Professional Documents

Culture Documents

Friction Loss in Pipe

Uploaded by

Jazmin GonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Friction Loss in Pipe

Uploaded by

Jazmin GonzalezCopyright:

Available Formats

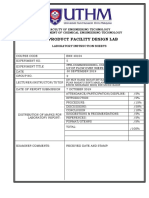

Friction Loss in Pipe Flow

INSTRUCTED BY: Mr. H Rathnasuriya

NAME INDEX NUMBER COURSE: GROUP: DATE OF PER: DATE OF SUB:

V.W.MEEMADUMA 090325G MPR B3 2010.08.03 2010.08.17

1.0 Introduction Energy Loses Occur in pipe flow due to frictional resistance at the pipe surface. Such head losses are known as frictional resistance head losses. It is important to determine frictional head losses in many pipe flow problems. Objectives To verify that the friction factor in pipe flow varies as expressed in the Darcy-Weisbach and HagenPoiseuille equations for a (a) Small diameter pipe (3 mm) (b) Commercially used PVC pipe (c) Commercially used Galvanized Iron (GI) pipe Theory The frictional head loss (hf) depends on the type of flow, which can be laminar or turbulent. In laminar flow, fluid flows in layers with orderly movement of fluid particles while in Turbulent flow fluid particles move in a disorderly manner, as shown in Figure below.

Whether the flow is laminar or turbulent is decided by a non-dimensional Reynolds number Re which is expressed as Re = Where = Fluid density, v = Flow Velocity, D = pipe diameter, = Fluid viscousity

In pipes, the flow is laminar when Re < 2000 and turbulent when Re > 4000 with flow transition taking place when 2000 < Re < 4000 Various scientists had a need to evaluate the frictional head loss for a given pipe flow. As a result of this, certain formulae were created, some experimentally while others theoretically. From these formulae two equations for the two separate flow states of turbulent and laminar are used commonly by engineers to model pipe systems today. For turbulent flow hf is given by the Darcy-Weisbach equation,

hf = where = friction factor, L = pipe length and g = Accelaration due to gravity

For Laminar Flow hf is determined by the Hagen-Poiseuille Equation, hf =

If the Hagen-Poiseuille Equation is expressed in the form of the Darcy-Weisbach equation, an equivalent

friction factor can be defined for laminar flow so that hf = = yielding =

Apart from these equations, some other empirical equations are used occasionally Eg: The Hazen-Williams formula hf = here C is a dimensional constant dependent on the pipe material and diameter and having values between 75-150. In both these cases, the friction factor can be found using several different methods. 1. Applying the Colebrook-White equation The general form of the Colebrook-White equation is as follows

Where k = surface roughness of the pipe, D = diameter of pipe and Here = f(( ) therefore it is solved by iterative methods However at lower Re values (Re 4000)

= friction factor

<<<

Then at lower Re values (Re )

0 Therefore

These are known as Prandtl and Von Karmann equations.

2. Using the Moody Diagram The Variation of with the relative roughness and Re values are graphically expressed in the Moody

diagram. This diagram has been obtained through a various number of experimental data and any pipe obeying normal frictional flows will have values within the chart in the respected areas ( turbulent or laminar). This method is rather easier and less time consuming than solving the above mentioned equations.

3. Using Wallingford charts or tables The Darcy-Weisbach equation and the Colebrook-White equation have been graphically represented in charts for the hydraulic design of channels and pipes and have been tabularly represented in tables for the hydraulic design of channels and pipes which have been published by the Hydraulic research station, Wallingford, UK. Thus the name Wallingford charts and Wallingford tables being given to them. These provide yet another convenient method for engineers to obtain various properties for a pipe flow, not only the friction factor but also the required pipe diameter for a certain flow rate or the velocity in a pipe for a particular roughness value hence eliminating the need to be involved in tedious sums using the Colebrook-White equation.

Apparatus 1. Pipe Friction Apparatus 1 (for pipe with small diameter)

2. Pipe Friction Apparatus 2 (For larger diameter pipes)

3. Stop Watch 4. Measuring Vessel 5. Ruler/Measuring Tape Methodology

For horizontal pipe of uniform diameter, hf ( frictional head loss) can be expressed as hf = Where P1 and P2 are the pressures at sections (1) and (2) respectively, as shown in the above diagram, which can be measured by the piezometers or the differential manometer.

V can be expressed as V= in which flow rate = Q = where is the volume of outflow in a time

Re can be calculated by the equation given earlier and therefore can be calculated using the Darcy-Weisbach equation and the Darce-Weisbach equivalent for the Hagen-Poiseuille equation. hf = and Re =

(where V =

and Re =

then, hf =

2.0 Procedure Fix the apparatus as shown in the above diagrams for the two pipe cases. Once a specific flow rate is set by the water pump do not adjust the pump, only adjust the flow rate through the control valve at the down stream end. First compare manometer readings at minimum and maximum output flow rates in pipes and divide the difference in readings by the number of records to be taken in order to approximate a periodical change in pressures to obtain flow rate values. Obtain steady flow rates for different manometer readings and record them. For each flow the outflow in a time is measured three times for an average value to be taken for better accuracy of experimental values. Measure the length of Pipe. Record the diameter of the pipe. Special considerations to be taken when handling the pipe of small diameter Special care should be taken to observe that the manometric liquid and piezometric liquids do not mix. Also the dropping of the piezometric liquid level inside the pipe should be avoided. To obtain a larger range or readings the internal pressure of the piezometric apparatus can be increased by using a bicycle pump, but attention should be paid to the piezometric levels to ensure none of the above mentioned occurs.

3.0 Calculations PVC Pipe a1x10- a2x10- deltaVx103(m) 3(m) 6(m3) t1 Qx106(m3/s) hfx103(m) lambdax10 9 Re 2.35637E12 36224.79 2.50563E12 30727.57 2.58649E12 27753.28 2.86606E12

t2

t3

21.9

10940 27.17 26.82 27.06 404.9352252 187.74

19.9

8.5

10940 31.76 31.87 31.92 343.4850863 143.64

19

9.4

10940 35.36 35.13

35.3 310.2372625 120.96

17.5

10.5

4790 19.13 19.16 18.81 251.6637478

88.2

22513.4

16.7

11.4

4790 22.34 22.65 22.41 213.2047478

66.78

3.0235E12 19072.92 3.30259E12 16050.88 3.38077E12 13342.14 3.70012E12 10322.93 4.29399E12

16

11.9

4790 26.34 26.76 26.99

179.423149

51.66

15.4

12.5

4790 32.16 32.06 32.13 149.1437468

36.54

14.8

12.9

4790 40.95 41.25 42.33

115.393881

23.94

14.3

13.2

4790 58.89

59 58.42 81.50416879

13.86

7291.22

Length (m) = 6.16 Diameter (m) = 0.016

GI Pipe a1x103(m) a2x103(m) deltaVx106(m3) Qx106(m3/s) hfx103(m) lambdax10 9 1.76645E11 1.73278E11 1.71574E11 1.73635E11 1.67813E11 1.71973E11 1.67087E11 1.64611E11 1.65147E11 1.57708E11 3.35429E12

t1

t2

t3

Re

26.3

24.3

4790

61.75

61.49

61.24

77.89462272

25.2

6026.652

28.2

22.5

4790

36.39

35.68

36.16

132.7727987

71.82

10272.54

29.3

21.4

4790

30.6

30.99

29.89

157.0835155

99.54

12153.44

30.5

20.3

4790

26.8

27.14

27.05

177.4293123

128.52

13727.58

32.5

18.4

4790

22.24

22.86

22.62

212.1972829

177.66

16417.55

34.1

16.8

4790

20.61

20.37

20.91

232.1861367

217.98

17964.08

36

15

4790

18.75

18.33

18.29

259.5268196

264.6

20079.41

37.7

13.6

10940

39.09

38.99

39.09

280.1058291

303.66

21671.59

39

12.5

10940

36.95

37.38

37.59

293.2451751

333.9

22688.17

40.5

11

10940

35.3

34.69

33.67

316.6120008

371.7

24496.05

42.5

9.5

10940

15.02

15.27

14.91

726.1061947

415.8

56178.32

Length (m) = 6.16 Diameter (m) = 0.0185

a1x103(m)

a2x103(m)

deltaVx106(m3)

t1

t2

t3

Qx106(m3/s)

hfx103(m)

lambdax10 9 1.16077E10 7.23745E11 5.79647E11 4.49807E11 3.36683E11 4.16378E11 4.05102E11 3.93745E11 3.60702E11 3.45923E11 3.5498E11 3.78253E11 3.48446E11 3.39445E11 3.34813E11 3.51978E11 3.55044E11

Re

390

355

100

76.97

76.92

76.84

1.300221038

35

620.3493

393

347

100

52.94

52.91

53.07

1.88774226

46

900.6619

398

339

100

41.59

42.08

41.91

2.388915432

59

1139.777

402

326

100

32.39

32.7

32.38

3.077870114

76

1468.485

412

311

200

48.77

48.82

48.71

4.101161996

101

1956.708

455

257

200

38.23

38.75

39.22

5.163511188

198

2463.566

493

211

200

31.86

32.05

32.13

6.247396918

282

2980.699

410

37

250

34.46

34.11

34.34

7.287921485

373

3477.145

494

38

300

35.98

35.93

34.99

8.419083255

456

4016.834

528

15

300

33.13

32.42

33.15

9.118541033

513

4350.553

274

317

400

43.22

43.61

42.89

9.250693802

541.8

4413.604

272

319

400

42.25

42.38

43.45

9.369144285

592.2

4470.118

272

319

400

40.51

41.11

41.31

9.761652973

592.2

4657.388

271

320

400

39.27

39.35

40.21

10.09845998

617.4

4818.082

268

322

400

37.7

37.2

37.52

10.67425725

680.4

5092.801

266

324

400

37.82

36.66

36.74

10.78942636

730.8

5147.75

264

326

500

44.83

45.19

45.03

11.10699741

781.2

5299.266

4.0 Discussion Significance of Frictional Head loss in the analysis of pipe flow Analysis of pipe flow deals with the characteristics of fluid flowing within a pipe. The flow rate between points of the pipe, the velocity of the fluid, etc In an ideal pipe having no head loss one could simply find all above mentioned factors if the necessary data about the pipe was given, since the Head differences at two points would be the same. However if there were to be some limiting force against the flow of the water, the analysis of the flow would not be as straight forward. As there is no ideal pipe in practical applications there will always exist a frictional head loss, no matter how minimal it maybe, affecting the fluid flow in the pipe. More accurately there will be two types of head loss, frictional and local, but in civil engineering applications where we deal with considerably larger pipes with a small number of bends the local losses reduce to something comparatively negligible. Hence the frictional head loss becomes the major component. Therefore it is vital that frictional head loss be taken into account when analysing pipe flows. Smooth Turbulent Flow

If the Renault Number in a fluid undergoing turbulent flow is close to the value 4000 then it is knows as a smooth turbulent flow. Rough Turbulent Flow

If the Renault Number in a fluid undergoing turbulent flow is very high then it is knows as a rough turbulent flow. Transitional Turbulent Flow

Transitional turbulent flow is a region in between the smooth turbulent flow and rough turbulent flow having fluid with a moderate Renault number. Hydraulically Smooth Pipes

If the Flow rate inside a pipe can produce a laminar flow then the pipe is said to be a hydraulically smooth pipe. Concrete, Cast iron, Copper and Glass all produce smooth pipes. The surface roughness plays a major role in deciding the flow rate at which turbulent flow occurs. Therefore a material with higher surface roughness can cause turbulent flows at lower flow rates. Hydraulically Rough Pipes

The flow rate in a pipe producing turbulent flow is said to be a hydraulically rough pipe. The surface roughness values of these pipes are considerably higher, which causes the flow rate to be turbulent at a lower flow rate than a smooth pipe having identical dimensions. Behaviour of friction factor and Moody Diagram

For low Re values the fluid remains laminar. Therefore the relationship between the friction factor and the Re number is = (64/Re) while for turbulent flows the relationship becomes much more complicated. Hence the curvatures in the Moody diagram.

Effect of Aging of pipes and friction factor

Aging of a pipe is its prolonged usage. As a pipe is used for a long time, if improperly maintained the interior will be encrusted with scale, dirt, tubercules or other foreign matter. This causes an increase in roughness value of the pipe but comparatively the diameter of the pipe is considered as unchanged. Therefore the relative roughness of the pipe will increase. According to the Moody diagram this increase in relative roughness will cause an increase in the friction factor as well. ( some studies have shown a 4 inch diameter steel pipe undergoing a 20% increase in friction factor after its roughness was increased by twice the value from 3 years usage). Local Losses and their significance in engineering applications

Apart from the Frictional Head losses, Local Head losses ( minor head losses) are incurred at pipe bends, junctions and valves. These losses occur due to eddy formation generated by the fluid at the fitting. For cases where pipes are shorter the local losses could be higher than the frictional head loss, therefore it is important to consider this in such situations or there would be an error in any assumption made about the flow system. Local head loss can be expressed in the form hl =kl Where kl = constant for a particular fitting An expression can be derived for kl in terms of the area of the pipe. The types of local losses are 1. Sudden Contraction

2. Sudden Expansion

3. Head Losses due to Bending

4. Losses due to pipe junctions

5.0 References Flows of fluids through valves, fittings and Pipes. Crane (p12) Hydraulics in Civil and Environmental Engineering, Taylor & Francis, 2004, (p112)

You might also like

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Friction Losses in PipesDocument8 pagesFriction Losses in Pipeskelechi2475% (8)

- Frictional Losses in PipesDocument15 pagesFrictional Losses in Pipesxxxxx100% (3)

- Lab Report 2Document16 pagesLab Report 2Limmy Yingran0% (1)

- Flow in Pipes CompleteDocument21 pagesFlow in Pipes CompleteSYaz WAni67% (6)

- Lab Report 2 - Head Loss in Pipe & BendsDocument20 pagesLab Report 2 - Head Loss in Pipe & BendsChris Ang76% (21)

- Friction Losses in Pipes Consisting of Bends and ElbowsDocument11 pagesFriction Losses in Pipes Consisting of Bends and Elbowswhoelse_i86% (28)

- Energy Losses in Bends and FittingsDocument11 pagesEnergy Losses in Bends and FittingsQuenneBelocura100% (1)

- Energy Losses in BendsDocument8 pagesEnergy Losses in BendsVikramSingh0% (3)

- Lab - #5. - Hydraulic JumpDocument6 pagesLab - #5. - Hydraulic JumpCarlos J. SantacruzNo ratings yet

- MEC2404 Frictional Flow in Pipe Lab RepoDocument10 pagesMEC2404 Frictional Flow in Pipe Lab Repoatik100% (1)

- Fluid Lab 2 - Bernoulli ExpDocument19 pagesFluid Lab 2 - Bernoulli ExpCik Tiem Ngagiman89% (65)

- Flow Over NotchDocument15 pagesFlow Over NotchMan Made Man100% (14)

- 6-Energy Loss in BendsDocument12 pages6-Energy Loss in BendsMaysara Maawia Mukhtar60% (10)

- Verification of Bernoulli's Theorem Fluid Mechanics ReportDocument8 pagesVerification of Bernoulli's Theorem Fluid Mechanics Reportprajwal mNo ratings yet

- Friction Losses in Straight PipeDocument10 pagesFriction Losses in Straight Pipewhoelse_i86% (7)

- Manning's Roughness Coefficient (N)Document11 pagesManning's Roughness Coefficient (N)Khurram MumtazNo ratings yet

- Flow Through A Pipe Orifice Meter LabDocument8 pagesFlow Through A Pipe Orifice Meter LabHenDricky MagosiNo ratings yet

- Flow of Water by Notch and WeirsDocument15 pagesFlow of Water by Notch and WeirsCik Tiem Ngagiman93% (29)

- Pipe Friction Lab ReportDocument13 pagesPipe Friction Lab Reportharrov455% (11)

- To Investigate The Relationship Between The Specific Energy and Depth of The Flow at A Constant Discharge in Lab Flume.Document3 pagesTo Investigate The Relationship Between The Specific Energy and Depth of The Flow at A Constant Discharge in Lab Flume.Shaheer AhmadNo ratings yet

- Venturimeter LAB ReportDocument7 pagesVenturimeter LAB ReportJames Roy100% (1)

- Bernoulli's Theorem DemonstrationDocument17 pagesBernoulli's Theorem DemonstrationjjNo ratings yet

- University of Mauritius: Faculty of Engineering Mechanical & Production Engineering DepartmentDocument17 pagesUniversity of Mauritius: Faculty of Engineering Mechanical & Production Engineering Departmenthansley100% (1)

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Experiment 3 Bernoulli's TheoremDocument26 pagesExperiment 3 Bernoulli's TheoremSaber Minato Azrul100% (1)

- Experiment 1 - Friction Losses in Pipes-ReportDocument41 pagesExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram67% (3)

- Energy Losses in BendsDocument10 pagesEnergy Losses in BendsAngelica Joyce BenitoNo ratings yet

- Fric Flow Ours FINAL VR 2Document14 pagesFric Flow Ours FINAL VR 2Edwin Jesu DassNo ratings yet

- Experiment BernoulliDocument17 pagesExperiment BernoulliHafiniHambali94% (33)

- Experiment To Verify Bernoulli's PrincipleDocument8 pagesExperiment To Verify Bernoulli's PrincipleKarishma JuttunNo ratings yet

- Exp.5 - Flow Over Wiers GROUP 2Document20 pagesExp.5 - Flow Over Wiers GROUP 2Gua HantuNo ratings yet

- Expt 1 - Friction Loses in PipesDocument20 pagesExpt 1 - Friction Loses in PipesFauzi Helmi67% (6)

- Institution Registration Number Name Course Unit Name Unit Code LecturerDocument9 pagesInstitution Registration Number Name Course Unit Name Unit Code LecturerJosline MuriikiNo ratings yet

- Experiment 1 - Friction Losses in Pipes-ReportDocument41 pagesExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram68% (53)

- Lab Experiments Losses in PipeDocument14 pagesLab Experiments Losses in Pipesawmag123No ratings yet

- Weir Experiments.02Document14 pagesWeir Experiments.02alex100% (2)

- Bernoulli's Theorem Lab ReportDocument4 pagesBernoulli's Theorem Lab ReportKevin Jonathan KusumaNo ratings yet

- Head Loss Due To Pipe FittingDocument6 pagesHead Loss Due To Pipe Fittingmhk00133% (3)

- Exp 2 Friction LossesDocument15 pagesExp 2 Friction LossesDonna Mae Ramos Galaez0% (1)

- Lab 2 - Flow Over WeirsDocument10 pagesLab 2 - Flow Over WeirszickmoderatoNo ratings yet

- Sharp Crested WeirDocument7 pagesSharp Crested WeirMohamad Zahir Razak100% (1)

- Losses in BendsDocument5 pagesLosses in BendsAnonymous hWMDyBFGc1100% (1)

- Lab 5 Flow Over Weir ExampleDocument19 pagesLab 5 Flow Over Weir ExampleAmy FarhanaNo ratings yet

- Exp 5 Head Loss Due To FrictionDocument17 pagesExp 5 Head Loss Due To FrictionnileshNo ratings yet

- Exp 2-Bernoulli Theorem Report-CompletedDocument5 pagesExp 2-Bernoulli Theorem Report-Completedorange_jasm1ne8892100% (2)

- Lab Report 5. Investigating The Hydraulic JumpDocument12 pagesLab Report 5. Investigating The Hydraulic Jumpfazeen100% (1)

- Center of PressureDocument5 pagesCenter of PressureEdrees Jamal100% (6)

- Lab Manual (Hydraulics Engineering)Document34 pagesLab Manual (Hydraulics Engineering)Shahid Kamran63% (8)

- Flow Through An OrificeDocument7 pagesFlow Through An OrificeVinay Shenoy100% (1)

- Lab Report Performance Characteristics of Centrifugal PumpDocument10 pagesLab Report Performance Characteristics of Centrifugal PumpRam Krishna Singh85% (33)

- Exp of Darcy-WeisbachDocument3 pagesExp of Darcy-Weisbachnur azraNo ratings yet

- Fluids Case Study On Head LossDocument18 pagesFluids Case Study On Head LossJosh JacoboskiNo ratings yet

- Verification of Bernoulli'S Theorem: Group 4 Experiment F6 Aaditi S Basarkar, Deeksha Jena, Apeksha Dixit, Arya AgarwalDocument24 pagesVerification of Bernoulli'S Theorem: Group 4 Experiment F6 Aaditi S Basarkar, Deeksha Jena, Apeksha Dixit, Arya AgarwalArya AgarwalNo ratings yet

- Bernoulli 08 LabDocument20 pagesBernoulli 08 LabsdjdsfNo ratings yet

- The Merican Niversity in Airo: Chool of Ciences and NgineeringDocument18 pagesThe Merican Niversity in Airo: Chool of Ciences and NgineeringKarim KhalafNo ratings yet

- FCE 322: Fluid Mechanics Lab Report: Venturi Meter ExperimentDocument15 pagesFCE 322: Fluid Mechanics Lab Report: Venturi Meter ExperimentKen MutuiNo ratings yet

- Pumps Calculation Example:: The Following Variables Are GivenDocument5 pagesPumps Calculation Example:: The Following Variables Are GivensukirajNo ratings yet

- WN ARGU KU Pumps-Calculation en USDocument5 pagesWN ARGU KU Pumps-Calculation en USsalamakotbNo ratings yet

- P&id: Na-A64714.001Document2 pagesP&id: Na-A64714.001Muhammad SalmanNo ratings yet

- Surging in A Centrifugal CompressorDocument3 pagesSurging in A Centrifugal CompressorJoy Prokash RoyNo ratings yet

- Tube Selection ChartDocument6 pagesTube Selection Chartjkruise100% (1)

- Virtual Instruments and Experiments in Engineering Education Lab Setup With Hydraulic PumpDocument8 pagesVirtual Instruments and Experiments in Engineering Education Lab Setup With Hydraulic PumpFabian MartinezNo ratings yet

- Frame Mount 7.5": Performance Curve: Fixed SpeedDocument24 pagesFrame Mount 7.5": Performance Curve: Fixed SpeedVladimir E. BalvinNo ratings yet

- NPSH Calculations PDFDocument10 pagesNPSH Calculations PDFAman MaharNo ratings yet

- Nozzle RepairDocument3 pagesNozzle RepairCarlos MolinaNo ratings yet

- Improving Reliability of Commonly Used Hydraulic Valves 2017 PDFDocument96 pagesImproving Reliability of Commonly Used Hydraulic Valves 2017 PDFDavid DelgadoNo ratings yet

- BY Tamil Selvam 2282ADocument11 pagesBY Tamil Selvam 2282AKarthickNo ratings yet

- CONTROLl AUXILIAR de Las BDocument48 pagesCONTROLl AUXILIAR de Las BJorge Luis Cervantes Carrillo100% (1)

- Reducer DimensionsDocument7 pagesReducer DimensionsadnansirajNo ratings yet

- Combibloc Tehnicni PDFDocument1 pageCombibloc Tehnicni PDFRyan PatraNo ratings yet

- Types of Fluid FlowDocument9 pagesTypes of Fluid FlowHammad KhanNo ratings yet

- Pipeline Surge CalcDocument8 pagesPipeline Surge CalcBassem BalghouthiNo ratings yet

- Ce8302 Fluid Mechanics CivilDocument2 pagesCe8302 Fluid Mechanics CivilersnkrishnanNo ratings yet

- Aw 78-24-27 2015 PDFDocument57 pagesAw 78-24-27 2015 PDFJade GeronimoNo ratings yet

- Double Vane Type PumpDocument5 pagesDouble Vane Type PumpMiguel VlntìnNo ratings yet

- Ball Valve White PaperDocument2 pagesBall Valve White Paperhamid vahedil larijaniNo ratings yet

- Valve Material Specification A1MDocument9 pagesValve Material Specification A1Mchintan100% (1)

- Ecm660 III Parts BookDocument548 pagesEcm660 III Parts BookVicctor Piña100% (1)

- Experiment 3: Bernoulli'S Principle Demonstration 1. Program Outcomes (Pos) Addressed by The ExperimentDocument9 pagesExperiment 3: Bernoulli'S Principle Demonstration 1. Program Outcomes (Pos) Addressed by The ExperimentJheo TorresNo ratings yet

- Wilo Sub TWI Borehole Data SheetDocument8 pagesWilo Sub TWI Borehole Data Sheetniqo hamamNo ratings yet

- Hangers (Tyco 2019)Document13 pagesHangers (Tyco 2019)Rainier Gemuel TomNo ratings yet

- Flow NozzleDocument2 pagesFlow NozzlesumeghNo ratings yet

- TPac DBL SureFire PreactionDocument28 pagesTPac DBL SureFire PreactionIonut SomneaNo ratings yet

- General Arrangement Drawing For Slug Catcher Rev.c IfaDocument1 pageGeneral Arrangement Drawing For Slug Catcher Rev.c IfaMe RahmanNo ratings yet

- (R.K. Bansal) A Textbook of Fluid MechanicsDocument578 pages(R.K. Bansal) A Textbook of Fluid MechanicsDr. Chandan Sharma85% (13)

- T KrayDocument8 pagesT KrayAbdurrahman Abu AdibNo ratings yet

- Economizer Design CalculationsDocument4 pagesEconomizer Design CalculationsDaniyal HashmiNo ratings yet

- Fluid Mechanics: Chapter-4Document11 pagesFluid Mechanics: Chapter-4Ahmed SuhailNo ratings yet