Professional Documents

Culture Documents

Stair Case Design

Uploaded by

Yogen SthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stair Case Design

Uploaded by

Yogen SthaCopyright:

Available Formats

Stair case design 1

Let the depth of slab (D) = 150mm

Load calculation

1. Loads on going

Considering 1m width of slab,

Dead load of slab on slope (Ws) = 0.15×1×25

= 3.75 KN/m

Dead load of slab on horizontal span

W =Ws ¿¿

= 3.75 ¿ ¿

= 4.341 KN/m

Dead load of one step= 0.5×R×T×25 = 0.5×0.175×0.3×25

= 0.656 KN

0.656

Load of slope per meter length = = 2.19KN/m

0.3

Total dead load =4.341+2.19 = 6.531 KN/m

Live load = 4KN/m2×1m =4 KN/m

Total service load = (6.531+4) KN/m = 10.531 KN/m

Factored load = 1.5×10.531 KN/m = 15.8 KN/m

2. Load of landing (A)

Self weight of slab = 25×0.15 = 3.75 KN/m

Live load = 4KN/m2×1m = 4KN/m

Total load = 7.75 KN/m

Factored load = (1.5×7.75)KN/m =11.625 KN/m

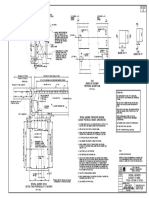

Fig:- First flight Loading diagram

(15.8 ×1.5 ×0.75)+(11.625 ×2.05 ×2.525)

R B=

3.55

=21.96 KN

RA= (15.8×1.5+11.625×2.05)-21.96

=25.57 KN

Let point of zero shear force occurs at distance “X” from A

Or, 25.57-(15.8×1.5)-(11.625×(X-1.5))=0

∴ X= 1.661m (from A)

Maximum bending moment= 25.57×1.661-15.8×1.5×0.911-11.625×0.161×0.0805

= 20.73 KN-m

Check:

Maximum BM from B = 21.96×1.889-11.625×1.889×0.9445

= 20.74 KN-m

M 20.74 × 10⁶

Depth of slab d=

√ 0.138∗σck∗b

Hence, adopt 150mm overall depth.

=

√ 0.138× 20× 1000

= 86.67mm <150mm OK

Use, 12mm diameter bars.

Effective depth (d)=150-20-6 = 124mm

Reinforcement:

Ast ×σy

Mu =0.87×σy×Ast×d 1− ( b × d × σck )

Ast × 415

20.74×106= 0.87×415×Ast×124 1−

6 2

( 1000 ×124 × 20 )

20.74×10 =44770.2Ast-7.492A st

∴ Ast=506.12 mm2

Use 12mm∅ bar, Ast = 113.1mm2

No of bars required=1.9× ( 506.12

113.1 )

= 9 Nos.

1900

Spacing ¿ = 211 mm

9

113.1 ×1000

Ast provided = ( 150 )

=754mm2 > 506.12 mm2 OK

0.12

Distribution r/t @ 0.12% of area (Ast)= ×1000×150=180mm2

100

Use 10mm∅ bars Ast=78.54mm

∴ Spacing, Sv=1000× ( 78.54

180 )

=436.33mm

∴ Adopt spacing =300mm

Hence, provide 1-10mm bar as temperature reinforcement in each riser.

Check for shear:

Vu 25.57 ×1000

Nominal shear stress, τv = = = 0.206N/mm2

bd 1000× 124

100 Ast 100× 754

% of Tension steel = = = 0.608 %

bd 1000× 124

Shear strength of M20 concrete for 0.608%

τc= 0.52 N/mm2

τ’c =1.3×0.52 =0.676N/mm2 > τv OK

Maximum shear stress, τc max =2.8 N/mm2

τc <τ’c <τc max OK

Check for development length:

For M20 concrete & Fe 415 steel

Ld = 47Ф

0.87 ×σy × ∅ 0.87 × 415× 12

Development length Ld= = =564.14mm

4 × τbd 4 ×1.6 × 1.2

M1

Ld≤ 1.3 + L0

Vu

We have,

754

M1= 20.74× =30.9KN-m

506.12

Vu = 25.57 KN

M1

Ld≤ 1.3 + L0

Vu

30.9 ×10⁶

Or, 47∅≤ 1.3

25.57 × 1000

∴∅≤33.42 mm

Since bar diameter provided is 12mm<33.42mm …………………….. (OK).

Hence, provide 750mm development length.

Stair case design 2

Let the depth of slab (D) = 150mm

Load calculation

1. Loads on going

Considering 1m width of slab,

Dead load of slab on slope (Ws) = 0.15×1×25

= 3.75 KN/m

Dead load of slab on horizontal span

W =Ws ¿¿

= 3.75 ¿ ¿

= 4.341 KN/m

Dead load of one step= 0.5×R×T×25 = 0.5×0.175×0.3×25

= 0.656 KN

0.656

Load of slope per meter length = = 2.19KN/m

0.3

Total dead load =4.341+2.19 = 6.531 KN/m

Live load = 4KN/m2×1m =4 KN/m

Total service load = (6.531+4) KN/m = 10.531 KN/m

Factored load = 1.5×10.531 KN/m = 15.8 KN/m

2. Load of landing (A)

Self weight of slab = 25×0.15 = 3.75 KN/m

Live load = 4KN/m2×1m = 4KN/m

Total load = 7.75 KN/m

Factored load = (1.5×7.75)KN/m =11.625 KN/m

In a distance of 2150mm, the total factored load =11.625 KN/m

In a distance of 150mm from the wall, there will be no live load in accordance with clause 33.2

of IS456:2000. In a distance equal to 150mm from the wall and a distance equal to 75mm inside

the wall only dead load will be considered.

Total factored load =1.5×3.75 = 5.625 KN/m

Fig:- First flight Loading diagram

( 15.8× 2.4 ×1.2 ) + ( 11.625 × 2.15× 3.475 ) +(5.625 ×0.225 × 4.6625)

R B=

4.775

= 28.955KN

RA= (15.8×2.4+11.625×2.15+5.625×0.225)-28.955

=35.224 KN

Let point of zero shear force occurs at distance “X” from A

Or, 35.224-15.8×X=0

∴ X= 2.23m (from A)

Maximum bending moment= 35.224×2.23-15.8×2.23×1.115

= 39.264 KN-m

Check:

Maximum BM from B = 28.955×2.545-5.625×0.225×2.4325-11.625×2.15×1.245-15.8×0.17×0.085

= 39.266 KN-m

M 39.266 × 10⁶

Depth of slab d=

√ 0.138∗σck∗b

Hence, adopt 150mm overall depth.

=

√ 0.138× 20× 1000

= 119.3mm <150mm OK

Use, 12mm diameter bars.

Effective depth (d)=150-20-6 = 124mm

Reinforcement:

Ast ×σy

Mu =0.87×σy×Ast×d 1− ( b × d × σck )

Ast × 415

39.266×106= 0.87×415×Ast×124 1−

6 2

( 1000 ×124 × 20 )

39.266×10 =44770.2Ast-7.492A st

∴ Ast=1067.9 mm2

Use 12mm∅ bar, Ast = 113.1mm2

No of bars required=1.5× ( 1067.9

113.1 )

= 15 Nos.

1500

Spacing ¿ = 100 mm

15

113.1 ×1000

Ast provided =( 100 )

=1131mm2 > 1067.9 mm2 OK

0.12

Distribution r/t @ 0.12% of area (Ast)= ×1000×150=180mm2

100

Use 10mm∅ bars Ast=78.54mm

∴ Spacing, Sv=1000× ( 78.54

180 )

=436.33mm

∴ Adopt spacing =300mm

Hence, provide 1-10mm bar as temperature reinforcement in each riser.

Check for shear:

Vu 35.224 ×1000

Nominal shear stress, τv = = = 0.284N/mm2

bd 1000× 124

100 Ast 100 ×1131

% of Tension steel = = = 0.912%

bd 1000× 124

Shear strength of M20 concrete for 0.912%

τc= 0.6 N/mm2

τ’c =1.3×0.6 =0.78N/mm2 > τv OK

Maximum shear stress, τc max =2.8 N/mm2

τc <τ’c <τc max OK

Check for development length:

For M20 concrete & Fe 415 steel

Ld = 47Ф

0.87 ×σy × ∅ 0.87 × 415× 12

Development length Ld= = =564.14mm

4 × τbd 4 ×1.6 × 1.2

M1

Ld≤ 1.3 + L0

Vu

We have,

1131

M1= 39.266× =41.586KN-m

1067.9

Vu = 35.224 KN

M1

Ld≤ 1.3 + L0

Vu

41.586× 10⁶

Or, 47∅≤ 1.3

35.224 × 1000

∴∅≤32.65 mm

Since bar diameter provided is 12mm<32.65mm …………………….. (OK).

Hence, provide 750mm development length.

You might also like

- Slab (S) : ReinforcementDocument5 pagesSlab (S) : ReinforcementSajal9474No ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- 7 One Way SlabDocument4 pages7 One Way SlabPronay DhakNo ratings yet

- Design CalculationDocument23 pagesDesign CalculationKathir VelNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Ipt Design WorkDocument43 pagesIpt Design WorkMorice RwakataleNo ratings yet

- Slab DesignDocument6 pagesSlab DesignThea DoradoNo ratings yet

- Two Way Slab (First Slab Level Slabs)Document15 pagesTwo Way Slab (First Slab Level Slabs)Anjali DudhyalNo ratings yet

- Design A RCC Retaining Wall To Retain Earth Up ToDocument9 pagesDesign A RCC Retaining Wall To Retain Earth Up ToMuhammad Farooq Zia100% (1)

- Design of SlabDocument26 pagesDesign of SlabSumanth SangemNo ratings yet

- Design of isolated square footing beneath columnDocument7 pagesDesign of isolated square footing beneath columnbikramNo ratings yet

- Analysis, Design &modelling of A Multi-Storey Commercial BuildingDocument54 pagesAnalysis, Design &modelling of A Multi-Storey Commercial BuildingSyed AhmedNo ratings yet

- Design of Staircase Practical ExampleDocument24 pagesDesign of Staircase Practical ExamplePralhad KoreNo ratings yet

- RCD2601 B0 LS05 Annexure GDocument17 pagesRCD2601 B0 LS05 Annexure Gstella mkokoNo ratings yet

- Design Composite Girder.Document42 pagesDesign Composite Girder.arabindaNo ratings yet

- STEP OF Square Footing DesignDocument10 pagesSTEP OF Square Footing DesignPhreetzi ÜnseenNo ratings yet

- STRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGDocument5 pagesSTRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGNabin Acharya100% (1)

- Analysis, Design &modelling of A Multi-Storey Commercial BuildingDocument54 pagesAnalysis, Design &modelling of A Multi-Storey Commercial BuildingSyed AhmedNo ratings yet

- Detailed Design Design of SlabDocument4 pagesDetailed Design Design of Slabnandheeswaran rNo ratings yet

- Block ShearDocument14 pagesBlock ShearSubramaniNo ratings yet

- Week 5 Assignment SolutionDocument2 pagesWeek 5 Assignment Solutionamin alzuraikiNo ratings yet

- Slab Design & LoadingDocument41 pagesSlab Design & Loadingzures gustiabaniNo ratings yet

- Dog Legged Staircase 1Document4 pagesDog Legged Staircase 1VijithNo ratings yet

- 2018 May 29 Circular Tank With WaterDocument4 pages2018 May 29 Circular Tank With WaterPRAKASHNo ratings yet

- Design of Square FoundationDocument5 pagesDesign of Square FoundationLAgoonNo ratings yet

- DESIGN OF CIRCULAR WATER TANKDocument6 pagesDESIGN OF CIRCULAR WATER TANKPRAKASHNo ratings yet

- ##FNuj Slab NotesDocument36 pages##FNuj Slab NotesthembalethuNo ratings yet

- Design of Bank Building in MSECDocument82 pagesDesign of Bank Building in MSECjahanger ali SNo ratings yet

- Week 9 Lecture Material - WatermarkDocument62 pagesWeek 9 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- 550x550 Column Design (Page 96-101)Document6 pages550x550 Column Design (Page 96-101)Aashu chaudharyNo ratings yet

- Waffle design numericalDocument8 pagesWaffle design numericalersunilsingh1No ratings yet

- 4 Creative and Innovative Project Reports 2021-2022Document12 pages4 Creative and Innovative Project Reports 2021-2022Najamool Hoda AnsariNo ratings yet

- Stair case design load calculationDocument4 pagesStair case design load calculationParves UddinNo ratings yet

- Maxspan Slab WordDocument3 pagesMaxspan Slab WordJames Aswa100% (1)

- Residential house design calculationsDocument24 pagesResidential house design calculationsPEng. Tech. Alvince KoreroNo ratings yet

- Design of Staircase: at Ground FloorDocument24 pagesDesign of Staircase: at Ground FloorAmit GuptaNo ratings yet

- Shyam Design of SlabDocument5 pagesShyam Design of SlabShyamNo ratings yet

- Irrigation Division Chunar, Mirzapur: Design of Slab of Jirgo DamDocument4 pagesIrrigation Division Chunar, Mirzapur: Design of Slab of Jirgo Damgovind narayan ShuklaNo ratings yet

- Slab Design KatakpurDocument18 pagesSlab Design Katakpursakar shresthaNo ratings yet

- 3.5 Designof The Ground Beam: Giving DataDocument3 pages3.5 Designof The Ground Beam: Giving DataMohamed FarahNo ratings yet

- Slab S: Effective Span in Short DurationDocument3 pagesSlab S: Effective Span in Short DurationSajal9474No ratings yet

- Reference Calculations Output CASE 1:empty Culvert: 4 H 112.5 4 X 2 7.031 KN/MDocument8 pagesReference Calculations Output CASE 1:empty Culvert: 4 H 112.5 4 X 2 7.031 KN/MSolomon ElumaNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingMaheshreddyNo ratings yet

- Design of SlabsDocument10 pagesDesign of SlabsMaheshreddyNo ratings yet

- Q1. A Linear Resistance Potentiometer Is 50mm Long & IsDocument7 pagesQ1. A Linear Resistance Potentiometer Is 50mm Long & IsshubhamNo ratings yet

- Design of INTZE Tank50000Glns Only DesignPDFDocument17 pagesDesign of INTZE Tank50000Glns Only DesignPDFMike VictorNo ratings yet

- Null 4Document5 pagesNull 4emranahmed056studentNo ratings yet

- BeamsDocument4 pagesBeamsthirangaNo ratings yet

- 8b.design of Control Room BuildingDocument49 pages8b.design of Control Room BuildingNuru TwahaNo ratings yet

- Assignment StructureDocument11 pagesAssignment StructureCivil EngineerNo ratings yet

- Design of Structures: 120 LB/FT 30 2500lb/ FT 4000 Psi F 40,000 PsiDocument10 pagesDesign of Structures: 120 LB/FT 30 2500lb/ FT 4000 Psi F 40,000 PsiSajid NazirNo ratings yet

- Imtiaz Ali 70110394 - 2 - BDocument7 pagesImtiaz Ali 70110394 - 2 - BImtiaz RahiNo ratings yet

- Design of BeamsDocument19 pagesDesign of BeamssnsatyanarayanaNo ratings yet

- Assignment: Homework QuestionsDocument11 pagesAssignment: Homework QuestionsCivil EngineerNo ratings yet

- 4.5 - Design of DRS - Simply SupportedDocument18 pages4.5 - Design of DRS - Simply Supportedron thombareNo ratings yet

- Imtiaz Ali 70110394 B 3Document4 pagesImtiaz Ali 70110394 B 3Imtiaz RahiNo ratings yet

- Auditorium Building DesignDocument28 pagesAuditorium Building DesignChandra Sekar100% (1)

- SADDDASWDocument9 pagesSADDDASWMatt DesignNo ratings yet

- Design of Mat FoundationDocument9 pagesDesign of Mat FoundationYogen SthaNo ratings yet

- Design of BeamDocument6 pagesDesign of BeamYogen SthaNo ratings yet

- Geotechnical Design Standard - Minimum RequirementsDocument28 pagesGeotechnical Design Standard - Minimum RequirementsTesCospNo ratings yet

- Design of Mat FoundationDocument9 pagesDesign of Mat FoundationYogen SthaNo ratings yet

- Eurocode 7 Geotechnical Design Worked ExamplesDocument172 pagesEurocode 7 Geotechnical Design Worked ExamplesJevgenijs Kolupajevs100% (1)

- Bridge Abutment PDFDocument14 pagesBridge Abutment PDFYogen SthaNo ratings yet

- Basement Shear Wall PDFDocument3 pagesBasement Shear Wall PDFYogen SthaNo ratings yet

- Structural Design Report PDFDocument32 pagesStructural Design Report PDFYogen SthaNo ratings yet

- Design of Culvert - Jal Dubba PDFDocument12 pagesDesign of Culvert - Jal Dubba PDFYogen SthaNo ratings yet

- Design of Culvert - Jal Dubba PDFDocument12 pagesDesign of Culvert - Jal Dubba PDFYogen SthaNo ratings yet

- Bridge Abutment PDFDocument14 pagesBridge Abutment PDFYogen SthaNo ratings yet

- Structural Design Report PDFDocument32 pagesStructural Design Report PDFYogen SthaNo ratings yet

- Basement Shear Wall PDFDocument3 pagesBasement Shear Wall PDFYogen SthaNo ratings yet

- DSR Book Vol 2 2016 (English Version) Final (Full Permission)Document258 pagesDSR Book Vol 2 2016 (English Version) Final (Full Permission)Shyam Kumar88% (16)

- Fire Flow CalculationDocument2 pagesFire Flow Calculationcoolsummer1112143No ratings yet

- Karaikudi Our TNPSC CESE AE Civil Result in 2019 Exam 436 + Selections Out of 573 PostsDocument12 pagesKaraikudi Our TNPSC CESE AE Civil Result in 2019 Exam 436 + Selections Out of 573 PostsGokul ParthibanNo ratings yet

- Midas Civil Training - 0220-Edit-Final PDFDocument48 pagesMidas Civil Training - 0220-Edit-Final PDFgundulp100% (2)

- Column HP10 To Base Plate Connection Report PDFDocument7 pagesColumn HP10 To Base Plate Connection Report PDFAhmed AlmayaliNo ratings yet

- Bearing Pad "A" Bearing Pad "B": Bd-Id1EDocument11 pagesBearing Pad "A" Bearing Pad "B": Bd-Id1EJUAN RULFONo ratings yet

- Despiece RINNAI LNOXDocument15 pagesDespiece RINNAI LNOXIgnacio LopezNo ratings yet

- Jetty AreaDocument6 pagesJetty AreashrieersNo ratings yet

- AISC 13ed - LRFD Bolted Moment Connections Post r4Document614 pagesAISC 13ed - LRFD Bolted Moment Connections Post r4kfischer13No ratings yet

- Development of Project Risk Ma PDFDocument32 pagesDevelopment of Project Risk Ma PDFMega AriantiNo ratings yet

- Frame and Fork Exploded View DiagramDocument52 pagesFrame and Fork Exploded View DiagramAnonymous b84Dcgh7No ratings yet

- Construction Safety Form SubmissionDocument2 pagesConstruction Safety Form SubmissionRuel BariaNo ratings yet

- Australian Standard: Residential Slabs and Footings Part 1: ConstructionDocument36 pagesAustralian Standard: Residential Slabs and Footings Part 1: ConstructionXiaobing YangNo ratings yet

- ICP Design Methods For Driven Piles in Sands and CDocument14 pagesICP Design Methods For Driven Piles in Sands and CBinSayeedNo ratings yet

- Hawaii Historic Housing Study-SchofieldDocument20 pagesHawaii Historic Housing Study-SchofieldPat Appel100% (1)

- Kemper DistributionDocument16 pagesKemper Distributionask101No ratings yet

- Ind PamDocument47 pagesInd PamAbhishek PandaNo ratings yet

- Sandvik Wx6000 Tensioned Screening MediaDocument6 pagesSandvik Wx6000 Tensioned Screening MediaLachezar VelkovNo ratings yet

- Ag Ser8300 Fcu A4 PDFDocument32 pagesAg Ser8300 Fcu A4 PDFMarin MariusNo ratings yet

- Structural ReviewerDocument23 pagesStructural ReviewerrogggNo ratings yet

- CP150 SMDocument50 pagesCP150 SMjacklyn ade putra100% (1)

- CRS New Brochure 2018Document24 pagesCRS New Brochure 2018gugiNo ratings yet

- Programme Narrative of Roads and Infrastructure in West Bay Block A 2500Document5 pagesProgramme Narrative of Roads and Infrastructure in West Bay Block A 2500Santhosh PalaniappanNo ratings yet

- Soil Stabilization ProjectDocument53 pagesSoil Stabilization Projectrohit attri100% (2)

- UntitledDocument42 pagesUntitledShafkat SaminNo ratings yet

- Alform System Formwork Procedures October 2016Document40 pagesAlform System Formwork Procedures October 2016Syerifaizal Hj. MustaphaNo ratings yet

- Simple 4: 'file:///conversion/tmp/scratch/359433723.xls'#$BEAM DESIGN Last Updated: 2007Document1 pageSimple 4: 'file:///conversion/tmp/scratch/359433723.xls'#$BEAM DESIGN Last Updated: 2007امين الزريقيNo ratings yet

- Mantri Pinnacle - Tender Comparative - Rates With Celestia - 27 Oct 2010Document27 pagesMantri Pinnacle - Tender Comparative - Rates With Celestia - 27 Oct 2010raviNo ratings yet

- Hoja Tecnica Mech Accesorios en GeneralDocument27 pagesHoja Tecnica Mech Accesorios en GeneralcarlosNo ratings yet

- Ramp Layout and DesignDocument1 pageRamp Layout and DesignHassanIsmailJenehaNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Visions Of Technology: A Century Of Vital Debate About Machines Systems AFrom EverandVisions Of Technology: A Century Of Vital Debate About Machines Systems ARating: 4 out of 5 stars4/5 (9)

- RoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingFrom EverandRoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingNo ratings yet

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- Artificial Intelligence: Data Analytics and Innovation for BeginnersFrom EverandArtificial Intelligence: Data Analytics and Innovation for BeginnersRating: 5 out of 5 stars5/5 (3)