Professional Documents

Culture Documents

Load Calc PDF

Load Calc PDF

Uploaded by

Monowarul IslamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Load Calc PDF

Load Calc PDF

Uploaded by

Monowarul IslamCopyright:

Available Formats

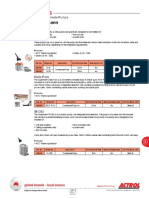

HRPQC-03 (7/03)

APPLICATIONS NOTE DIMENSIONS

(FEET)

ROOM ROOM BTUH BTUH

AREA VOLUME TYPICAL HEAVY

0°F. ROOM DIMENSIONS

(FEET)

ROOM ROOM BTUH BTUH

AREA VOLUME TYPICAL HEAVY

-10°F. ROOM DIMENSIONS

(FEET)

ROOM ROOM BTUH BTUH

AREA VOLUME TYPICAL HEAVY

-20°F. ROOM

(add 15% to loads for 10' height) W L H SQ. FT. CU. FT LOAD LOAD

(add 15% to loads for 10' height) (add 15% to loads for 10' height)

W L H SQ. FT. CU. FT LOAD LOAD W L H SQ. FT. CU. FT LOAD LOAD

Quick Calculations Tables give typical and heavy load estimates 6 6 8 36 288 4522 6570 Typical Load Conditions: 6 6 8 36 288 4859 7070 Typical Load Conditions: 6 6 8 36 288 5187 7570 Typical Load Conditions:

based on the conditions in each room temperature table. Condi- 6 8 8 48 384 5296 7390 The Cold Solutions Program 6 8 8 48 384 5692 7960 6 8 8 48 384 6076 8510 The Cold Solutions Program

The Cold Solutions Program

6 10 8 60 480 6020 8170 6 10 8 60 480 8573 10890 6 10 8 60 480 6908 9390

tions include construction, loading, and room surroundings. automatically figures typical loads. automatically figures typical loads. automatically figures typical loads.

8 8 8 64 512 6193 8360 8 8 8 64 512 6654 8990 8 8 8 64 512 7104 9610

Here are the “typical” conditions: Here are the “typical” conditions: Here are the “typical” conditions:

8 10 8 80 640 7032 9270 8 10 8 80 640 7555 9960 8 10 8 80 640 8066 10640

If your conditions are very different from the typical or heavy 8 12 8 96 768 7830 10140

Product - In at +10°

8 12 8 96 768 8413 10890

Product - In at 0°

8 12 8 96 768 8982 11620

Product - In at -10°

8 14 8 112 896 8597 10980 8 14 8 112 896 9239 11790 8 14 8 112 896 9865 12580

conditions, then figure a load estimate specifically for your job. 8 16 8 128 1024 9341 11790

a) Specific heat of product is 0.45 8 16 8 128 1024 10039 12660 a) Specific heat of product is 0.45 8 16 8 128 1024 10720 13500

a) Specific heat of product is 0.45

Here are three suggestions to help you get an accurate load 8 18 8 144 1152 10065 12580

BTU per pound 8 18 8 144 1152 10818 13510 BTU per pound 8 18 8 144 1152 11553 14410

BTU per pound

b) Product loaded in a 24 hour period 8 20 8 160 1280 12225 14780 b) Product loaded in a 24 hour period b) Product loaded in a 24 hour period

estimate for your application: 8 20 8 160 1280 11402 13800 8 20 8 160 1280 13031 15730

8 22 8 176 1408 12097 14570 c) Freezing point of product is 27° 8 22 8 176 1408 12973 15600 c) Freezing point of product is 27° 8 22 8 176 1408 13830 16600 c) Freezing point of product is 27°

8 24 8 192 1536 12779 15320 d) Reduce product to 0° in 24 hours 8 24 8 192 1536 13708 16400 d) Reduce product to -10° in 24 hours 8 24 8 192 1536 14617 17460 d) Reduce product to -20° in 24 hours

a. You can use the paper and pencil calculation in 8 26 8 208 1664 13451 16060 e) Pounds of +10° product EQUALS 8 26 8 208 1664 14432 17200 e) Pounds of 0° product EQUALS 8 26 8 208 1664 15392 18310 e) Pounds of -10° product EQUALS

Heatcraft Refrigeration Products’ Engineering Manual 8 28 8 224 1792 14115 16800 room volume (cu. ft.) 8 28 8 224 1792 15146 17980 room volume (cu. ft.) 8 28 8 224 1792 16156 19140 room volume (cu. ft.)

8 30 8 240 1920 14770 17520 External Temperatures 8 30 8 240 1920 15851 18760 External Temperatures 8 30 8 240 1920 16912 19970 External Temperatures

(H-ENG-1) 8 32 8 256 2048 16549 19520

8 32 8 256 2048 15417 18240 a) 95° on all four walls a) 95° on all four walls 8 32 8 256 2048 17659 20780 a) 95° on all four walls

b. You can use the box load software, in the Calculation Toolbox 10 10 8 100 800 7980 10310 b) 115° on the ceiling (solar effect) 10 10 8 100 800 8573 11070 b) 115° on the ceiling (solar effect) 10 10 8 100 800 9152 11810 b) 115° on the ceiling (solar effect)

of the Cold Solutions Program provided by a Sales Rep 10 12 8 120 960 8883 11300 c) 55° on the floor 10 12 8 120 960 9543 12130 10 12 8 120 960 10187 12940 c) 55° on the floor

c) 55° on the floor

10 14 8 140 1120 9752 12250 10 14 8 140 1120 10477 13150 10 14 8 140 1120 11185 14020

QUICK CALCULATIONS c. Or you can call your Sales Representative for assistance 10

10

16

18

8

8

160

180

1280

1440

11224

12045

13630

14530

Insulation - 4" Urethane

4" urethane on the walls, ceiling,

and floor with R = 25 and k = 0.16

10

10

16

18

8

8

160

180

1280

1440

12028

12911

14580

15550

Insulation - 4" Urethane

4" urethane on the walls, ceiling,

and floor with R = 25 and k = 0.16

10

10

16

18

8

8

160

180

1280

1440

12815

13758

15520

16550

Insulation - 4" Urethane

4" urethane on the walls, ceiling,

and floor with R = 25 and k = 0.16

Before you do a, b, or c, get this information about your job: 10 20 8 200 1600 12849 15430 10 20 8 200 1600 13775 16500 10 20 8 200 1600 14682 17560

for 1. Room information:

10

10

24

28

8

8

240

280

1920

2240

14413

15931

17170

18860

Infiltration - 2 times Average

a) 95° air enters room through the

10

10

24

28

8

8

240

280

1920

2240

15457

17090

18360

20170

Infiltration - 2 times Average

a) 95° air enters room through the

10

10

24

28

8

8

240

280

1920

2240

16480

18227

19530

21460

Infiltration - 2 times Average

a) 95° air enters room through the

WALK-IN COOLERS •Length, width, and height of the box in feet

•Temperature of the refrigerated room (°F)

12

12

12

14

8

8

144

168

1152

1344

9887

11483

12410

13920

door at 50% relative humidity

b) The door openings cause TWICE

12

12

12

14

8

8

144

168

1152

1344

10621

12305

13310

14890

door at 50% relative humidity

b) The door openings cause TWICE

12

12

12

14

8

8

144

168

1152

1344

11338

13108

14190

15850

door at 50% relative humidity

b) The door openings cause TWICE

the number of air changes listed in the number of air changes listed in

and •Relative humidity in the refrigerated room (if specified)

12

12

16

18

8

8

192

216

1536

1728

12423

13338

14970

15990 ‘AVERAGE AIR CHANGES FOR

12

12

16

18

8

8

192

216

1536

1728

13314

14297

16010

17100

the number of air changes listed in

‘AVERAGE AIR CHANGES FOR

12

12

16

18

8

8

192

216

1536

1728

14185

15236

17030

18180 ‘AVERAGE AIR CHANGES FOR

•Summertime design ambient temperature (°F). This is STORAGE ROOMS’ table 12 20 8 240 1920 15260 18160 STORAGE ROOMS’ table STORAGE ROOMS’ table

FREEZERS usually the temperature expected at the location of an air

12

12

20

22

8

8

240

264

1920

2112

14235

15115

16990

17970 Miscellaneous 12 22 8 264 2112 16206 19220 Miscellaneous

12

12

20

22

8

8

240

264

1920

2112

16246

17274

19300

20430 Miscellaneous

14 14 8 196 1568 12547 15110 a) Lighting - One watt per square 14 14 8 196 1568 13446 16160 a) Lighting - One watt per square 14 14 8 196 1568 14326 17190 a) Lighting - One watt per square

cooled condensing unit which cools the room 14 16 8 224 1792 14554 17390

14 16 8 224 1792 13580 16260 foot of floor area foot of floor area 14 16 8 224 1792 15509 18490 foot of floor area

2. Insulation information: 14 20 8 280 2240 14587 17520 b) ‘People Load’ - charged at 1person 14 20 8 280 2240 16696 19780 b) “People Load - charged at 1person 14 20 8 280 2240 17795 21030 b) “People Load - charged at 1person

•Type of insulation, insulation thickness (inches), and external 14 24 8 336 2688 15574 18750 per 25000 cu. ft. of room volume 14 24 8 336 2688 19202 22530

per 25000 cu. ft. of room volume 14 24 8 336 2688 20441 23920 per 25000 cu. ft. of room volume

16 16 8 256 2048 14704 17530 16 16 8 256 2048 15761 18740 16 16 8 256 2048 16795 19920

temperatures on walls, ceiling, floor c) Motors - charged at 1 HP per c) Motors - charged at 1 HP per c) Motors - charged at 1 HP per

16 20 8 320 2560 17318 20420 16 20 8 320 2560 18533 21790 16 20 8 320 2560 29124 32530

12500 cu. ft. of room volume 12500 cu. ft. of room volume 12500 cu. ft. of room volume

BTUH LOADS for: 3. Infiltration load information:

•The temperature (°F) of the entering air and the relative

16

18

24

18

8

8

384

324

3072

2592

19416

17429

22800

20550

‘Heavy Load’ Conditions:

16

18

24

18

8

8

384

324

3072

2592

20786

18652

24320

21930

‘Heavy Load’ Conditions:

16

18

24

18

8

8

384

324

3072

2592

22129

19850

25820

23270

‘Heavy Load’ Conditions:

Same as ‘Typical’ except: Same as ‘Typical’ except: Same as ‘Typical’ except:

6’ x 6’ to 40’ x 40’ Rooms humidity of the entering air. Also, an estimate of the door

18

18

20

24

8

8

360

432

2880

3456

18592

20863

21870

24460

a) Pounds of product is 3 times cu. ft.

18

18

20

24

8

8

360

432

2880

3456

19900

22336

23330

26090 a) Pounds of product is 3 times cu. ft.

18

18

20

24

8

8

360

432

2880

3456

21182

23781

24760

27680

a) Pounds of product is 3 times cu. ft.

usage - average, heavy, etc. 20 20 8 400 3200 19842 23300

b) People load is 1 person 20 20 8 400 3200 21240 24850 b) People load is 1 person 20 20 8 400 3200 22611 26370

b) People load is 1 person

with 8’ Ceilings •Does the box have glass doors? Dock doors? How many? 20

20

24

28

8

8

480

560

3840

4480

22911

25289

26530

29260

Safety Factor - 10%

10% safety factor is added to the

20

20

24

28

8

8

480

560

3840

4480

24503

27054

28260

31160

Safety Factor - 10%

10% safety factor is added to the

20

20

24

28

8

8

480

560

3840

4480

26066

28788

29950

33030

Safety Factor - 10%

10% safety factor is added to the

4. Product load information:

at -20°F. to +35°F. •What is the product or product mix?

20

20

32

36

8

8

640

720

5120

5760

28058

30347

32380

35020

product, transmission, infiltration,

and miscellaneous loads described

20

20

32

36

8

8

640

720

5120

5760

29993

32449

34450

37260

product, transmission, infiltration,

and miscellaneous loads described

20

20

32

36

8

8

640

720

5120

5760

31894

34516

36490

39460

product, transmission, infiltration,

and miscellaneous loads described

•How many pounds of product entering at what temperature? 20 40 8 800 6400 33231 38070 above. 20 40 8 800 6400 35515 40470 above. 20 40 8 800 6400 37762 42840 above.

40 24 8 960 7680 37745 43290 Run time - 18 hrs, electric defrost 40 24 8 960 7680 40316 45980 Run time - 18 hrs, electric defrost 40 24 8 960 7680 42487 48270 Run time - 18 hrs, electric defrost

•How long (hours) does it take to load the product into room?

Based on 95°F. Ambient •How quickly (hours) should the room pull the product down

40

40

28

32

8

8

1120

1280

8960

10240

42361

46722

48420

53490

18 hour condensing unit run time.

The BTU load for 24 hours is

40

40

28

32

8

8

1120

1280

8960

10240

45232

49870

51390

56730

18 hour condensing unit run time.

The BTU load for 24 hours is

40

40

28

32

8

8

1120

1280

8960

10240

48059

52973

54320

59940

18 hour condensing unit run time.

The BTU load for 24 hours is

to what temperature? 40 36 8 1440 11520 51218 58500 divided by 18 to yield the hourly 40 36 8 1440 11520 54656 62020

divided by 18 to yield the hourly 40 36 8 1440 11520 58047 65490 divided by 18 to yield the hourly

40 40 8 1600 12800 55479 63460 40 40 8 1600 12800 59186 67250 40 40 8 1600 12800 62848 71000

•How many pounds of fruit and vegetables are in the room? heat load reported in this table. heat load reported in this table. heat load reported in this table.

(respiration load)

5. Miscellaneous loads information:

•How many people work in the room?

QUICK CALCULATIONS for QUICK CALCULATIONS for QUICK CALCULATIONS for

•What is the lighting (watts)? FREEZERS FREEZERS FREEZERS

© 2003, Heatcraft Refrigeration Products LLC •How many motors (HP) do work in the room?

HEAT EQUIVALENT HEAT EQUIVALENT AVERAGE AIR CHANGES

DIMENSIONS ROOM ROOM BTUH BTUH 30°F. ROOM DIMENSIONS ROOM ROOM BTUH BTUH 35°F. ROOM

-10°F. to 0°F. Reach-Ins 35°F. to 40°F. Reach-Ins EQUATION (FEET) AREA VOLUME TYPICAL HEAVY (add 15% to loads for 10' height) (FEET) AREA VOLUME TYPICAL HEAVY

(add 15% to loads for 10' height)

W L H SQ. FT. CU. FT LOAD LOAD W L H SQ. FT. CU. FT. LOAD LOAD

in BTUH per HP of Electric of Occupancy for Storage Rooms due to for 6 6 8 36 288 3483 5190 Typical Load Conditions: 6 6 8 36 288 4986 6540

Room Volume Approximate Room Volume Approximate

Motors Openings & Infiltration Door Openings & Infiltration Heat Conduction 6 8 8 48 384 4095 5910 6 8 8 48 384 5884 7470

Typical Load Conditions:

The Cold Solutions Program The Cold Solutions Program

Cubic Feet BTUH Cubic Feet BTUH 6 10 8 60 480 4668 6590 automatically figures typical loads. 6 10 8 60 480 6729 8350

automatically figures typical loads.

Inside Outside Room Heat Equivalent Room Room Room Q Total = U x A x (°F. out - °F. in) 8 8 8 64 512 4812 6760

Here are the “typical” conditions: 8 8 8 64 512 6939 8570

Motor Refrigeration Refrigeration per person Temp. 8 10 8 80 640 5485 7580 8 10 8 80 640 7934 9600

Here are the “typical” conditions:

Volume Temp.

4 - 10 1000 4 - 10 950 - 1150 HP Space Space

Temperature Above 32°F. Below 32°F. 8 12 8 96 768 6126 8360

BTU / 24 Hours Cu. Ft. Legend: Product - In at +10°

8 12 8 96 768 8887 10590

Product - In at 40°

8 14 8 112 896 6744 9120 8 14 8 112 896 9808 11550

11 - 18 1350 11 - 18 1100 - 1300 200 44.0 33.5 “Q Total” is total heat transfer in BTU a) Specific heat of product is 0.90 a) Specific heat of product is 0.90

1/8 to 1/2 4250 2545 50°F. 17280 8 16 8 128 1024 7343 9860

BTU per pound

8 16 8 128 1024 10626 12410

BTU per pound

19 - 35 1900 19 - 28 2100 250 38.0 29.0 per hour (BTUH) 8 18 8 144 1152 7927 10580 8 18 8 144 1152 11581 13410

1/2 to 3 3700 2545 40°F. 20160 300 34.5 26.2 “U” is coefficient of heat transfer in 8 20 8 160 1280 9078 11740 b) Product loaded in a 24 hour period 8 20 8 160 1280 12588 14310

b) Product loaded in a 24 hour period

c) Freezing point of product is 27°

3 to 20 2950 2545 30°F. 22800 400 29.5 22.5 BTU / (hour x sq. ft. x °F.) 8 22 8 176 1408 9639 12440 c) Freezing point of product is 27° 8 22 8 176 1408 13434 15190

d) Reduce product to 35° in 24 hours.

500 26.0 20.0 8 24 8 192 1536 10192 13130 d) Reduce product to 30° in 24 hours 8 24 8 192 1536 14267 16060

“x” is the symbol for multiply

36 - 55 2900 29 - 38 2600 Use “motor inside” when BOTH 20°F. 25200 600 23.0 18.0 8 26 8 208 1664 10736 13820 e) Pounds of +40° product EQUALS 8 26 8 208 1664 15585 17420

e) Pounds of 40° product entering the

800 20.0 15.3 “A” is area in square feet room is two times room cu. ft.

56 - 75 4200 39 - 68 3500 the motor and the work done 10°F. 28800 1000 17.5 13.5 “(°F. out - °F. in)” is the temperature on

8 28 8 224 1792 11273 14490 room volume (cu. ft.) 8 28 8 224 1792 16398 18270

External Temperatures

8 30 8 240 1920 11804 15170 External Temperatures 8 30 8 240 1920 17203 19120

by the motor are inside the 0°F. 31200 a) 95° on all four walls,

76 - 100 5500 69 - 100 5700 1500 14.0 11.0 the outside less the temperature 8 32 8 256 2048 12330 15830 a) 95° on all four walls 8 32 8 256 2048 18001 19960

b) 115° on the ceiling (solar effect)

refrigerated room. -10°F. 33600 2000 12.0 9.3 on the inside of the insulation 10 10 8 100 800 6252 8520 b) 115° on the ceiling (solar effect) 10 10 8 100 800 9072 10790

3000 9.5 7.4 c) 55° on the floor

10 12 8 120 960 6984 9430 c) 55° on the floor 10 12 8 120 960 10164 11930

4000 8.2 6.3 Insulation - 4" Styrofoam

Use “motor outside” when the If occupancy is unknown U = 1 divided by R 10 14 8 140 1120 7691 10310 Insulation - 4" Urethane 10 14 8 140 1120 11221 13040

a) 4" Styrofoam on the wall & ceiling,

Based on a minimum 1-1/2 inch Based on a minimum 1 inch 5000 7.2 5.6 10 16 8 160 1280 8956 11610

work done by the motor is allow one person per 24 U = k x (insulation thickness) 4" urethane on the walls, ceiling, 10 16 8 160 1280 12398 14120

with R = 16.7 and k = 0.24

urethane foam insulated fixture, urethane foam insulated fixture, 6000 6.5 5.0 10 18 8 180 1440 9626 12460 10 18 8 180 1440 13406 15170

inside the refrigerated room, hours for each 25,000 cubic 8000 5.5 4.3 k = (insulation thickness) / R and floor with R = 25 and k = 0.16 b) 6” concrete on the floor,

18 hours per day compressor 16 hours per day compressor 10 20 8 200 1600 10282 13290 10 20 8 200 1600 14890 16710

but the motor is outside of the 10000 4.9 3.8 Infiltration - 2 times Average with R = 4.8 and k = 1.25

run time. run time. feet of space. Insulation thickness is inches. 10 24 8 240 1920 11560 14920 10 24 8 240 1920 16823 18740

refrigerated room. 15000 3.9 3.0 a) 95° air enters room through the Infiltration - 2 times Average

10 28 8 280 2240 12804 16520 10 28 8 280 2240 18709 20720

door at 50% relative humidity a) 95° air enters room through the

12 12 8 144 1152 7805 10460 12 12 8 144 1152 11391 13220

b) The door openings cause TWICE door at 50% relative humidity

12 14 8 168 1344 9177 11910 12 14 8 168 1344 12728 14470

the number of air changes listed in b) The door openings cause TWICE

12 16 8 192 1536 9948 12890 12 16 8 192 1536 13887 15680

REACH-IN GLASS DOOR LOADS ‘AVERAGE AIR CHANGES FOR the number of air changes listed in

Electrical Formulas 12 18 8 216 1728 10700 13850

STORAGE ROOMS’ table

12 18 8 216 1728 15518 17370

‘AVERAGE AIR CHANGES FOR

LIGHTS Room BTUH

12 20 8 240 1920 11438 14800 12 20 8 240 1920 16633 18550

STORAGE ROOMS’ table.

(Heaters, Resistive Loads) 12 22 8 264 2112 12164 15740 Miscellaneous 12 22 8 264 2112 17732 19710

Miscellaneous

Typically 1 to 1-1/2 watts per square foot. Cutting or storage rooms Temperature per Door Glass door loads have been 14 14 8 196 1568 10054 13030 a) Lighting - One watt per square 14 14 8 196 1568 14046 15850

a) Lighting - One watt per square

can be double the storage figure. adjusted for run time load. 14 16 8 224 1792 10907 14130 foot of floor area 14 16 8 224 1792 15828 17700

foot of floor area

Single Phase Loads: 35°F. 1060 14 20 8 280 2240 12560 16270 b) ‘People Load’ - charged at 1person 14 20 8 280 2240 18329 20340

b) “People Load - charged at 1 person

Watts = Amps times Volts [P = I x E] 30°F. 960 Multiply number of doors by

14 24 8 336 2688 14597 18800 per 25000 cu. ft. of room volume 14 24 8 336 2688 20756 22910

per 25000 cu. ft. of room volume

Each watt is multiplied by 3.42 BTU per watt to get BTUH and then 16 16 8 256 2048 11842 15340 16 16 8 256 2048 17240 19200

Amps = Watts divided by Volts [I = P / E] multiplied by 24 to get the daily load. 0°F. 1730 the door load listed and add to c) Motors - charged at 1 HP per c) Motors - charged at 1 HP per

16 20 8 320 2560 14093 18160 16 20 8 320 2560 19987 22100

-10°F. 1730 12500 cu. ft. of room volume 16000 cu. ft. of room volume

Volts = Amps divided by Watts [E = P / I] hourly heat load in the tables. 16 24 8 384 3072 15846 20480 16 24 8 384 3072 22656 24930

‘Heavy Load’ Conditions: ‘Heavy Load’ Conditions:

-20°F. 1730 18 18 8 324 2592 14189 18290 18 18 8 324 2592 20132 22260

Same as ‘Typical’ except: Same as ‘Typical’ except:

18 20 8 360 2880 15164 19580 18 20 8 360 2880 21615 23830

a) Pounds of product is 3 times cu. ft. a) Pounds of product is 3 times cu. ft.

Three Phase Loads: (where the loads on each phase are equal) 18 24 8 432 3456 17071 22120 18 24 8 432 3456 25018 27410

b) People load is 1 person

20 20 8 400 3200 16216 20990

b) People load is 1 person

20 20 8 400 3200 23713 26030

Watts = 1.732 times Amps times Volts [P = 1.732 x I x E] HEAT GAIN For the heat gain from lift trucks Safety Factor - 10% Safety Factor - 10%

MEAT CUTTING / PREP ROOM 20 24 8 480 3840 18854 24190 20 24 8 480 3840 27005 29370

Amps = Watts divided by Volts [I = P / (1.732 x E)] for battery operated with internal combustion engines, 20 28 8 560 4480 22108 28150 10% safety factor is added to the 10% safety factor is added to the

20 28 8 560 4480 30084 32650

Volts = Amps divided by Watts (E = P / (1.732 x I)] derive the equivalent HP by product, transmission, infiltration, product, transmission, infiltration,

lift trucks Floor BTUH Meat/Prep. Room loads based on 20 32 8 640 5120 23277 30020 20 32 8 640 5120 33608 36370

and miscellaneous loads described

multiplying engine HP by daily per Square Feet of Floor 20 36 8 720 5760 25219 32670 and miscellaneous loads described

(typically 4 - 5 equivalent HP) hours of operation and dividing by Square continuous operation and include

20 36 8 720 5760 36595 39550

above.

Feet 20 40 8 800 6400 27714 35730 above. 20 40 8 800 6400 40190 43200

24 (typically 4 - 5 equivalent HP). 55°F. 50°F. allowances for average number of 40 24 8 960 7680 31681 41100 Run time - 18 hrs, electric defrost 40 24 8 960 7680 45633 49040

Run time - 16 hrs., air defrost

Battery Heat gain Approx. personnel, processing equipment, 16 hour condensing unit run time.

operated per hour total Multiply the equiv. HP by 75000 100 93 105 40 28 8 1120 8960 35721 46410 18 hour condensing unit run time. 40 28 8 1120 8960 51628 55280

etc., with glass panel in one wall The BTU load for 24 hours is

load of lift truck weight for the additional BTU/day. 200 88 99 40 32 8 1280 10240 39570 51670 The BTU load for 24 hours is 40 32 8 1280 10240 57408 61460

and walls and ceilings insulated divided by 16 to yield the hourly

capacity, operation, of lift truck, 300 85 95 40 36 8 1440 11520 43516 56880 divided by 18 to yield the hourly 40 36 8 1440 11520 63278 67580

with 3 inches of styrene with box heat load reported in this table.

POUNDS BTUH POUNDS If motor or loading conditions are 400 81 90 40 40 8 1600 12800 47289 62060 heat load reported in this table. 40 40 8 1600 12800 68954 73650

Heatcraft Refrigeration Products LLC not known then calculate one 500 78 87 located in air conditioned area.

2175 West Park Place Boulevard • Stone Mountain, GA 30087 USA motor HP for each 16000 cu. ft. in 600 75 85 Evaporator should be low outlet

2000 14000 6000

770-465-5600 • Fax: 770-465-5990 700 72 81 velocity type to avoid drafts and

a storage cooler and 12500 cu. ft.

www.heatcraftrpd.com

4000 21000 8000

in a storage freezer. Loading

800 69 78

should be selected for continuous QUICK CALCULATIONS for QUICK CALCULATIONS for

6000 23000 12000 900 67 75

docks and high distribution operation and not less than 30°F.

8000 26000 14000

warehouses are heavier.

1000

1200

65

62

73

69 evaporator temperature. COOLERS COOLERS

You might also like

- MEM554 - Thermalfluids Lab Computer Linked RefrigerationDocument25 pagesMEM554 - Thermalfluids Lab Computer Linked Refrigerationsayabudakcomey75% (12)

- Kitchen Ventilation (DW172)Document6 pagesKitchen Ventilation (DW172)Vishal Mohite100% (2)

- Midea SERVICE MANUAL PDFDocument44 pagesMidea SERVICE MANUAL PDFAhmed Azad67% (3)

- Carrier Cold Room Calculaton PDFDocument28 pagesCarrier Cold Room Calculaton PDFMohammad Amer93% (61)

- Welcome To The PMG Educational Program: Sponsored byDocument51 pagesWelcome To The PMG Educational Program: Sponsored byRAMESHNo ratings yet

- Chapter 7 Cycle Diagrams and The Simple Saturated Cycle - Page117Document18 pagesChapter 7 Cycle Diagrams and The Simple Saturated Cycle - Page117Ahmed AzadNo ratings yet

- Searle Engineers HandbookDocument31 pagesSearle Engineers HandbookDavidB1206No ratings yet

- 3 Thermal LoadsDocument19 pages3 Thermal LoadsJaime Fernando Leon TerrazosNo ratings yet

- Glass Unit V Air-Conditioning Load CalculationDocument26 pagesGlass Unit V Air-Conditioning Load CalculationASWIN KUMAR N SNo ratings yet

- Fcsi Quiz - Halton Hood LoadDocument19 pagesFcsi Quiz - Halton Hood LoadblindjaxxNo ratings yet

- 3 Thermal LoadsDocument19 pages3 Thermal LoadsLaUpa Ricra PaUlNo ratings yet

- SCE Research Paper PDFDocument12 pagesSCE Research Paper PDFmuoi2002No ratings yet

- Je Professional InstituteDocument126 pagesJe Professional InstituterihanNo ratings yet

- Cooling Load Estimation For Hibir BoatDocument10 pagesCooling Load Estimation For Hibir BoatAdi WahyudiNo ratings yet

- Air-Conditioning Load EstimationDocument23 pagesAir-Conditioning Load Estimationtkm2004No ratings yet

- The Residential HVAC Design ProcessDocument131 pagesThe Residential HVAC Design Processmarjan 01100% (3)

- 4 Load EstimationDocument175 pages4 Load Estimationhasan bishNo ratings yet

- HVAC Basics - ADocument39 pagesHVAC Basics - AAbhik Bhattacharjee100% (1)

- Efficient Display Case Refrigeration: Practical GuideDocument7 pagesEfficient Display Case Refrigeration: Practical GuideCyduck GuevarraNo ratings yet

- The Basics of Heating, Ventilation and Air ConditioningDocument96 pagesThe Basics of Heating, Ventilation and Air Conditioningsakshi1405No ratings yet

- Heat Gain Due To InfiltrationDocument18 pagesHeat Gain Due To InfiltrationNg Swee Loong Steven100% (2)

- 346N No06 HVAC Cooling LoadDocument33 pages346N No06 HVAC Cooling LoadmartinqNo ratings yet

- Lecture 6 - Air Conditioning Princples & SyatemsDocument12 pagesLecture 6 - Air Conditioning Princples & SyatemsMuhammad Faiz bin Ahmad ShafiNo ratings yet

- Cooling Load Calculation FormulaDocument2 pagesCooling Load Calculation FormulaYamte VawaNo ratings yet

- A Simple Technique For Refrigerant Mass MeasurementDocument11 pagesA Simple Technique For Refrigerant Mass MeasurementDaniel WeeksNo ratings yet

- Marine AC CalculationDocument10 pagesMarine AC CalculationPratikno SajaNo ratings yet

- Low Cost Temperature & Humidity Chamber: Open Access Case StudyDocument9 pagesLow Cost Temperature & Humidity Chamber: Open Access Case StudyAlejandro Renato Rengifo LedesmaNo ratings yet

- Square Foot "Rule of Thumb":: How To Estimate A Cooling Load (And Maybe Heating Load)Document7 pagesSquare Foot "Rule of Thumb":: How To Estimate A Cooling Load (And Maybe Heating Load)Arturo Del-RioNo ratings yet

- MethodologyDocument3 pagesMethodology무제untitledNo ratings yet

- Revised Heat Gain Rates From Typical Commercial Cooking Appliances From RPDocument36 pagesRevised Heat Gain Rates From Typical Commercial Cooking Appliances From RPReza KhajeNo ratings yet

- Potato Cold Storage Load CalculationsDocument3 pagesPotato Cold Storage Load CalculationsSamiYousif100% (1)

- DR ApichitDocument139 pagesDR ApichitMuh. Yousuf KhanNo ratings yet

- HVAC Thermal Load EstimatingDocument28 pagesHVAC Thermal Load EstimatingIntisar Ali SajjadNo ratings yet

- Air Cond Load EstDocument28 pagesAir Cond Load Estari_aristaNo ratings yet

- Cooling Load and Heating Load PrincipleDocument18 pagesCooling Load and Heating Load PrincipleSaif AliNo ratings yet

- Practice PE Exam: HVAC Breadth and DepthDocument3 pagesPractice PE Exam: HVAC Breadth and DepthAhmed EbrahimNo ratings yet

- HVACDocument27 pagesHVACajuhaseenNo ratings yet

- Refrigeration and Air ConditioningDocument1 pageRefrigeration and Air Conditioningnavalzero910No ratings yet

- Cooling Load CalculationDocument14 pagesCooling Load CalculationVũ Hằng PhươngNo ratings yet

- Chapter One 1.0 Introdiction History of Air Conditioning SystemDocument79 pagesChapter One 1.0 Introdiction History of Air Conditioning Systemikperha jomafuvweNo ratings yet

- Hvac Load CalculationDocument20 pagesHvac Load CalculationLalit Sisodia75% (4)

- Hvacr 222 AbbieDocument39 pagesHvacr 222 AbbieApril FenolanNo ratings yet

- Design of HVAC SystemsDocument32 pagesDesign of HVAC Systemspriyanthabandara100% (1)

- Basics of Air ConditioningDocument28 pagesBasics of Air ConditioningdavinderNo ratings yet

- Air Change LoadDocument4 pagesAir Change LoadagazamiNo ratings yet

- Presentation 1Document51 pagesPresentation 1Cedrick S TanNo ratings yet

- Phuong Phap Tinh Tai Theo Phan Mem MistralDocument8 pagesPhuong Phap Tinh Tai Theo Phan Mem Mistralntt_121987No ratings yet

- Air Conditioner BasicsDocument18 pagesAir Conditioner BasicsBenjamin YusuphNo ratings yet

- ISO 7547-2004 Ships and Marine Technology - Air-Conditioning and Ventilation of Accommodation Spaces - Design Conditions and Basis of CalculationsDocument11 pagesISO 7547-2004 Ships and Marine Technology - Air-Conditioning and Ventilation of Accommodation Spaces - Design Conditions and Basis of CalculationsBerkNo ratings yet

- Marine Hvac SystemDocument58 pagesMarine Hvac SystemSiti Aishah Hussien100% (3)

- Refrigeration Comp. LinkedDocument6 pagesRefrigeration Comp. LinkedDin TescoNo ratings yet

- Cooling Load Calculation: (Aircon Lab)Document24 pagesCooling Load Calculation: (Aircon Lab)matthew ocampoNo ratings yet

- R&T 2001 - Cold Storage Warehouse Dock Study - JekelDocument12 pagesR&T 2001 - Cold Storage Warehouse Dock Study - JekelPRKrauseNo ratings yet

- RacDocument26 pagesRacgurunakhale123No ratings yet

- Air Systems Air Systems Component Technology Component TechnologyDocument46 pagesAir Systems Air Systems Component Technology Component TechnologyHilario SoriaNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- The Home Owner's Guide to HVAC: The Envelope and Green TechnologiesFrom EverandThe Home Owner's Guide to HVAC: The Envelope and Green TechnologiesNo ratings yet

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManFrom EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNo ratings yet

- Career as an Air Conditioning TechnicanFrom EverandCareer as an Air Conditioning TechnicanRating: 5 out of 5 stars5/5 (2)

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- 121 DC Circuits E104A Course Outline V2Document8 pages121 DC Circuits E104A Course Outline V2Ahmed AzadNo ratings yet

- Mode NG I 111116Document68 pagesMode NG I 111116Ahmed AzadNo ratings yet

- IPM TroubleshootingDocument1 pageIPM TroubleshootingAhmed Azad100% (2)

- Correction of Service Manual Si-18 M-11011Document18 pagesCorrection of Service Manual Si-18 M-11011Ahmed AzadNo ratings yet

- Guide To Good Commercial Refrigeration Practice: Safety & Environmental Considerations & StandardsDocument20 pagesGuide To Good Commercial Refrigeration Practice: Safety & Environmental Considerations & StandardsAhmed AzadNo ratings yet

- Priceguide Section 7 2015Document18 pagesPriceguide Section 7 2015Ahmed AzadNo ratings yet

- Split Air Conditioner TrainerDocument2 pagesSplit Air Conditioner TrainerAhmed AzadNo ratings yet

- Chart Metric Imp ConvDocument1 pageChart Metric Imp ConvAhmed AzadNo ratings yet

- Ben 3proj3 RevDocument6 pagesBen 3proj3 RevAhmed AzadNo ratings yet

- Commercial Dehumidifier ManualDocument10 pagesCommercial Dehumidifier ManualAhmed AzadNo ratings yet

- Flammable Refrigerants SafetyDocument75 pagesFlammable Refrigerants SafetyAhmed AzadNo ratings yet

- Johnson-Controls Informatiebrochure p216 enDocument8 pagesJohnson-Controls Informatiebrochure p216 enAhmed AzadNo ratings yet

- Sound Insulation EngDocument8 pagesSound Insulation EngAhmed AzadNo ratings yet

- Unit 10Document14 pagesUnit 10Ahmed AzadNo ratings yet

- 00Document60 pages00Ahmed AzadNo ratings yet

- Hydraulics TLTDocument55 pagesHydraulics TLTАлександрNo ratings yet

- Manual de AlternadoresDocument55 pagesManual de Alternadoresjosue bladimyrNo ratings yet

- Numerical and Experimental Comparison of A Tandem and Single Vane Deswirler Used in An Aero Engine Centrifugal CompressorDocument10 pagesNumerical and Experimental Comparison of A Tandem and Single Vane Deswirler Used in An Aero Engine Centrifugal CompressorBrahimABDNo ratings yet

- Chapter 1 Introduction To Automation SystemDocument53 pagesChapter 1 Introduction To Automation Systemhashim_mokhtar9286No ratings yet

- OM - Panigale V2 - MY20 - enDocument246 pagesOM - Panigale V2 - MY20 - enNyende DanielNo ratings yet

- Sisto-C: 1. InstallationDocument1 pageSisto-C: 1. InstallationEric LarrondoNo ratings yet

- Unsteady Bernoulli Equation: Advanced Fluid M Ech AnicsDocument13 pagesUnsteady Bernoulli Equation: Advanced Fluid M Ech AnicsThomas SantosaNo ratings yet

- GP170101 Firefighting Equipment PDFDocument26 pagesGP170101 Firefighting Equipment PDFegfernandez21No ratings yet

- Hunger VDS2: Valve Seat Refacing ToolDocument4 pagesHunger VDS2: Valve Seat Refacing ToolOrlando GalvanNo ratings yet

- ABB Softstarter HandbookDocument92 pagesABB Softstarter HandbookAffan ZainunNo ratings yet

- Answers For Module 2 AssignmentDocument3 pagesAnswers For Module 2 AssignmentJusticeMacroNo ratings yet

- Module 7 - Tutorial 1 (Shear Strength) (OK)Document2 pagesModule 7 - Tutorial 1 (Shear Strength) (OK)Asfin HaqueNo ratings yet

- ES 204 Assignment 16-b Solutions (Due 03/02) : One Sided The VideoDocument7 pagesES 204 Assignment 16-b Solutions (Due 03/02) : One Sided The VideoSirilak KlakwongNo ratings yet

- Talal Alanazi, BS, MS, PMP®: Lancaster University - Lancaster, UKDocument2 pagesTalal Alanazi, BS, MS, PMP®: Lancaster University - Lancaster, UKanushNo ratings yet

- Manual HVX - Englisch 2011Document97 pagesManual HVX - Englisch 2011DSNo ratings yet

- Flow Past Sphere Comparision of LBM Vs FVMDocument6 pagesFlow Past Sphere Comparision of LBM Vs FVMsumeet.beaconNo ratings yet

- Lawn Star Spare Parts Manual 2019-11-04Document116 pagesLawn Star Spare Parts Manual 2019-11-04Melvyn GambleNo ratings yet

- Daikin AHU Catalogue (Draft)Document9 pagesDaikin AHU Catalogue (Draft)oleolo ibrahim100% (1)

- Proforma Invoice - Npoly - 24.01.24Document4 pagesProforma Invoice - Npoly - 24.01.24npengineering4No ratings yet

- Air Hybrid Cycle Mod 3Document27 pagesAir Hybrid Cycle Mod 3Parveen Kumar100% (1)

- Recommendations For Cot GrindingDocument6 pagesRecommendations For Cot GrindingSouvik KarmakarNo ratings yet

- Physics PYQs (2017-2021)Document12 pagesPhysics PYQs (2017-2021)bhopalrajak786No ratings yet

- Discover 125 ST 0Document82 pagesDiscover 125 ST 0Samy SaraviaNo ratings yet

- Daikin VRFDocument16 pagesDaikin VRFobNo ratings yet

- Asme b16.20 Spiral Wound Gaskets Technical BulletinDocument4 pagesAsme b16.20 Spiral Wound Gaskets Technical BulletinChristian Lopez Mendez100% (1)

- Rudolf Ortvay Problem Solving Contest in PhysicsDocument8 pagesRudolf Ortvay Problem Solving Contest in PhysicsronsbfrndsNo ratings yet

- Analisa Perbandingan NPHR Saat Mill E: in Service Dan Out ServiceDocument8 pagesAnalisa Perbandingan NPHR Saat Mill E: in Service Dan Out ServiceMuh Aslam NurNo ratings yet

- AGN 017 - Unbalanced Loads: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesDocument9 pagesAGN 017 - Unbalanced Loads: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesJhay Phee LlorenteNo ratings yet

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- Powerboss SW 9xr 9xv Am9d Am9lpg Parts Manual 1Document117 pagesPowerboss SW 9xr 9xv Am9d Am9lpg Parts Manual 1Green DesertNo ratings yet