Professional Documents

Culture Documents

Method Statement 8 Oct

Uploaded by

sandesh negiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement 8 Oct

Uploaded by

sandesh negiCopyright:

Available Formats

METHOD STATEMENT FOR INSTALLATION

1.1 GENERAL

This method statement shall be viewed with the NCRTC document for Method Statement of Slab

Track System for PORR Slab in the Underground Section. The Floating Track Slab with discrete

bearing for the Steel Spring MSS system is supported on the 1st stage concrete/ tunnel invert (U/G

track) by means of a steel spring element to transfer the load to the substructure. These discrete

bearings are all-time accessible from the top and provide advantages for night maintenance. This

Document shall be read in conjunction with latest revisions of all the drawing and documents

indicated in reference.

1.2 SURFACE PREPARATION

The surface of 1st stage concrete tunnel invert (U/G track) shall be cleaned of any loose material,

dust, and debris. There should not be any undulations/ extrusion like nails, metal wire gravels, etc.

exceeding 2-3mm in height, water should not be present on the surface. The location of Steel

Springs shall be marked by GERB personnel and the surface shall be made flat (trowel-finish) within

a tolerance of ± 3 mm.

Fig 1 - Nails on the surface Fig 2 - Concrete Gravels

Fig 3 – First Stage Concrete Area below FST (Black Highlight)

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

Fig 4 - Dirt removing by Air Blower Fig 5 Surface Grinding for Levelling Undulations

In case top of first stage concrete differs (higher or lower) from the desired the level accounting

tolerance as stated above, same shall be made good to required level by chipping or grouting with

Fosroc Conbextra GP2 or equivalent make and grade in a band of 600 mm wide i.e. 300 mm on

either side of center line of GSI or KYM elements as marked at site and for a full width of 2500 mm

of floating slab i.e. 1250 mm with respect to floating track slab center line as shown in below section.

Fig 6 – Schematic Details for Levelling (600 mm x 2500 mm) at MSS Locations

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

1.3 DRAINAGE

The track drainage shall be provided on the second stage concrete as per drainage provisions

already considered and shown in project General Arrangement (GA) Drawings. However, in small

stretch in down line and in upline (if so required though not envisaged at this stage), central drain

in first stage concrete shall be provided as per details indicated in GA drawings. Schematic details

shown in Figure below

Details - Z

Figure 7 – Drainage Details for Central Drain in First Stage Concrete

1.4 DE-BONDING SHEET

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

A debonding sheet customized and supplied by GERB shall be used to prevent bonding of track

slab with the first stage concrete. It shall be laid on the 1st stage concrete and all the joints shall be

taped/ sealed properly to prevent leakage of slurry. This debonding sheet is not required at transition

zone below stiffness transition material.

Fig 8 – Typical Site Picture showing Debonding sheet placed over First Stage Concrete

1.5 REINFORCEMENT

Steel housings shall be marked and placed as per the eneral arrangement drawings under the

supervision of GERB installation engineer. Reinforcement shall then be placed as per the track slab

reinforcement drawings and suitable shuttering / formwork shall be placed at sides and other

opening areas

Fig 9 - Schematic Details of Reinforcement at Site

1.6 SACRIFICIAL FORMWORK /EMBEDDED PLATE

At the end of each FST, suitable notch at each end of the FST is envisaged to install the KYM

steel spring elements. Notch shall be provided as per the dimension details indicated in the

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

GA Drawings. 10 thick L shape steel plate with lugs shall be provided by others at site and

shall be used as embedded plate as well as formwork for the notch.

KYM elements shall be placed after installation of GSI elements under GERB supervision.

Levelling shall be done using necessary shims to be supplied by GERB.

L Shape Steel

embedment w/ lugs

Plan Section

Fig 10 – Schematic Details of Notch for KYM Elements at each FST end

Section Detail - X

Fig 11 – Sacrificial Formwork/Embedment Plate at each FST end for KYM Element

1.7 LAYING OF TRANSITION MATERIAL

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

Transition material mat shall be laid directly over first stage concrete. Suitable Tape supplied

by GERB shall be used to cover the joints of transition material sheet from the top as shown

in below Figure. Over the transition material mat, a thin sheet shall be laid covering the full

width of transition material before laying of reinforcements of track slab.

Tape by GERB

Cover Sheet by GERB

1.8 CASTING OF TRACKSLAB

Concreting of floating track slab (second stage concrete) shall be done as per engineering drawings

provided by GERB. It is recommended that the full segment of the slab is cast without interruption

except under unavoidable circumstances.

Needle vibrators may be used to ensure that the required concrete quality is achieved by avoiding

honey-combing in the slab.

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

1.9 INSTALLATION OF PORR TRACK SLAB

The PORR track slab and the LWR Rails shall be installed and adjusted at 30mm down with respect

to the final designed rail level. During placing of PORR slabs over second stage concrete 2 pieces

of buffer plank shall be placed between 2 PORR slabs at each ends of 2400 long gap over foam

sheet 270mmx2400mmx40 mm thick so that during grouting for PORR slab, lids over the housing

remain accessible post grouting and design gap of 270 mm remains available for ease of opening

the lid in future.

Both foam pieces and buffer plank (preferably wooden) shall be removed after grouting is over.

During the installation of spring elements, the final rail level shall be achieved using shims as per

standard GERB practice. The lifting of the track slab shall be carried out only after curing of grout

and second stage concrete.

Buffer Plank (preferably wooden &

reusable) 270mmx600mmx50mm thick

(by others) placed centrally over 40 mm

thick foam sheet 270mmx2400mm,

40mm thick (by GERB) which shall be

placed over steel housing gap between

PORR Slab

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

Foam Sheet (TYP) Buffer Plank (TYP)

1.10 ACCESS TO STEEL SPRING ELEMENT

In view of 270 mm gap between PORR slabs, lid of the housing of steel spring element which is

circular in shape matching with housing at top shall be modified slightly at the edges along the

longitudinal direction of track so that total width of lid is reduced slightly by 2 to 3 mm to provide

extra ease while opening of the housing lid in post installation situation. Lid can any way always be

slightly tilted also while opening which is otherwise is not regular event as such.

About 268 mm

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

1.11 LIFTING OF THE FLOATING TRACK SLAB

The lifting of the floating track slab (second stage concrete) shall be performed only after the

concrete has gained the design strength as per the below installation guidelines

Remove the housing lid, placing of steel spring unit

Lifting process is done by compressing the spring unit with the help of

hydraulic jacks and then shimming to the desired height by hydraulic

jacks and other tools, supplied by GERB on returnable basis.

The Track slab can be adjusted to an accuracy of zero tolerance

Once the final desired rail level is achieved, the shims are locked with a

locking plate and the lid is sealed.

The gaps between the two adjacent sides of track slabs (second stage

concrete with and without MSS/Tunnel wall as the case may be) both in

the longitudinal and lateral direction are covered with an EPDM sheet to

prevent the ingress of any dust particles and debris.

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

1.12 MANPOWER AND TOOLS

GERB shall provide a “Hydraulic Jacking System” for the lifting and installation of a floating track

slab. This shall also comprise of E-pumps (110, 220 V) or hand pumps, jacking devices, manifolds

with pressure gauges, compression adaptors, and hoses. During installation of Spring units / lifting

of slab, the track contractor shall provide the required workmen for transporting the material to the

location and to assist GERB installation team.

Usually, with 4 to 5 workmen and 2 GERB engineers, a single slab of approximately 100 m can be

installed in one day. More teams can be assigned depending on project schedule requirement.

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

1.13 REFERENCES

No Description

Dwg/Doc No

1 General Arrangement Drawing with MSS N1351723-01-DN to 08-DN

2 Reinforcement Drawings - Downline N1351723-12 to 35 DN

3 Bar Bending Schedule N1351723/BBS -12 to 35 DN

Dynamic & Static Analysis Report of Floating Track

4 23-1738-A

Slab - FST 2 to 7

Dynamic & Static Analysis Report of Floating Track

5 23-1738-B

Slab - FST 1 & 8

6 Nothing Eastin Coordinates N1351723/DN/NEC

7 Misc Dwg -Steel Embedment details at Notch area N1351723/Misc/Sketch-1

8 General Arrangement Drawing with MSS N1351723- 1 UP to 10-UP

9 Reinforcement Drawings N1351723 - 12 to 40-UP

10 Bar Bending Schedule N1351723/BBS -12 to 40-UP

11 North- East Coordinates N1351723/UP/NEC

GERB Vibration Control Systems Pvt Ltd. Tel : 91-120-4751600

2403, 4th Floor, B-36, ETT Tower-2 E-mail : gerbindia@vsnl.com

Noida Expressway, Sector 132 Website : www.gerb.in

NOIDA – 201 302 (U.P.), INDIA

An ISO 9001:2008 & OHSAS 18001 : 2007 Certified Company

Wholly owned by GERB – Germany

You might also like

- Technical Specifications & BOQ For PEB at KasnaDocument6 pagesTechnical Specifications & BOQ For PEB at KasnaAbhinav Tewari100% (2)

- Technology Development For Hardfacing ofDocument2 pagesTechnology Development For Hardfacing ofabraham silva hernandezNo ratings yet

- Final BUA BOQ Tender - OB Plot and Podium - 03.09.21Document11 pagesFinal BUA BOQ Tender - OB Plot and Podium - 03.09.21Jaysukh N SapraNo ratings yet

- Almost Everthing For MEPDocument55 pagesAlmost Everthing For MEPdkpushp100% (4)

- 2019-10-01 - GMR Safran PEB Works - BOQ - Rev5Document11 pages2019-10-01 - GMR Safran PEB Works - BOQ - Rev5Rakesh Sharma50% (2)

- PPPL-21362 (R-0) Techno Commercial OfferDocument8 pagesPPPL-21362 (R-0) Techno Commercial OfferAtul Kumar EngineerNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Shallow FoundationDocument14 pagesShallow Foundationedmond100% (3)

- Do 050 S2007-Mse SpecsDocument12 pagesDo 050 S2007-Mse SpecsCarol SantosNo ratings yet

- LCP Purlins GirtsDocument16 pagesLCP Purlins GirtsGarfieldNo ratings yet

- Boq LicDocument78 pagesBoq LicMohit vyasNo ratings yet

- Foundations Lighting Columns PDFDocument2 pagesFoundations Lighting Columns PDFtexas_peteNo ratings yet

- Estimate-With Peb-KiDocument4 pagesEstimate-With Peb-KiswapnilNo ratings yet

- B.O.Q. For 15x30 - DUPLEXDocument23 pagesB.O.Q. For 15x30 - DUPLEXabdulkareemebookNo ratings yet

- Auditorium B.O.Q All Complete PDFDocument51 pagesAuditorium B.O.Q All Complete PDFDeepak Chandola100% (4)

- Bill of Quantities (Example)Document18 pagesBill of Quantities (Example)Chan Siew ChongNo ratings yet

- Foundation Course On DRS: (District Regulating Station)Document22 pagesFoundation Course On DRS: (District Regulating Station)ToniNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Method Statement Construction of Chambers-Concrete WorksDocument6 pagesMethod Statement Construction of Chambers-Concrete WorksLovemore Makora MukondomiNo ratings yet

- Shanghai Tower PDFDocument14 pagesShanghai Tower PDFFaisal Nasim0% (1)

- Assessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012Document39 pagesAssessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012abhi_luvme03100% (1)

- TBM 1 (Week 1 - July 19)Document1 pageTBM 1 (Week 1 - July 19)sandesh negiNo ratings yet

- Boq R2Document4 pagesBoq R2swapnilNo ratings yet

- PWD Schedule1st Corrigendum 2015-2016 Sor NH 1Document4 pagesPWD Schedule1st Corrigendum 2015-2016 Sor NH 1তীর্থ বিশ্বাসNo ratings yet

- EE/RPD-I/Kasturba NagarDocument9 pagesEE/RPD-I/Kasturba NagarAbhay KumarNo ratings yet

- 50 PAC CofforDocument37 pages50 PAC CofforTamene TayeNo ratings yet

- ID-814446 - 180 Feet Tower Technical SpecificationsDocument7 pagesID-814446 - 180 Feet Tower Technical Specificationspriyanka dasNo ratings yet

- Asphaltic Plug Joint - Bridge Repair ManualDocument4 pagesAsphaltic Plug Joint - Bridge Repair ManualJohn Rheynor MayoNo ratings yet

- Site Offices and HousingDocument38 pagesSite Offices and HousingMuhammad Al azaweyNo ratings yet

- Bridge - 49.50Document24 pagesBridge - 49.50lse furnitureNo ratings yet

- Boq-Alphas Projects-Karanam IndustriesDocument6 pagesBoq-Alphas Projects-Karanam IndustriesswapnilNo ratings yet

- Item No. Particulars of Item Unit Quantity Rate in Fig. Rate in Words Amount (Nu) Earth WorkDocument5 pagesItem No. Particulars of Item Unit Quantity Rate in Fig. Rate in Words Amount (Nu) Earth WorkGautham GautiNo ratings yet

- NIT No. 19/Civil/D2/2019-20/02 Schedule of Quantity: Indian Institute of Technology KanpurDocument3 pagesNIT No. 19/Civil/D2/2019-20/02 Schedule of Quantity: Indian Institute of Technology KanpurASNo ratings yet

- PrecastDocument2 pagesPrecastsmithNo ratings yet

- Project:: Date & Revision NODocument4 pagesProject:: Date & Revision NODeepa Junnarkar DegwekarNo ratings yet

- Panels LeafletDocument3 pagesPanels Leafletshahul hameedNo ratings yet

- Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocument10 pagesReinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationKumar AtrayNo ratings yet

- Piling Works: Item Description Unit Qty Rate Amount (RM)Document8 pagesPiling Works: Item Description Unit Qty Rate Amount (RM)Suhaimi SuibNo ratings yet

- Schedule of Quantities RocketDocument9 pagesSchedule of Quantities RocketRoopakNo ratings yet

- Keystone Compac PDocument8 pagesKeystone Compac PcinevaundevaNo ratings yet

- Specification For Reinforced Soil WallDocument8 pagesSpecification For Reinforced Soil WallChin Thau WuiNo ratings yet

- Boq CandyDocument6 pagesBoq CandyHimanshuSrivastavaNo ratings yet

- Improving & Augumantation Existing Water Supply in Laxminagar Zone and Dharampeth ZoneDocument50 pagesImproving & Augumantation Existing Water Supply in Laxminagar Zone and Dharampeth ZoneRasadnya SirNo ratings yet

- 09 40 00 Metal FurringDocument7 pages09 40 00 Metal FurringKiran D AnvekarNo ratings yet

- Birla Aerocon Panel - Data CentersDocument3 pagesBirla Aerocon Panel - Data Centersshahul hameed100% (1)

- Boq Acr Section-3Document43 pagesBoq Acr Section-3p.v.v.satyanarayana MurthyNo ratings yet

- Standard SpecificationsDocument5 pagesStandard SpecificationsIan54321No ratings yet

- ROCK Fill Specifiation & StandardsDocument17 pagesROCK Fill Specifiation & StandardsibrahimNo ratings yet

- Bill of Quantities For Gechi ECD Center Remaining WorksDocument4 pagesBill of Quantities For Gechi ECD Center Remaining WorksAmos KormeNo ratings yet

- Appendix 2 Final BoqDocument50 pagesAppendix 2 Final BoqPatrick SipatelaNo ratings yet

- EARLY WORKS - Civil & Preliminary BOQDocument1 pageEARLY WORKS - Civil & Preliminary BOQDeepa Junnarkar DegwekarNo ratings yet

- Construction QuoteDocument4 pagesConstruction QuoteNox PlayerNo ratings yet

- BOQ Smartfren BB00120 Tanjung Binga (Outdoor GF)Document2 pagesBOQ Smartfren BB00120 Tanjung Binga (Outdoor GF)Setiawan RustandiNo ratings yet

- Final Draft - Specification - ISEJ65 - 22 - 02 - 2021Document2 pagesFinal Draft - Specification - ISEJ65 - 22 - 02 - 2021Uday KumarNo ratings yet

- Techno-Commercial Offer of PEB Building With CivilDocument5 pagesTechno-Commercial Offer of PEB Building With CivilRashu GuptaNo ratings yet

- Voestalpine Stahl GMBH - CC8 Caster For High-Quality Grades and Exposed Automotive Steel Using Danieli TechnologyDocument10 pagesVoestalpine Stahl GMBH - CC8 Caster For High-Quality Grades and Exposed Automotive Steel Using Danieli TechnologyJJNo ratings yet

- BOQ Bhatinda Civil 541 - 2Document35 pagesBOQ Bhatinda Civil 541 - 2Sanjay BansalNo ratings yet

- C11 2Document44 pagesC11 2Digambar JadhavNo ratings yet

- SECTION 09390 Floor Hardener Part I - General General RequirementsDocument3 pagesSECTION 09390 Floor Hardener Part I - General General RequirementsIm ChinithNo ratings yet

- July 2022 EvaluationDocument8 pagesJuly 2022 EvaluationWade Smith - Executive ProducerNo ratings yet

- BOQ Sector-63 NoidaDocument3 pagesBOQ Sector-63 NoidaSahadev TyagiNo ratings yet

- Concrete and BeamsDocument13 pagesConcrete and BeamsDaniel HamiltonNo ratings yet

- TCVN 6052-1995Document6 pagesTCVN 6052-1995api-36973960% (1)

- Katalog SPRigWP JALANDocument1 pageKatalog SPRigWP JALANemroesmanNo ratings yet

- Toll Plaza Structure - Technical SpecificationsDocument3 pagesToll Plaza Structure - Technical SpecificationsNeeraj SinghNo ratings yet

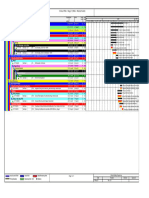

- Critical Path - New AshokNagar - Meerut South - 18apr24Document1 pageCritical Path - New AshokNagar - Meerut South - 18apr24sandesh negiNo ratings yet

- BOQ and rate for boundary wallDocument2 pagesBOQ and rate for boundary wallsandesh negiNo ratings yet

- Customer Life Time Value & New Product DevelopmentDocument24 pagesCustomer Life Time Value & New Product Developmentsandesh negiNo ratings yet

- Task and Responsibilities of The ManagerDocument16 pagesTask and Responsibilities of The Managersandesh negiNo ratings yet

- AIAI GC - QAQC Dept Organization Chart-03042024-ModelDocument1 pageAIAI GC - QAQC Dept Organization Chart-03042024-Modelsandesh negiNo ratings yet

- TtactbelDocument2 pagesTtactbelsandesh negiNo ratings yet

- Environmental PollutionDocument53 pagesEnvironmental Pollutionsandesh negiNo ratings yet

- Curve Data DN LineDocument1 pageCurve Data DN Linesandesh negiNo ratings yet

- E GovernanceDocument5 pagesE Governancesandesh negiNo ratings yet

- Stage 1 Activities As Per R02 (With Access Dates & Key Dates Included)Document1 pageStage 1 Activities As Per R02 (With Access Dates & Key Dates Included)sandesh negiNo ratings yet

- Package 10 (Tender)Document3 pagesPackage 10 (Tender)sandesh negiNo ratings yet

- Introduction To Civil Eng.8283109.powerpointDocument8 pagesIntroduction To Civil Eng.8283109.powerpointsandesh negiNo ratings yet

- Great Math Formula With ExamplesDocument37 pagesGreat Math Formula With Examplessandesh negi100% (1)

- AssignmentDocument1 pageAssignmentsandesh negiNo ratings yet

- Unit 2 Ground Improvement TechniquesDocument33 pagesUnit 2 Ground Improvement Techniquessandesh negiNo ratings yet

- 4 Gorton CastleDocument53 pages4 Gorton Castlesandesh negiNo ratings yet

- Logic GatesDocument8 pagesLogic Gatessandesh negiNo ratings yet

- PND1000 3 AccessoriesDocument40 pagesPND1000 3 AccessoriesPartsGopher.comNo ratings yet

- 3 - Absolute, Effective and Relative PermeabilitiesDocument34 pages3 - Absolute, Effective and Relative PermeabilitiesAhmad MammadovNo ratings yet

- ASME B 16.34: Technical Specification For Gate, Globe & Check ValvesDocument2 pagesASME B 16.34: Technical Specification For Gate, Globe & Check ValvesJKKNo ratings yet

- System Practices For Halocarbon Refrigerants: Refrigerant Flow RatesDocument30 pagesSystem Practices For Halocarbon Refrigerants: Refrigerant Flow RatesChristine Joy Allas RapanotNo ratings yet

- Aluminium in India - Journal July 2021Document36 pagesAluminium in India - Journal July 2021chintan pandyaNo ratings yet

- Master Pack NW ResumenDocument30 pagesMaster Pack NW ResumenJesusNo ratings yet

- 15CV36 2Document9 pages15CV36 2SachinNo ratings yet

- Wiring Diagrams. Compact NSX. ContentsDocument9 pagesWiring Diagrams. Compact NSX. ContentsBojan KitanovskiNo ratings yet

- Page 0027Document1 pagePage 0027Matteo BaldassariNo ratings yet

- Crowen Site B+G+9 SN Material StandardDocument7 pagesCrowen Site B+G+9 SN Material StandardbirukNo ratings yet

- Mobiltherm 600 Series FactsheetDocument1 pageMobiltherm 600 Series FactsheetJessica ChandlerNo ratings yet

- Data Sheet Schott® Borofloat: Chemical PropertiesDocument2 pagesData Sheet Schott® Borofloat: Chemical PropertiesDiego SaenzNo ratings yet

- Example Ass 1 Budget & Costing 2022Document78 pagesExample Ass 1 Budget & Costing 2022Steve LiNo ratings yet

- OGPW Centra CoreDocument1 pageOGPW Centra Coreaoc_speedNo ratings yet

- Torre Protec FWSDocument8 pagesTorre Protec FWSCharly Columb100% (1)

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- 2019 Hosco CatalogDocument56 pages2019 Hosco CatalogSeng Cyan100% (1)

- Manual Allem BradleyDocument212 pagesManual Allem BradleyKaaberNo ratings yet

- S70ENDocument18 pagesS70ENarkadi oikhmanNo ratings yet

- Therma V 2p Leaft - FinalDocument2 pagesTherma V 2p Leaft - FinalpredragstojicicNo ratings yet

- 10.3 SAU-SAO 025 Technical Selection R01Document3 pages10.3 SAU-SAO 025 Technical Selection R01Harry CulNo ratings yet

- Con Twisted TapeDocument10 pagesCon Twisted TapeRaj BhaiNo ratings yet

- Mechster 5310 (N) G: (Novolac Epoxy Vinyl Ester Gelcoat Resin)Document1 pageMechster 5310 (N) G: (Novolac Epoxy Vinyl Ester Gelcoat Resin)reinpolyNo ratings yet

- Intergas HRE MV1 PDFDocument48 pagesIntergas HRE MV1 PDFRichard KrillNo ratings yet

- Bezinal2000 ENG - 2010-1Document2 pagesBezinal2000 ENG - 2010-1Olman LeivaNo ratings yet