Professional Documents

Culture Documents

Mit Unit 1

Uploaded by

uhwb352441Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mit Unit 1

Uploaded by

uhwb352441Copyright:

Available Formats

UNIT 1

1. VARIOUS OPERATING FORCES

Deflecting Force (Td):

Also called as operating force

Makes the pointer to move from zero position to indicating position

Zero position is when the instrument is disconnected from supply

It converts the electric current or voltage into a mechanical force

It is produced by (i) magnetic (ii) thermal (iii) electrostatic (iv) induction

Controlling Force (Tc):

Pointer movement will be infinite when no opposing force

This opposing force is called controlling force

It is equal and opposite of the deflecting force

Used to stop the pointer at the indicating position

Under steady state, Td = Tc

It also bring the pointer to zero when deflecting force is removed

Damping Force (Tdamp):

It also opposes the deflecting force

It is used to bring the pointer to rest quickly

Otherwise the needle will oscillate for some time at indicating position

Damping is divided into (i) under damping (ii) critical damping (iii) over damping

2. VARIOUS EFFECTS USED IN AN INSTRUMENT

MAGNETIC EFFECT

Like poles repel and unlike poles attract.

This effect is used to create the deflecting force.

A magnetic field is set up around a current carrying conductor.

When two magnetic poles are brought near the conductor, a force acts on the

conductor

Eg: PMMC meters

THERMAL EFFECT

Current is passed through a small wire

Heat is produced on it

The heat effect is used to create the deflecting force using a thermocouple

Eg: Thermocouple

ELECTROSTATIC EFFECT

When two plates are charged, there is a force of attraction or repulsion

This effect is used to create the deflecting force

Eg: Voltmeters

INDUCTION EFFECT

Aluminium disc is placed between the poles of electromagnet

An EMF is induced in the disc which produces a current

Interaction of induced current on magnetic field makes the disc to rotate

This effect is used to create the deflecting force

Eg: Energy meter

3. SPRING CONTROL

Consists of two phosphor bronze

spiral springs

One end is attached to the

spindle and other to a lever

Springs wound in opposite

direction to each other.

When the pointer moves, one

spring winds and other spring

unwinds.

This produces the controlling

torque

When the deflecting torque

stops, wind spring brings the

moving system back to zero

position

Deflecting torque is proportional

to the current Td I

Controlling torque is

proportional to the angle of

deflection Tc θ

Under steady state Tc = Td i.e. θ

I

4. GRAVITY CONTROL Two small weights are attached

to the moving system – control

weight & balance weight

Position of the weight is

adjustable

Control weight produces the

controlling torque due to gravity

Balance weight balances the

moving system

When the pointer deflects

through an angle θ°, weights also

moves θ°

A component of the weight W sin

θ acts at a distance L producing

the control torque

Controlling torque Tc = W l sin θ

Tc sin θ

Controlling torque is

proportional to the sine of angle

of deflection

Under steady state Td = Tc i.e. I

sin θ

5. VARIOUS DAMPING SYSTEMS

AIR FRICTION DAMPING It consists of a light aluminum

piston attached to the moving

system.

The piston moves in a fixed air

chamber closed at one end.

When the piston moves into the

chamber, the air inside is

compressed

The pressure of air opposes the

motion of piston and hence the

pointer.

When the piston moves out of air

chamber, pressure inside the

chamber reduces

Outside air pressure opposes the

motion of piston and hence the

pointer.

FLUID FRICTION DAMPING

Oil is used in place of air.

A circular disc is attached to the

pointer

The disc is completely

submerged in oil

When the pointer moves, the disc

moves in oil.

This frictional force is produced

and provides the damping

As the viscosity of oil is greater,

the damping force is also greater.

EDDY CURRENT DAMPING When a conductor moves in a

magnetic field an emf is induced

in it.

If closed path is provided, an

eddy current flows.

The current interacts with the

magnetic field to produce an

electromagnetic torque which

opposes the motion.

6. COMPARISON OF ANALOG AND DIGITAL INSTRUMENTS

Sl No DIGITAL INSTRUMENTS ANALOG INSTRUMENTS

1 Indicates the value in decimal form Displays the value in terms of

deflection of pointer on a scale

2 Has much greater accuracy Accuracy of +/- 0.1 % on full scale

3 Relatively complex operation Simple parts and operate under wide

range of environment

4 Resolution of one part in several Resolution of one part in several tens

thousand

5 No loading effect May load the circuit

6 Free from parallax error Gives parallax error

7 Speed of reading is high Speed of reading is low

8 Cost is high Cost is low

9 Wide range of measurements Limited range of measurement

10 Readings can be stored Readings cannot be stored

7. COMPARISON OF SPRING CONTROL AND GRAVITY CONTROL

Sl No SPRING CONTROL GRAVITY CONTROL

1 Cost is high Cost is less

2 Uniform scale Scale is not uniform

3 Fatigue present Fatigue not present

4 Can be used in any position Used in vertical position only

5 Accuracy depends on temperature Independent of temperature

6 Losses tension due to ageing Unaffected by ageing

7 Used as portable instruments Used for panel board meter only

8. FUNCTIONS OF MEASUREMENT SYSTEM

Indicating Function:

If an instrument conveys the result of measurement as a deflection of a pointer,

it performs indicating function.

Example: The deflection of pointer of a speedometer indicates the speed of the

automobile.

Recording function:

If an instrument conveys the result of measurement against time in paper, it

performs recording function.

Example: A strip chart recorder records the instantaneous value of temperature

on a paper chart

Controlling function:

If an instrument uses the result of measurement to control the original

measured quantity, it performs controlling function:

Example: Thermostats for temperature control, Floats for level control

9. APPLICATIONS OF MEASUREMENT SYSTEM

Monitoring of process and operations

In monitoring application, Measuring Instruments simply indicate the value

and they do not serve any control functions.

Example: Ammeter, voltmeter and wattmeter indicates the value at that instant.

Control of processes and opertions

In controlling application, measuring system takes action to make the error zero

so that desired value of variable is achieved

Example: Refrigerator system which employs thermostatic control

Experimental engineering analysis

In experimental application, measuring system is used for solving engineering

problem. This has many uses such as:

Testing the validity of theoretical predictions.

Formulations of generalized empirical relationships

Determination of system parameters, variables and performance indices.

To find solutions of mathematical relationships.

10. CLASSIFICATION OF INSTRUMENTS

A. ABSOLUTE INSTRUEMNTS

These instruments give the quantity under measurement in terms of the

physical constant of the instrument

Example: Tangent galvanometer, Rayleigh’s current balance

B. SECONDARY INSTRUMENTS

These instruments give the quantity to be measured with the help of graduated

scale.

These instruments are calibrated by comparing with an absolute instrument..

Example: volt meter, glass thermometer and pressure gauge.

They are further classified as follows:

Indicating instruments

Indicates the quantity at that time only

Value is given by a pointer on a graduated scale

Eg: Ammeter, Voltmeter

Recording instruments

Gives continuous record of quantity over a period of time

Makes use of a pen on a graph paper

Instantaneous value can be read

Paper rotates on a drum or disc

Eg: Recording MD meters, Recording Pyrometers

Integrating instruments

Gives total consumption of quantity over a time

The value is the product of electrical quantity and time

Eg: Energy meter, Ampere-hour meter

C. ANALOG AND DIGITAL INSTRUMENTS

Instruments that indicate the quantity by a pointer on a continuous scale are

called analog instruments.

Instruments that display the value of the quantity in discrete numerals are

called digital instruments

3 MARK QUESTIONS

7. ERROR

1. FUNCTIONS OF MEASUREMENT

SYSTEM It is the difference between the

measured value and the true value

Indicating function Error = Measured value – True value

Recording function

Controlling function 8. ERROR CORRECTION

It is the opposite of error

2. APPLICATIONS OF MEASUREMENT It is the difference between the true

SYSTEM value and the measured value

Error correction = True value –

Monitoring of process and operations Measured value

Control of process and operations

Experimental and engineering analysis 9. INSTRUMENT EFFICIENCY

3. CLASSIFICATION OF INSTRUMENTS It is the ratio of measured quantity at

full scale to the power taken at full

Absolute instrument scale

Secondary instrument Instrument efficiency =

o Indicating instrument 𝑀𝑒𝑎𝑠𝑢𝑟𝑒𝑑 𝑞𝑢𝑎𝑛𝑡𝑖𝑦 𝑎𝑡 𝑓𝑢𝑙𝑙 𝑠𝑐𝑎𝑙𝑒

o Recording instrument 𝑃𝑜𝑤𝑒𝑟 𝑡𝑎𝑘𝑒𝑛 𝑎𝑡 𝑓𝑢𝑙𝑙 𝑠𝑐𝑎𝑙𝑒

o Integrating instrument

Analog and digital instruments

10. ADV OF ANALOG INSTRUMENTS

4. TRUE VALUE

Simple in construction

It is the exact value or the perfectly Simple in operation

correct value Cheaper in cost

It is the average of infinite values Portable

It is usually taken from laboratory

standard 11. DIS ADV OF ANALOG INSTRUMENTS

5. ACCURACY

Lack of accuracy

Closeness with which the value Resolution is low

approaches the true value Parallax error

It is confirmative to truth

12. ADV OF DIGITAL INSTRUMENTS

6. PRECISION

Digital readings are obtained

Ability to give consistent reading Readings can be adjusted to any

Successive readings do no differ number of decimals

Offer high input impedance and no

loading effect

Readings can be stored in a memory

Consumes less power

You might also like

- Turbulence Phenomena: An Introduction to the Eddy Transfer of Momentum, Mass, and Heat, Particularly at InterfacesFrom EverandTurbulence Phenomena: An Introduction to the Eddy Transfer of Momentum, Mass, and Heat, Particularly at InterfacesNo ratings yet

- Topics To Be Discussed: - Voltmeter Sensitivity. - Voltmeter LoadingDocument90 pagesTopics To Be Discussed: - Voltmeter Sensitivity. - Voltmeter LoadingPadarbinda SamalNo ratings yet

- Measuring Instrument (BEE)Document11 pagesMeasuring Instrument (BEE)Omnath DixitNo ratings yet

- WINSEM2019-20 ECE1005 ETH VL2019205005123 Reference Material I 01-Jun-2020 Measuring Instruments Basics and PMMCDocument30 pagesWINSEM2019-20 ECE1005 ETH VL2019205005123 Reference Material I 01-Jun-2020 Measuring Instruments Basics and PMMCBadhan PaulNo ratings yet

- Electrical Measurement & Measuring InstrumentsDocument41 pagesElectrical Measurement & Measuring InstrumentsMuniyasamyNo ratings yet

- Lecture 1423813026Document53 pagesLecture 1423813026BenNo ratings yet

- Material - CompleteDocument84 pagesMaterial - CompleteApoorvNo ratings yet

- 2130903Document18 pages2130903mitaliNo ratings yet

- Electrical Measurements & InstrumentationDocument86 pagesElectrical Measurements & InstrumentationDulecha Adane DulechaNo ratings yet

- Electricity Basics: Resistance, Inductance AND CapacitanceDocument39 pagesElectricity Basics: Resistance, Inductance AND CapacitanceLee TalierNo ratings yet

- Electrical Measurements & Instrumentation NotesDocument86 pagesElectrical Measurements & Instrumentation Notesthirupathi.eeegnitNo ratings yet

- Essential Components of Indicating InstrumentsDocument6 pagesEssential Components of Indicating InstrumentsHina AsifNo ratings yet

- Controlling ForceDocument72 pagesControlling Forcedon aNo ratings yet

- Unit 2 Electrical InstrumentDocument45 pagesUnit 2 Electrical InstrumentBoopathy C P100% (1)

- Week-4 Lecture-4 Analog Indicating Instruments: Chapter 2: BakshiDocument33 pagesWeek-4 Lecture-4 Analog Indicating Instruments: Chapter 2: Bakshiahmad khanNo ratings yet

- AnalogDocument37 pagesAnalogchiin anthonyNo ratings yet

- Ac 1Document11 pagesAc 1adarshdeshmukh09No ratings yet

- Transverse WavesDocument4 pagesTransverse WavesRatnasari Mohamad AshaariNo ratings yet

- Senior Two Physics Notes (August 2021)Document47 pagesSenior Two Physics Notes (August 2021)Gabriel100% (3)

- Elements of IndicatingDocument4 pagesElements of IndicatingGlen SudarsonNo ratings yet

- Deflecting Torque (T) or Deflecting ForceDocument2 pagesDeflecting Torque (T) or Deflecting ForceSiddhartha SahaNo ratings yet

- Eem 03Document14 pagesEem 03Abhisek MaharanaNo ratings yet

- Unit 4 Bee NotesDocument47 pagesUnit 4 Bee NotesSagar VatsNo ratings yet

- Simple Harmonic Motion and ElasticityDocument73 pagesSimple Harmonic Motion and ElasticityasaadadadsaddNo ratings yet

- Measuring InstrumentsDocument8 pagesMeasuring Instrumentsatul206No ratings yet

- Oscillating Systems: Caduyac Fillone Lofranco Nolan SerquiñaDocument13 pagesOscillating Systems: Caduyac Fillone Lofranco Nolan Serquiñaランベイ リチャードNo ratings yet

- Electromagnetic InductionDocument26 pagesElectromagnetic Inductionqpncsoriano100% (1)

- 301 CHP7Document27 pages301 CHP7aleenhaidarNo ratings yet

- Circular MotioDocument51 pagesCircular MotioRusher AkoNo ratings yet

- DC Machine-1 GENERATORSDocument25 pagesDC Machine-1 GENERATORSSanyaNo ratings yet

- Electrical Principles 2 (CCEET 2)Document25 pagesElectrical Principles 2 (CCEET 2)Bernard MunyithyaNo ratings yet

- PMMCDocument44 pagesPMMCMeesixNo ratings yet

- Rotational Motion - II: Reading: Chapter 11Document19 pagesRotational Motion - II: Reading: Chapter 11J KNo ratings yet

- Turbovisory System: By: Oliver AdakDocument40 pagesTurbovisory System: By: Oliver AdakKrishna KumarNo ratings yet

- Physics Class X Selina - ForceDocument18 pagesPhysics Class X Selina - ForceProteep MitraNo ratings yet

- Adobe Scan 21 Apr 2023Document5 pagesAdobe Scan 21 Apr 2023B LAKSHMI PRIYANo ratings yet

- LEP 1.3.31 Moment of Inertia and Torsional Vibrations: Related Topics ProblemsDocument3 pagesLEP 1.3.31 Moment of Inertia and Torsional Vibrations: Related Topics ProblemsBhanuka SamarakoonNo ratings yet

- LN8Document145 pagesLN8Fun Fun Tik TokNo ratings yet

- Unit-2 EMIDocument71 pagesUnit-2 EMIsagarpandit2No ratings yet

- Forces O LevelsDocument50 pagesForces O LevelsMuhammad Ali AbbasNo ratings yet

- TOPIC 1 - Alternating CurrentDocument39 pagesTOPIC 1 - Alternating CurrentF1038 IFFAH SYAZANA BINTI MD HASNIN HADINo ratings yet

- A5 Physics LabDocument10 pagesA5 Physics LabBetty Njeri MbuguaNo ratings yet

- Impulse Vs Reaction TurbineDocument4 pagesImpulse Vs Reaction Turbineramar MNo ratings yet

- Literature SurveyDocument9 pagesLiterature SurveyamaraadhithiyaNo ratings yet

- SHM Notes CompleteDocument58 pagesSHM Notes CompleteTushar SinghNo ratings yet

- Lab Mannual-Melde's Experiment-1 PDFDocument13 pagesLab Mannual-Melde's Experiment-1 PDFRahulNo ratings yet

- Torque Measurement... : Mechanical Dynamometers.. S.SANJAY (18P221)Document52 pagesTorque Measurement... : Mechanical Dynamometers.. S.SANJAY (18P221)vijay AmirtharajNo ratings yet

- Dynamometer Type Wattmeter WorkingDocument6 pagesDynamometer Type Wattmeter Workingsandeep rawatNo ratings yet

- Mechanical Vibration: Chapter - 1Document29 pagesMechanical Vibration: Chapter - 1abebawalemkerNo ratings yet

- Measuring Instruments: By: Nafees Ahmed, Asstt, Prof, EE Deptt, DIT, DehradunDocument39 pagesMeasuring Instruments: By: Nafees Ahmed, Asstt, Prof, EE Deptt, DIT, DehradunSarthak Singh ChandelNo ratings yet

- Mech Engg - GovernorsDocument6 pagesMech Engg - GovernorsRajesh PandaNo ratings yet

- 6.1 Circular MotionDocument50 pages6.1 Circular MotionJiwoo SeoNo ratings yet

- What Is VibrationDocument29 pagesWhat Is Vibrationravi_fdNo ratings yet

- Analog Sensors For Motion Measurement: Presented By: Chinmay PimpalkhareDocument38 pagesAnalog Sensors For Motion Measurement: Presented By: Chinmay PimpalkhareM KEERTHIKANo ratings yet

- EEM Unit 2Document20 pagesEEM Unit 2Bhavesh BodkeNo ratings yet

- 04 C Wave BehaviorDocument106 pages04 C Wave BehaviorKatia Reales PazNo ratings yet

- Equilibrium (PROBLEMS)Document4 pagesEquilibrium (PROBLEMS)UnknownNo ratings yet

- 03 Circular Motion Final CWDocument30 pages03 Circular Motion Final CWjagan9912342495No ratings yet

- PHYS 211 6.STATIC 1ST CONDITION MergedDocument36 pagesPHYS 211 6.STATIC 1ST CONDITION MergedLEENo ratings yet

- Ce Board Nov 2020hydraulicsset 5 PDF FreeDocument2 pagesCe Board Nov 2020hydraulicsset 5 PDF FreeKrysha RomaineNo ratings yet

- Lecture 04 - Interference and ApplicationsDocument27 pagesLecture 04 - Interference and ApplicationsArc ZeroNo ratings yet

- Electrical Design Machine 1 Final - Asilo Justine Troy D.Document14 pagesElectrical Design Machine 1 Final - Asilo Justine Troy D.Hok HokNo ratings yet

- CHM2 11 - 12 Q3 0702 FDDocument49 pagesCHM2 11 - 12 Q3 0702 FDKim balugayNo ratings yet

- Waves and Sound-02-Subjective SolvedDocument10 pagesWaves and Sound-02-Subjective SolvedRaju SinghNo ratings yet

- Btech Ee 3 Sem Electrical Measurements and Instrumentation Kee302 2022Document2 pagesBtech Ee 3 Sem Electrical Measurements and Instrumentation Kee302 2022Priyanshu SuryavanshiNo ratings yet

- Dewpoint DDP1060CM Drainage Pump Product CatalogueDocument2 pagesDewpoint DDP1060CM Drainage Pump Product CataloguelocoNo ratings yet

- Tests Performed in An Alternator: Dcresistancetest Open Circuit Test Short Circuit TestDocument30 pagesTests Performed in An Alternator: Dcresistancetest Open Circuit Test Short Circuit TestOSAMANo ratings yet

- Chapter 13 Drill: Section I: Multiple ChoiceDocument7 pagesChapter 13 Drill: Section I: Multiple ChoiceRadhika C.No ratings yet

- ICM-SU-5140-C.1 - FlowDocument37 pagesICM-SU-5140-C.1 - FlowShivani DubeyNo ratings yet

- Operation Manual: JencoDocument13 pagesOperation Manual: JencotadilakshmikiranNo ratings yet

- Principles of Refrigeration: Standard Template Options and Samples - Mar 2016 - EMR:jmk 1Document17 pagesPrinciples of Refrigeration: Standard Template Options and Samples - Mar 2016 - EMR:jmk 1JhurremNo ratings yet

- EMI Filter Design For DC DC ConverterDocument3 pagesEMI Filter Design For DC DC ConverterBt TNo ratings yet

- Kee101t Ee Aktu QP-2020-21Document14 pagesKee101t Ee Aktu QP-2020-21Sudhir ChandNo ratings yet

- Play Tennis TreeDocument1 pagePlay Tennis TreeSabi UllahNo ratings yet

- JEST 2020 Physics Solutions Scienceteen 0cktrpDocument45 pagesJEST 2020 Physics Solutions Scienceteen 0cktrpVAISHNAVI V.GNo ratings yet

- Electronic Engine Controls TDV8 3.6Document17 pagesElectronic Engine Controls TDV8 3.6elisei sorinNo ratings yet

- Silo - Tips - Instruction Manual Digital Manifold For Hvac R Systems Manual de Instrucciones Manifold Digital Hvac RDocument12 pagesSilo - Tips - Instruction Manual Digital Manifold For Hvac R Systems Manual de Instrucciones Manifold Digital Hvac RfeletnorNo ratings yet

- Chapter 2. Sensors and ActuatorsDocument58 pagesChapter 2. Sensors and ActuatorsTesfaye Olana100% (1)

- 12th Physics - One ShotDocument62 pages12th Physics - One ShotmaheshNo ratings yet

- Electric Machines - Ashfaq HusainDocument642 pagesElectric Machines - Ashfaq Husainwocaja8645100% (1)

- Ecs Txo 2520Document2 pagesEcs Txo 2520miri10861No ratings yet

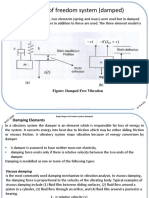

- Single Degree of Freedom System (Damped)Document13 pagesSingle Degree of Freedom System (Damped)Vjh GNo ratings yet

- Module 1 (Mathematics, Science, and Technology) Bsba 2 (Final Copy)Document7 pagesModule 1 (Mathematics, Science, and Technology) Bsba 2 (Final Copy)frederick liponNo ratings yet

- Pharmaceutical MeasurementDocument9 pagesPharmaceutical Measurementmematugoldahmunu21No ratings yet

- Experiment (1) : ObjectivesDocument9 pagesExperiment (1) : ObjectivesAmd HNo ratings yet

- Thermal Management of Electronics Using Phase ChangeDocument9 pagesThermal Management of Electronics Using Phase ChangeRaj kumarNo ratings yet

- CP List MaterialDocument2 pagesCP List MaterialRendy YuliantoNo ratings yet

- TransformerDocument2 pagesTransformerBsal SokoNo ratings yet