Professional Documents

Culture Documents

Gpti Qicl J931 Mut 026

Uploaded by

uselessinstaid52Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gpti Qicl J931 Mut 026

Uploaded by

uselessinstaid52Copyright:

Available Formats

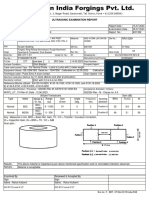

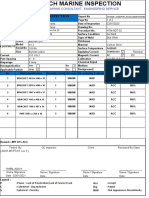

ULTRASONIC EXAMINATION REPORT

Date of REPORT No & Rev no: GPTI-QICL-J931-MUT-026 PAGE: 1 OF 2

Examination: 09.03.2023

Client: AIR PRODUCTS/NEOM / QICL Job No:- J931

Location: QICL,HAMRIYAH PHASE 2 Item Id: J931-11-2022

Project: NEOM GREEN HYDROGEN ELEMENTS Drawing No: - QICL-J931-11-32-DRG-GEN-01 REV-D /

PM210011-QI700-9V3-00015 Rev-03

Connecting cable type and length: LEMO TO MICRODOT Special attachment/ Equipment/Blocks: N/A

Examination Method and Technique : CONTACT METHOD AND PULSE Tag No:

ECHO

Calibration Block No: QICL-J931-CB02 Thk: 63mm Reference Reflectors: 2.5mm SDH

CALIBRATION DATA

Reflector Beam Reflector

Probe Reflector No. % Echo Beam Path % Echo % Echo Beam Path

No Path No

45 0 1/4 80 26 1/2 60 43 3/4 26 69

45 0 7/4 33 114 3/2 29 139 5/4 20 163

45 0 9/4 14 204

Acceptance Criteria: ASME SEC VIII Div-2 ED 2021

Damping / Reject Setting: OFF/ZERO QICL-J931-11-32-MUT-01 Rev-C

UT Procedure & Rev.: QICL-J931-11-32-MUT-01

PROBE TYPE TR/00 45 0 60 0 70 0

Flaw Detector: USM 35 X DAC

Make WK WK NA NA

Sr. No. 42582 22166 NA NA Serial No: 17714

Crystal Size / Diameter Calibration Certification No: GPTI/UT/CAL -106/2022

mm 10Ø 10Ø NA NA

Frequency MHz 5 MHZ 4MHZ NA NA Calibration Certificate Due Date : 17.06.2023

Base Metal Type & Thickness: CS,& 63mm

Primary Reference dB 1st BWE@80% of FSH 51dB NA NA

Weld Type / Configuration: DOUBLE V BUTT

Scanning Sensitivity dB +6 +6 NA NA

Test Range (mm) 0-150 0-250 NA NA Couplant Brand Name & Type: POLYCELL

Surface Condition Scan Face : FROM ID SURFACE

/Preparation GROUND FLASH

Access Limitations (if Any):

* 100% UT(45 TRANSVERSE DIRECTION) WAS CARRIED OUT ON VESSEL J931-11-2022 CIRC. SEAM WELD

* RECORDABLE INDICATION WAS OBSERVED.

* FOUND ACCEPTABLE AS PER SPECIFICATION.

* FOR WELD DETAILS REFER CONTINUATION SHEET.

ACCEPT REJECT

TEST RESULT ✘

CLIENT REP. : AI / TPI. :

TECHNICIAN : BARATH ELLAPPAN

NAME : NAME ;

LEVEL : II

SIGNATURE : SIGNATURE :

SIGNATURE :

DATE : 09.03.2023 DATE : DATE :

Report Form no-GPI/NDT/UT/001, REV-4 (Rev-date : 26/07/2020)

Disclaimer : This report is a property of GPTI & valid only if signed and stamped by GPTI Technician. Under no Circumstances will GPTI accept any

liability for loss or damage; consequential or otherwise caused by use or misuse of the test results. The test report shall not be reproduced in full or in part for

any promotional or publicity purpose without the written consent from GPTI

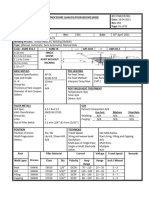

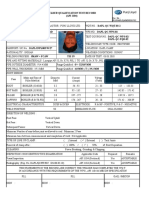

ULTRASONIC EXAMINATION REPORT

(CONTINUATION SHEET)

DATE : 09.03.2023 REPORT NO. & Rev no: GPTI-QICL-J931-MUT-026 PAGE : 2 OF 2

RESULT

WELD I.D. Welder ID

Location no weld Beam path Distance from Depth from Echo

height

Defect

Length Flaw Type

& probe Size (mm) Reference 'O' scan face (mm) % DAC (mm) ACC REJ

60 10680 25 62 SPOT ROUNDED P

AS PER

(J931-11-22) WELD

HISTORY 45T 22000mm 86 11950 60 108 12 ROUNDED P

CS-10

SHEET

65 11940 45 91 10 ROUNDED P

CLIENT REP. : AI / TPI. :

TECHNICIAN : BARATH ELLAPPAN

NAME : NAME ;

LEVEL : II

SIGNATURE : SIGNATURE : SIGNATURE :

DATE : DATE :

DATE : 09.03.2023

Report Form no-GPI/NDT/UT/001, REV-4 (Rev-date : 26/07/2020)

Disclaimer : This report is a property of GPTI & valid only if signed and stamped by GPTI Technician. Under no Circumstances will GPTI

accept any liability for loss or damage; consequential or otherwise caused by use or misuse of the test results. The test report shall not be

reproduced in full or in part for any promotional or publicity purpose without the written consent from GPTI

Report Form no-GPI/NDT/UT/001, REV-4 (Rev-date : 26/07/2020)

Disclaimer : This report is a property of GPTI & valid only if signed and stamped by GPTI Technician. Under no Circumstances will GPTI

accept any liability for loss or damage; consequential or otherwise caused by use or misuse of the test results. The test report shall not be

reproduced in full or in part for any promotional or publicity purpose without the written consent from GPTI

You might also like

- Power Up 5 Activity Book PDFDocument10 pagesPower Up 5 Activity Book PDFsafa afndi0% (1)

- XML Bursting StepsDocument6 pagesXML Bursting StepsDhinakaranNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Doosan Power Systems Indai PVT Limited: System CalibrationDocument3 pagesDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- CAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Document3 pagesCAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Komang Triwahyudi100% (1)

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- RUNOUTDocument1 pageRUNOUTvishal.bdyNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Liquid Penetrant Testing Report: Sievert Emirates Inspection LLCDocument1 pageLiquid Penetrant Testing Report: Sievert Emirates Inspection LLCAvijit DebnathNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- A-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportDocument4 pagesA-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportHari KarthickNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- Int'L NDT Services: Magnetic Particle Examination ReportDocument3 pagesInt'L NDT Services: Magnetic Particle Examination Reportsarsan nedumkuzhiNo ratings yet

- Example of Inspection Report 3Document11 pagesExample of Inspection Report 3SAIFUDDIN NUR AKMALNo ratings yet

- L&t-Ut-Se-1678 - R1 30-03-2023Document1 pageL&t-Ut-Se-1678 - R1 30-03-2023SamirNo ratings yet

- Electro Meter Corporation P-5, C.I.T Road KOLKATA - 700014Document2 pagesElectro Meter Corporation P-5, C.I.T Road KOLKATA - 700014Saptarshi DasNo ratings yet

- ARKAN SHADES Welding Inspection & Paint InspectionDocument2 pagesARKAN SHADES Welding Inspection & Paint InspectionSpectex dubaiNo ratings yet

- VTR 20 KP+FollowersDocument20 pagesVTR 20 KP+FollowersANDRES LLAGUARIMAY CHIPANANo ratings yet

- RTCLNT 142111 Wa 44Document1 pageRTCLNT 142111 Wa 44Mitul KapadiaNo ratings yet

- Kolkata: Calibration: Ofcalibration: IDocument4 pagesKolkata: Calibration: Ofcalibration: IjamilNo ratings yet

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Example of Inspection Report 2Document3 pagesExample of Inspection Report 2SAIFUDDIN NUR AKMALNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- MTPT ReprotDocument3 pagesMTPT Reprotmohd as shahiddin jafriNo ratings yet

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- Pallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportDocument1 pagePallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportCharles JacobNo ratings yet

- PQR PT Bse WPS 07Document2 pagesPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Spci Cemex STR 312 Q01 0001Document8 pagesSpci Cemex STR 312 Q01 0001angelito bernalNo ratings yet

- 114486-UT-008 Attemperator Outlet T-PieceDocument2 pages114486-UT-008 Attemperator Outlet T-PieceDave CheungNo ratings yet

- WQT - WPS 03Document6 pagesWQT - WPS 03Gururaj P KundapurNo ratings yet

- MT RSDocument37 pagesMT RSdeari nur azisNo ratings yet

- UT PLTU BTG Turbine 1-DikonversiDocument2 pagesUT PLTU BTG Turbine 1-DikonversiWawan KurniawanNo ratings yet

- Ipcc Ufd Report-001Document1 pageIpcc Ufd Report-001mahmoudNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- Analyzer Data SheetDocument3 pagesAnalyzer Data Sheetsokrat sebtiNo ratings yet

- PR RepairDocument1 pagePR Repairaxis inspection solutionsNo ratings yet

- Report # 016-220127-PDocument1 pageReport # 016-220127-Pibrahim hegazyNo ratings yet

- Ec-2692-220-2 - Void 4SDocument3 pagesEc-2692-220-2 - Void 4SMatheus Fabrício TeixeiraNo ratings yet

- Magnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceDocument4 pagesMagnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceSulthan HanifNo ratings yet

- WQT - WPS 02Document33 pagesWQT - WPS 02Gururaj P KundapurNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Bis-Dk-Rt-1051 - Ip2022-NaDocument2 pagesBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNo ratings yet

- 114486-UT-006 HP Primary Superheater Outlet ManifoldDocument2 pages114486-UT-006 HP Primary Superheater Outlet ManifoldDave CheungNo ratings yet

- RT VL 4023 SPOOL PIECEDocument1 pageRT VL 4023 SPOOL PIECEsanthakumarNo ratings yet

- Sage X3 General Navigation and User Interface: Devin CenekofskyDocument4 pagesSage X3 General Navigation and User Interface: Devin CenekofskyMohamed AliNo ratings yet

- All Translations of PSSDocument574 pagesAll Translations of PSSricklagarto70No ratings yet

- Big Data Module 2Document31 pagesBig Data Module 2Mahmoud ElnahasNo ratings yet

- (ECE271) (11ES) (Group 1) Report Lab 1Document9 pages(ECE271) (11ES) (Group 1) Report Lab 1Trần Việt PhươngNo ratings yet

- Nissan Datascan User Manual 1.0Document21 pagesNissan Datascan User Manual 1.0LuisAntonioPeñalozaNo ratings yet

- ZFS Overview and Design Guide PDFDocument79 pagesZFS Overview and Design Guide PDFraghuNo ratings yet

- PAMB10/11: Precision Pressure IndicatorsDocument2 pagesPAMB10/11: Precision Pressure IndicatorsEliana GuzmanNo ratings yet

- Ka-En 3A: Material Safety Data SheetDocument3 pagesKa-En 3A: Material Safety Data SheetWANDANo ratings yet

- Transition To European Medical Device Regulation (MDR) : Ongoing ChallengesDocument23 pagesTransition To European Medical Device Regulation (MDR) : Ongoing ChallengesMohammed HammedNo ratings yet

- Aricent USSD WhitePaperDocument18 pagesAricent USSD WhitePaperChakravarthi ChittajalluNo ratings yet

- EON Group MISDocument19 pagesEON Group MISOnirulPathanNo ratings yet

- Micromotion MVD Direct Connect ManualDocument3 pagesMicromotion MVD Direct Connect ManualrickyNo ratings yet

- Kelman Transport X2 DGA Brochure en 2018-06-33118 A4 HRDocument2 pagesKelman Transport X2 DGA Brochure en 2018-06-33118 A4 HRAns MehmoodNo ratings yet

- Lab-07-Tuning RMAN Backup PerformanceDocument4 pagesLab-07-Tuning RMAN Backup PerformanceArif AhmadNo ratings yet

- Error LogDocument4 pagesError LogSyalom SibNo ratings yet

- STK350 030Document5 pagesSTK350 030tthutchNo ratings yet

- Abap Uni Code FeaturesDocument54 pagesAbap Uni Code Featuresroys4396510No ratings yet

- TOYOTADocument12 pagesTOYOTAZhasmin ElmuratovaNo ratings yet

- Titan Max Series MPPT Solar Charge Controller Catalog - V1.4Document4 pagesTitan Max Series MPPT Solar Charge Controller Catalog - V1.4Cristian Javier AránNo ratings yet

- Checkpoint 5400Document4 pagesCheckpoint 5400alexvelezNo ratings yet

- Suzuki JimnyDocument20 pagesSuzuki Jimnycolourhut100% (1)

- Guide: IBM Maximo Asset Configuration ManagerDocument140 pagesGuide: IBM Maximo Asset Configuration ManagerGayatri AtishNo ratings yet

- Mrtu6202204 210909aDocument37 pagesMrtu6202204 210909aGhulam ZakyNo ratings yet

- Computer in ManufacturingDocument5 pagesComputer in ManufacturingMohd Khairul FahmiNo ratings yet

- HCL Info Annual Report 2008-09Document162 pagesHCL Info Annual Report 2008-09Ankit Jain100% (1)

- Friction Stir Welding ReportDocument35 pagesFriction Stir Welding ReportTelvinNo ratings yet

- Full Air SuspensionDocument5 pagesFull Air Suspensionmonikaneha123No ratings yet

- PA-POS-2OC3 Two-Port Packet-over-SONET Port Adapter Installation and ConfigurationDocument100 pagesPA-POS-2OC3 Two-Port Packet-over-SONET Port Adapter Installation and ConfigurationOscar Suazo SantosNo ratings yet