Professional Documents

Culture Documents

RCD - 5th MEETING

Uploaded by

Glenny VelasquezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCD - 5th MEETING

Uploaded by

Glenny VelasquezCopyright:

Available Formats

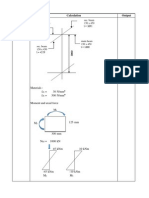

T-BEAM ANALYSIS

- Rectangular ang inaanalyze, pero ang totoong resistance ng concrete is more than sa size niya since

may slab pa

- Tf = Thickness ng slab

- Sa actual, con nuous ang slab, hanggang saan iaanalyze ang Bf.

- May formula tayo for Bf, usually ginagamit yung yellow. Yung green ay equivalent lang ng yellow BUT

symmetrical.

- Bf , choose the SMALLEST.

- S1 = Clear spacing (hindi isasama yung center ng beam)

- Pag sinabing clear measurement, yun yung center to center ng beam

- Magiging center to center spacing kapag equal yung S1 , S2 , & Bw

I. CASE 1: compression block, a < flange thickness, tf

- Pag yung “a” hindi lumagpas sa flange

- a = depth of compression of concrete

- para ka lang nag aanalyze ng shape type na rectangle here or malapad na beam. Kasi yung shaded

region region yung imumul ply sa 0.85f’c.

- Therefore 0.85f’caBf

II. CASE 2: Compression Block, a > Flange Thickness, Tf

- Pag yung “a” lumagpas sa thickness ng flange

- Ex. tf = 100 , then a = 200 , therefore hindi na rectangle yung area mo, haha in na siya sa dalawa

- Kahit anong ha basta alam mo yung centroid since mag momoment ka don, and area since

mumul ply mo siya sa 0.85f’c

- Magiging dalawa yung C. C1 & C2

- Just get the areas of As then mul ply to 0.85f’c

- C1 – nag aact sa centroid ng A1 . | C2 – nag aact sa centroid nung dalawang nasa pakpak

- Parang yung last example nakaraan, nagmoment sa taas papuntang tension: fd + fd

- Ngayon naman sa baba mag moment papuntang compression; fd + fd parin

DESIGN PROCEDURE FOR T-BEAM

- Adjacent means katabi

- Span, yung perpendicular distance

- Slab thickness, ayun narin yung flange thickness

Bf = 6000/4 = 1500 is the smallest, therefore eto yung gagami n na Bf and yung ans.

Bf = 16(120) + 250 = 2170

Bf = 3000/2 + 3000/2 + 250 =3250

- Pag ginamit yung nasa green, same lang din lalabas sa pangatlong Bf since symmetrical naman

- Pang GENERAL yung yellow, while pang SYMMETRICAL yung green

Step 1: ASSUME CASE 1, STEEL YIELDS

0.85f’cabf = Asfy | 0.85(21)a(700) = 500π (420) | a= 52.79987653mm

As= 500π therefore, CASE 1 (Correct Assumption)

- If mali yung assumption, meaning mali yung formula ng area mo, gagawin mong area ng T

c = 62.1175018 mm | fs = 600 (500- 62.1175018)/62.1175018 = 4229.556748 Kn

therefore, Steel yields and tension controlled

Step 2: ULTIMATE MOMENT CAPACITY

Mu = ΦC(d-a/2) = (0.90) 0.85(21)(52.79987653)(700)[500-52.79987653/2) = 281.2052517 kN <- ans

- Kung ano yung pinakatuktok ng slab, yun yung start ng height ng T-BEAM

- Pag nagbigay ng Height sa beam hanggang top ng slab yun

- Pag doubly reinforced, andun yung bakal sa loob ng slab

- Actual, con nuous yung mga beams, so dapat alam yung bf or the Effec ve Flange Width

Para malaman yung Bf , ung tatlong color na formula (yellow (interior/general), orange (exterior), and

green (symmetrical) then smallest yung pipiliin lagi.

- This me lalagpas na tayo sa flange, so true T-Beam analysis na mangyayari

- Hinaha sa dalawa para maging rectangular and aalamin kung nasan yung centroid

- Since pag nag moment tayo, may compressive force, C sa taas then dapat alam na n kung san mag aact

- @T-Beam Design, same lang halos ng procedure sa rectangular, nadagdagan lang nag assump on which

is yung kung hanggang saan ang “a”

- Dapat alam mo pano gawin yung figure base sa given

- pag center to center yung given pwedeng gawin yung symmetrical na formula

- pag walang sinabi sa problem, assume Interior

- S1 is always nasa kaliwa, then S2 sa kanan

- Basta Capacity ang tanong C=T na agad, kahit anong shape pa yan

- Pag nag coconclude, sa design lang yung I coconclude mo kung singly or doubly

Step 1: C = T, ASSUME STEEL YIELDS, a < tf

0.85 (21) a (700) = 1024π (420) | a = 108.1341471 mm 108.1341471 > 100 therefore, a > tf

As = 1024 π Wrong assumption

Step 2: REVISE ASSUMPTION, a > tf , ASSUME STEEL YIELDS

Ac = A1 + A2 | A1 = 300a ; A2 = (200*100)2 = 40000 | Ac = 300a + 40000

0.85 (21) (300a + 40000)= 1024π (420) | a = 118.9796766mm a > tf

Correct Assumption

c = 139.9760902 mm | fs= 600(500-139.9760902)/139.9760902 = 1543.223172

Correct Assumption, Steel Yields & Tension Controlled

- Kung ayaw mo mag compare sa 1000, divide mo, fs/200 000 = dapat mas Malaki sa 0.005 para tension

controlled. Yung sagot yung pwede mong maging reduc on factor base dun sa graph.

- Looking sa figure dapat maimagine mo yung mga forces since tatlo na forces mo. 1Tension force and 2

Compression force since hina mo sa dalawa yung compression areas.

- Importante na naiin ndihan yung graph at wag puro memorize para kahit anong shape, masosolve mo

- Pag analysis, dalawang case, Case 1 & Case 2. Pwede to mag transi onpag less than 1000 but greater

than fy

Step 3: ULTIMATE MOMENT CAPACITY

Mn = C1 (d-a/2) + C2 (d-a/2) = 0.85(21)300a(500-a/2) + 0.85(21)(40000) (500-100/2)

Mn = 601.9649566 kN Mu = 0.90 (601.9649566 kN ) = 541.7684609 kN <- ans.

a. Step 1: ASSUME SINGLY, a< tf , Tension Controlled

- Moment due to DL and LL tong mga to, para maging ul mate, gamit ng Load Combina ons

Mu = 1.2(150) + 1.6(120) = 372 kN-m | 372 kN-m = 0.90(0.85)(20.7)(a)(820)(470-a/2)

a = 65.5205761 ; Correct Assump on, a< tf

c =77.0830307 mm | fs = 600(470 - 77.0830307) / 77.0830307 = 3058.392741 kN

Correct Assump on, Steel Yields, Tension Controlled, Singly Reinforced

Step 2: DETERMINE THE As & As min, C = T

0.85(20.7)(65.5205761)(820)=As(414) | As = 2283.392077 mm <- ans

- For ρmin , b is always bw

- Pag f’c is 31 pababa, mas malaki lagi si 1.4/fy

As min = ρmin bd = 397 mm (pasok sa min) | ρmin = 0.0027 or 0.00338

b. Step 1: ASSUME SINGLY, a< tf , Tension Controlled

Mu = 1.2(195) + 1.6(210) = 570 kN-m | 570 kN-m = 0.90(0.85)(20.7)(a)(820)(470-a/2)

a = 105.1614937 ; Wrong Assump on, a> tf

REVISE ASSUMPTION, assume a> tf

Mu = Φ[ C1(d-a/2) + C1(d-100/2)] = 0.90 [ (0.85(20.7)

570 kN-m = 0.90 [ (0.85)(20.7)(250a)(470-a/2) + (0.85)(20.7)(57000)(470-100/2)

a = 117.2119544 mm ; Correct Assump on a> tf

Ac = A1 + A2 | A1 = 250a ; A2 = (285*100)2 = 57000 | Ac = 250a + 57000

c = 137.8964169 mm | fs = 600 (470-137.8964169) /137.8964169 =1445.013252 kN

Correct Assump on, Tension Controlled, Singly

Step 2: DETERMINE THE As & As min, C = T

0.85(20.7)( 250a + 57000)=As(414) | As = 3667.877016 mm <- ans

- For ρmin , b is always bw

- Pag f’c is 31 pababa, mas malaki lagi si 1.4/fy

As min = ρmin bd = 446.5 mm (pasok sa min) | ρmin = 0.0027 or 0.0038

IRREGULAR BEAMS ANALYSIS

- Pag design walang bakal, pag analysis may bakal

- @RCD, importante na naiintindihan mo yung stress diagram kasi dun tayo kukuha ng solution

- Pag hindi na regular, C = T ,

C = 0.85 f’c (area ng concrete)

- Then for moment arm, dapat alam mo yung centroid ng irregular shape.

- Pag Analysis, FIRST STEP IS C=T LAGI

Step 1: C = T , ASSUME a< tf , STEEL YIELDS

0.85(21)a(150) = 1024π (345) | a = 414.5142307 ; wrong assumption, a> tf

As = 1024 π

REVISE ASSUMPTION, assume a> tf

Ac = A1 + A2 | A1 = 22500 ; A2 = 450(a-150) | Ac = 22500 + 450(a-150)

0.85(21)(22500 + 450(a-150)) = 1024π (345) : a = 234.1714102mm; correct assumption a> tf

c = 275.4957767mm ; fs = 600(625-275.4957767)/ 275.4957767mm = 738.3218401

Steel yields, fs > fy

Step 2: ULTIMATE MOMENT CAPACITY

εt = fs / Es = 738.3218401 / 200000 = 0.003691609201

Φ = 0.8001228397

Mu = 0.8 ((0.85)(21)22550(625-75)) + (0.85)(21)(37867.13459)(625-(150+42.0857051))

Mu = 411.2029 (420.93 sagot ni sir, ALWAYS SHIFT STORE VALUES HANGGANG WALA PA SA FINAL ANS!!!)

You might also like

- Analysis of Reinforced Concrete BeamsDocument5 pagesAnalysis of Reinforced Concrete BeamsMauricio SanchezNo ratings yet

- Stress Analysis of ShaftDocument5 pagesStress Analysis of Shaftyashar2500100% (2)

- Chapter 2-Doubly Reinforced BeamDocument32 pagesChapter 2-Doubly Reinforced BeamEarl Rajim RiogelonNo ratings yet

- Analysis of Doubly Reinforced Concrete BeamsDocument20 pagesAnalysis of Doubly Reinforced Concrete BeamsKhalil FanousNo ratings yet

- Transcription NaminDocument17 pagesTranscription NaminJimwell ManaloNo ratings yet

- RCD - 4th MEETINGDocument7 pagesRCD - 4th MEETINGGlenny VelasquezNo ratings yet

- Irregular Beam Capacities and DesignDocument12 pagesIrregular Beam Capacities and DesignJohn Rhey Almojallas BenedictoNo ratings yet

- Ultimate Strength Design (Doubly)Document17 pagesUltimate Strength Design (Doubly)C.j. CaparasNo ratings yet

- Mathcad - 13-Column DesignDocument34 pagesMathcad - 13-Column DesignShivakumar Patil50% (2)

- Design of Beam-Aci-11-01-05Document23 pagesDesign of Beam-Aci-11-01-05aomareltayeb100% (1)

- Be First Year Engineering Semester 1 2019 December Engineering Mechanics Emrev 2019'c' SchemeDocument43 pagesBe First Year Engineering Semester 1 2019 December Engineering Mechanics Emrev 2019'c' Schemesinghsitturaj78No ratings yet

- Example:-: 1-Properites of SectionsDocument7 pagesExample:-: 1-Properites of Sectionsmahmoud elkhedrNo ratings yet

- Analysis of Singly Reinforced BeamDocument4 pagesAnalysis of Singly Reinforced Beamils411No ratings yet

- A. Shear and Moment Diagram: Draw The Shear and Moment Diagrams For The Beam Shown. Segments AC and CE Are Connected by Pin CDocument4 pagesA. Shear and Moment Diagram: Draw The Shear and Moment Diagrams For The Beam Shown. Segments AC and CE Are Connected by Pin CStefanGraczykNo ratings yet

- Stress and Strain Exercises 2022Document6 pagesStress and Strain Exercises 2022TashNo ratings yet

- 5 - RCE-design-of-Tbeam-and-double-reinforcedDocument33 pages5 - RCE-design-of-Tbeam-and-double-reinforced'Riky Dwi Prasetyo'No ratings yet

- FE Reinforced ConcreteDocument34 pagesFE Reinforced ConcreteAdriano GuedesNo ratings yet

- Example 11 - One-Way Slab & SW InstructionsDocument9 pagesExample 11 - One-Way Slab & SW InstructionsLemuel TeopeNo ratings yet

- A. Reading Assignment: Analysis of Members With Axial Loads and MomentsDocument19 pagesA. Reading Assignment: Analysis of Members With Axial Loads and MomentsIhab El AghouryNo ratings yet

- 4b-Flexural Analysis of Reinforced Concrete T-Section BeamsDocument14 pages4b-Flexural Analysis of Reinforced Concrete T-Section Beamsßlack ßoodyNo ratings yet

- Reinforced Concrete Beam Design SolutionsDocument26 pagesReinforced Concrete Beam Design Solutionslxndare musik m100% (1)

- Summative Exam - Group 3Document20 pagesSummative Exam - Group 3Esperidion G. SaquinNo ratings yet

- Example: 56 Mpa 50 Mm Ρ 56 Mpa 56 MpaDocument22 pagesExample: 56 Mpa 50 Mm Ρ 56 Mpa 56 MpaJimmy Caesario DenataNo ratings yet

- Perancangan Struktur Beton Bab - 3Document14 pagesPerancangan Struktur Beton Bab - 3Fadhil DzulfikarNo ratings yet

- May 2018 With SolutionDocument34 pagesMay 2018 With SolutionSagar AhireNo ratings yet

- RCC and Pre-stressTYS Exp - 246Document50 pagesRCC and Pre-stressTYS Exp - 246BIJAY KRISHNA DASNo ratings yet

- Reinforced Concrete Column: ConditionDocument3 pagesReinforced Concrete Column: ConditionJheo TorresNo ratings yet

- ENGINEERING MECHANICS TITLEDocument46 pagesENGINEERING MECHANICS TITLEmuradNo ratings yet

- Mathcad - Central BeamDocument4 pagesMathcad - Central BeamRudrabir GhantiNo ratings yet

- Design of Truck-Mounted Crane: King Saud University Collage of Engineering Mechanical Engineering DepartmentDocument16 pagesDesign of Truck-Mounted Crane: King Saud University Collage of Engineering Mechanical Engineering DepartmentAnonymous TiVNvdLNo ratings yet

- At Very Low Cutting SpeedsDocument40 pagesAt Very Low Cutting SpeedsThulasi Ram100% (1)

- Chapter6 Fatigue ProblemDocument8 pagesChapter6 Fatigue Problemkhubaib_1987No ratings yet

- 1.0 Specification: Ref Output CalculationDocument4 pages1.0 Specification: Ref Output CalculationLuqman YusofNo ratings yet

- STRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGDocument5 pagesSTRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGNabin Acharya100% (1)

- Design of Water Tank-311207Document32 pagesDesign of Water Tank-311207Uttam Kumar GhoshNo ratings yet

- Indrumator Metal - EGDocument37 pagesIndrumator Metal - EGhooky1100% (1)

- Hit Tulangan Abutment JembatanDocument7 pagesHit Tulangan Abutment JembatanMuhammad Hamzah100% (1)

- Analysis and Design of T-BeamDocument28 pagesAnalysis and Design of T-BeamhuyxpkissNo ratings yet

- Semana 08 - Mathcad - N5-06 Diseno Viga Doblemente ArmadaDocument10 pagesSemana 08 - Mathcad - N5-06 Diseno Viga Doblemente ArmadaStefany SilveiraNo ratings yet

- Stair Case Design - at Design OfficeDocument14 pagesStair Case Design - at Design OfficeShamen AmarasekaraNo ratings yet

- Assignment StructureDocument11 pagesAssignment StructureCivil EngineerNo ratings yet

- Ipt Design WorkDocument43 pagesIpt Design WorkMorice RwakataleNo ratings yet

- Worked Example (Not in Notes) : Reinforced Concrete Beam: Z F A Z F M BD F A F D Z F B F A X E F D XDocument5 pagesWorked Example (Not in Notes) : Reinforced Concrete Beam: Z F A Z F M BD F A F D Z F B F A X E F D XJakir Hussain SyedNo ratings yet

- Ub Mae 311Document7 pagesUb Mae 311Deepak KumarNo ratings yet

- Comparative Design of Biaxial R.C. Columns to CodesDocument14 pagesComparative Design of Biaxial R.C. Columns to CodesMouhamad WehbeNo ratings yet

- Design of Stair Case With Central Stringer BeamDocument45 pagesDesign of Stair Case With Central Stringer BeamCONSTHURAG2012No ratings yet

- Perhitungan Balok SloofDocument5 pagesPerhitungan Balok SloofUray ZieldaNo ratings yet

- Prestress 3.0Document10 pagesPrestress 3.0Jonel CorbiNo ratings yet

- Manual Design of One Way Slab (Continous Slab)Document5 pagesManual Design of One Way Slab (Continous Slab)Struct Soft CentreNo ratings yet

- FUNDRAX1Document6 pagesFUNDRAX1kannan100% (1)

- Design of Sla1.docx - Interior Panel.Document7 pagesDesign of Sla1.docx - Interior Panel.Dai DonNo ratings yet

- Design of SlabDocument48 pagesDesign of SlabErnestNo ratings yet

- Laboratory Exercises in Astronomy: Solutions and AnswersFrom EverandLaboratory Exercises in Astronomy: Solutions and AnswersNo ratings yet

- Instructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYFrom EverandInstructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)