Professional Documents

Culture Documents

Ii (Specti I ( (LLTS) A L-Eading NDT: Tndustrial Ser//Ices Cornpany

Uploaded by

আশার আলোOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ii (Specti I ( (LLTS) A L-Eading NDT: Tndustrial Ser//Ices Cornpany

Uploaded by

আশার আলোCopyright:

Available Formats

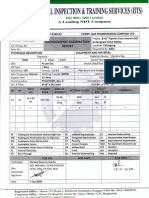

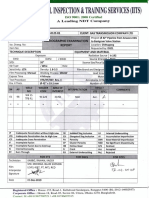

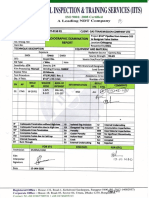

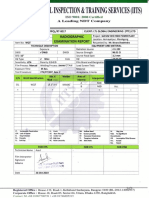

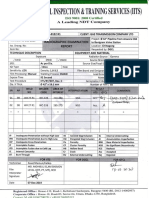

TNDUSTRIAL II{SPECTI()I{ & TRAII{II{G SER\/ICES (llTS)

ISO 900L: 2OO8 Certified

A l-eading NDT CornPanY

REPoRT NO: GTCL/MAPP/S-E/RT-0140 R1 CLIENT: GAS TRANSMISSION COMPANY LTD

Project: O 42" Papeline from Anwora

Test Date: !4-lan-2O20

CGS to Banigram Valve Station

lso. Drawg. No: Location: Chittagong

Item No: Requested by: DGCL

TECHNIQUE DESCRIPTION EQUIPMENT AND MATERIAL

Exposu re Radiation Source Gamma Ray

SWSI V DWSI I DWDI Source Strength 88.93

SFD: As per Dia. Source Size/Focal Spot 312.5 mm

lQlType J wire Hole tQl 06 FE EN

Sensitivitv:S2% Densitv: 1.8-3.5 Film Brand and Designation Fuii , D7

Film Processing: Manual Welding Process:SMAW Lead Screens 0.005" Thick

Expose Time 25 mnts Material API 5L X 70

Test Procedure !!TS/RT/007, Rev. C Acceptance Criteria API STD 1104

Dia. X Thick. O 42" x 19.1 mm Number of Film 01

: ,! I rlll'iri

ri5N! [NNXt$.tX::.... ,,tNsRR*RE[*.Ttii

tdIlFsT,t$ i*...-

.:;G,S(

w#L7

01 97

R1

wc-202 115-130 12" NSD Acc A

IP lnadequate Penetration without High-low rsr lsolated Slag lnclusion IU lnternal Undercutting

IPD lnadequate Penetration due to Hieh-Low ESI Elongated Slag lnclusion AI Accumulation lmperfection

tcP lnadequate Cross Penetration Po Porosity BM! Base Material lmperfection

IF lncomplete Fusion CP Cluster Porosity NSD No Significant Discontinuity

IFD lncomplete Fusion due to Cold Lap HB Hollow Bead R/S Reshoot

tc lnternal Concavitv Cr Crack Acc Accepted

BT Burn Throush EU External Undercutting nej Reiected

FOR DGCL FOR GTCL

Technician Mahadi/Mamun/Kabbo

MD. MOHIBUL ISLAM SHOVON @L

Film LEVEL-il(RT, PT, MT), RCO \'v,a ) >D'.rc

lnterpreter

Signature -*.N2-

Date 15-Jan-20

Registered Office : I{ouse-132, Road-l, I(ellaboncl sardarpara, Rangpur-54oo (BL-2O12-L4OO2937)

Corporate Oflice : Ilouse-18, Road-O3, Sector-O4, lJttata, Dhaka-1230, Bangladesh'

Contact: N{ +88 0196770072l / +8801746695315

You might also like

- Industrial Inspecti N Training (IITS) A L-Eading NDT: CornparryDocument1 pageIndustrial Inspecti N Training (IITS) A L-Eading NDT: Cornparryআশার আলোNo ratings yet

- N (Dustrtal Str//Ices Cornparry: Ri (Specti0I (& (LLTS) A I-Eading NDTDocument1 pageN (Dustrtal Str//Ices Cornparry: Ri (Specti0I (& (LLTS) A I-Eading NDTআশার আলোNo ratings yet

- Industriat Training (IITS) A I-Eading NF) T: Inspection CornparryDocument1 pageIndustriat Training (IITS) A I-Eading NF) T: Inspection Cornparryআশার আলোNo ratings yet

- Ii (Dustrial Training (Iits) A L-Eading NFDLF Cornpany: & SeryicffiDocument1 pageIi (Dustrial Training (Iits) A L-Eading NFDLF Cornpany: & Seryicffiআশার আলোNo ratings yet

- Industrial Training Sir//Ices A L-Eading ND:F: Inspection (Iits) CornpanyDocument1 pageIndustrial Training Sir//Ices A L-Eading ND:F: Inspection (Iits) Cornpanyআশার আলোNo ratings yet

- Ii (Dustrial Inspecti N Training (IITS) A L-Eading NDT: CornparryDocument1 pageIi (Dustrial Inspecti N Training (IITS) A L-Eading NDT: Cornparryআশার আলোNo ratings yet

- LTL 162 MWPP - RT-0017 26-Oct-19Document1 pageLTL 162 MWPP - RT-0017 26-Oct-19Anonymous RKaM4PqDNo ratings yet

- Ii (Specti I (& (LLTS) A F.Eading NDT: Traiim (GDocument1 pageIi (Specti I (& (LLTS) A F.Eading NDT: Traiim (Gআশার আলোNo ratings yet

- Index: Industrial Inspection & Training Services (IITS)Document35 pagesIndex: Industrial Inspection & Training Services (IITS)Md Rahul HossainNo ratings yet

- $ni) ) Ffi: (Liis)Document1 page$ni) ) Ffi: (Liis)আশার আলোNo ratings yet

- Pallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportDocument1 pagePallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportCharles JacobNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Ama Uruk RT FWT 002Document5 pagesAma Uruk RT FWT 002Aws AbduljaleelNo ratings yet

- Radiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0015 Client: Gas Transmission Company LTDDocument1 pageRadiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0015 Client: Gas Transmission Company LTDMd Ashikur RahmanNo ratings yet

- Insptcti0N (LLTS) A I-Eading I/Dt: IrainingDocument1 pageInsptcti0N (LLTS) A I-Eading I/Dt: Irainingআশার আলোNo ratings yet

- RT ReportDocument4 pagesRT ReportWeldcast Ndt100% (1)

- RT ReportDocument1 pageRT ReportAsit Baran KarmakarNo ratings yet

- Ii (Dustrial Inspecti I (A I-Eading NDT CornpanyDocument2 pagesIi (Dustrial Inspecti I (A I-Eading NDT CornpanyasikurNo ratings yet

- Final Insepection Reports and WPS PQRDocument14 pagesFinal Insepection Reports and WPS PQRVikas Verma100% (1)

- Epz NCS RT 02Document1 pageEpz NCS RT 02Mijanur RahmanNo ratings yet

- RT Technique-Report FormatDocument1 pageRT Technique-Report FormatMahesh Pandit100% (1)

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- Kamlesh Kumar Singh Engineers Pvt. LTDDocument24 pagesKamlesh Kumar Singh Engineers Pvt. LTDAADARSHNo ratings yet

- F10 03-H-MergedDocument6 pagesF10 03-H-MergedLokeshNo ratings yet

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- (LRJRL : Sree Sai Not ServicesDocument2 pages(LRJRL : Sree Sai Not ServicesNiranjan KumarNo ratings yet

- Invoice-WPQT Welder PTMDocument5 pagesInvoice-WPQT Welder PTMFerdie OSNo ratings yet

- PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument13 pagesPT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomNo ratings yet

- Hil Renukoot Ut 2022-2023Document249 pagesHil Renukoot Ut 2022-2023duttcon engineeringNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Prosedure WElding Overlay PlateDocument1 pageProsedure WElding Overlay Plateary jordanNo ratings yet

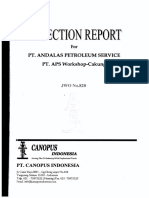

- Canopus: Pt. Andalas Petroleum Service PT. APS Workshop-CakungDocument11 pagesCanopus: Pt. Andalas Petroleum Service PT. APS Workshop-CakungArpan SuyandiNo ratings yet

- A1001 EXE A23003 ELEO Fiche - Technique - 6mm - SolaireDocument1 pageA1001 EXE A23003 ELEO Fiche - Technique - 6mm - Solaireo.sbai.sfecoNo ratings yet

- Kuwait Oil Company (K.S.C.) : Gas Projects ManagementDocument3 pagesKuwait Oil Company (K.S.C.) : Gas Projects ManagementdrkongalaNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Inspection Report SPK 136 Rev.1Document7 pagesInspection Report SPK 136 Rev.1Ageng LaksitoNo ratings yet

- 10th Ep CablesDocument10 pages10th Ep CablesSagar BhaiNo ratings yet

- Example Report TOFD 2 INT-GP1186-09-70 PDFDocument1 pageExample Report TOFD 2 INT-GP1186-09-70 PDFEMTC EMTCNo ratings yet

- Example Report TOFD 2 INT-GP1186!09!70Document1 pageExample Report TOFD 2 INT-GP1186!09!70EMTC EMTC100% (1)

- Genturbo: Hrbs (Amp T Etet)Document5 pagesGenturbo: Hrbs (Amp T Etet)Muhammad Kholis JaimonNo ratings yet

- Temp - Measuring ProbeDocument1 pageTemp - Measuring ProbeSudhan SudhanPowerTechNo ratings yet

- 004 MTDocument1 page004 MTMerdeka RimatuNo ratings yet

- 4 (Nse"r.: MaterialDocument78 pages4 (Nse"r.: MaterialAvishek GuptaNo ratings yet

- Ir Formate of RT Report 2Document1 pageIr Formate of RT Report 2shashi.ndt13No ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- 65-Muffle Furnace Calibration CartificateDocument1 page65-Muffle Furnace Calibration CartificateCustomer SupportNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- CC 12X14 600V RamcroDocument1 pageCC 12X14 600V RamcroOscar NaranjoNo ratings yet

- Zppg-Aico-Sas-Rt-0698 - 21-10-2018 (Pew)Document1 pageZppg-Aico-Sas-Rt-0698 - 21-10-2018 (Pew)Ahmed ThaerNo ratings yet

- Report Blasting PDFDocument22 pagesReport Blasting PDFLord MobileNo ratings yet

- RTCLNT 142111 Wa 44Document1 pageRTCLNT 142111 Wa 44Mitul KapadiaNo ratings yet

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 188Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 188JHONATAN RODRIGUEZ VENTONo ratings yet

- AS-BUILT DRG. - 33KV VCB Panel PDFDocument54 pagesAS-BUILT DRG. - 33KV VCB Panel PDFrana abrar100% (1)

- RT Report For CastingDocument1 pageRT Report For CastingSwarup mishraNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Ii (Dustrial Inspecti N Training (IITS) A L-Eading NDT: CornparryDocument1 pageIi (Dustrial Inspecti N Training (IITS) A L-Eading NDT: Cornparryআশার আলোNo ratings yet

- Client: Comparuy Test Date: 24-Dec-2019: Refcirt GAS I-TeDocument1 pageClient: Comparuy Test Date: 24-Dec-2019: Refcirt GAS I-Teআশার আলোNo ratings yet

- Ii (Specti I (& (LLTS) A F.Eading NDT: Traiim (GDocument1 pageIi (Specti I (& (LLTS) A F.Eading NDT: Traiim (Gআশার আলোNo ratings yet

- Insptcti0N (LLTS) A I-Eading I/Dt: IrainingDocument1 pageInsptcti0N (LLTS) A I-Eading I/Dt: Irainingআশার আলোNo ratings yet

- $ni) ) Ffi: (Liis)Document1 page$ni) ) Ffi: (Liis)আশার আলোNo ratings yet

- Ilovepdf MergedDocument503 pagesIlovepdf MergedHemantNo ratings yet

- Tribes Without RulersDocument25 pagesTribes Without Rulersgulistan.alpaslan8134100% (1)

- Wine TourismDocument9 pagesWine Tourismyarashovanilufar1999No ratings yet

- Aashto M288-17 Product Selection GuideDocument1 pageAashto M288-17 Product Selection GuideDem DemNo ratings yet

- CSWIP-WP-19-08 Review of Welding Procedures 2nd Edition February 2017Document6 pagesCSWIP-WP-19-08 Review of Welding Procedures 2nd Edition February 2017oberai100% (1)

- Man Bni PNT XXX 105 Z015 I17 Dok 886160 03 000Document36 pagesMan Bni PNT XXX 105 Z015 I17 Dok 886160 03 000Eozz JaorNo ratings yet

- Supply List & Resource Sheet: Granulation Techniques DemystifiedDocument6 pagesSupply List & Resource Sheet: Granulation Techniques DemystifiedknhartNo ratings yet

- Engineering Management: Class RequirementsDocument30 pagesEngineering Management: Class RequirementsMigaeaNo ratings yet

- 1973 Further Discussion of Fiedler's Contingency Model of Leadership EffectivenessDocument8 pages1973 Further Discussion of Fiedler's Contingency Model of Leadership EffectivenesslengocthangNo ratings yet

- Passage To Abstract Mathematics 1st Edition Watkins Solutions ManualDocument25 pagesPassage To Abstract Mathematics 1st Edition Watkins Solutions ManualMichaelWilliamscnot100% (50)

- Regulasi KampenDocument81 pagesRegulasi KampenIrWaN Dompu100% (2)

- Intelligent Status Monitoring System For Port Machinery: RMGC/RTGCDocument2 pagesIntelligent Status Monitoring System For Port Machinery: RMGC/RTGCfatsahNo ratings yet

- CycleMax IntroDocument13 pagesCycleMax IntroIslam AtefNo ratings yet

- Structural Design Basis ReportDocument31 pagesStructural Design Basis ReportRajaram100% (1)

- Anker Soundcore Mini, Super-Portable Bluetooth SpeakerDocument4 pagesAnker Soundcore Mini, Super-Portable Bluetooth SpeakerM.SaadNo ratings yet

- Church and Community Mobilization (CCM)Document15 pagesChurch and Community Mobilization (CCM)FreethinkerTianNo ratings yet

- Daftar ObatDocument18 pagesDaftar Obatyuyun hanakoNo ratings yet

- Point and Figure ChartsDocument5 pagesPoint and Figure ChartsShakti ShivaNo ratings yet

- EPW, Vol.58, Issue No.44, 04 Nov 2023Document66 pagesEPW, Vol.58, Issue No.44, 04 Nov 2023akashupscmadeeaseNo ratings yet

- Exploring-Engineering-And-Technology-Grade-6 1Document5 pagesExploring-Engineering-And-Technology-Grade-6 1api-349870595No ratings yet

- KK AggarwalDocument412 pagesKK AggarwalEnrico Miguel AquinoNo ratings yet

- Polysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Document1 pagePolysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Carlos JiménezNo ratings yet

- Title: Smart Monitoring & Control of Electrical Distribution System Using IOTDocument27 pagesTitle: Smart Monitoring & Control of Electrical Distribution System Using IOTwaleed HaroonNo ratings yet

- 5.0008786 Aluminum GrapheneDocument11 pages5.0008786 Aluminum GrapheneBensinghdhasNo ratings yet

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectDocument13 pagesStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorNo ratings yet

- Understanding The Contribution of HRM Bundles For Employee Outcomes Across The Life-SpanDocument15 pagesUnderstanding The Contribution of HRM Bundles For Employee Outcomes Across The Life-SpanPhuong NgoNo ratings yet

- Hofstede's Cultural DimensionsDocument35 pagesHofstede's Cultural DimensionsAALIYA NASHATNo ratings yet

- BIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Document32 pagesBIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Md TayfuzzamanNo ratings yet

- Load Chart Crane LiftingDocument25 pagesLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)