Professional Documents

Culture Documents

78.operation For Nitrogen Compressor

Uploaded by

TRONGKIMOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

78.operation For Nitrogen Compressor

Uploaded by

TRONGKIMCopyright:

Available Formats

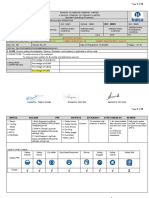

Operation for nitrogen compressor

valAppro

Name Operation for nitrogen compressor Person Team Plant

in charge Leader Manager

No. Date 2019-03-27

Dept. PP Production Team Writer

/ / /

Rev. Date Description

0 2019-03-27 First Issue

In charge

Dept.Agreement

AgreementContents

/ / / / / / /

Distribution

A4 (210 x 297mm) PP PRODUCTION TEAM

Doc. Name Doc. No. Initial Date Revised Date Rev Page

Operation for nitrogen

D-4200-200 2019-03-27 - 0 2/5

compressor

TABLE OF CONTENTS

1. Purpose...............................................................................................................3

2. Equipment Specification....................................................................................3

3. Check List before Operation..............................................................................3

4. Operation sequence............................................................................................3

4.1 Start-up.......................................................................................................3

4.2 Stop............................................................................................................3

5. Maintenance and Inspection...............................................................................4

6. Precautions and safety measures........................................................................4

A4 (210 x 297mm) PP PRODUCTION TEAM

Doc. Name Doc. No. Initial Date Revised Date Rev Page

Operation for nitrogen

D-4200-200 2019-03-27 - 0 3/5

compressor

1. Purpose

This procedure is aimed at Operation for nitrogen compressor

2. Equipment Specification

Fan Motor

Equi

Purpose Capacity Head Speed Power Current Remark

pment No.

m3/h mmH2O RPM kW Ampere

C-4603

3. Check List before Operation

1) Power off C-4603

4. Commissioning sequence

Mechanical check completed

4.1 C-4603 activation

- Put CW in service to E-4611,E-4612

4.2 C-4603 start up

1) Open ①②

2) Recycle N2 by opening ③ PV-46401 at 100%

3) Power on C-4603

- Start C-4603

4) Pressure up by closing ③ PV-46401 slowly, then place in auto mode

5) Open user valve slowly

6) Check noise, Seal leak in C-4603

A4 (210 x 297mm) PP PRODUCTION TEAM

Doc. Name Doc. No. Initial Date Revised Date Rev Page

Operation for nitrogen

D-4200-200 2019-03-27 - 0 4/5

compressor

A4 (210 x 297mm) PP PRODUCTION TEAM

Doc. Name Doc. No. Initial Date Revised Date Rev Page

Operation for nitrogen

D-4200-200 2019-03-27 - 0 5/5

compressor

5. Maintenance and Inspection

1) Bearing temperature shall not exceed 40 ° C above the ambient air temperature.

2) Grease injection to bearing housing should be done once / two months by machinery team.

(Grease injection is performed when an abnormal sound occurs.)

3) Grease injection to motor should be done by instrument/electric team.

4) Inspection shall be carried out once a day and once per month for vibration measurements.

6. Precautions and safety measures

1) When working, be sure to work with two people a set.

2) Every time work is done, it should be contacted by radio and familiar with state of

interworking.

A4 (210 x 297mm) PP PRODUCTION TEAM

You might also like

- 88.normal Operation For PelletizerDocument5 pages88.normal Operation For PelletizerTRONGKIMNo ratings yet

- 101.S-4501 Steamer Cyclone Cleaning ProcedureDocument6 pages101.S-4501 Steamer Cyclone Cleaning ProcedureTRONGKIMNo ratings yet

- CMM 3-1480 (32-45-68) PDFDocument140 pagesCMM 3-1480 (32-45-68) PDFSERGIO ALEJANDRO LEON TORRESNo ratings yet

- MM Pa-23 ApacheDocument582 pagesMM Pa-23 ApacheMaicon FrancaNo ratings yet

- Ohm IpcDocument154 pagesOhm IpcGeMoCon GmbHNo ratings yet

- Calentamientos de Series Escavadoras Series B Sebe6949Document4 pagesCalentamientos de Series Escavadoras Series B Sebe6949Jorge Luis Cervantes CarrilloNo ratings yet

- G3406 Cylinder LinersDocument3 pagesG3406 Cylinder LinersnobodymagdesignNo ratings yet

- Manual de Componente Frenos Lj-25Document156 pagesManual de Componente Frenos Lj-25Oficina TecnicaNo ratings yet

- ARN-P-ES-00-013 Spec For Surface Preparation, Painting & Galvanizing - Rev.1 PDFDocument38 pagesARN-P-ES-00-013 Spec For Surface Preparation, Painting & Galvanizing - Rev.1 PDFaditia nugraha100% (1)

- IDBC-TS-MTTDS-FGR623304 Rev 50 Production Flowline Pig ReceiverDocument18 pagesIDBC-TS-MTTDS-FGR623304 Rev 50 Production Flowline Pig ReceiverTifano KhristiyantoNo ratings yet

- AK0804.815.TSP.000.REV0 BlowerDocument13 pagesAK0804.815.TSP.000.REV0 Blowerwlater06No ratings yet

- Rg-380E/44 H Series Main Aircraft Battery Component Maintenance ManualDocument36 pagesRg-380E/44 H Series Main Aircraft Battery Component Maintenance Manualekonugroho1293No ratings yet

- Sles-p-im-0126m-Injection Trouble Shooting Solution Guide Manual Rev01Document55 pagesSles-p-im-0126m-Injection Trouble Shooting Solution Guide Manual Rev01Jaganathan.SNo ratings yet

- 11Document66 pages11makeencvNo ratings yet

- 3795-210-S20 - C04-0006 R0 Equipment Data Curves For Item No 20-P-223 AB - Flare K.O Drum Pump CommentedDocument2 pages3795-210-S20 - C04-0006 R0 Equipment Data Curves For Item No 20-P-223 AB - Flare K.O Drum Pump CommentedFomaa ElsayedNo ratings yet

- Adjusting Suction Press & Speed C-2650Document12 pagesAdjusting Suction Press & Speed C-2650adi SaputraNo ratings yet

- MEG-PRG-NISSAN-001-100 Rev 001-Automatic Inspection Machine PDFDocument18 pagesMEG-PRG-NISSAN-001-100 Rev 001-Automatic Inspection Machine PDFMerced HernandezNo ratings yet

- Manual de Mantenimieno Del PapyerDocument1,561 pagesManual de Mantenimieno Del PapyerBRAYAN DAVID CHAMBO GONZALEZNo ratings yet

- 22 SOP of Vaccum PullingDocument18 pages22 SOP of Vaccum PullingSiddhant Satpathy100% (1)

- Rec Ncd6e 5640 PDFDocument7 pagesRec Ncd6e 5640 PDFOscar MolinaNo ratings yet

- Provision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) ProjectDocument15 pagesProvision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) Projectmohsin moin100% (1)

- SIL 23701 (International)Document4 pagesSIL 23701 (International)EleazarNo ratings yet

- YET-AGRU-EXE-MEB-000-PCMM-PRC-0008-B Nitrogen (N2) System (Review & Check)Document14 pagesYET-AGRU-EXE-MEB-000-PCMM-PRC-0008-B Nitrogen (N2) System (Review & Check)mohsin moin100% (1)

- YET-AGRU-EXE-MEB-000-PCMM-PRC-0007-A Fuel Gas ProcedureDocument14 pagesYET-AGRU-EXE-MEB-000-PCMM-PRC-0007-A Fuel Gas Proceduremohsin moin100% (1)

- Auxiliary Power Unit Safir 5K/G Mi Manual For The Operation and Technical MaintenanceDocument178 pagesAuxiliary Power Unit Safir 5K/G Mi Manual For The Operation and Technical MaintenanceIvan100% (2)

- Air Cooled Heat Exchangers Design CriteriaDocument17 pagesAir Cooled Heat Exchangers Design CriteriaReza Salimi100% (1)

- Rg-390E/H Series Main Aircraft Battery Component Maintenance ManualDocument36 pagesRg-390E/H Series Main Aircraft Battery Component Maintenance ManualAsahel Hernández Cano100% (1)

- Piping Material Class Specification: Nf3 Plant of BipcDocument55 pagesPiping Material Class Specification: Nf3 Plant of BipcermusatNo ratings yet

- Inspection Program Rev.1Document64 pagesInspection Program Rev.1Jerson serrano100% (1)

- Agco Wheeler 2018Document108 pagesAgco Wheeler 2018Josenaldo Freitas SantosNo ratings yet

- Pa 42 720Document989 pagesPa 42 720Ruth SantanaNo ratings yet

- (GAS TURBINE MS 5001 PA) Volume IDocument159 pages(GAS TURBINE MS 5001 PA) Volume Ihayder ahmed100% (2)

- Enerpac LPHT312: Operation & Maintenance ManualDocument26 pagesEnerpac LPHT312: Operation & Maintenance ManualMohammed Al-BayatiNo ratings yet

- s10332300-3014 - 0 Instrument Air SupplyDocument8 pagess10332300-3014 - 0 Instrument Air Supplyappril26No ratings yet

- 5 DAILY CHECK (DL) Rev. 2Document9 pages5 DAILY CHECK (DL) Rev. 2YERSON MUNARNo ratings yet

- CMM 3-1527 - Main Wheel - (32-45-45) - Cessna 525Document91 pagesCMM 3-1527 - Main Wheel - (32-45-45) - Cessna 525Lucas AlvesNo ratings yet

- DFM S7 Operation Manual V 1.0Document80 pagesDFM S7 Operation Manual V 1.0Brion Bara IndonesiaNo ratings yet

- Pre-Commissioning and Commissioning ProceduresDocument34 pagesPre-Commissioning and Commissioning ProceduresSaheb Yadav100% (1)

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- SM 753-586Document1,013 pagesSM 753-586Victor Ramirez83% (6)

- DGS Replacement Procedure 28KA3122A&BDocument20 pagesDGS Replacement Procedure 28KA3122A&Bofon OML102No ratings yet

- 73 13 00 045Document4 pages73 13 00 045jivomirNo ratings yet

- Fire Proofing Revised Procedure - C02Document47 pagesFire Proofing Revised Procedure - C02wassim nasriNo ratings yet

- 303-14 Electronic Engine Controls - Removal and Installation - Catalyst Monitor SensorDocument4 pages303-14 Electronic Engine Controls - Removal and Installation - Catalyst Monitor SensorCARLOS LIMADANo ratings yet

- UPD-KM-G8-VL-MN-2002 - Installation, Operation and Maintenance Manual Rev.0Document8 pagesUPD-KM-G8-VL-MN-2002 - Installation, Operation and Maintenance Manual Rev.0Sudar MyshaNo ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument10 pagesService Bulletin: Piper Considers Compliance MandatoryJean AbrialNo ratings yet

- PumaDocument4 pagesPumaAriyantoNo ratings yet

- Revision Index Description and / or Revised Sheets: Technical Specification Un - Rio / Atp - Ro 1 of 73 75Document255 pagesRevision Index Description and / or Revised Sheets: Technical Specification Un - Rio / Atp - Ro 1 of 73 75neivaprojetosNo ratings yet

- Recording Parameters C-2650Document13 pagesRecording Parameters C-2650adi SaputraNo ratings yet

- SIPP-VM-CH-71-0301 - IFR - 2 - Dust Suppression System Technical Specification PDFDocument39 pagesSIPP-VM-CH-71-0301 - IFR - 2 - Dust Suppression System Technical Specification PDFoujda1977No ratings yet

- G3406 Piston Cooling TubesDocument2 pagesG3406 Piston Cooling TubesnobodymagdesignNo ratings yet

- IDBC-TS-MRTBA-C00000-42 Rev A TBE For Instrument Air Compressor and Air DryerDocument45 pagesIDBC-TS-MRTBA-C00000-42 Rev A TBE For Instrument Air Compressor and Air DryerAnggun RushNo ratings yet

- PA44 Maintenance Manual 761-664 Rev PR190830 Des 2019Document311 pagesPA44 Maintenance Manual 761-664 Rev PR190830 Des 2019aditya nugrahaNo ratings yet

- Speed Switch 3602043Document154 pagesSpeed Switch 3602043GeMoCon GmbH100% (1)

- PAG PDC MP ARLS SPC 001 Specification For Piping Material Class REV.a IFRDocument15 pagesPAG PDC MP ARLS SPC 001 Specification For Piping Material Class REV.a IFRChieAstutiaribNo ratings yet

- DGS MU 202 - Rev 2Document43 pagesDGS MU 202 - Rev 2JOHN DANIALNo ratings yet

- AMENDMENT01 - GAIL Usar 2022 01 17 05 - 17 - 01Document157 pagesAMENDMENT01 - GAIL Usar 2022 01 17 05 - 17 - 01Debkanta DasNo ratings yet

- Incinerators: SectionDocument18 pagesIncinerators: SectionFRANKLIN REVILLANo ratings yet

- BSI Combustion Chamber LEAP NOV-01-2022Document45 pagesBSI Combustion Chamber LEAP NOV-01-2022Jason LapeNo ratings yet

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantFrom EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryRating: 4 out of 5 stars4/5 (5)

- Cummins - QSB4.5 CM2350Document18 pagesCummins - QSB4.5 CM2350bedoo54100% (2)

- PPR (3-2015) Code 138Document1 pagePPR (3-2015) Code 138hamadaNo ratings yet

- Dodge Charger 69 RT BlueDocument1 pageDodge Charger 69 RT BluekevinNo ratings yet

- Manuals 167d 167da 167ds 167das Switching Valves Instruction Manual Fisher en en 6075304Document12 pagesManuals 167d 167da 167ds 167das Switching Valves Instruction Manual Fisher en en 6075304shb soomroNo ratings yet

- PSV For Testing Calibration Form (Empty)Document1 pagePSV For Testing Calibration Form (Empty)Jorge GarciaNo ratings yet

- GROUND DISTRIBUTION - Honda Civic Hybrid 2005 - SYSTEM WIRING DIAGRAMSDocument9 pagesGROUND DISTRIBUTION - Honda Civic Hybrid 2005 - SYSTEM WIRING DIAGRAMSbazucaNo ratings yet

- 2014 Nissan-Datsun Versa Sedan Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pages2014 Nissan-Datsun Versa Sedan Engine Controls (Powertrain Management) - ALLDATA RepairChino PlagaNo ratings yet

- 4LE2 Parts CatalogDocument45 pages4LE2 Parts CatalogKevin LiuNo ratings yet

- PRECIOXELAG260719Document48 pagesPRECIOXELAG260719Sabrina Valentina SoffiaturoNo ratings yet

- VGRS Actuator MalfunctionDocument3 pagesVGRS Actuator MalfunctionHenry YogaswaraNo ratings yet

- Electrical WiringDocument86 pagesElectrical Wiringche-ahmad-majdi-7191100% (1)

- Loading Equipment For Amsco Evolution™ Steam Sterilizers: ApplicationDocument4 pagesLoading Equipment For Amsco Evolution™ Steam Sterilizers: ApplicationniNo ratings yet

- Manual Do Proprietario NH190Document153 pagesManual Do Proprietario NH190Francisco S. AlmeidaNo ratings yet

- C HZS Maintenance ManualDocument15 pagesC HZS Maintenance ManualTUNAS ADITYA PUTRANo ratings yet

- Parts Bulletin: 4000 Series Long Block-Gas Engine BOM UpdateDocument3 pagesParts Bulletin: 4000 Series Long Block-Gas Engine BOM UpdatebaljeetjatNo ratings yet

- JOT Power Slip LifterDocument2 pagesJOT Power Slip LifterRakefsNo ratings yet

- cbr24 9150Document11 pagescbr24 9150arman esmaeilpoorNo ratings yet

- Ar190078 19Document4 pagesAr190078 19SEMENIUC MIHAELANo ratings yet

- Brochure Turbina Vertical AMPDocument1 pageBrochure Turbina Vertical AMPAmedt García HernándezNo ratings yet

- ZF As Tronic Schematic E PDFDocument2 pagesZF As Tronic Schematic E PDFMuhamedomar Jojo Jojo83% (12)

- D01 - Service Manual - ENG - Vers 2015 01 - KleinDocument152 pagesD01 - Service Manual - ENG - Vers 2015 01 - KleinAaron AndersNo ratings yet

- (175 Ton) Krupp KMK 5175 MetricDocument19 pages(175 Ton) Krupp KMK 5175 Metricjijesh rkNo ratings yet

- A3-Electrical Machines-2-SyllabusDocument3 pagesA3-Electrical Machines-2-SyllabusVinayaniv YanivNo ratings yet

- ClutchesDocument76 pagesClutchesAravind Lakhan90% (10)

- Omega J1065 Brosura Tehnica enDocument2 pagesOmega J1065 Brosura Tehnica enAdrian StiubeNo ratings yet

- Grove RT 9130E PDFDocument356 pagesGrove RT 9130E PDFKrum Kashavarov100% (1)

- Benelli TRK502 Workshop ManualDocument408 pagesBenelli TRK502 Workshop ManualEmiliano Roberto Arocha Corso100% (11)

- Ujian Ogos Bahasa Inggeris Tingkatan 1 KSSMDocument8 pagesUjian Ogos Bahasa Inggeris Tingkatan 1 KSSMlydia lydiaNo ratings yet

- Eumach - Umc - 5 Axis VMC Umc-1000Document16 pagesEumach - Umc - 5 Axis VMC Umc-1000Abhishek VelagaNo ratings yet

- BMW 1 Series - Pdf.asset.1618548287287Document15 pagesBMW 1 Series - Pdf.asset.1618548287287belleNo ratings yet