Professional Documents

Culture Documents

QN E121.00003 000 PDF

Uploaded by

Aditya JainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QN E121.00003 000 PDF

Uploaded by

Aditya JainCopyright:

Available Formats

CONTRACT NO.

: 705077

PROJECT TITLE:-

QAFCO-3 SHUTDOWN 2019

PROJECT NO: A3-17

DOCUMENT TITLE:

ADEQUACY CHECK REPORT FOR PRIMARY REFORMER STACK

DESIGN CONSULTANT: MAIN CONTRACTOR:

0 14/03/19 ISSUED FOR COMMENTS HT ALS KM

Prepared Checked Approved Approved

Rev Date Description

by by by Qcon by QAFCO

Document No. QN-E121.00003-000 Sht. 1 of

33 Rev. 0

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

CONTENTS

U U Page

ABBREVIATION......................................................................................................... 3

1- General ................................................................................................................. 4

1.1- Introduction

1.2- Design Methodology/Sketch

1.3- Input References

1.4- Codes and standard

1.5- Software

1.6- Input Data

2- Design Load............................................................................................................... 9

2.1- Dead and Live Load

2.2- Wind Load calculation

2.3- Vortex shedding (Dynamic effect)

2.4- Earthquake Load

3- Design of Stack Shell............................................................................................ 14

3.1- Basic Condition for Determining Allowable Stress

3.2- Longitudinal Compression (Case#1)

3.3- Longitudinal Compression and Bending Combination (Case#2)

3.4- Circumferential Stress (Case#3)

3.5- Combined Longitudinal and Circumferential Compressive Stress (Case#4)

3.6- Circumferential Compression in Stiffener

3.7- Ovalling Check

4- Design Of Stack Base Part ............................................................................................. 19

4.1- Anchor chair calculation

5- Deflection check.......................................................................................................... 25

6- Breeching Opening Stiffener Design............................................................................ 26

7- Platform cleat to Shell connection check................................................................... 28

8- Conclusion.................................................................................................................. 33

Doc No: QN-E121.00003-000 Rev.0 Page 2 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

ABBREVIATION:

QAFCO - Qatar Fertilizer Company

QCS - Qatar Construction Standards

ASME - American Society of Mechanical Engineers

ASCE - American Society of Civil Engineers

UBC - Uniform Building Code

AISC - American Institute of Steel Construction

Doc No: QN-E121.00003-000 Rev.0 Page 3 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

1. GENERAL

13B

1.1 Introduction:

This report document contains the structural verification for the Primary reformer stack

that is installed in Qafco, Qatar. The stack is 34.8 meters in height, and external

diameter is 3460 mm from the base to the top. Wall thickness is 10 mm from base to

the elevation of 9195mm, 8mm for another 9550 mm meters and 6 mm for the 16000

mm.

Lining 50 mm, LWI 20 Castable 1204 degree C. Density: 930 kg/m3 on C.S chain link

reinforcement, inside of the shell.

There are 5 existing platforms located at an elevation of 5200, 11200, 17200, 23200 and

28475 mm, for maintenance and inspection purpose. Opening for gas inlet is provided

near the base of the stack, and the opening size is 3060 mm high and 2240 mm wide.

Now, a new platform will be constructed in the top section of the stack, located below

the nozzle elevation 27500 mm, shell thickness of 6 mm. The objective of this report is

to include this additional platform load in the stack design calculation and check if the

stack is adequately strengthened.

1.2 Design Methodology and Sketch:

The basic design code used for designing this stack is ASME STS-1-2006, “Steel Stacks”.

The design procedure followed in this report is briefly explained below. The structural

integrity and safety of the stack, under different loading conditions and failure scenarios

are taken into consideration.

1. The applicable loadings as per clause 4.3 are determined. These loadings majorly

include:

a. Dead Load

The dead load shall consist of weight of the steel stack, stiffeners, flanges, and

permanent accessories such as ladders, platforms.

b. Live load

The platform walkway area is calculated and live load is uniformly distributed over

this area.

c. Wind Load /Seismic load

Seismic loads are calculated in this report, but it has lesser effect compared to wind

action. Therefore, Wind pressure is the governing factor in this design.

2. Shell Strength check:

In operating condition, the stack structure (ie. cylindrical body and stiffeners) are

subjected to compressive and bending stresses in longitudinal and circumferential

direction, under various loading condition. As per clause 4.4.1 to 4.4.5, the design will

be checked for different load cases and the stresses are determined. Allowable stresses

are determined as per clause 4.4.

Doc No: QN-E121.00003-000 Rev.0 Page 4 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

3. Dynamic effects due to wind:

The steel stack is a light weight, flexible structure with low inherent structural damping,

therefore the effects of dynamic effects of wind is considered. The stack will be checked

for vortex shedding and ovalling resonance. If the critical velocity exceeds the design

velocity, then the dynamic effects can be safely ignored.

4. Anchor chair calculation:

The Base plate thickness is calculated by assuming the baseplate is in compression

state. The anchor bolts are sized to resist the wind force/Moment. Pressure vessel

design handbook by Bednar forms the basis of this calculation. CodeCalc software is

used to perform this design.

5. Deflection check:

Pressure vessel Handbook by Moss, Procedure4.4 “deflection in towers” is used to

check the deflection in the stack. Deflection due to Uniform Vessel, Non-uniform load

case is considered.

6. Structural shell discontinuities/ Shell opening for Gas inlet:

a. The sides of the breeching opening act as columns or tension members to

withstand the reaction loads coming on the horizontal girder above and below.

The strength of the plane cut through the opening at any elevation shall be

adequate to withstand the applied load.

b. The top and bottom of breeching opening shall be adequately reinforced to

transfer the discontinuous of shell stress back to the full circumference of the

shell. The required section modulus is calculated and checked with the actual

section property.

7. Platform to Shell Connection:

Local stresses are developed at the Platform–to-shell Connection region. The maximum

reaction loads (taken from the platform structure design report) are applied at this

junction and the WRC analysis is performed using Codecalc software. Adequate

reinforcement will be provided to minimize the stresses.

Doc No: QN-E121.00003-000 Rev.0 Page 5 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

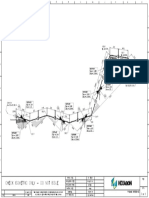

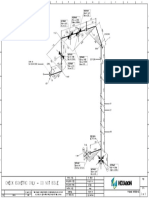

Sketch

U

(Reference drawing: Primary Reformer Steel arrangement Stack, QA-UD-T121.00019-001)

Doc No: QN-E121.00003-000 Rev.0 Page 6 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

1.3 Input References:

a. Primary stack assembly drawing ,” QA-UD-T121.00019-001

b. Anchor bolt detail drawing, QA-UD-T121.00019-003

c. General Requirements to Civil works and structures, CEMS-PT-S700.01004

d. Access Platform and detail drawing, QN-D121.00001-000

1.4 Codes and Standard:

The following Codes and Standards are referred:

a. ASME Steel Stacks, STS-1-2006

b. Qafco General Specification for civil works and structures

c. ASCE 7-10, For Wind loads

d. UBC 97 for Seismic loads

e. AISC Manual of Steel Construction (Allowable Stress Design, 9th Edition)

f. Structural Engineering Handbook, Gaylord & Gaylord : Section 30: Chimneys

1.5 Softwares used:

- CodeCalc for Anchor chair calculation.

- CodeCalc Platform to Shell WRC analysis

Doc No: QN-E121.00003-000 Rev.0 Page 7 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

1.6 Input Data:

Stack Geometric Data

Stack Outside Diameter : 3460 mm

Stack Height : 34800 mm

Design Condition

Wind Data: (Reference document: CEMS-PT-S700.01004)

U

Basic Wind Speed : 33.4 m/s EXPOSURE C

Wind code : ASCE 7-10

Seismic Data: (Reference document: CEMS-PT-S700.01004)

U

Seismic Category : ZONE 1 Z=0.075 (Qatar region)

Site Class : D

Risk category : III

Dead and Live load: (Reference document: CEMS-PT-S700.01004)

U

Dead Load includes Stack wall, platforms and ladders, stiffeners. Miscellaneous weight of

10% will be considered to the dead weight calculated.

Live load, uniformly distributed over the platform region: 5kN/m2

Lining 50 mm, LWI 20 Castable 1204 degree C. Density: 930 kg/m3 on C.S chain link

reinforcement.

Material : SA 36/S275 JR ( For Shell Plates)

EN 8.8 (For Anchor bolts)

Corrosion Allowance :0 mm

Internal Lining : 50 mm

Yield Strength @design temperature : 275 N/mm2

Elasticity Modulus : 190.95 KN/mm2

Minimum Shell Thickness : 6 mm

Doc No: QN-E121.00003-000 Rev.0 Page 8 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

2.DESIGN LOADS

2.1 Dead and Live Load

Table-1 Dead and Live Load

No. Hz(n-1) Hz(n) Hi (mm) Ti (mm) Di (mm) Wsi (kN) Wli (kN) Wa (kN) Cumulative

weight

(mm) (mm)

(kN)

1 0 1720 1720 10 3440 14.6 14.6 415

2 1720 4220 2500 10 3440 21.2 21.2 400

3 4220 6720 2500 10 3440 21.2 10 31.2 379

4 6720 9220 2500 10 3440 21.2 21.2 348

5 9220 11720 2500 8 3444 17.0 10 27.0 327

6 11720 14220 2500 8 3444 17.0 17.0 300

7 14220 16720 2500 8 3444 17.0 17.0 283

8 16720 18800 2080 8 3444 14.1 10 24.1 266

9 18800 21300 2500 6 3448 12.8 12.8 242

10 21300 23800 2500 6 3448 12.8 10 22.8 229

11 23800 26300 2500 6 3448 12.8 12.8 206

12 26300 28800 2500 6 3448 12.8 150 162.8 193

13 28800 31300 2500 6 3448 12.8 12.8 31

14 31300 33800 2500 6 3448 12.8 12.8 18

15 33800 34800 1000 6 3448 5.1 5.1 5

Where:

No.: Section No.

Hz: Height above ground

Hi: Height of ith section

Ti: Un-corroded shell thickness of i section

Di: Stack inside diameter

Total

Wsi : Stack shell weight 225 kN

Wli : Live loads (5.0 kN/m²,Platform/Ladder ( 4 nos)) 190 kN

Wa : Wsi +Wli 415 kN

Wco: Lining and chain reinforcement weight 55 kN

Wt : Total load 495 kN

( including 10% additional load on Dead weight)

Doc No: QN-E121.00003-000 Rev.0 Page 9 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

2.2 WIND LOAD CALCULATION

0B

Design Wind Load

1B

2B (In accordance with Document: CEMS-PT-S700.01004, ASCE 7, Section6.0, Wind loads)

qz=0.613 (V^2).I.Kzt.Kz .Kd (Eq.6-15)

Where:

qz: Wind pressure (N/m2)

Kzt : Topographic factor = 1.0

Kd : Wind directionality factor (Table 6-4, for Chimneys, Round): 0.95

Kz : Velocity pressure exposure coefficient(Table 6.3): 1.3(max)

Iw: Importance factor (Table 6.1, for category III): 1.15

Exposure C

V : basic wind speed based on 3sec gust velocity: 33.4 mps

Force due to wind:

F = qz * G* Cf * Af (Eq.6-25)

Where,

qz: Velocity Pressure at height ‘h’

G: Gust-effect factor = 0.85 (sec 6.5.8.1)

Cf: Shape factor = 0.83 (Round chimney, H/D>7, figure 6-19)

Af: Projected Area Normal to the wind = Do*Hi*1.2

(Additional factor of 1.2 is multiplied to take into account the platform and ladder, Stiffener

projections)

Do: Outside diameter of Stack

Hi: Height of the section

Doc No: QN-E121.00003-000 Rev.0 Page 10 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

Table-2 WIND LOAD DUE TO ALONG WIND

No Hz(n-1) Hz(n) Hi Do Ti Kz q(z) Fx Vtotal M total

(mm) (mm) (mm) (mm) (mm) (㎏/m2) (kN) (kN) (kN-m)

1 0 1720 1720 3460 10 0.85 64.8 3.20 84.77 1525.9

2 1720 4220 2500 3460 10 0.85 64.8 4.65 81.57 1346.0

3 4220 6720 2500 3460 10 0.94 71.7 5.14 76.92 1153.9

4 6720 9220 2500 3460 10 0.98 74.7 5.36 71.78 969.0

5 9220 11720 2500 3460 8 1.04 79.3 5.69 66.42 797.0

6 11720 14220 2500 3460 8 1.09 83.1 5.96 60.73 637.7

7 14220 16720 2500 3460 8 1.13 86.1 6.18 54.77 492.9

8 16720 18800 2080 3460 8 1.13 86.1 5.14 48.58 364.4

9 18800 21300 2500 3460 6 1.17 89.2 6.40 43.44 260.6

10 21300 23800 2500 3460 6 1.21 92.2 6.62 37.04 166.7

11 23800 26300 2500 3460 6 1.24 94.5 6.78 30.42 91.3

12 26300 28800 2500 3460 6 1.26 96.1 6.89 23.63 42.5

13 28800 31300 2500 3460 6 1.26 96.1 6.89 16.74 58.6

14 31300 33800 2500 3460 6 1.28 97.6 7.00 9.85 20.9

15 33800 34800 1000 3460 6 1.3 99.1 2.84 2.84 2.1

where :

No.: section No.

Hz : height above ground

Hi : height of i section qz=Wind pressure

Ti : uncorroded shell thickness Fx : force by wind on the shell section

th

of i section Vtotal = Total Shear force by wind

Do : stack outside diameter=2600mm Mtotal = Total moment by wind

c.o.g: center of force is considered at 0.6h, which is safe above the actual point.

Wind Loads:

Base Shear: 84.77 kN

Base Moment: 1525.9 kN-m

Doc No: QN-E121.00003-000 Rev.0 Page 11 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

2.3 Vortex Shedding

14B

Stack Natural Frequency in First Mode (in accordance with Gaylord Gaylord’s Handbook)

f1 = 3.9*D/H²*sqrt(E/Ws) : natural frequency (Hz) 2.8 Hz

Where:

D : diameter (in) 136.2 in= 3460 (mm)

H : height of stack 1370 in= 34800 (mm)

E: modulus of elasticity (psi) 27740000 psi= 1950315

(kg/cm2)

3

WS: unit weight of shell (lb/in3 ) 0.284 lb/in³= 0.00785(kg/cm )

Vortex Shedding (in accordance with ASME STS-1)

Vc = f1*D/St : critical wind speed (ft/sec) 158.76 ft/sec 48.4 (m/s)

where :

f1 : natural frequency in first mode (Hz) 2.8 Hz

D : stack diameter (ft) 11.4 ft= 3460 (mm)

St = strouhal number 0.2

= 0.2 when A/D ≥15 or single stack

= 0.16+(A/D-3)/300 when A/D < 15

A : center to center spacing for interference effects (ft) N/A

α'

Vzcr = b'(Zcr/33) *22*Vr/15 : mean hourly wind speed at Zcr 89.9 ft/sec = 27.4 (m/s)

Where:

b' : terrain exposure constants 0.65 FOR EXPOSURE C

α' : terrain exposure constants 0.154 FOR EXPOSURE C

Zcr: the elevation to 5/6 stack height (ft) 95.14 ft=29000(mm)

Vr = V*I0.5 : the reference design speed (mph) 80.1 mph= 35.8(m/s)

Vortex shedding occurrence evaluation

※ Vc= 48.4 m/sec > 1.2*Vzcr =32.88 m/sec

Since Vc > 1.2Vzcr , the response Vortex shedding can be ignored.

15BU

Doc No: QN-E121.00003-000 Rev.0 Page 12 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

2.4 Earthquake Load

16B

Seismic Base Shear (in accordance with I.B.C 2009,UBC 1997)

V = C*W = 0.10*W =40 kN

where :

C= 0.1

C=Cv*I/(RT) 0.099

Cmax=2.5CaI/R 0.103

Cmin=0.11Ca I 0.013

Seismic zone : 1

Z : seismic zone factor (Table 16-I) 0.075

Cv : seismic coefficient given in table 16-R of UBC 0.18

Soil profile type : according to the contract spec Sd

R : behavior coefficient of building (Table 16-P-R U.B.C 97) 2.9

T : fundamental period of building =h^(3/4)*0.0488 0.69

I : seismic importance factor (Table 16-K) 1.0

Ca= seismic coefficient according to (Table 16-Q) 0.12

W : total weight = 330 kN ( Live load of 25% is considered)

Base Shear: 40.0kN

Base Moment: 820.0 kN-m

Note: Since, the Seismic load is lesser than the Wind loads, the governing case for the stack design

will be Wind case.

Doc No: QN-E121.00003-000 Rev.0 Page 13 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

3. DESIGN OF STACK SHELL (in accordance with ASME STS-1)

Stack structural integrity and stability is checked for the various design loads calculated in the

earlier section. The actual and allowable stresses for the different load cases are determined as

per ASME STS-1 (clause 4.4). The calculation shown below verifies that the requirements of the

code are met and the stresses are well within the permissible limits.

3.1 Basic Condition for determining allowable stress

t/D ≤ (10*FY)/E,

6B

Since, this requirement is met; the stack must satisfy following four load cases:

7B

3.2 CASE 1 : Longitudinal Compression

P/A ≤ Scl where,

Scl = E*t*Y/(4*D*F.S) when t/D ≤ 2.8*FY/E

= FY(1-0.3*KS)*Y/F.S when 2.8*FY/E < t/D ≤ 10*FY/E

Y = 1 when Le/r ≤ 60 and FY ≤ 50ksi

= 21,600/(18,000+(Le/r)2) when Le/r > 60 and Fy ≤ 50ksi

2

8B KS = ((10*FY/E-t/D)/(7.2*FY/E))

3.3 CASE 2 : Longitudinal Compression and Bending Combination

P/A + M*D/(2*ISECTION) ≤ Sbl

3.4 CASE 3 : Circumferential Stress

3B

9B fc = qz*D/(288*t) (psi)

The circumferential stress shall be less than the allowable stress, Scc

fc ≤ Scc

where, Scc = 1.3*E*K*(t/D)1.5/(F.S*ls /D)

when 0≤ t/D ≤ 2.8*FY/E, K = 1

when 2.8*FY/E < t/D ≤ 10*FY/E,

K = 1.68*FY*D/(E*t)+0.465-0.0232*E*t/(FY*D)

3.5 CASE 4 : Combined Longitudinal and Circumferential Compressive Stress

(P/A + M*D/(2*ISECTION))/Sbl+(fc/SCC)2 ≤ 1.0

Doc No: QN-E121.00003-000 Rev.0 Page 14 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

3.6 Circumferential Compression in Stiffener

4B

The size of stiffeners shall satisfy the following three requirements:

10B

The moment of inertia of plate section and stiffener

1B

IS+P 3= q*lS*D *F.S/(3456*E)

The area of plate section and stiffener

AS+P = q*lS*D*F.S/(288*Sccs)

Sccs = 0.25*E*I/(F.S*R2)

The section modulus of plate section and stiffener

12B

SS+P2 = qz*D *ls*F.S/(1830*Fy)

where,

Fy = Yield strength at design temperature : 0.275 kN/mm2

E = Modulus of elasticity at design temperature : 191.13 kN/mm2

F.S = Factor of Safety : 1.5

Le = two times the overall stack height for cantilever stack : 69600 mm

Scl = Allowable longitudinal compressive stress

Sbl = Allowable combined longitudinal compressive and bending stress

Scc = Allowable circumferential compressive stress

q = The external wind pressure or stack draft pressure

qz = The external wind pressure on stack at elevation under consideration

P = the dead load of stack above elevation under consideration

A = the cross-section area of stack plate

r = Radius of gyration of chimney at the considered section

Y = stress reduction factor

t = Shell thickness

D = Outside Diameter of Cylinder

LS = spacing of stiffeners: 9500mm

Doc No: QN-E121.00003-000 Rev.0 Page 15 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

TABLE-3 SHELL

STRENGTH CHECK (1/2)

Hz1 A Sp ISECTION qz

(mm) (N/m^2)

No. Hz (mm) tr (mm) D (mm) (cm^2) (cm^3) (cm^4)

1 0 1720 10 3434 1075.7 93429.2 16041795.5 635.0

2 1720 4220 10 3434 1075.7 93429.2 16041795.5 635.0

3 4220 6720 10 3434 1075.7 93429.2 16041795.5 702.3

4 6720 9220 10 3434 1075.7 93429.2 16041795.5 732.2

5 9220 11720 8 3438 862.1 74786.3 12855768.2 777.0

6 11720 14220 8 3438 862.1 74786.3 12855768.2 814.3

7 14220 16720 8 3438 862.1 74786.3 12855768.2 844.2

8 16720 18800 8 3438 862.1 74786.3 12855768.2 844.2

9 18800 21300 6 3442 647.7 56122.0 9658600.9 874.1

10 21300 23800 6 3442 647.7 56122.0 9658600.9 904.0

11 23800 26300 6 3442 647.7 56122.0 9658600.9 926.4

12 26300 28800 6 3442 647.7 56122.0 9658600.9 941.3

13 28800 31300 6 3442 647.7 56122.0 9658600.9 941.3

14 31300 33800 6 3442 647.7 56122.0 9658600.9 956.3

15 33800 34800 6 3442 647.7 56122.0 9658600.9 971.2

Section Properties

U

Where:

No.: section no.

Hz: height above ground Hi: height of i section

D: Shell diameter of i section tr : corroded shell thickness of i section

A: corroded area of i section

Isection: moment of inertia of corroded section

Sp: Section modulus of section

Doc No: QN-E121.00003-000 Rev.0 Page 16 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

Table-4 SHELL

STRENGTH CHECK (2/2)

M A B C D E F G (F+G)

(kN-m) fc P/A MD/2I Sbl=Scl Scc Unity

(N/mm^2) (N/mm^2) (kN/mm2) (N/mm2) check

No. (N/mm^2) (B+C)/D (A/E) Combined

Stress

Ratio

1 1525.9 0.111 3.8575 16.33 98.525 9.994 0.205 0.01114 0.205

2 1346.0 0.111 3.7218 14.41 98.525 9.994 0.184 0.01114 0.184

3 1153.9 0.123 3.5247 12.35 98.525 9.994 0.161 0.01232 0.161

4 969.0 0.128 3.2345 10.37 98.525 9.994 0.138 0.01284 0.138

5 797.0 0.170 3.7901 10.66 78.728 7.147 0.184 0.02385 0.184

6 637.7 0.179 3.4770 8.53 78.728 7.147 0.152 0.02499 0.153

7 492.9 0.185 3.2800 6.59 78.728 7.147 0.125 0.02591 0.126

8 364.4 0.185 3.0829 4.87 78.728 7.147 0.101 0.02591 0.102

9 260.6 0.256 3.7308 4.64 58.977 4.639 0.142 0.05517 0.145

10 166.7 0.265 3.5338 2.97 58.977 4.639 0.110 0.05706 0.114

11 91.3 0.271 3.1825 1.63 58.977 4.639 0.082 0.05847 0.085

12 42.5 0.276 2.9856 0.76 58.977 4.639 0.063 0.05941 0.067

13 58.6 0.276 0.4726 1.04 58.977 4.639 0.026 0.05941 0.029

14 20.9 0.280 0.2757 0.37 58.977 4.639 0.011 0.06036 0.015

15 2.1 0.284 0.0788 0.04 58.977 4.639 0.002 0.06130 0.006

Stresses check

U

The Stresses under different load cases are checked and are found to be well within the

acceptable limit.

3.7 Oval ling Check (in accordance with ASME STS-1)

Oval ling natural frequency (f0)

f0=680*tr/D2 (Hz), where tr: corroded thickness

f0=1.25 Hz

Critical wind velocity for oval ling (Vco)

Vco=f0*D/(2*S) (ft/s) 35.4 ft/s

where,

S = Strouhl number =

0.2

Since, Vco<Vz (mean hourly wind speed), therefore stiffeners are required.

Doc No: QN-E121.00003-000 Rev.0 Page 17 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

Required minimum section modulus of stiffeners (Ss):

Ss = (2.52x10-3)(vco)2*D2*Is/σa (in^3) = 0.62 in^3

Is= Spacing between circumferential stiffeners: 9500 mm

σa = allowable tensile stress in stack stiffener = 0.6Fy =20450 psi

Min. Stiffener Size selected: 75*75*8

Note: The actual section modulus is more than the required. Therefore, the selected stiffener size is

safe.

Stiffener design: Circumferential compression check

1. Minimum Moment of Inertia:

=0.291 in4

2. Minimum Shell + Stiffener Area:

=0.26 in2

3. Required Section modulus:

=3.29 in3

Min. Stiffener size selected is angle 75*75*8

Note: Min. section modulus of plate section alone is more than the required. Therefore,

stiffener size selected is OK.

Doc No: QN-E121.00003-000 Rev.0 Page 18 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

4. DESIGN OF STACK BASE PART

5B

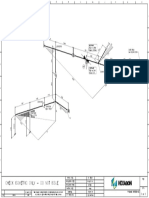

UAnchor Chair calculation:

The calculation is performed in CodeCalc software. The anchor chair dimensions are taken from

existing stack drawing. The figure shown below is taken from the software, shows the input

anchor chair dimensions. The dead load and wind load/moment calculated in previous pages are

taken as loads to check the anchor chair design.

Input:

Analyze or Design the Basering AORD Analyze

Design Temperature for Basering RNGTMP 85.00 C

Thickness of Basering TBA 25.0000 mm

Basering Material S275

Basering Material UNS Number

Inside Diameter of Basering DI 3410.000 mm

Outside Diameter of Basering DO 3740.000 mm

Bolt Material SA-193 B7

Bolt Material UNS Number G41400

Bolt Operating Allowable Stress SA 172.38 MPa

Bolt Ambient Allowable Stress SABAMB 172.38 MPa

Diameter of Bolt Circle DC 3590.000 mm

Nominal Diameter of Bolts BND 42.0000 mm

Type of Thread Series TEMA Metric Thread

Number of Bolts NGIV 24

Skirt Material S275

Skirt Material UNS Number

Skirt Operating Allowable Stress SKTOPE 180.00 MPa

Skirt Ambient Allowable Stress SKTAMB 180.00 MPa

Skirt Thickness TS 10.0000 mm

Doc No: QN-E121.00003-000 Rev.0 Page 19 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

Skirt Temperature SKTTEM 220.0000 C

Outside Diameter of Skirt at Base DS 3460.000 mm

Outside Diameter of Skirt at Bottom Head SKTHED 3460.000 mm

Joint Efficiency of Skirt Weld ARCJNT 1.0000

Nominal Compressive Stress of Concrete FPC 20.6 MPa

Thickness of Gusset Plates TGA 15.0000 mm

Temperature for Gusset Plates GUSTMP 85.0000 C

Average Width of Gusset Plates AVGWDT 300.0000 mm

Gusset Material S275

Gusset Material UNS Number

Gusset Plate Elastic Modulus E 199955.0 MPa

Gusset Plate Yield Stress SY 275.00 MPa

Gusset Operating Allowable Stress Sgus 180.00 MPa

Height of Gussets HG 280.0000 mm

Distance from Bolts to Gussets CG 70.0000 mm

Number of Gussets per bolt NG 2

Thickness of Top Ring/Plate TTA 38.0000 mm

Radial Width of the Top Ring/Plate TOPWTH 130.0000 mm

Top Ring or Plate Type per Moss Continuous Ring

External Corrosion Allowance CA 0.0000 mm

Dead Weight of Vessel DW 0.4950E+06 N

Operating Weight of Vessel ROW 0.4950E+06 N

Test Weight of Vessel TW 0.0000 N

Operating Moment on Basering ROM 0.1525E+10 N-mm

Test Moment on Basering TM 0.0000 N-mm

Calculation:

U

RESULTS FOR BASERING ANALYSIS : ANALYZE OPTION

U

1. Calculation of load per bolt:

Calculation of Load per Bolt, Operating Condition:

W/Bolt = (( 4 * M/DC ) - W ) / RN per Jawad Farr, Eq. 12.3

W/Bolt = (( 4 * .15244E+10 / 3590.000 ) - 494999 ) / 24

W/Bolt = 50144.8281 N

Required Area for Each Bolt, Based on Max Load 290.9302 mm^2

Area Available in a Single Bolt 1018.2180 mm^2

Area Available in all the Bolts 24437.2305 mm^2

Bolt Stress Based on Approximate Analysis 49.25 MPa

Note: The anchor bolt size and quantity is ok as the available area is more than the

required bolt area.

Doc No: QN-E121.00003-000 Rev.0 Page 20 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

2. Basering/Baseplate thickness calculation:

Thickness of Basering under compression:

This is a equation for a simple cantilever beam. The beam is assumed to be

supported at the bottom shell, and loaded with uniform concrete load due to

combined stack weight and bending moment due to wind.

Geometry property:

Concrete Contact Area of Base Ring 1853147.00 mm^2 (Base ring area)

Concrete Contact Section Modulus of Base Ring 1586552832.00 mm^3

(Circular ring section modulus)

Stresa cting on concrete:

Calculation of Concrete Load, Operating Condition:

SC = ((ABT*SA+W)/CA) + M/CZ per Jawad & Farr Eq. 12.1

SC = ((24437.2305*172 +494999 )/1853147 ) + .15250E+10/.15866E+10

SC = 3.50 MPa

Thickness of cantilever, t :

Method 1:

Calculation of Basering Thickness, (Simplified):

TB = RW * SQRT( 3 * SC / S ) + CA per Jawad & Farr Eq. 12.12

TB = 140.0000 * SQRT( 3 * 3 / 352 ) + 0.0000

TB = 24.1664 mm

Method 2:

Results of Neutral Axis Shift Calculation:

Bearing Pressure on Concrete 1.60 MPa

Stress in Bolt 30.00 MPa

Calculation of Basering Thickness, (N.A. Shift):

TBNA = RW * SQRT( 3 * SCNA / S) + CA per Jawad & Farr Eq. 12.12

TBNA = 140.0000 * SQRT( 3 * 1 / 352 ) + 0.0000

TBNA = 16.3515 mm

Doc No: QN-E121.00003-000 Rev.0 Page 21 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

3. Top ring thickness design under Tension:

The thickness is calculated using simple beam formulae. The beam is

supported between 2 gussets with a point load in the middle equal to the

maximum bolt load.

Method 1:

Required Thickness of Top Ring/Plate in Tension:

(Calculated as a fixed beam per Megyesy)

FT = (SA*ABSS), Bolt Allowable Stress * Area

RM = (FT*2.0*CG)/8.0, Bending Moment

SB = (1.5*BASOPE), Allowable stress * 1.5

WT = (TOPWTH - BND), Width of Section

T = SQRT( 6 * RM / ( SB * WT )) + CA

T = SQRT( 6 * 3071518 / ( 352 * 88.0000 )) + 0.0000

T = 24.3743 mm

Method 2:

Required Thickness of Continuous Top Ring per Moss:

a = ( Dc-Ds )/2 Skirt Distance to Bolt Circle

P = Sa * Abss Maximum Bolt Load

l = Avgwdt Average Gusset Width

g1 = Gamma 1 Constant Term f( b/l )

g2 = Gamma 2 Constant Term f( b/l )

g = Flat distance/2 Nut 1/2 Dimension (from Tema)

Fb = ( 1.5 * Basope ) Allowable Stress

Mo = P/(4 pi)[1.3(ln((2lsin(pi a/l)/(pi g)))+1]-[(.7-g2)P/(4 pi)]

Tc = ( 6 * Mo / Fb )^1/2 + CA Required Thickness

Tc = ( 6 * 26731 / 352 )^1/2 + 0.0000

Tc = 21.3308 mm

Doc No: QN-E121.00003-000 Rev.0 Page 22 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

4. Required Thickness of gusset:

In Tension:

Tensile stress is force ( derived from allowable bolt stress times bolt area)

by the area of the gusset ( thickness * half times width of the gusset)

Required Thickness of Gusset in Tension (based on avg. crossection) [T]:

= (( SA * ABSS ) / ( NG * Sgus * ( AVGWDT )) + CA

= (( 172.4 * 1018.218 ) / ( 2 * 180.0 * 300.000 )) + 0.000

= 1.6251 mm

Actual thickness as entered by user 15.0000 mm

In Compression:

In Compression, the software uses iterative process to calculate the required

thickness. Calculation is performed as per AISC 1.5.1.3. The actual compression is

calculated and compared with allowable compression per AISC. The thickness is then

modified and another calculation performed until the actual and allowed compression

is within one half of one percent of one another.

Required Thickness of Gusset in Compression, per AISC E2-1 9th Ed.

1. Allowed Compression at Given Thickness:

Factor Kl/r Per E2-1 129.1811

Factor Cc Per E2-1 119.8022

All. Buckling Str. per E2-2 61.70 MPa

Act. Buckling Str. at Given Thickness 19.50 MPa

Required Gusset thickness, + CA 10.2330 mm

2. Allowed Compression at Calculated Thickness:

Factor Kl/r Per E2-1 189.3590

Factor Cc Per E2-1 119.8022

All. Buckling Str. per E2-2 28.72 MPa

Act. Buckling Str. at Calculated Thickness 28.59 MPa

SUMMARY OF BASERING THICKNESS CALCULATIONS

Required Basering Thickness (simplfied) 24.1664 mm

Required Basering Thickness (N.A. Shift) 16.3515 mm

Actual Basering Thickness as entered by user 25.0000 mm

Required Top Ring/Plate Thickness as a Fixed-Beam 24.3743 mm

Required Top Ring Thickness per Moss(Type 4) 21.3308 mm

Actual Top Ring Thickness as entered by user 38.0000 mm

Required Gusset thickness, + CA 10.2330 mm

Actual Gusset Thickness as entered by user 15.0000 mm

Note: The stresses in base ring, Top ring, gusset and bolts are within the allowable

limit. The actual thickness is more than the required thickness. Therefore the Anchor

chair design is safe.

Doc No: QN-E121.00003-000 Rev.0 Page 23 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

5. Bottom section of Stack shell (Referred to as skirt in the below

calculation):

Software performs the stress calculation (In both Tension and compression) for

this bottom Shell section. The below calculation shows that the required

thickness is less than the actual provided. Therefore the corroded shell

thickness of 10 mm is also more than required thickness of 5.49 mm.

TENSILE STRESS CALCULATIONS FOR SKIRT AT TOP HEAD:

S = M/( PI*R^2*T ) - F/(2*PI*R*T)

Operating Dead Load Test Load

Skirt Rad. Given by User 1730.0000 1730.0000 1730.0000 mm

Skirt Thkn. Given by User 10.0000 10.0000 10.0000 mm

Bndg. Mom. Given by User 0.153E+10 0.153E+10 0.000E+00 N-mm

Axial Force Given by User 495000.0 495000.0 0.0 N

Actual Stress in Skirt 11.7 11.7 0.0 MPa

Allowed Stress in Skirt 144.0 144.0 216.0 MPa

THICKNESS CALCULATION FOR SKIRT:

Required Thickness 0.8097 0.8097 0.0000 mm

Actual Thickness as Given 10.0000 10.0000 10.0000 mm

COMPRESSIVE STRESS CALCULATIONS AT BASE OF SKIRT:

S = M/(PI*R^2*T) + F/(2*PI*R*T)

Operating Dead Load Test Load

Skirt Rad. Given by User 1730.0000 1730.0000 1730.0000 mm

Skirt Thkn. Given by User 10.0000 10.0000 10.0000 mm

Bndg. Mom. Given by User 0.153E+10 0.153E+10 0.000E+00 N-mm

Axial Force Given by User 495000.0 495000.0 0.0 N

Actual Stress in Skirt 20.8 20.8 0.0 MPa

Allowed Stress in Skirt 67.7 67.7 101.6 MPa

THICKNESS CALCULATION FOR SKIRT AXIAL COMPRESSION:

Required Thickness 5.4870 5.4870 0.0000 mm

Actual Thickness as Given 10.0000 10.0000 10.0000 mm

SUMMARY OF SKIRT THICKNESS:

Operating Dead Load Test Load

Req. Thickness, Tension 0.8097 0.8097 0.0000 mm

Req. Thickness, Comp. 5.4870 5.4870 0.0000 mm

Actual Thickness as Given 10.0000 10.0000 10.0000 mm

Doc No: QN-E121.00003-000 Rev.0 Page 24 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

5. Deflection Check

Deflection of the stack under Wind

Load

Deflection due to Uniform Vessel, Non-uniform load can be obtained from the formula as

below:

(Reference Dennis Moss : Procedure 4.4 Tower Deflection)

L = Length of stack, in

I = Moment of inertia (Mid section), in^4

wmax = uniformly distributed load at top of vessel , lb/in.

wmin = uniformly distributed load at bottom of vessel , lb/in.

E = Modulus of Elasticity, psi

d = deflection, inch

Calculation for the deflection of the Stack :

U U

L = 1370.1 (34.8 m) in

I = 116329 in^4

Wmin = 12.6 (224.2 kg/m) lb/in

Wmax = 19.2 (342.5 kg/m) lb/in

E = 27740000 psi

Deflection, d = 2.4 inch

= 61 mm

Permissible Deflection h/200 = 174 mm

The deflection of the stack is less than the allowable deflection.

Doc No: QN-E121.00003-000 Rev.0 Page 25 of 33

AD

DEQUACY CHEECK REPORT FOR

PRIMARY REF

FORMER STAC

CK

6. Breaching

B Op

pening Stifffener Design

n

Breeeching ope ening Stiffeener desig

gn (Type I)

( As per "Steel Plate

P Engineeering Data" ,P

Part V, Self supported

s sta

acks)

Input Datta

Breechingg opening sizze(length x width)

w : 3060

0mmx 2240 mm m 10

0624.34 in22

Maximum width w=2/3

3.Do 7.57 ft

Inside Are

ea of Stack A= π.D^2/4 14

4573.86 in22

Duct locattion around 7.5' abovee ground

Vertical Stiffener

S des

sign:

Area Required:

= 21.10 in2

2

where,

W': Arc length off the 2400 mm

m

opening

94.49 in

hickness of sttack at opening location

t: Max. th 10.00 mm m

0.39 in

de Diameter of Stack

Do: Outsid 3460 mm m

11.35 feeet

C: As sho

own in figure 3

3050.00 mm m

10.01 feeet

Stiffener size

s selected

d : 20 thk platte

Stack Wall Area (Corrroded) 130.66 in2

2

Total Area

A Provide

ed 135.31 in2

2

Doc No: QN-E121.00003-000 Rev.0

0 Page

e 26 of 33

AD

DEQUACY CHEECK REPORT FOR

PRIMARY REF

FORMER STAC

CK

Circular Ring Design(W

With

Stiffener)):

UDL Load

d carried by Ring

R :

= 1

1186.86 lb//in

where,

V: Total Direct

D load 495.00 kN

N

111375 lb

M1: Wind Moment at the

t given poiint 1525.9 kN

N.m

135

504215 lb.in

Bending moment

m in sttack cut-out region

r 'Mq'

= 883

3024.09 lb.in

Total Bending momennt M=M1

1+Mq 14387

7239.09 lb.in

Allowable Bending Strress' Sa' = 25

5816.00 psi

Required Section mo odulus = 557.30 in3

3

'Zr'

Stiffener size

s selectedd : 6 thk plate

e +10thk ring g

Section modulus

m in Sttack wall = 5701 in3 3

Note: Secction moduluss of stack sh hell is sufficie

ent. Thereforre, the stiffen

ner plate prov

vided

is OK.

Doc No: QN-E121.00003-000 Rev.0

0 Page

e 27 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

7.Platform cleat to Shell Joint check Description: Platform cleat

Diameter Basis for Vessel Vbasis OD

Cylindrical or Spherical Vessel Cylsph Cylindrical

Internal Corrosion Allowance Cas 0.0000 mm

Vessel Diameter Dv 3460.000 mm

Vessel Thickness Tv 6.000 mm

Design Temperature 220.00 C

Vessel Material S275

Vessel UNS Number

Vessel Cold S.I. Allowable Smc 180.00 MPa

Vessel Hot S.I. Allowable Smh 180.00 MPa

Attachment Type Type Rectangular

Parameter C11 C11 75.00 mm

Parameter C22 C22 200.00 mm

Thickness of Reinforcing Pad Tpad 6.000 mm

Pad Parameter C11P C11p 250.000 mm

Pad Parameter C22P C22p 400.000 mm

Design Internal Pressure Dp 0.001 MPa

Include Pressure Thrust No

External Forces and Moments in WRC 107 Convention:

Radial Load (SUS) P 34769.0 N

Longitudinal Shear (SUS) Vl 56603.0 N

Circumferential Shear (SUS) Vc 41371.0 N

Circumferential Moment (SUS) Mc 110000.0 N-mm

Longitudinal Moment (SUS) Ml 987000.0 N-mm

Torsional Moment (SUS) Mt 10000000.0 N-mm

Use Interactive Control No

WRC107 Version Version March 1979 ( B1 & B2 )

Include Pressure Stress Indices per Div. 2 No

Compute Pressure Stress per WRC-368 No

WRC 107 Stress Calculation for SUStained loads:

Radial Load P 34769.0 N

Circumferential Shear VC 41371.0 N

Longitudinal Shear VL 56603.0 N

Circumferential Moment MC 110000.0 N-mm

Longitudinal Moment ML 987000.0 N-mm

Torsional Moment MT 10000000.0 N-mm

Dimensionless Parameters used : Gamma = 144.17

Dimensionless Loads for Cylindrical Shells at Attachment Junction:

-------------------------------------------------------------------

Curves read for 1979 B1/B2 Beta Figure Value Location

-------------------------------------------------------------------

N(PHI) / ( P/Rm ) 0.050 4C 24.633 (A,B)

N(PHI) / ( P/Rm ) 0.050 3C 22.338 (C,D)

M(PHI) / ( P ) 0.032 2C1 0.127 (A,B)

M(PHI) / ( P ) 0.032 1C 0.176 (C,D)

N(PHI) / ( MC/(Rm**2 * Beta) ) 0.030 3A 2.202 (A,B,C,D)

M(PHI) / ( MC/(Rm * Beta) ) 0.032 1A 0.099 (A,B,C,D)

N(PHI) / ( ML/(Rm**2 * Beta) ) 0.042 3B 11.876 (A,B,C,D)

M(PHI) / ( ML/(Rm * Beta) ) 0.035 1B1 0.056 (A,B,C,D)

N(x) / ( P/Rm ) 0.041 3C 24.135 (A,B)

Doc No: QN-E121.00003-000 Rev.0 Page 28 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

N(x) / ( P/Rm ) 0.041 4C 25.397 (C,D)

M(x) / ( P ) 0.043 1C1 0.152 (A,B)

M(x) / ( P ) 0.043 2C 0.106 (C,D)

N(x) / ( MC/(Rm**2 * Beta) ) 0.030 4A 2.824 (A,B,C,D)

M(x) / ( MC/(Rm * Beta) ) 0.039 2A 0.057 (A,B,C,D)

N(x) / ( ML/(Rm**2 * Beta) ) 0.042 4B 3.199 (A,B,C,D)

M(x) / ( ML/(Rm * Beta) ) 0.043 2B1 0.080 (A,B,C,D)

Stress Concentration Factors Kn = 1.00, Kb = 1.00

Stresses in the Vessel at the Attachment Junction

| Stress Values at |

| ( MPa) |

Type of | |

Stress Load| Au Al Bu Bl Cu Cl Du Dl |

-------------------------------------------------------------------------

Circ. Memb. P | -41.3 -41.3 -41.3 -41.3 -37.4 -37.4 -37.4 -37.4|

Circ. Bend. P | -183.7 183.7 -183.7 183.7 -255.3 255.3 -255.3 255.3|

Circ. Memb. MC | 0.0 0.0 0.0 0.0 -0.1 -0.1 0.1 0.1|

Circ. Memb. MC | 0.0 0.0 0.0 0.0 -8.1 8.1 8.1 -8.1|

Circ. Memb. ML | -5.5 -5.5 5.5 5.5 0.0 0.0 0.0 0.0|

Circ. Bend. ML | -38.5 38.5 38.5 -38.5 0.0 0.0 0.0 0.0|

| |

Tot. Circ. Str.| -269.0 175.4 -180.9 109.5 -300.9 226.0 -284.6 209.9|

-------------------------------------------------------------------------

Long. Memb. P | -40.4 -40.4 -40.4 -40.4 -42.5 -42.5 -42.5 -42.5|

Long. Bend. P | -220.1 220.1 -220.1 220.1 -153.7 153.7 -153.7 153.7|

Long. Memb. MC | 0.0 0.0 0.0 0.0 -0.2 -0.2 0.2 0.2|

Long. Bend. MC | 0.0 0.0 0.0 0.0 -3.8 3.8 3.8 -3.8|

Long. Memb. ML | -2.5 -2.5 2.5 2.5 0.0 0.0 0.0 0.0|

Long. Bend. ML | -44.4 44.4 44.4 -44.4 0.0 0.0 0.0 0.0|

| |

Tot. Long. Str.| -307.4 221.6 -213.6 137.7 -200.2 114.8 -192.2 107.5|

-------------------------------------------------------------------------

Shear VC | 23.0 23.0 -23.0 -23.0 0.0 0.0 0.0 0.0|

Shear VL | 0.0 0.0 0.0 0.0 -11.8 -11.8 11.8 11.8|

Shear MT | 222.2 222.2 222.2 222.2 222.2 222.2 222.2 222.2|

| |

Tot. Shear| 245.1 245.1 199.2 199.2 210.4 210.4 233.9 233.9|

-------------------------------------------------------------------------

Str. Int. | 534.1 492.4 399.7 399.3 466.9 435.2 476.9 479.0|

Dimensionless Parameters used : Gamma = 287.83

Dimensionless Loads for Cylindrical Shells at Pad edge:

-------------------------------------------------------------------

Curves read for 1979 B1/B2 Beta Figure Value Location

-------------------------------------------------------------------

N(PHI) / ( P/Rm ) 0.114 4C 33.576 (A,B)

N(PHI) / ( P/Rm ) 0.114 3C 16.707 (C,D)

M(PHI) / ( P ) 0.086 2C1 0.031 (A,B)

M(PHI) / ( P ) 0.086 1C ! 0.070 (C,D)

N(PHI) / ( MC/(Rm**2 * Beta) ) 0.085 3A 12.143 (A,B,C,D)

M(PHI) / ( MC/(Rm * Beta) ) 0.084 1A 0.071 (A,B,C,D)

N(PHI) / ( ML/(Rm**2 * Beta) ) 0.099 3B 27.100 (A,B,C,D)

M(PHI) / ( ML/(Rm * Beta) ) 0.086 1B1 0.019 (A,B,C,D)

N(x) / ( P/Rm ) 0.101 3C 19.525 (A,B)

N(x) / ( P/Rm ) 0.101 4C 35.886 (C,D)

M(x) / ( P ) 0.103 1C1 0.052 (A,B)

M(x) / ( P ) 0.103 2C ! 0.036 (C,D)

N(x) / ( MC/(Rm**2 * Beta) ) 0.085 4A 22.668 (A,B,C,D)

M(x) / ( MC/(Rm * Beta) ) 0.095 2A 0.029 (A,B,C,D)

N(x) / ( ML/(Rm**2 * Beta) ) 0.099 4B 11.375 (A,B,C,D)

M(x) / ( ML/(Rm * Beta) ) 0.093 2B1 0.024 (A,B,C,D)

Stress Concentration Factors Kn = 1.00, Kb = 1.00

Doc No: QN-E121.00003-000 Rev.0 Page 29 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

Stresses in the Vessel at the Edge of Reinforcing Pad

| Stress Values at |

| ( MPa) |

Type of | |

Stress Load| Au Al Bu Bl Cu Cl Du Dl |

-------------------------------------------------------------------------

Circ. Memb. P | -112.7 -112.7 -112.7 -112.7 -56.1 -56.1 -56.1 -56.1|

Circ. Bend. P | -182.1 182.1 -182.1 182.1 -406.0 406.0 -406.0 406.0|

Circ. Memb. MC | 0.0 0.0 0.0 0.0 -0.4 -0.4 0.4 0.4|

Circ. Memb. MC | 0.0 0.0 0.0 0.0 -9.0 9.0 9.0 -9.0|

Circ. Memb. ML | -13.3 -13.3 13.3 13.3 0.0 0.0 0.0 0.0|

Circ. Bend. ML | -21.7 21.7 21.7 -21.7 0.0 0.0 0.0 0.0|

| |

Tot. Circ. Str.| -329.7 77.8 -259.8 61.0 -471.5 358.5 -452.6 341.3|

-------------------------------------------------------------------------

Long. Memb. P | -65.5 -65.5 -65.5 -65.5 -120.4 -120.4 -120.4 -120.4|

Long. Bend. P | -304.0 304.0 -304.0 304.0 -210.5 210.5 -210.5 210.5|

Long. Memb. MC | 0.0 0.0 0.0 0.0 -1.3 -1.3 1.3 1.3|

Long. Bend. MC | 0.0 0.0 0.0 0.0 -3.2 3.2 3.2 -3.2|

Long. Memb. ML | -7.9 -7.9 7.9 7.9 0.0 0.0 0.0 0.0|

Long. Bend. ML | -24.2 24.2 24.2 -24.2 0.0 0.0 0.0 0.0|

| |

Tot. Long. Str.| -401.6 254.8 -337.5 222.2 -335.4 92.0 -326.4 88.2|

-------------------------------------------------------------------------

Shear VC | 13.8 13.8 -13.8 -13.8 0.0 0.0 0.0 0.0|

Shear VL | 0.0 0.0 0.0 0.0 -11.8 -11.8 11.8 11.8|

Shear MT | 66.6 66.6 66.6 66.6 66.6 66.6 66.6 66.6|

| |

Tot. Shear| 80.4 80.4 52.9 52.9 54.9 54.9 78.4 78.4|

-------------------------------------------------------------------------

Str. Int. | 453.8 285.9 364.3 238.0 490.8 369.4 490.2 363.7|

WRC 107/537 Stress Summations:

Vessel Stress Summation at Attachment Junction

Type of Stress Values at |

Stress Int. (MPa ) |

Location Au Al Bu Bl Cu Cl Du Dl |

-------------------------------------------------------------------------

Circ. Pm (SUS) 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1|

Circ. Pl (SUS) -46.8 -46.8 -35.7 -35.7 -37.5 -37.5 -37.3 -37.3|

Circ. Q (SUS) -222.2 222.2 -145.2 145.2 -263.5 263.5 -247.2 247.2|

-------------------------------------------------------------------------

Long. Pm (SUS) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Long. Pl (SUS) -42.9 -42.9 -37.9 -37.9 -42.7 -42.7 -42.4 -42.4|

Long. Q (SUS) -264.5 264.5 -175.7 175.7 -157.5 157.5 -149.8 149.8|

-------------------------------------------------------------------------

Shear Pm (SUS) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Shear Pl (SUS) 23.0 23.0 -23.0 -23.0 -11.8 -11.8 11.8 11.8|

Shear Q (SUS) 222.2 222.2 222.2 222.2 222.2 222.2 222.2 222.2|

Pm (SUS) 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1|

-------------------------------------------------------------------------

Pm+Pl (SUS) 67.9 67.9 59.8 59.8 52.1 52.1 51.9 51.9|

-------------------------------------------------------------------------

Pm+Pl+Q (Total) 534.0 492.4 399.7 399.3 466.8 435.2 476.9 479.0|

Doc No: QN-E121.00003-000 Rev.0 Page 30 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

Stress Summation Comparison:

Type of | Max. S.I. S.I. Allowable | Result |

Stress Int. | MPa | |

-------------------------------------------------------------------------

Pm (SUS) | 0.07 180.00 | Passed |

Pm+Pl (SUS) | 67.87 270.00 | Passed |

Pm+Pl+Q (TOTAL)| 534.04 540.00 | Passed |

WRC 107/537 Stress Summations:

Vessel Stress Summation at Reinforcing Pad Edge

Type of Stress Values at |

Stress Int. (MPa ) |

Location Au Al Bu Bl Cu Cl Du Dl |

-------------------------------------------------------------------------

Circ. Pm (SUS) 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1|

Circ. Pl (SUS) -125.9 -125.9 -99.4 -99.4 -56.5 -56.5 -55.6 -55.6|

Circ. Q (SUS) -203.8 203.8 -160.4 160.4 -415.0 415.0 -397.0 397.0|

-------------------------------------------------------------------------

Long. Pm (SUS) 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1|

Long. Pl (SUS) -73.4 -73.4 -57.6 -57.6 -121.7 -121.7 -119.1 -119.1|

Long. Q (SUS) -328.2 328.2 -279.9 279.9 -213.7 213.7 -207.3 207.3|

-------------------------------------------------------------------------

Shear Pm (SUS) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Shear Pl (SUS) 13.8 13.8 -13.8 -13.8 -11.8 -11.8 11.8 11.8|

Shear Q (SUS) 66.6 66.6 66.6 66.6 66.6 66.6 66.6 66.6|

Pm (SUS) 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1|

-------------------------------------------------------------------------

Pm+Pl (SUS) 129.2 129.2 103.4 103.4 123.7 123.7 121.2 121.2|

-------------------------------------------------------------------------

Pm+Pl+Q (Total) 453.7 286.0 364.2 238.1 490.7 369.5 490.1 363.8|

Stress Summation Comparison:

Type of | Max. S.I. S.I. Allowable | Result |

Stress Int. | MPa | |

-------------------------------------------------------------------------

Pm (SUS) | 0.14 180.00 | Passed |

Pm+Pl (SUS) | 129.19 270.00 | Passed |

Pm+Pl+Q (TOTAL)| 490.71 540.00 | Passed |

Note: From the reaction table, the maximum load case is selected and the Platform cleat to

shell region analysis is performed for that load case. The stresses are checked and are within

the limit.

Doc No: QN-E121.00003-000 Rev.0 Page 31 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

The reinforcement detail is shown below:

Doc No: QN-E121.00003-000 Rev.0 Page 32 of 33

ADEQUACY CHECK REPORT FOR

PRIMARY REFORMER STACK

8. Conclusion:

The Stack is checked under different failure scenarios and the existing design is safe for the

additional platform loads.

The maximum combined longitudinal and circumferential compressive stress ratio in Stack

shell is 0.205, which is less than 1. The section property at the duct opening region is also

sufficient.

The dynamic wind load effects on the steel structure are ignored as the critical velocity is

1.2 times more than the mean hourly speed.

The maximum deflection at the top of the stack is 61mm, which is less than permissible

value of 174 mm.

The required thickness in anchor chair base ring, gusset plate, and top ring are less than the

actual thickness. Also, the bolt size and quantity provided are sufficient to withstand the

bending moment caused by wind.

Platform cleat –RF pad--Shell junction attachment detail is shown in the report above. The

analysis is performed with the maximum reaction loads coming at this region and the safe

pad and the cleat dimensions are determined.

Doc No: QN-E121.00003-000 Rev.0 Page 33 of 33

You might also like

- Problem 2.1: Solutions To Chapter 2 Exercise ProblemsDocument58 pagesProblem 2.1: Solutions To Chapter 2 Exercise ProblemsGhazi AlArfaj50% (4)

- Strength of Plate Girders in Shear (K. Basler)Document62 pagesStrength of Plate Girders in Shear (K. Basler)Maria FabianaNo ratings yet

- DOCUMENT NO.: IPPX-6394-8310-TN-050-0001 PROJECT NAME: 1.2 MMTPA PX-PTA Project, IOCL Paradip Refinery Toyo Job No.: 6394Document38 pagesDOCUMENT NO.: IPPX-6394-8310-TN-050-0001 PROJECT NAME: 1.2 MMTPA PX-PTA Project, IOCL Paradip Refinery Toyo Job No.: 6394Gautam AcharyyaNo ratings yet

- OBE Requirement-Application of Thermodynamics in Industrial EngineeringDocument3 pagesOBE Requirement-Application of Thermodynamics in Industrial Engineeringjoys alcosinNo ratings yet

- 00calculation Sheet For MMII Compressor Shed1Document31 pages00calculation Sheet For MMII Compressor Shed1clarkgaguiNo ratings yet

- 33-F09221S-T0501-A6C-001 003 Calculations and Appendix PDFDocument190 pages33-F09221S-T0501-A6C-001 003 Calculations and Appendix PDFUzair Maqbool KhanNo ratings yet

- Lecture 15A.7-Tubular Joints in Offshore StructuresDocument23 pagesLecture 15A.7-Tubular Joints in Offshore StructuresLinh TranNo ratings yet

- C 36 Engg Design Basis STR and Arch 1422532512Document40 pagesC 36 Engg Design Basis STR and Arch 1422532512Ramesh Subramani RamachandranNo ratings yet

- Calculation Report For New Substation Building C0148.64-2.41-680-B-EDocument361 pagesCalculation Report For New Substation Building C0148.64-2.41-680-B-EkarthiNo ratings yet

- (A-165-EL) Eng'g Spec For Design Loads - Rev.3 PDFDocument25 pages(A-165-EL) Eng'g Spec For Design Loads - Rev.3 PDFmihir_jha2No ratings yet

- (WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGDocument36 pages(WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGsholehamikNo ratings yet

- Seismic Load Considered Is As Per SAES-A-112. If Calculated The Value Shall Be 0.02 (See The Calculation Below.)Document2 pagesSeismic Load Considered Is As Per SAES-A-112. If Calculated The Value Shall Be 0.02 (See The Calculation Below.)Mohamed RafikNo ratings yet

- Design Calculations For Grade Beams and Columns For Auxiliary Piperack CU 1308Document101 pagesDesign Calculations For Grade Beams and Columns For Auxiliary Piperack CU 1308MSW Engineering ConsultantsNo ratings yet

- 2304-300-47-RD-S-001 - C - Valve Pit Analysis and Design ReportDocument30 pages2304-300-47-RD-S-001 - C - Valve Pit Analysis and Design Reportchukudi oguneNo ratings yet

- LC161076 MTKF 1 12 0001 PDFDocument176 pagesLC161076 MTKF 1 12 0001 PDFAnonymous twOrHKNo ratings yet

- Sea TransportationDocument8 pagesSea TransportationMark Samsel RohanNo ratings yet

- 01 Rpspl-Civil-Doc-Ct-01-31-01-20 PDFDocument75 pages01 Rpspl-Civil-Doc-Ct-01-31-01-20 PDFkapilNo ratings yet

- J322-ST-RP-010 - Inplace Analysis For Building B-02 - Rev 4 PDFDocument57 pagesJ322-ST-RP-010 - Inplace Analysis For Building B-02 - Rev 4 PDFgk80823No ratings yet

- MM-ZTK-1B-WP6-STR-MTO-2001 Rev.B1 PDFDocument105 pagesMM-ZTK-1B-WP6-STR-MTO-2001 Rev.B1 PDFvu tuanNo ratings yet

- Jeddah South Thermal Power Plant Stage-I: OwnerDocument23 pagesJeddah South Thermal Power Plant Stage-I: OwnerAmr AbdeinNo ratings yet

- Qap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresDocument23 pagesQap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresAnonymous uLAATWpfNo ratings yet

- 00 UBT C 51 001 001 (Rev.X2)Document597 pages00 UBT C 51 001 001 (Rev.X2)Amr AbdeinNo ratings yet

- Structural Linear BucklingDocument18 pagesStructural Linear BucklingKhusi1No ratings yet

- TEP-1225310-F99-2394 Scaffolding Design Drawing & Calculation Loading Bay of Gate Valve 24 Inchi at PR Train 3Document16 pagesTEP-1225310-F99-2394 Scaffolding Design Drawing & Calculation Loading Bay of Gate Valve 24 Inchi at PR Train 3yana dermayuNo ratings yet

- Lifting Analysis Report - Mahadi KurniawanDocument31 pagesLifting Analysis Report - Mahadi KurniawanDian SasNo ratings yet

- TP 1U61A CV 1800 CAL 0030 R0 - Trestle Supp ReportDocument224 pagesTP 1U61A CV 1800 CAL 0030 R0 - Trestle Supp Reportramesh_madkatte1082No ratings yet

- 1090-Structural Design Basis For Brazil ProjectDocument7 pages1090-Structural Design Basis For Brazil Projectask.kulkarni KulkarniNo ratings yet

- SAMPLE HILTI SolutionDocument6 pagesSAMPLE HILTI SolutionJester AbucayNo ratings yet

- Vent Stack Foundation CalDocument11 pagesVent Stack Foundation CalBenedict OgbaghaNo ratings yet

- Main Plnat Wind LoadDocument780 pagesMain Plnat Wind LoadArmie May RicoNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument25 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectToy GamesNo ratings yet

- ReportRack CraddleDocument25 pagesReportRack CraddleMochammad ShokehNo ratings yet

- CB3 EC 50 CA 005 A4 Rev.1 Pump ShelterDocument101 pagesCB3 EC 50 CA 005 A4 Rev.1 Pump ShelterRomawi StevyandiNo ratings yet

- J336-ST-DOC-RPT-001 - Analysis of CSC Tank Frame - Rev 0Document21 pagesJ336-ST-DOC-RPT-001 - Analysis of CSC Tank Frame - Rev 0Thomas StephenNo ratings yet

- SL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFDocument633 pagesSL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFsaeed ghafoori100% (1)

- Seismic Load Calculation 3.5: Page 15 of 152Document3 pagesSeismic Load Calculation 3.5: Page 15 of 152phanikrishnabNo ratings yet

- S 000 5310 001 (Structual)Document33 pagesS 000 5310 001 (Structual)Midhun K ChandraboseNo ratings yet

- Sum FHT MD-SLDDocument5 pagesSum FHT MD-SLDNebula RockbandNo ratings yet

- Design Calculation Report Shelter Guebiba BaseDocument35 pagesDesign Calculation Report Shelter Guebiba BaseAkram FerchichiNo ratings yet

- CS-007-070 Calc. StructureDocument104 pagesCS-007-070 Calc. StructureAndiWSutomo100% (1)

- Structural Calculation For Skid - 08.02.2024 CommentedDocument104 pagesStructural Calculation For Skid - 08.02.2024 Commentedkehape8723No ratings yet

- Pump Shelter Steel Structure Design Calculation FEM MethodDocument79 pagesPump Shelter Steel Structure Design Calculation FEM Methodcharleshutabara951No ratings yet

- Structural CalculationsDocument112 pagesStructural Calculationsmechpandian100% (1)

- Jacket Miscellaneous Structure DesignDocument6 pagesJacket Miscellaneous Structure DesignBolarinwaNo ratings yet

- HSD 0 Ge S DB 001 (Structural Bod) c01Document58 pagesHSD 0 Ge S DB 001 (Structural Bod) c01Dinhtai NguyenNo ratings yet

- Seismic Design Calculation p1 To p9Document9 pagesSeismic Design Calculation p1 To p9Ivan RocoNo ratings yet

- Petrofac International LimitedDocument33 pagesPetrofac International LimitedALBERTNo ratings yet

- 1.2 JT01-RO-N-FC-0003 - Structural Design Brief - Topside Structures - REV01ADocument78 pages1.2 JT01-RO-N-FC-0003 - Structural Design Brief - Topside Structures - REV01AGopalakrishnan DhandapaniNo ratings yet

- SP 1275 Rev 02 Spec and Criteria For Design of Civil Building Works Update 03 96Document200 pagesSP 1275 Rev 02 Spec and Criteria For Design of Civil Building Works Update 03 96santhosh kumar BudiNo ratings yet

- 91-XT00-J-301 Rev.ADocument27 pages91-XT00-J-301 Rev.AErin JohnsonNo ratings yet

- RTPR-ENG-REP-00XX - A Steelwork Transfer E3D To Shop Detailing Testing ReportDocument27 pagesRTPR-ENG-REP-00XX - A Steelwork Transfer E3D To Shop Detailing Testing ReportJustine Lloyd Bautista100% (1)

- Sachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Document5 pagesSachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Costas SachpazisNo ratings yet

- Design Load Basis Report Tensile Canopy - Vedvan - Noida - R0Document27 pagesDesign Load Basis Report Tensile Canopy - Vedvan - Noida - R0Neeraj KumarNo ratings yet

- Petrofac International LimitedDocument33 pagesPetrofac International LimitedHanafiahHamzahNo ratings yet

- Seafastening For Pelikan - 12mm Thickness PlateDocument12 pagesSeafastening For Pelikan - 12mm Thickness PlateHafidNo ratings yet

- Chirukhistsqali Weir RHS Manhole Chamber Calculation ReportDocument36 pagesChirukhistsqali Weir RHS Manhole Chamber Calculation Reporthasan_kygszNo ratings yet

- Pile DesignDocument16 pagesPile DesignDivyesh100% (1)

- Foundation DesignDocument19 pagesFoundation DesignBolarinwa100% (1)

- p90264-11!99!91-0608 (Pipeline Mechanical Design Report)Document23 pagesp90264-11!99!91-0608 (Pipeline Mechanical Design Report)hasan.mohamed2305No ratings yet

- Bes A002 2005Document11 pagesBes A002 2005Deputy Chief Engineer TransgridNo ratings yet

- A Safety Evaluation of Offshore Lattice Boom CraneDocument6 pagesA Safety Evaluation of Offshore Lattice Boom Cranegusyahri001No ratings yet

- 3460 AST RPS 101 Design Brief 1Document10 pages3460 AST RPS 101 Design Brief 1Agung SugiwantoNo ratings yet

- FPSO - Technical Specification For Marine TransportationDocument11 pagesFPSO - Technical Specification For Marine Transportationdndudc100% (1)

- Garting 14122022 R0Document21 pagesGarting 14122022 R0Aditya JainNo ratings yet

- CTA The Methane CycleDocument9 pagesCTA The Methane CycleAditya JainNo ratings yet

- Wind Seismic DataDocument1 pageWind Seismic DataAditya JainNo ratings yet

- Ticket 1 PDFDocument3 pagesTicket 1 PDFAditya JainNo ratings yet

- 01 80 13 Project Site Design Criteria PDFDocument2 pages01 80 13 Project Site Design Criteria PDFAditya JainNo ratings yet

- Sa 1002 R0B PDFDocument1 pageSa 1002 R0B PDFAditya JainNo ratings yet

- Septic Tank Data Sheet PDFDocument2 pagesSeptic Tank Data Sheet PDFAditya JainNo ratings yet

- Tru Bore® Metric Tube Data Sheet PDFDocument2 pagesTru Bore® Metric Tube Data Sheet PDFAditya JainNo ratings yet

- S 10734 M53402 E 02 Rev 0 M01 NSC01 EP121 Feed Effluent Exchanger Detail Drawing PDFDocument1 pageS 10734 M53402 E 02 Rev 0 M01 NSC01 EP121 Feed Effluent Exchanger Detail Drawing PDFAditya JainNo ratings yet

- Contents EEMUA Publication 190 Edition1 May 2015Document4 pagesContents EEMUA Publication 190 Edition1 May 2015Aditya JainNo ratings yet

- s5gb Pms PDFDocument6 pagess5gb Pms PDFAditya JainNo ratings yet

- Sa 1002 R0 PDFDocument1 pageSa 1002 R0 PDFAditya JainNo ratings yet

- CFD Lesson AnsysDocument178 pagesCFD Lesson AnsysAditya JainNo ratings yet

- 1622-DES-CR-02 - Gas Cylinder Basket Design Report - R0Document23 pages1622-DES-CR-02 - Gas Cylinder Basket Design Report - R0Aditya Jain100% (1)

- Sa 1002 R0DDocument1 pageSa 1002 R0DAditya JainNo ratings yet

- Sa 1002 R0C PDFDocument1 pageSa 1002 R0C PDFAditya JainNo ratings yet

- Sa 1002 R0a PDFDocument1 pageSa 1002 R0a PDFAditya JainNo ratings yet

- 1622-DES-CR-01 - Gas Cylinder Basket Design Report - R0Document25 pages1622-DES-CR-01 - Gas Cylinder Basket Design Report - R0Aditya Jain100% (2)

- Cylinder Gas Rack Design Report - RR2-1Document34 pagesCylinder Gas Rack Design Report - RR2-1Aditya JainNo ratings yet

- Nozzle Calculation - Primary Reformer Stack-R0Document22 pagesNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Nozzle Calculation - Auxiliary Boiler Stack-R0Document13 pagesNozzle Calculation - Auxiliary Boiler Stack-R0Aditya JainNo ratings yet

- Imaging and Analysis of Nanowires: Key WordsDocument17 pagesImaging and Analysis of Nanowires: Key WordsAditya JainNo ratings yet

- Efroymson Rebecca Oak Ridge National Laboratory The Billion Ton 2016 Algae Resource Analysis. Prices To Procure The BiomassDocument19 pagesEfroymson Rebecca Oak Ridge National Laboratory The Billion Ton 2016 Algae Resource Analysis. Prices To Procure The BiomassAditya JainNo ratings yet

- Lec 36Document17 pagesLec 36Aditya JainNo ratings yet

- TEM Sample Preparations 100Document28 pagesTEM Sample Preparations 100mm11_nedNo ratings yet

- CH 3Document48 pagesCH 3hadeelNo ratings yet

- Construction and Building Materials: L.C. HollawayDocument27 pagesConstruction and Building Materials: L.C. HollawayZain SaeedNo ratings yet

- Ohm's LawDocument29 pagesOhm's LawRon RexNo ratings yet

- WS Class 11 Org ChemDocument4 pagesWS Class 11 Org ChemJavedNo ratings yet

- 2.1 Duct Design PP 1Document42 pages2.1 Duct Design PP 1quoc khanh NgoNo ratings yet

- Steam Conservation Armstrong GuideDocument56 pagesSteam Conservation Armstrong GuideeirdataNo ratings yet

- Chapter 5 Steam TurbineDocument13 pagesChapter 5 Steam TurbineHalil İbrahim KüplüNo ratings yet

- Synthesis of Uio-66 MOFDocument5 pagesSynthesis of Uio-66 MOFأبو البراء اليحيىNo ratings yet

- Mina Justa Project: Ausenco Document No. 101946-DS-0081 Marcobre Doc No. JU-001-06-AUS-5500-04-26-0081Document4 pagesMina Justa Project: Ausenco Document No. 101946-DS-0081 Marcobre Doc No. JU-001-06-AUS-5500-04-26-0081jorge floresNo ratings yet

- Paper 4 - Energy Auditor - Set A Key: General InstructionsDocument12 pagesPaper 4 - Energy Auditor - Set A Key: General InstructionsRichard RegidorNo ratings yet

- Rates of Reactions Notes and Practice QuestionsDocument10 pagesRates of Reactions Notes and Practice QuestionsEustina MumbireNo ratings yet

- A Natural Gas Fired Duplex Stirling For Domestic RefrigeratiDocument11 pagesA Natural Gas Fired Duplex Stirling For Domestic RefrigeratiditoNo ratings yet

- Right Container, Right Place, Right Time: Refrigerated ContainersDocument8 pagesRight Container, Right Place, Right Time: Refrigerated ContainersEl AskNo ratings yet

- Piezoelectric Material As Transducer & Energy Harvester Front PagesDocument8 pagesPiezoelectric Material As Transducer & Energy Harvester Front PagesAmbientNo ratings yet

- Design of Wing Spar Cross Section For Optimum Fatigue Life Design of Wing Spar Cross Section For Optimum Fatigue LifeDocument6 pagesDesign of Wing Spar Cross Section For Optimum Fatigue Life Design of Wing Spar Cross Section For Optimum Fatigue LifeAwan AJaNo ratings yet

- Ice Cream Lab ReportDocument1 pageIce Cream Lab Reportescuintla67% (3)

- Rate Law Worksheet AnswersDocument6 pagesRate Law Worksheet AnswersANGELYN SANTOSNo ratings yet

- ERPT - 012Q Rhodes - FundamentalsDocument3 pagesERPT - 012Q Rhodes - FundamentalsJoao Paulo VissottoNo ratings yet

- 103 PipenetDocument23 pages103 PipenetLucious LightNo ratings yet

- Thin-Film Interference - Wikipedia, The Free EncyclopediaDocument4 pagesThin-Film Interference - Wikipedia, The Free EncyclopediananotoysNo ratings yet

- CBSE Class 8 Science WorksheetDocument2 pagesCBSE Class 8 Science Worksheetravilulla33% (3)

- Birefringe p5422 eDocument6 pagesBirefringe p5422 eGugunGunandarNo ratings yet

- Module 1-Review of General ChemistryDocument17 pagesModule 1-Review of General ChemistryMicth Laica BetoyaNo ratings yet

- Chapter 2Document33 pagesChapter 2mtas97No ratings yet

- 1 s2.0 S0006349517304411 mmc2 PDFDocument21 pages1 s2.0 S0006349517304411 mmc2 PDFBrandon LEeNo ratings yet

- Bismuth To GoldDocument20 pagesBismuth To GoldTony Gary67% (3)