Professional Documents

Culture Documents

Geo Fabric Tubing Installation Procedure

Uploaded by

MunnazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geo Fabric Tubing Installation Procedure

Uploaded by

MunnazCopyright:

Available Formats

Procedure

Laying out of Geo Fabric Tubing on

Surface of TSF

Document Number: <Document ID>

Status: Draft

Version: 0.1

Effective: 12/02/2020

Review: N/A

Owner: [Operations Superintendent]

Table of Contents

1 Purpose................................................................................................................................2

2 Scope....................................................................................................................................2

3 Meaningful Heading...............................................................Error! Bookmark not defined.

3.1 Heading level 2...................................................................................................................................... 3

3.1.1 Heading level 3........................................................................................................................ 4

3.1.1.1 Heading level 4.................................................................Error! Bookmark not defined.

3.1.1.2 Document Style Names.................................................................................................... 5

4 Graphics..................................................................................Error! Bookmark not defined.

4.1 Tables.................................................................................................... Error! Bookmark not defined.

5 Document Information........................................................................................................8

5.1 Related Documents............................................................................................................................... 8

5.2 Reference Information........................................................................................................................... 8

5.3 Change Information............................................................................................................................... 8

Appendix A - Appendix Title..........................................................Error! Bookmark not defined.

Uncontrolled unless viewed on the intranet

<Site>

Procedure Laying out of Geo Fabric Tubing on Surface of TSF

1 Purpose

To provide a step by step procedure for the installation of the Geo Fabric tubes prior to filling onto the

surface of the Tailings Storage Facility .

To determine risks and controls for all steps of the procedure

2 Scope

Installation of Geofabric tubes on Tailings Dam Surface to meet the design criteria as set out by ATC

Williams

Document No: 115003.14-S01

Number: <Document ID> Status: Draft Effective 05/01/2015

: Page 2 of 8

Owner: [Operations Superintendent] Version: 0.1 N/A

Review:

Uncontrolled unless viewed on the intranet

<Site>

Procedure Laying out of Geo Fabric Tubing on Surface of TSF

Number: <Document ID> Status: Draft Effective 05/01/2015

: Page 3 of 8

Owner: [Operations Superintendent] Version: 0.1 N/A

Review:

Uncontrolled unless viewed on the intranet

<Site>

Procedure Laying out of Geo Fabric Tubing on Surface of TSF

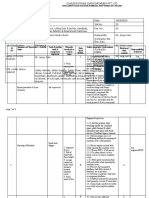

1.1 General Requirements

EQUIPMENT/TOOLS REQUIRED: Possi Track (Jake) Slings 6 * 3m + 1 * 20m

Volvo Loader (Daryll) Shackles * 4 ( 1 tonne)

Tow vehicle rope , star pickets * 12

Ply boards * 20

Supervisor ( Matt) Labourer * 1

QUALIFICATIONS/PRE-REQUISITES: KCE TSF Induction.

Working on TSF familiarisation

Personnel and Equipment Recovery from TSF procedure.

ISOLATION: As per the Mine Site’s Procedures

PERSONAL PROTECTIVE EQUIPMENT: As per the Mine Site Procedure

GENERIC HAZARDS: Slip/Trip/Fall Pinch Points

Lifting and crainage. Manual Handling

Tailings Surface Equipment Damage

3.1.1 Pre – Use Inspection

1.1.1.1

Carry out pre-use inspection on the Equipment not fit for purpose Pre use inspection checklist

mobile equipment being used on safety critical items

Possie must be signed off to

work on dam

Carry out pre-use inspection on the Lifting Equipment fails Check condition for Visible

lifting equipment being used damage.

Dogman to assess suitability

of lifting equipment

Carry Out Pre use inspection of Personnel / equipment Daily pre use dam inspection.

dam surface becomes stuck Use of stabilising boards on

identified areas

Number: <Document ID> Status: Draft Effective 05/01/2015

: Page 4 of 8

Owner: [Operations Superintendent] Version: 0.1 N/A

Review:

Uncontrolled unless viewed on the intranet

<Site>

Procedure Laying out of Geo Fabric Tubing on Surface of TSF

3.1.2 Setting up large Geo fab tube and plastic for install

Layout sandbags Ground condition and stability TSF inspection

Manual Handling Assess lift. Gain assistance

Suspend plastic on A Frame drag Ground condition and stability Pre use working on dam

onto dam in position and pull out to Slip trip fall assessment

position on dam surface Lifting Eyes on path

Not installed to design 2 person lift / assess lift for

Pinch Points correct technique.

Suspended load Install survey offset pegs for

positioning of plastic and

geotube.

No go zones

Pin plastic liner with sandbags Manual handling Position pallet of bags

adjacent to edge of plastic

liner to limit lifting

requirement.

Use correct lifting technique

Set up Possi on dam surface Ground condition and Trial traffic ability of possi

stability pre task .Use stability

boards in identified areas..

Use possi in straight pull

and avoid slewing

Suspend the large geotube on Ground condition and Flat level area for set up

spreader bar attached to loader stability has been identified.

Pinch points Gloves ,

Suspended loads No go zones

Connect bridle to possi for pulling of Interaction with personnel Isolation No go zones

tube. LTA attachment point Trained dogman to assess

HOLD POINT Review set up with relevant

Co- ordinator

Number: <Document ID> Status: Draft Effective 05/01/2015

: Page 5 of 8

Owner: [Operations Superintendent] Version: 0.1 N/A

Review:

Uncontrolled unless viewed on the intranet

<Site>

Procedure Laying out of Geo Fabric Tubing on Surface of TSF

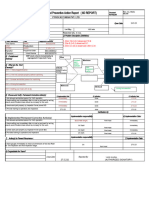

3.1.3 Installation of large Geo fab tube and plastic

Pull out geotube Rope interaction with Establish No go zones

Position possi at extremity personnel ( line of fire )

of larger tube position on Dam stability Continually assess

stability boards LTA lifting towing Dogman to assess ( Daryl

Attach rope to geotube equipment / attachment Hogan)

bridle and run through points

snatch block attached to Geo tube final position ATC Williams Design

possi and back to tow does not meet design Survey offsets installed

vehicle on roadway requirements Monitor position continually

Pull out geotube Geo tube / plastic is blown Use sandbags to hold

away geotube and plastic in

position.

Number: <Document ID> Status: Draft Effective 05/01/2015

: Page 6 of 8

Owner: [Operations Superintendent] Version: 0.1 N/A

Review:

Uncontrolled unless viewed on the intranet

<Site>

Procedure Laying out of Geo Fabric Tubing on Surface of TSF

3.1.4 Installation of small Geo fab tube and plastic

Position possi track on stabilising Ground condition and stability Pre use working on dam

boards Slip trip fall assessment

Suspend plastic on axle Lifting Use stabilising boards as

Not installed to design identified

Pull plastic into position

Pinch Points Eyes on path

Suspended load 2 person lift / assess lift for

correct technique.

Install survey offset pegs for

positioning of plastic and

geotube.

No go zones

Suspend geotube on axle Ground condition and stability Pre task dam inspection

Pinch points Gloves

Pull geotube into position

Does not meet design ITP sign off

Allow 3mt overlap to existing rolled

out tube

Repeat process for 2nd and third roll

Number: <Document ID> Status: Draft Effective 05/01/2015

: Page 7 of 8

Owner: [Operations Superintendent] Version: 0.1 N/A

Review:

Uncontrolled unless viewed on the intranet

<Site>

Procedure Laying out of Geo Fabric Tubing on Surface of TSF

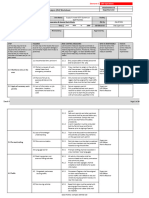

3 Document Information

Related documents and reference information in this section provides a single reference point to

develop and maintain site compliance information.

1.1 Related Documents

Related documents, listed in Table 3 -1 below, are internal documents directly related to or referenced

from this document.

Number Title

Document No:

115003.14- Fly Ash Trial Tender Specification and Scope of Works

S01

SWMS Fly Ash Geotube installation. ( Keller)

BBRA – Fly Ash Application trial.

Table 3- 1 – Related documents

3.1 Reference Information

Reference information, listed in Table 3 -2 below, is external information that is directly related to the

development of this document or referenced from within this document.

Reference Title

Table 3-2 – Reference information

3.2 Change Information

Full details of the document history are recorded in the document control register, by version. A

summary of the current change is provided in Error: Reference source not found below. Example

detail shown below.

Version Date Change Summary

1.0 14/02/2020

Number: <Document ID> Status: Draft Effective 05/01/2015

: Page 8 of 8

Owner: [Operations Superintendent] Version: 0.1 N/A

Review:

Uncontrolled unless viewed on the intranet

You might also like

- Unloading & Transporting Part & Machinery From LCTDocument7 pagesUnloading & Transporting Part & Machinery From LCTkurniarung oceandaNo ratings yet

- 001 - ITP Clearing - Revision 0Document3 pages001 - ITP Clearing - Revision 0randyNo ratings yet

- MS For PEB Erection R1Document16 pagesMS For PEB Erection R1Gabriel GabeNo ratings yet

- Mohamad FadliDocument6 pagesMohamad Fadlishamierrul shahliNo ratings yet

- 10.26.2020 20-029 Drilling Activity Using Drill MachineDocument4 pages10.26.2020 20-029 Drilling Activity Using Drill MachinePangky AbasoloNo ratings yet

- 10.11.20 - Fadak Safety Observation Report - Layla 380kV & 132kV OHTL ProjectDocument6 pages10.11.20 - Fadak Safety Observation Report - Layla 380kV & 132kV OHTL ProjecthassanNo ratings yet

- Hot Work Lifting Shifting and Unloading WorkDocument4 pagesHot Work Lifting Shifting and Unloading WorkAbhijit ParasharNo ratings yet

- JSA For Filter Cleaning by Steam and Water ManuallyDocument22 pagesJSA For Filter Cleaning by Steam and Water ManuallyThái Đạo Phạm LêNo ratings yet

- Submitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Document2 pagesSubmitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Ihwan AsrulNo ratings yet

- L02-02 Lifting Plan (Non Crane)Document2 pagesL02-02 Lifting Plan (Non Crane)Fabio CastroNo ratings yet

- DESCON HSE Report FormatDocument66 pagesDESCON HSE Report FormatMustafa Ricky Pramana Se100% (1)

- 10.HEMP - Mechanical Caliper CheckingDocument2 pages10.HEMP - Mechanical Caliper CheckingSuhaimi ZamzarinaNo ratings yet

- SPNZ Permit To Work ProcedureDocument31 pagesSPNZ Permit To Work ProcedureWale OyeludeNo ratings yet

- 0002 Rev 00 Jsa TR Seg Piping ErectionDocument11 pages0002 Rev 00 Jsa TR Seg Piping ErectionJayvee Baradas ValdezNo ratings yet

- PTW For DAM AreaDocument2 pagesPTW For DAM AreaAmigoz PearlNo ratings yet

- Block Work (Unit Masonary) RISK ASSESSMENTDocument8 pagesBlock Work (Unit Masonary) RISK ASSESSMENTVimal ViswanathNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 004 - ITP Asphalt - Revision 0Document5 pages004 - ITP Asphalt - Revision 0randyNo ratings yet

- PS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)Document27 pagesPS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)RABIE EL MAGHWRY ABDELKHALEK ELGHAMRY0% (1)

- 8D REPORT FOR GEAR STARTER CLUTCH BURR ISSUEDocument3 pages8D REPORT FOR GEAR STARTER CLUTCH BURR ISSUEParthiban DNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- JSA Contruction of Pipe Rack (3m) Footing Including Welding JobDocument10 pagesJSA Contruction of Pipe Rack (3m) Footing Including Welding Jobnoahlungu96No ratings yet

- SOP - 03 - Job Execution Procedure - Rev02Document9 pagesSOP - 03 - Job Execution Procedure - Rev02HasnainNo ratings yet

- Manual Loading of Chrome Ore Into Trucks- 019[1]Document8 pagesManual Loading of Chrome Ore Into Trucks- 019[1]syed aquibNo ratings yet

- JH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistDocument3 pagesJH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistYoung Lin SaengNo ratings yet

- Tsa-001 - Rev 0 - ExcavationDocument2 pagesTsa-001 - Rev 0 - ExcavationMusadiq HussainNo ratings yet

- Doha Metro Project Asset Fault/Defect ReportDocument3 pagesDoha Metro Project Asset Fault/Defect ReportfayasibrahimkuttyNo ratings yet

- Water FillingDocument4 pagesWater FillingAgung Juni KurniawanNo ratings yet

- Connect The PLC Control Cable With Air CompressorDocument5 pagesConnect The PLC Control Cable With Air CompressorAmrou Ben RjebNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- Work Instruction Template (Operational)Document5 pagesWork Instruction Template (Operational)haaNo ratings yet

- RA INSTALLATION Electrical PannelDocument7 pagesRA INSTALLATION Electrical PannelAmrou Ben RjebNo ratings yet

- Pipe Lowering JHADocument6 pagesPipe Lowering JHASalam AlkataluniNo ratings yet

- 80T Crane Routine Lifting Paper-1Document10 pages80T Crane Routine Lifting Paper-1shreeambikastore15No ratings yet

- MSP-IFR-2023-0321 incident final report crane tireDocument3 pagesMSP-IFR-2023-0321 incident final report crane tirelukmanNo ratings yet

- SOP for Manual Loading of Ore - 19Document7 pagesSOP for Manual Loading of Ore - 19syed aquibNo ratings yet

- 1017 NCR 225ESP Faults On Surface Layer of The Stack Pedestal Rev01Document4 pages1017 NCR 225ESP Faults On Surface Layer of The Stack Pedestal Rev01Dragoljub ĐorđevićNo ratings yet

- Gangway Air Hose BurstDocument3 pagesGangway Air Hose BurstIhwan AsrulNo ratings yet

- Phase 2 Expansion (Stage 2B - Separation & Processing Unit)Document1 pagePhase 2 Expansion (Stage 2B - Separation & Processing Unit)saravananNo ratings yet

- Taws Recieving SotreDocument5 pagesTaws Recieving SotresahilNo ratings yet

- RAMS Review for Telehandler WorksDocument30 pagesRAMS Review for Telehandler WorksArturNo ratings yet

- 1TB03300 300C04 STC Itp Me 0005Document4 pages1TB03300 300C04 STC Itp Me 0005heerkhanheerkhan435No ratings yet

- Control Plan Ingersol RandDocument2 pagesControl Plan Ingersol Randrgrao85No ratings yet

- NW-DH-QHSE-PTW-F-001 Permit to Work (7)Document2 pagesNW-DH-QHSE-PTW-F-001 Permit to Work (7)Bheramara CCPPNo ratings yet

- Dump Truck, Light Truck Commissioning Checklist: Toka Tindung ProjectDocument2 pagesDump Truck, Light Truck Commissioning Checklist: Toka Tindung Projectfiar malayadiNo ratings yet

- JSA Risk Assessment Form for Pile Cutting JobDocument13 pagesJSA Risk Assessment Form for Pile Cutting JobYusuf HeryanaNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Job Safety Analysis Work SheetDocument10 pagesJob Safety Analysis Work SheetJayvee Baradas ValdezNo ratings yet

- TOG Form 092A - Incident Investigation ReportDocument4 pagesTOG Form 092A - Incident Investigation ReportlinkencielNo ratings yet

- 15) SWP-15 Lifting Equipment, Appliances & GearsDocument8 pages15) SWP-15 Lifting Equipment, Appliances & GearsFIKdtec duplicateNo ratings yet

- Crane Lift RAMsDocument18 pagesCrane Lift RAMsKaren Olivier100% (1)

- 06 GO - NP02 - E1 - 1 GSM Antenna System-63Document29 pages06 GO - NP02 - E1 - 1 GSM Antenna System-63Khải Khà KhàNo ratings yet

- 101.SOP - PSG & BGKR Matting Board & Loading RAMDocument6 pages101.SOP - PSG & BGKR Matting Board & Loading RAMArjuna PetroNo ratings yet

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 pagesJsa-Rp-001 Site Preparation and General Earthworksibaig1970No ratings yet

- UtICO PTWDocument1 pageUtICO PTWsami gorsiNo ratings yet

- Project Project No. Rev No. Itp Description Prepared by DateDocument5 pagesProject Project No. Rev No. Itp Description Prepared by Datehuot phirunNo ratings yet

- GroutingDocument1 pageGroutingAlif Rahmat FebriantoNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- Updated Perth Oct 2018 ABDocument27 pagesUpdated Perth Oct 2018 ABMunnazNo ratings yet

- DP ATCW 2020 - Capping and Rehabilitation of Coal Tailings Storages PDFDocument12 pagesDP ATCW 2020 - Capping and Rehabilitation of Coal Tailings Storages PDFMunnazNo ratings yet

- IncidentsDocument18 pagesIncidentsMunnazNo ratings yet

- Effects of Void Red Om Liquefaction PDFDocument449 pagesEffects of Void Red Om Liquefaction PDFJose Antonio Palacios GuevaraNo ratings yet

- DP ATCW 2020 - Capping and Rehabilitation of Coal Tailings Storages PDFDocument12 pagesDP ATCW 2020 - Capping and Rehabilitation of Coal Tailings Storages PDFMunnazNo ratings yet

- Paper 2 - Conference PDFDocument8 pagesPaper 2 - Conference PDFMunnazNo ratings yet

- Paper 10 - Case Studies PDFDocument21 pagesPaper 10 - Case Studies PDFMunnazNo ratings yet

- Rum Jungle Rehab Proj Verhoevan 1988 PDFDocument36 pagesRum Jungle Rehab Proj Verhoevan 1988 PDFMunnazNo ratings yet

- Martin Et Al (2002) - Stability Analysis of Upstream Tailings Dams PDFDocument17 pagesMartin Et Al (2002) - Stability Analysis of Upstream Tailings Dams PDFMunnazNo ratings yet

- Rum Jungle Project PDFDocument15 pagesRum Jungle Project PDFMunnazNo ratings yet

- Thumb RuleDocument13 pagesThumb RuleAtiqur RahmanNo ratings yet

- Paperpdf 1365 EggDocument11 pagesPaperpdf 1365 EggMunnazNo ratings yet

- Paper 8 - AG PDFDocument10 pagesPaper 8 - AG PDFMunnazNo ratings yet

- Aboriginal Land Rights Report on Finniss River ClaimDocument116 pagesAboriginal Land Rights Report on Finniss River ClaimMunnazNo ratings yet

- Chapter 3B - Bearing CapacityDocument21 pagesChapter 3B - Bearing CapacitySnow YoshimaNo ratings yet

- Raj 2015 - Bearing Capacity of Shallow Foundation On Slope - A ReviewDocument16 pagesRaj 2015 - Bearing Capacity of Shallow Foundation On Slope - A ReviewMunnazNo ratings yet

- Standards Australia soil classification guideDocument1 pageStandards Australia soil classification guideMunnazNo ratings yet

- Design of Burried Pipe Design PDFDocument4 pagesDesign of Burried Pipe Design PDFVardhanNo ratings yet

- Global Bauxite WG Report CCC 4-InF.10-AnnexesDocument168 pagesGlobal Bauxite WG Report CCC 4-InF.10-AnnexesMunnazNo ratings yet

- Meyerhof (1957) - The Ultimate Bearing Capacity of Foundations On Slopes PDFDocument3 pagesMeyerhof (1957) - The Ultimate Bearing Capacity of Foundations On Slopes PDFMunnaz67% (3)

- Petition: Residents of or Within The Vicinity of Lawson Ave, Frankston SouthDocument2 pagesPetition: Residents of or Within The Vicinity of Lawson Ave, Frankston SouthMunnazNo ratings yet

- Fredlunds - Use of Grain-Size DistributionDocument15 pagesFredlunds - Use of Grain-Size DistributionMunnazNo ratings yet

- Dissertation2007 Seyfi PDFDocument50 pagesDissertation2007 Seyfi PDFMunnazNo ratings yet

- As 1289.6.4.2-1998Document13 pagesAs 1289.6.4.2-1998MunnazNo ratings yet

- Laser CommunicationsDocument19 pagesLaser CommunicationsRakeshNo ratings yet

- Park Residence BrochureDocument86 pagesPark Residence Brochureahmed ahmedNo ratings yet

- Field Engineer ResumeDocument3 pagesField Engineer ResumesambhuNo ratings yet

- Physics Cambridge Igcse Year 10 Paper 1Document18 pagesPhysics Cambridge Igcse Year 10 Paper 1Adibah AliasNo ratings yet

- Chapter 10Document9 pagesChapter 10J.K HomerNo ratings yet

- General notes and location planDocument1 pageGeneral notes and location planRamith De SilvaNo ratings yet

- Gorni SFHTHandbookDocument83 pagesGorni SFHTHandbookapi-3762011No ratings yet

- CAA Aircraft Maintenance Licence Exam ApplicationDocument5 pagesCAA Aircraft Maintenance Licence Exam ApplicationAbed Almajeed AlowioiNo ratings yet

- Most Open Valve Concept WWTP EE AnalysisDocument29 pagesMost Open Valve Concept WWTP EE AnalysisRahmi ArslanNo ratings yet

- Abraision ResistanceDocument28 pagesAbraision ResistancekattaaaaNo ratings yet

- P16NF06FP STMicroelectronicsDocument9 pagesP16NF06FP STMicroelectronicsSoniaNo ratings yet

- Study On The Strength of EarthbagsDocument28 pagesStudy On The Strength of EarthbagsZherrinore Rasay100% (1)

- Kleppner (Introduction To Mechanics) (Errata)Document3 pagesKleppner (Introduction To Mechanics) (Errata)almarpa0% (1)

- Chapter 09 Flow Measurement Applications Aps Compatibility ModeDocument12 pagesChapter 09 Flow Measurement Applications Aps Compatibility ModeBig BangNo ratings yet

- NetWare Is A Network Operating System Developed by NovellDocument23 pagesNetWare Is A Network Operating System Developed by NovellIndhukanth PvNo ratings yet

- India Geological India: GovernmentDocument7 pagesIndia Geological India: GovernmentAshish KumarNo ratings yet

- Sand Drag and Mud Bog RulesDocument7 pagesSand Drag and Mud Bog RulesWhitney Michelle BillingNo ratings yet

- The Modular Ratio in Reinforced Concrete Design (Manuscript) - A.KDocument15 pagesThe Modular Ratio in Reinforced Concrete Design (Manuscript) - A.KMohan ManickamNo ratings yet

- SAP HCI DevGuideDocument168 pagesSAP HCI DevGuideSrinivasan SriNo ratings yet

- BPUT Preformulation Studies Chapter 1 SummaryDocument18 pagesBPUT Preformulation Studies Chapter 1 Summarykartik sharmaNo ratings yet

- Business Process Management (BPM)Document14 pagesBusiness Process Management (BPM)zmrman0% (1)

- PHOTO FACT Folder: To OoDocument23 pagesPHOTO FACT Folder: To Oodds94No ratings yet

- Cse3024 Web-Mining Eth 1.1 47 Cse3024 PDFDocument12 pagesCse3024 Web-Mining Eth 1.1 47 Cse3024 PDFAyush SoodNo ratings yet

- Engineering Mechanics concepts in Rectilinear and Curvilinear MotionDocument12 pagesEngineering Mechanics concepts in Rectilinear and Curvilinear MotionMeverlyn RoqueroNo ratings yet

- Dropped ObjectsDocument26 pagesDropped Objectsgunnery0250% (2)

- Lossy Compression and Iterative Reconstruction For Encrypted ImageDocument22 pagesLossy Compression and Iterative Reconstruction For Encrypted ImageVanambhadi DeepuNo ratings yet

- Larsson Quotation Sample Lsh320m-0.4-VvvfDocument7 pagesLarsson Quotation Sample Lsh320m-0.4-VvvfvinayNo ratings yet

- Boq PDFDocument12 pagesBoq PDFChandeshwor Shah0% (1)

- Earth Retaining Structures GuideDocument36 pagesEarth Retaining Structures GuideHarpreet Singh100% (1)

![Manual Loading of Chrome Ore Into Trucks- 019[1]](https://imgv2-2-f.scribdassets.com/img/document/720649999/149x198/0aff8235b0/1712426574?v=1)