specification

22 Ensure Lintel anchorage & bearing is adequate as per approved drawing

23 Ensure Anchoring of holdfast is as specified.

C Post Masonry Checks

24 Ensure Date of Block work is mentioned

Ensure curing of block masonry carried out for a minimum 7-10 days after

25

construction.

26 Chasing and finishing of grooves done as specified.

27 Ensure electrical boxes not to be fixed back to back in 4’’ wall

Remarks :

Signature of Sub - Contractor & Date Signature of TPL-FQE & Date Signature of Customer / Inspection Authority & Date

Format No.08.03.05-FMT-C-BRK-CL-001-R00

Page: 1of1

You might also like

- Ledge Wall ConstructionDocument3 pagesLedge Wall ConstructionGabriel Gabe100% (1)

- Cable GlandingDocument5 pagesCable GlandingSourav RanaNo ratings yet

- Checklist For Tile FlooringDocument1 pageChecklist For Tile FlooringGabriel Gabe75% (4)

- PIP PNFS0001 Pipe Supports DetailsDocument167 pagesPIP PNFS0001 Pipe Supports DetailsSeungmin Paek67% (6)

- Checklist For Site WorksDocument18 pagesChecklist For Site Worksgkkeyen83% (40)

- Solid Block WorkDocument8 pagesSolid Block WorkGabriel GabeNo ratings yet

- Cathodic Protection & AC/DC Interference Mitigation Installation, Inspection & Test Plan (ITP)Document10 pagesCathodic Protection & AC/DC Interference Mitigation Installation, Inspection & Test Plan (ITP)wei gao100% (1)

- Checklist For Anchor Bolt FixingDocument1 pageChecklist For Anchor Bolt FixingGabriel Gabe100% (4)

- Itp Package UnitDocument2 pagesItp Package UnitWasim AhmedNo ratings yet

- MS For PEB Erection R1Document16 pagesMS For PEB Erection R1Gabriel GabeNo ratings yet

- Checklist For Earthing & Bonding System InstallationDocument1 pageChecklist For Earthing & Bonding System InstallationPrashant Kadam100% (2)

- Checklist For Earthing & Bonding System InstallationDocument1 pageChecklist For Earthing & Bonding System InstallationPrashant Kadam100% (1)

- Checklist For BackfillingDocument1 pageChecklist For BackfillingGabriel GabeNo ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- Electrical ConduitingDocument1 pageElectrical ConduitingGabriel GabeNo ratings yet

- ELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Document2 pagesELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Muhammad Irfan100% (1)

- Checklist For VDF WorksDocument1 pageChecklist For VDF WorksGabriel Gabe100% (2)

- Sanitary Fixtures Installation & TestingDocument1 pageSanitary Fixtures Installation & TestingGabriel GabeNo ratings yet

- Sanitary Fixtures Installation & TestingDocument1 pageSanitary Fixtures Installation & TestingGabriel GabeNo ratings yet

- Tank Fabrication ProcedureDocument11 pagesTank Fabrication ProcedureNurul100% (2)

- Interior & Exterior PaintingDocument11 pagesInterior & Exterior PaintingGabriel Gabe50% (2)

- Check List For Backfilling WorksDocument2 pagesCheck List For Backfilling WorksYash SharmaNo ratings yet

- Project Name Project No.: OOOO: General Cable Pulling WorksDocument8 pagesProject Name Project No.: OOOO: General Cable Pulling WorksReynante AlimNo ratings yet

- Master List of Checklist New With All LOGOsDocument22 pagesMaster List of Checklist New With All LOGOsRahul Jaiswal100% (1)

- World Bank Rural Water Supply Manual Vol2 Construction Supervision Manual 2012Document168 pagesWorld Bank Rural Water Supply Manual Vol2 Construction Supervision Manual 2012Brilian DwiNo ratings yet

- Quality Control Checklist Excavation: Consultant: Gulf Engineering&Industrial ConsultancyDocument12 pagesQuality Control Checklist Excavation: Consultant: Gulf Engineering&Industrial ConsultancyAlvin Badz0% (1)

- Kenr5396 04 01 AllDocument76 pagesKenr5396 04 01 AlllunikmirNo ratings yet

- Concrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17Document1 pageConcrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17mahesh naikNo ratings yet

- Checklist For VDFDocument1 pageChecklist For VDFGabriel GabeNo ratings yet

- GVPI Assessment-EASA 2014 v2Document7 pagesGVPI Assessment-EASA 2014 v2mersiumNo ratings yet

- Installation of Instrument Switches (Pressure - Flow - Temperature - Level) CLDocument1 pageInstallation of Instrument Switches (Pressure - Flow - Temperature - Level) CLZulfequar R. Ali KhanNo ratings yet

- Checklist For Painting WorksDocument1 pageChecklist For Painting WorksGabriel Gabe100% (2)

- Installation of Transmitter - Pressure - Flow-Level-Temperature Check ListDocument1 pageInstallation of Transmitter - Pressure - Flow-Level-Temperature Check ListZulfequar R. Ali Khan100% (1)

- Underground Drainage Pipes - Installation & TestingDocument1 pageUnderground Drainage Pipes - Installation & TestingBharathraj RajNo ratings yet

- Format of Plaster, Plumbing and Hydro TestDocument1 pageFormat of Plaster, Plumbing and Hydro Testmratyunjay tripathiNo ratings yet

- FRP Gratings FixingDocument1 pageFRP Gratings FixingBharathraj RajNo ratings yet

- ELECT-TIC-1.3 (WireCable Laying & Pulling)Document2 pagesELECT-TIC-1.3 (WireCable Laying & Pulling)Muhammad IrfanNo ratings yet

- Waste Management in Leather IndustryDocument27 pagesWaste Management in Leather IndustryStan Larisa50% (4)

- Materials Engineer Accreditation Examination ReviewerDocument67 pagesMaterials Engineer Accreditation Examination ReviewerJonathan Del Rosario100% (1)

- Installation of Granite CounterDocument1 pageInstallation of Granite CounterBharathraj RajNo ratings yet

- Material Traceability Inspection ReportDocument32 pagesMaterial Traceability Inspection ReportBalmiki SinghNo ratings yet

- Paver Blocks FixingDocument1 pagePaver Blocks FixingBharathraj RajNo ratings yet

- Structural Inspection Report - FinalDocument1 pageStructural Inspection Report - FinaltalhaNo ratings yet

- Ship Piping SystemDocument19 pagesShip Piping SystemAtandho Gama MagwasyarNo ratings yet

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Specs For NG - MFO Fired Thermal Oil HeaterDocument52 pagesSpecs For NG - MFO Fired Thermal Oil HeaterRakapradiftaNo ratings yet

- Check ListDocument19 pagesCheck ListPanruti S SathiyavendhanNo ratings yet

- Design For Manufacturing Concurrent EngineeringDocument41 pagesDesign For Manufacturing Concurrent Engineeringkaliyaram100% (1)

- PlumbingDocument1 pagePlumbingGabriel GabeNo ratings yet

- PlumbingDocument1 pagePlumbingGabriel GabeNo ratings yet

- Installation of Flow Meter Check ListDocument1 pageInstallation of Flow Meter Check ListZulfequar R. Ali Khan100% (2)

- Amarok 2011Document79 pagesAmarok 2011NPNo ratings yet

- Textile Warp SizingDocument19 pagesTextile Warp SizingAmir YasinNo ratings yet

- False CeilingDocument2 pagesFalse CeilingGabriel GabeNo ratings yet

- Adobe Scan 25-Oct-2022Document6 pagesAdobe Scan 25-Oct-2022himanshu koleyNo ratings yet

- Checklist For External Wall Cladding With Bison - Gypsum BoardDocument1 pageChecklist For External Wall Cladding With Bison - Gypsum BoardGabriel GabeNo ratings yet

- Adobe Scan 09-Mar-2023Document3 pagesAdobe Scan 09-Mar-2023himanshu koleyNo ratings yet

- Installation of Granite CounterDocument1 pageInstallation of Granite CounterGabriel GabeNo ratings yet

- ACP Cladding InstallationDocument1 pageACP Cladding InstallationGabriel GabeNo ratings yet

- Checklist For Marble Dry Cladding WorkDocument1 pageChecklist For Marble Dry Cladding WorkGabriel GabeNo ratings yet

- Check List - ConcretDocument1 pageCheck List - ConcretSharan BhamshettyNo ratings yet

- Checklist For Turnstile FixingDocument1 pageChecklist For Turnstile FixingGabriel GabeNo ratings yet

- Checklist For Glass DoorDocument1 pageChecklist For Glass DoorGabriel GabeNo ratings yet

- Installation of Beacon - Hooter - Manual Call Point (Fire & Gas) Check ListDocument1 pageInstallation of Beacon - Hooter - Manual Call Point (Fire & Gas) Check ListZulfequar R. Ali Khan100% (1)

- Project: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: VRF System Installation Inspection ChecklistDocument2 pagesProject: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: VRF System Installation Inspection ChecklistWasim AhmedNo ratings yet

- ITD-GEN-000-CIV-CHK-0005 - 0 - Building Civil ITPsDocument16 pagesITD-GEN-000-CIV-CHK-0005 - 0 - Building Civil ITPsBerry UmpolaNo ratings yet

- FM-PN-102-01 Blinding Concrete RecordsDocument1 pageFM-PN-102-01 Blinding Concrete RecordsWalid MahmoudNo ratings yet

- Project: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: Suspended Type Fan Installation ChecklistDocument2 pagesProject: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: Suspended Type Fan Installation ChecklistWasim AhmedNo ratings yet

- Checklist For Flush DoorDocument1 pageChecklist For Flush DoorGabriel GabeNo ratings yet

- F76005 - Cable Pulling Inspection ChecklistDocument1 pageF76005 - Cable Pulling Inspection ChecklistgameprabusinghjosephselvinNo ratings yet

- FQP Format Cqa-IV-r2 DT 200510Document2 pagesFQP Format Cqa-IV-r2 DT 200510sheb20040% (1)

- Blue Ladder Epc Solutions Pvt. LTD.: Job No. Project ClientDocument10 pagesBlue Ladder Epc Solutions Pvt. LTD.: Job No. Project ClientJitendra PNo ratings yet

- Fencing - ChecklistDocument1 pageFencing - ChecklistJOEL KISIMBANo ratings yet

- BMJV-QUA-F19 Method Statement Template R03 Storm WaterDocument11 pagesBMJV-QUA-F19 Method Statement Template R03 Storm WaterTaiwo OshinNo ratings yet

- Above Grade and Embedded Conduits ChecklistDocument1 pageAbove Grade and Embedded Conduits ChecklistsartajNo ratings yet

- Installation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListDocument1 pageInstallation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListZulfequar R. Ali KhanNo ratings yet

- Installation of Pressure (PG & DPG) & Level Gauge Check ListDocument2 pagesInstallation of Pressure (PG & DPG) & Level Gauge Check ListZulfequar R. Ali KhanNo ratings yet

- SECL-CV210-A4 Pre-Pouring InspectionDocument1 pageSECL-CV210-A4 Pre-Pouring InspectionhadefNo ratings yet

- 5.Rcc ConcreteDocument1 page5.Rcc ConcreteMuthu Kumar palaniNo ratings yet

- Boiler Inspection FormDocument1 pageBoiler Inspection Formjuarsa r100% (1)

- Checklist For Turnstile FixingDocument1 pageChecklist For Turnstile FixingGabriel GabeNo ratings yet

- MSDS - Sikafloor 291 Comp. CDocument7 pagesMSDS - Sikafloor 291 Comp. CGabriel GabeNo ratings yet

- GSB GradationDocument1 pageGSB GradationGabriel GabeNo ratings yet

- Checklist For Marble Dry Cladding WorkDocument1 pageChecklist For Marble Dry Cladding WorkGabriel GabeNo ratings yet

- Sikafloor 290 - TDSDocument4 pagesSikafloor 290 - TDSGabriel GabeNo ratings yet

- Hydrostatic - Pneumatic Test Inspection ReportDocument1 pageHydrostatic - Pneumatic Test Inspection ReportGabriel GabeNo ratings yet

- RFICDocument1 pageRFICGabriel GabeNo ratings yet

- Interior & Exterior PlasteringDocument7 pagesInterior & Exterior PlasteringGabriel GabeNo ratings yet

- Apcrda - Go-Type-1, Go-Type-2 & Group-D Housing Project - Package 3Document4 pagesApcrda - Go-Type-1, Go-Type-2 & Group-D Housing Project - Package 3Gabriel GabeNo ratings yet

- Checklist For Excavation: Sl. No Description Points Yes No RemarksDocument1 pageChecklist For Excavation: Sl. No Description Points Yes No RemarksGabriel GabeNo ratings yet

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraNo ratings yet

- HZS150P-36: Polycrystalline Solar Module FeatureDocument2 pagesHZS150P-36: Polycrystalline Solar Module FeatureEdrViidaurreGonzalesNo ratings yet

- Specification of Stainless Steel Pipe Fittings and FlangesDocument1 pageSpecification of Stainless Steel Pipe Fittings and Flangesnarendar.1No ratings yet

- En 4J2 1F PDFDocument634 pagesEn 4J2 1F PDFCristhian CazasNo ratings yet

- System Reference.Document28 pagesSystem Reference.Ronald Bienemi PaezNo ratings yet

- Properties of ConcreteDocument27 pagesProperties of ConcreteEman AgiusNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/42Document13 pagesCambridge IGCSE: CHEMISTRY 0620/42Maram MohanNo ratings yet

- Impression Compound 1Document16 pagesImpression Compound 1hbux64551No ratings yet

- TLA 1000 LiteratureDocument2 pagesTLA 1000 Literaturechandraprakashhh0% (1)

- Brochure WB146 5Document10 pagesBrochure WB146 5Daniel FuhrNo ratings yet

- 2018 PP Ce Pet PaperDocument10 pages2018 PP Ce Pet PaperULISESNo ratings yet

- Colour Coding of pipes-SADocument9 pagesColour Coding of pipes-SAjeykumar.BalannairNo ratings yet

- Introducing Eggshell Waste For Paper Industry: Part I Suitability For Bagasse PulpDocument5 pagesIntroducing Eggshell Waste For Paper Industry: Part I Suitability For Bagasse Pulpnctneo .01No ratings yet

- Manual: Order Number Order Part Doc-ID Language 229983 WS ADS - 229983#1 - 00Document194 pagesManual: Order Number Order Part Doc-ID Language 229983 WS ADS - 229983#1 - 00Huseyin Gokhan Adiman100% (1)

- C M DDocument13 pagesC M DanjuvNo ratings yet

- Mini Interruptores Termomagnéticos e Interruptores DiferencialesDocument52 pagesMini Interruptores Termomagnéticos e Interruptores DiferencialesJay SantanNo ratings yet

- ASTM D-3177 Azufre Total en CarbonDocument4 pagesASTM D-3177 Azufre Total en CarbonGilda Elizabeth Caballero LumbaNo ratings yet

- Tunnel Invert ConcreteDocument11 pagesTunnel Invert ConcretekumarNo ratings yet

- Mineral Deposits in India - Chief Mineral Resources - Global Production - Domestic Production - Applications - Contemporary IssuesDocument21 pagesMineral Deposits in India - Chief Mineral Resources - Global Production - Domestic Production - Applications - Contemporary IssuessriharshaNo ratings yet