Professional Documents

Culture Documents

Handout 4 - Strengthening by Gluing Screwing

Uploaded by

jav ezdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handout 4 - Strengthening by Gluing Screwing

Uploaded by

jav ezdCopyright:

Available Formats

Strengthening Timber Floors using (Gluing and) Screwing

Strengthening of Timber Floor by (Gluing and) Screwing

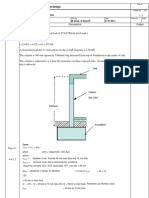

Sk1 -Existing Floor Section Sk2 - Strengthened Floor

Existing Properties

Section Modulus Z = (50 X 2252) / 6 = 421.9 x 103 mm3

Mom. of Inertia I = (50 x 2253) / 12 = 4746.1 x 104 mm4

Strengthened Floor Properties

Calculate y’ (First Moment of Area about O-O)

y’ = {(225 x 50) x (132.5) + (350 x 20) x (10)} / {(225 x 50) + (350 x 20)}

= 85.5mm

Composite Mom. of Inertia Icomp

= (350 x 203) / 12 + 7000 x (85.5 – 10)2 + 4746.1 x 104 + (20 + 112.5 – 85-5)2

= (23.3 + 3990.2 + 4746.1 + 2485.1) x 104

= 11244.7 x 104 mm4

Top Section Modulus ZT

= 11244.7 x 104 / 85.5 = 1315.2 x 103 mm3

Bottom Section Modulus ZB

= 11244.7 x 104 / 159.5 = 705.0 x 103 mm3

Strengthening Timber Floors using (Gluing and) Screwing

Consider the Following Arrangement

Floor Span = 5m

Dead Loading = 0.5 kN/m2

Live Loading = 3.0 kN/m2

W (per joist) = 0.35 x 5 x 3.5 = 6.125 kN R = 3.063 kN

M (per joist) = 6.125 x 5 x 0.125 = 3.83 kN-m

Existing Joists

fmax = (3.83 x 106) / 421.9 x 103 = 9.07 N/mm2

Strengthened Joists

fmax = (3.83 x 106) / 705.0 x 103 = 5.43 N/mm2

Check Horizontal Shear between Boarding and Joist

Consider following Free Body Diagrams (FBDs)

FBD – Joist Element FBD – Flooring Element

Joist Element

Resolving vertically

Q + w(dx) = Q + dQ → dQ/dx = w

Moments about A

M + w(dx) / 2 + (Q + dQ) dx = M + dM

Ignoring 2nd orders → dM/dx = Q

Strengthening Timber Floors using (Gluing and) Screwing

Flooring Element

Sy (dx) bj = ∫ (𝑑𝑀)𝑦(𝑑𝑦)𝑏(𝑓𝑙𝑜𝑜𝑟𝑖𝑛𝑔)/𝐼

.

Sy bj /bf = ∫ .

𝑄𝑦(𝑑𝑦)/𝐼 where dM/dx = Q

Sy = 0.5 x [(85.5)2 – (65.5)2] (Q / I) (bf / bj)

Where bf & bj are the widths of the flooring and joist, respectively.

At the support,

Q = 3.063 x 103 mm3, I = 11244.7 X 104 mm4, bf / bj = 350 / 50 = 7

So,

Sy = 0.5 x (150 x 20) x (3.063 x 103 x 7) / (11244.7 x 104)

= 0.29 N/mm2

Ignoring gluing and assuming screws with a safe capacity of 300-400N (say 350N)

Required screws per metre = (0.29 x 50 x 1000) / 350 = 41 !

Spacing = 1000 / 41 = 25mm – too close - permissible = 10d = 50mm

At 1m out from support Q reduces to 3.063 – (0.35 x 3.5) = 1.835 kN

Sy then becomes (1.835 / 3.063) x 0.29 = 0.174 N/mm 2, and spacing is now 41 mm

→ Gluing is critical

You might also like

- Design of Isolated Square (Axially Loaded) Pad FootingDocument7 pagesDesign of Isolated Square (Axially Loaded) Pad FootingNikhil100% (1)

- Design of FootingDocument67 pagesDesign of FootingHarlene Marie M. Ilagan100% (1)

- Design of Axially Loaded Sloped Footing DataDocument11 pagesDesign of Axially Loaded Sloped Footing DataFatima tuz ZohraNo ratings yet

- Design of FootingDocument31 pagesDesign of FootingAbhinav100% (1)

- Column and Foundation DesignDocument12 pagesColumn and Foundation DesignMohafisto SofistoNo ratings yet

- Design ExamplesDocument12 pagesDesign ExamplesBrajesh Suman100% (1)

- Design of Steel Structure (Chapter 2) by DR R BaskarDocument57 pagesDesign of Steel Structure (Chapter 2) by DR R Baskarelect aksNo ratings yet

- Slab Design To BS 8110Document11 pagesSlab Design To BS 8110Samuel Antobam100% (2)

- Example 2 Simply Supported Beam - Flanged Section PDFDocument7 pagesExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (1)

- Design of BeamsDocument19 pagesDesign of BeamssnsatyanarayanaNo ratings yet

- Design CalculationDocument23 pagesDesign CalculationKathir VelNo ratings yet

- Two Way Slab (First Slab Level Slabs)Document15 pagesTwo Way Slab (First Slab Level Slabs)Anjali DudhyalNo ratings yet

- Design of Square FootingDocument8 pagesDesign of Square FootingvishalNo ratings yet

- Strap Footing DesignDocument5 pagesStrap Footing DesignNabin Acharya100% (1)

- Stepped FootingDocument12 pagesStepped FootingV.m. RajanNo ratings yet

- Beam Design ExampleDocument4 pagesBeam Design ExampleVinod Achi VenugopalanNo ratings yet

- Problem Set 2 - Fluid MachineryDocument1 pageProblem Set 2 - Fluid MachineryRonard Pa–aNo ratings yet

- Centrifugal Compressor Inducer PDFDocument11 pagesCentrifugal Compressor Inducer PDFmistrycsNo ratings yet

- Summative Test #4 Science 6Document2 pagesSummative Test #4 Science 6chona redillasNo ratings yet

- Design Composite Girder.Document42 pagesDesign Composite Girder.arabindaNo ratings yet

- 550x550 Column Design (Page 96-101)Document6 pages550x550 Column Design (Page 96-101)Aashu chaudharyNo ratings yet

- Design of Square FoundationDocument5 pagesDesign of Square FoundationLAgoonNo ratings yet

- Staircase DesignDocument4 pagesStaircase DesignDrafters EngineeringNo ratings yet

- Perhitungan Penulangan Pile CapDocument4 pagesPerhitungan Penulangan Pile CapZulfikar N JoelNo ratings yet

- RCD2601 B0 LS05 Annexure GDocument17 pagesRCD2601 B0 LS05 Annexure Gstella mkokoNo ratings yet

- Naseer Al JihadmeDocument33 pagesNaseer Al JihadmeMuhammad ImranNo ratings yet

- Design of Earthquake Resistant StructureDocument23 pagesDesign of Earthquake Resistant Structuregtarun22guptaNo ratings yet

- Lec 55Document7 pagesLec 55kassembaalbakiNo ratings yet

- Simple Conncrete Beam DesignDocument1 pageSimple Conncrete Beam DesignPaul KarijaNo ratings yet

- Design Isolated FootingDocument4 pagesDesign Isolated FootingMaheshreddyNo ratings yet

- 4.5 - Design of DRS - Simply SupportedDocument18 pages4.5 - Design of DRS - Simply Supportedron thombareNo ratings yet

- Design Slab Over Sluice GatesDocument5 pagesDesign Slab Over Sluice GatesNeil AgshikarNo ratings yet

- Stair Case DesignDocument6 pagesStair Case DesignYogen SthaNo ratings yet

- Design Calculations For Primary Beam Connections As Welded Connections R2Document6 pagesDesign Calculations For Primary Beam Connections As Welded Connections R2Rajesh PoreNo ratings yet

- Lec 49Document7 pagesLec 49Gilbert SmithNo ratings yet

- Pad Foundation Design Example Eurocode 2Document5 pagesPad Foundation Design Example Eurocode 2tedy yidegNo ratings yet

- Manyam Dr.s House 2.5Document33 pagesManyam Dr.s House 2.5Durga Rama Swamy KalvakolanuNo ratings yet

- Manyam Dr.s HouseDocument33 pagesManyam Dr.s HouseDurga Rama Swamy KalvakolanuNo ratings yet

- 5L DesignDocument23 pages5L Designsam 08No ratings yet

- CalculationDocument10 pagesCalculationVIKRAM DESURKARNo ratings yet

- A. Design of Flanged Beam SectionDocument7 pagesA. Design of Flanged Beam SectionWilson PatyalNo ratings yet

- Section 12Document7 pagesSection 12Mubeen AkhtarNo ratings yet

- WorkedExamplestoBS8110-min RemovedDocument6 pagesWorkedExamplestoBS8110-min RemovedZack DaveNo ratings yet

- Slpoed Footing PDFDocument11 pagesSlpoed Footing PDFChandu ReddyNo ratings yet

- Mavoko CalculationsDocument24 pagesMavoko CalculationsPEng. Tech. Alvince KoreroNo ratings yet

- Bab V Balok Induk: Gambar 5.1 Profil Baja WFDocument15 pagesBab V Balok Induk: Gambar 5.1 Profil Baja WFBintang Laksamana E.PNo ratings yet

- Dead Lod Brige DesignDocument6 pagesDead Lod Brige DesigntizazuNo ratings yet

- 6.4 Design of Isolated Footing Beneath ColumnDocument7 pages6.4 Design of Isolated Footing Beneath ColumnbikramNo ratings yet

- STEP OF Square Footing DesignDocument10 pagesSTEP OF Square Footing DesignPhreetzi ÜnseenNo ratings yet

- Block ShearDocument14 pagesBlock ShearSubramaniNo ratings yet

- Slab (S) : ReinforcementDocument5 pagesSlab (S) : ReinforcementSajal9474No ratings yet

- Design of Pre-Cast Stair According To Bs 8110, 1997: First Flight 1. Design InputDocument2 pagesDesign of Pre-Cast Stair According To Bs 8110, 1997: First Flight 1. Design InputJD Hema100% (1)

- Slab Design As Per Is 4562000Document12 pagesSlab Design As Per Is 4562000Roman BaralNo ratings yet

- Design - of - Combined - Footing C2 G4Document8 pagesDesign - of - Combined - Footing C2 G4Aditya HadoleNo ratings yet

- Lecture 3b NewDocument12 pagesLecture 3b NewJohaNo ratings yet

- Design of One WayslabsDocument20 pagesDesign of One WayslabsAhmedNo ratings yet

- Vibration Serviceability of Composite SlabsDocument8 pagesVibration Serviceability of Composite SlabsDelahan AbatyoughNo ratings yet

- Lecture 3b Design and DetailingDocument12 pagesLecture 3b Design and DetailingSirleh SalazaryNo ratings yet

- Week 11 Lecture Material - WatermarkDocument57 pagesWeek 11 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- Structural Design of A Reinforced Concrete Balcony Slab To BS 8110Document4 pagesStructural Design of A Reinforced Concrete Balcony Slab To BS 8110OscarKonzultNo ratings yet

- Design of Axially Loaded Pad Footing (Square) DataDocument8 pagesDesign of Axially Loaded Pad Footing (Square) DataBush RcNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Handout 3 - Floor Strengthening Using New JoistsDocument9 pagesHandout 3 - Floor Strengthening Using New Joistsjav ezdNo ratings yet

- Highways Guide V2 2023Document102 pagesHighways Guide V2 2023jav ezdNo ratings yet

- Handout 1 - Raised Collar RoofsDocument4 pagesHandout 1 - Raised Collar Roofsjav ezdNo ratings yet

- Handout 2 - 'Wheelbarrow' Beam RepairDocument2 pagesHandout 2 - 'Wheelbarrow' Beam Repairjav ezdNo ratings yet

- Rheem Ra2060ajvcb Article 1405358021530 en SsDocument28 pagesRheem Ra2060ajvcb Article 1405358021530 en SsAlejandro MurciaNo ratings yet

- FCCU Equipment Layout ListDocument3 pagesFCCU Equipment Layout Listnas_mech8208No ratings yet

- EG280-140N Technical DatasheetDocument1 pageEG280-140N Technical DatasheetalstomNo ratings yet

- Coronas de Giro 2017 BehDocument31 pagesCoronas de Giro 2017 BehdanielNo ratings yet

- RefractometerDocument2 pagesRefractometerDimas Firmanda Al RizaNo ratings yet

- AQA Trilogy Unit 66 Waves Test-AnswersDocument4 pagesAQA Trilogy Unit 66 Waves Test-AnswersBilaal SohailNo ratings yet

- BES15a - Mechanics of Deformable Bodies Lecture Notes #6 Bsme 3ADocument6 pagesBES15a - Mechanics of Deformable Bodies Lecture Notes #6 Bsme 3AbrodyNo ratings yet

- Automotive CableDocument10 pagesAutomotive CableEquipmentDesignNo ratings yet

- Electric Generator - Groupe Electrogene - Generador ElectricoDocument12 pagesElectric Generator - Groupe Electrogene - Generador ElectricoDaniel Alejandro Hernandez ToldoNo ratings yet

- Users Manual Bas Rde-1 (Preliminary)Document25 pagesUsers Manual Bas Rde-1 (Preliminary)2017013030 AndikaNo ratings yet

- Bonding Theories (CFT&LFT)Document54 pagesBonding Theories (CFT&LFT)delicakimmNo ratings yet

- Cu 104Document16 pagesCu 104PonyPantsNo ratings yet

- Tutorial - 1 Property TablesDocument2 pagesTutorial - 1 Property TablesNur Farah NadiahNo ratings yet

- Chapter 3 ExerciseDocument2 pagesChapter 3 ExerciseDawitNo ratings yet

- Phys234h Lecture03Document29 pagesPhys234h Lecture03Jessa Balanay GalaponNo ratings yet

- Glass Edge Work and ProcessingDocument8 pagesGlass Edge Work and ProcessingAndreaski LamboNo ratings yet

- CE 405 Experiment 3 1 1Document6 pagesCE 405 Experiment 3 1 1Irish AnneNo ratings yet

- Materials: Ffect of Accelerator Dosage On Fresh ConcreteDocument19 pagesMaterials: Ffect of Accelerator Dosage On Fresh ConcreteRizeruNo ratings yet

- Catalytic Degradation of Plastic Waste To Liquid Fuel Over Commercial Cracking Catalysts Effect of Polymer To Catalyst Ratio/acidity ContentDocument7 pagesCatalytic Degradation of Plastic Waste To Liquid Fuel Over Commercial Cracking Catalysts Effect of Polymer To Catalyst Ratio/acidity ContentZahid FarooqNo ratings yet

- Alfa Laval Aalborg Shell and Tube Heat Exchangers - Product OverviewDocument1 pageAlfa Laval Aalborg Shell and Tube Heat Exchangers - Product Overviewagus sutiawanNo ratings yet

- Prediction of Flow Field For A 2-D Mixed Compression Supersonic InletDocument5 pagesPrediction of Flow Field For A 2-D Mixed Compression Supersonic InletAzeem KhanNo ratings yet

- APPSC Municipal AE SyllabusDocument4 pagesAPPSC Municipal AE SyllabusPrasanna KumarNo ratings yet

- Hypoplasticity For Beginners: January 2000Document7 pagesHypoplasticity For Beginners: January 2000abelkrusnik02No ratings yet

- Chapter 3 ConvectionDocument137 pagesChapter 3 ConvectionHải MâyNo ratings yet

- Lecture 6 Arch - DamDocument25 pagesLecture 6 Arch - DamChanako DaneNo ratings yet

- Sample Questions - Chapter 25Document6 pagesSample Questions - Chapter 25Glenn Farah Faye RausaNo ratings yet

- Subject: Fluid Mechanics - II: Class: BME - II, Section: A+BDocument2 pagesSubject: Fluid Mechanics - II: Class: BME - II, Section: A+BSaujatya MandalNo ratings yet