Professional Documents

Culture Documents

Job Safety Analysis (Jsa) : CONTRACT N° .

Job Safety Analysis (Jsa) : CONTRACT N° .

Uploaded by

ghazi kallelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis (Jsa) : CONTRACT N° .

Job Safety Analysis (Jsa) : CONTRACT N° .

Uploaded by

ghazi kallelCopyright:

Available Formats

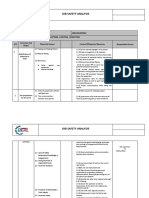

THE PROVISION OF PIPELINE INSTALLATION

SERVICES

SMG1 FLOWLINE PROJECT

JSA

CONTRACT N°……………………………………………………………….. Rev: 0

Page: 1 of 2

JOB SAFETY ANALYSIS (JSA)

Location: Person in charge: Date:

Work activity (Job): pipe bending

Work team:

Potential accidents or hazards Recommendations to eliminate or reduce potential hazards associated

Sequence of basic job steps

associated with each step with each step

Machine moving:

Loading bending machine Falls from same level, falls from a) Inspect before machine, lifting equipment and track.

different level, falling objects. b) Follow audio and visual signals

Struck against object, Struck by object. c) Use guards, warning signs, to mark areas under load.

Caught in or compressed by equipment Use restricted loading area.

or objects. Caught in or crushed in

collapsing materials

Inspect before machine, lifting a) Hazardous working conditions. a) Inspect and be familiar with the load weight, size and shape

equipment and track. capacity loading and unloading of the hoisting equipment.

b) Select proper equipment for the job.

c) Install guards to prevent access to areas with moving overhead

objects.

d) Follow safe work procedures. Identify, isolate and remove

hazardous packages.

e) Make sure there is no danger of hazardous exposure. Use

adequate personal protective equipment

Lifting a) Hit by hoisted load. a) Follow audio and visual signals.

b) Hit by or coming under b) Use guards, warning signs, to mark areas under load.

THE PROVISION OF PIPELINE INSTALLATION

SERVICES

SMG1 FLOWLINE PROJECT

JSA

CONTRACT N°……………………………………………………………….. Rev: 0

Page: 2 of 2

Transporting machine a) Hit by rollover or tip over of a) Good housekeeping. Follow safe operating procedures

equipment or vehicle b) Use adequate personal protection

b) Hit persons passing by close c) Ensure good visibility

to the lift truck d) Use warning sounds, lights and signs

Unloading a) Hit by hoisted load. a) Follow audio and visual signals

b) Hit by or coming under shifting b) Use guards, warning signs, to mark areas under load.

load. c) Use restricted unloading area.

Installing bending machine a) Being hit by the part of the a) Use proper manual to install bending machine.

machine b) Installation must be conducted by competent and trained person

Bending pipe:

Put the pipe on the bending machine a) Hit by the pipe a) Use of tag line to guide the pipe during lifting operation.

b) Pipe drop during lifting b) Follow audio and visual signals

c) Fixation of the pipe c) Use restricted lifting area.

d) Use competent person for fixation

e) use of proper PPE

Bending the pipe a) dysfunction of bending machine a) Inspection of the machine and following the machine manual.

b) Hit by hydraulic system b) task conducted by competent person

c) Hit by the pipe c) Stay away from machine and pipe during bending operation.

d) Setup a bending restricted area.

Remove pipe from bending machine. a) Hit by the pipe c) Use of tag line to guide the pipe during lifting operation.

b) Pipe drop during lifting d) Follow audio and visual signals

e) Use restricted lifting area.

You might also like

- DMV Cheat Sheet California en Car PremiumDocument59 pagesDMV Cheat Sheet California en Car Premiumavalon.protter08No ratings yet

- Jsa For Pipe Laying Water and Sewer-1Document8 pagesJsa For Pipe Laying Water and Sewer-1Mikael Naqib83% (6)

- Announcements For Flight AttendatnsDocument13 pagesAnnouncements For Flight AttendatnsSteve Cali100% (4)

- Stub Axle Design Stub Axle Design Stub Axle Design Stub Axle DesignDocument1 pageStub Axle Design Stub Axle Design Stub Axle Design Stub Axle DesignNano NanoNo ratings yet

- IATA Ground Operations Manual (IGOM) : EditionDocument4 pagesIATA Ground Operations Manual (IGOM) : EditionJorge29% (7)

- Height Safety Ppe Inspection ChecklistDocument4 pagesHeight Safety Ppe Inspection ChecklistAdisorNo ratings yet

- JW TICO Product Guide Issue 1-18 PDFDocument48 pagesJW TICO Product Guide Issue 1-18 PDFgkdora574No ratings yet

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- KERJA MEROBOH BANGUNANxxxDocument13 pagesKERJA MEROBOH BANGUNANxxxSawLaiBoyanNo ratings yet

- Confined Space Entry Permit: Smg1 Flowline ProjectDocument2 pagesConfined Space Entry Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- Dettol Spray Data SheetDocument5 pagesDettol Spray Data Sheetimmunosaran88No ratings yet

- i) ii) iii) (Scale) : (SIZE) (Colour) 非1:1Document19 pagesi) ii) iii) (Scale) : (SIZE) (Colour) 非1:1Filipe ConceiçãoNo ratings yet

- AHU AssemblyDocument3 pagesAHU AssemblyKrishna Patil100% (1)

- Basic HIRA (Hazards & Risk Assessment of Solar PV Project)Document22 pagesBasic HIRA (Hazards & Risk Assessment of Solar PV Project)Moloy GoswamiNo ratings yet

- EE314 Lab 1 FinalDocument19 pagesEE314 Lab 1 FinalCarlos BabuNo ratings yet

- Tg06-48 Written Fall Protect Plan-PDF-EnDocument4 pagesTg06-48 Written Fall Protect Plan-PDF-EnZeeshan BajwaNo ratings yet

- User Manual Rish Insu 10Document10 pagesUser Manual Rish Insu 10Manoj TyagiNo ratings yet

- Cement Lining of PipesDocument28 pagesCement Lining of PipesvenkyNo ratings yet

- Encor: Pure Acrylic Latex For Interior and Exterior PaintsDocument2 pagesEncor: Pure Acrylic Latex For Interior and Exterior PaintsAPEX SONNo ratings yet

- Is 3521.1999 PDFDocument17 pagesIs 3521.1999 PDFDipankar ChakrabortyNo ratings yet

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinNo ratings yet

- Plastering Jha With Work at HeightDocument4 pagesPlastering Jha With Work at HeightJayson ArellanoNo ratings yet

- Safety Audit of A Petroleum RefineryDocument39 pagesSafety Audit of A Petroleum RefinerySai Tarun GanapavarapuNo ratings yet

- Qcs 2010 Section 11 Part 2.3.02 SHE Procedures - COSHH (CONTROL OF SU PDFDocument16 pagesQcs 2010 Section 11 Part 2.3.02 SHE Procedures - COSHH (CONTROL OF SU PDFbryanpastor106No ratings yet

- Top 5 HazardsDocument13 pagesTop 5 HazardsJunard M. Lu HapNo ratings yet

- 4 JHA On Erection of Auxilary Transformers and Main TransformersDocument4 pages4 JHA On Erection of Auxilary Transformers and Main TransformersPiyush SinghNo ratings yet

- HIP-Rabigh Development ProjectDocument5 pagesHIP-Rabigh Development ProjectDarius DsouzaNo ratings yet

- JSA Manual Excavation and Cable LayingDocument3 pagesJSA Manual Excavation and Cable Layingimran100% (1)

- DLPS JsaDocument23 pagesDLPS JsaDLPS HSENo ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- Job Safety Analysis: Submitted By: Jheremae Deypalubos Submitted To: Engr. Charlie TaclendoDocument5 pagesJob Safety Analysis: Submitted By: Jheremae Deypalubos Submitted To: Engr. Charlie TaclendoMikaNo ratings yet

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- JSA Mobile Crane Pipe Installation Tandem LiftDocument3 pagesJSA Mobile Crane Pipe Installation Tandem LiftSyed HarisNo ratings yet

- Power Shovel Operation: Surface Metal and Nonmetal MinesDocument16 pagesPower Shovel Operation: Surface Metal and Nonmetal MinesHowk RiosNo ratings yet

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- PIPELINE - IF KitsDocument10 pagesPIPELINE - IF KitscamgovaNo ratings yet

- BLASTING&PAINTINGDocument10 pagesBLASTING&PAINTINGLajapathi RaiNo ratings yet

- 20 Inch - MS - Loading Unloading - ButeneDocument5 pages20 Inch - MS - Loading Unloading - ButeneHSE ENNKAYNo ratings yet

- JSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadDocument1 pageJSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadRyanNo ratings yet

- SOP 002 Damp MoppingDocument2 pagesSOP 002 Damp MoppingMade Gilee100% (1)

- Excavation JSA HSE ProfessionalsDocument2 pagesExcavation JSA HSE ProfessionalsSamadov 13No ratings yet

- Risk Assessment - CableDocument6 pagesRisk Assessment - Cablemohamad hafiz0% (2)

- CSSB - HIRARC 003 - Site SurveyDocument3 pagesCSSB - HIRARC 003 - Site Surveymarzukimuhammad.jmNo ratings yet

- Lifting Operation (JSA)Document4 pagesLifting Operation (JSA)abdullah ashrafNo ratings yet

- (Edit) SWP Bolt TensioningDocument4 pages(Edit) SWP Bolt Tensioningainun mardiahNo ratings yet

- Window WashingDocument2 pagesWindow Washingnoty boyNo ratings yet

- Risk Assessment - Vessel InstallationDocument5 pagesRisk Assessment - Vessel InstallationKono Nor AtanNo ratings yet

- Test 4Document9 pagesTest 4Ahmed HamadNo ratings yet

- Demolition XXXDocument13 pagesDemolition XXXSawLaiBoyanNo ratings yet

- SAFETY Work Methodology of Installation of Fire AlarmDocument3 pagesSAFETY Work Methodology of Installation of Fire AlarmAlvin PangilinanNo ratings yet

- JSA Mobile CranesDocument2 pagesJSA Mobile CranesAmanya DickallansNo ratings yet

- HTCI - METHOD STATEMENT-Foundation & Erection Works of Steel PolesDocument9 pagesHTCI - METHOD STATEMENT-Foundation & Erection Works of Steel PolesFrancis GonzalesNo ratings yet

- Plinth Work+dismantling StructureDocument8 pagesPlinth Work+dismantling StructureMuhammad NaqiuNo ratings yet

- Standard Operation Procedure: Task: Floor Buffing SOP 005Document2 pagesStandard Operation Procedure: Task: Floor Buffing SOP 005Made GileeNo ratings yet

- Inspection Format For Health and Safety Conditions at Work FIELDDocument3 pagesInspection Format For Health and Safety Conditions at Work FIELDScribdTranslationsNo ratings yet

- MEthdstatemet For GRP Pipe Puddle Flange Installation (Complete)Document13 pagesMEthdstatemet For GRP Pipe Puddle Flange Installation (Complete)Mdubdt100% (1)

- Kerja-Kerja Meroboh: Presenter: XXXXXXXXDocument13 pagesKerja-Kerja Meroboh: Presenter: XXXXXXXXSawLaiBoyanNo ratings yet

- JPPL Ehs 19 03 SWP 02Document12 pagesJPPL Ehs 19 03 SWP 02MohamedSaidNo ratings yet

- Crane Safety Training CLP. 15.11.2016 .Pps PDFDocument117 pagesCrane Safety Training CLP. 15.11.2016 .Pps PDFJSW Bellary, Project100% (1)

- Guide To Excavation For TrenchesDocument41 pagesGuide To Excavation For Trencheschianz6977No ratings yet

- Hazrd Identification Plan - July 2019Document11 pagesHazrd Identification Plan - July 2019Manny MisaNo ratings yet

- Method Statement: Fabrication of Rebar Cages in CaissonDocument3 pagesMethod Statement: Fabrication of Rebar Cages in CaissonhanisahhamzahNo ratings yet

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- Methodlogy of Blasting For ICHSDocument10 pagesMethodlogy of Blasting For ICHSDhaneswar SwainNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document7 pagesJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Cutting & Grinding & WeldingDocument2 pagesCutting & Grinding & Weldingghazi kallelNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document2 pagesJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

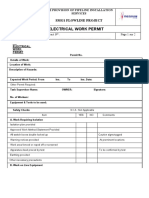

- Electrical Work Permit: Smg1 Flowline ProjectDocument2 pagesElectrical Work Permit: Smg1 Flowline Projectghazi kallel33% (3)

- Excavation Permit: Smg1 Flowline ProjectDocument2 pagesExcavation Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- Cold Work Permit: Smg1 Flowline ProjectDocument2 pagesCold Work Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- Accident Incident Reporting and Investigation PolicyDocument9 pagesAccident Incident Reporting and Investigation Policyghazi kallelNo ratings yet

- Copttm Combined Sections A To HDocument531 pagesCopttm Combined Sections A To HBen SuttonNo ratings yet

- E E F A L C: Instituto Guillermo Enrique HudsonDocument3 pagesE E F A L C: Instituto Guillermo Enrique HudsonBiancaNo ratings yet

- CIDB Guidelines MWEPDocument35 pagesCIDB Guidelines MWEPDerick Chia100% (1)

- Ir Spad Cases 2022-23Document47 pagesIr Spad Cases 2022-23mr.jk333No ratings yet

- EnglishFile4e Intermediate TG PCM Grammar 6ADocument1 pageEnglishFile4e Intermediate TG PCM Grammar 6AB McNo ratings yet

- Traffic Science TSC1125NDocument9 pagesTraffic Science TSC1125NNhlanhla MsomiNo ratings yet

- Design and Operations Best Practice Guide: Loading BayDocument16 pagesDesign and Operations Best Practice Guide: Loading BaygilNo ratings yet

- 1 s2.0 S2352146517306555 Main PDFDocument11 pages1 s2.0 S2352146517306555 Main PDFMiguela SantosNo ratings yet

- Jsa (Job Safety Analysis)Document2 pagesJsa (Job Safety Analysis)Ruben Mejia100% (1)

- C. B. Winkler. UMTRI. TMC. Columbus. October, 2000.: Rollover Accidents Roll Stability The Role of SuspensionsDocument7 pagesC. B. Winkler. UMTRI. TMC. Columbus. October, 2000.: Rollover Accidents Roll Stability The Role of SuspensionsepesanoNo ratings yet

- Rtari: RemainDocument10 pagesRtari: RemainLucas KnightNo ratings yet

- Letter No Regarding Proposal of Boundary Wall 1Document2 pagesLetter No Regarding Proposal of Boundary Wall 1aeofficebakhasarmavsariNo ratings yet

- Oeb Tracking PolicyDocument7 pagesOeb Tracking PolicybarbarbiroUNo ratings yet

- REFLECTIONDocument4 pagesREFLECTIONmia edNo ratings yet

- A Perfect Storm: Australian Inter-State Freight SurgesDocument44 pagesA Perfect Storm: Australian Inter-State Freight SurgesPedro Henriques100% (1)

- IOT Based Accident Detection and PreventionDocument6 pagesIOT Based Accident Detection and PreventionShivani PatilNo ratings yet

- Preparation: Graded Listening: The Survivor Episode 1: Finding Jane - Level B1 - ExercisesDocument2 pagesPreparation: Graded Listening: The Survivor Episode 1: Finding Jane - Level B1 - ExercisesNicolas Vanegas100% (1)

- Listening Test at The Airport A2b1 9th Grade Information Gap Activities 102185Document2 pagesListening Test at The Airport A2b1 9th Grade Information Gap Activities 102185Thanh Hien Nguyen ThiNo ratings yet

- ACSF 25 15 (Industry) FeedbackOnProposedDecelerationThresholds - Industry - v2Document2 pagesACSF 25 15 (Industry) FeedbackOnProposedDecelerationThresholds - Industry - v2-Luci-No ratings yet

- Transportation Management Plan (TMP) : Golden Gate Bridge Moveable Median Barrier ProjectDocument284 pagesTransportation Management Plan (TMP) : Golden Gate Bridge Moveable Median Barrier ProjectFAUZIAH BADRUNNo ratings yet

- Injured PassengerDocument7 pagesInjured PassengerBlueMetal MilitiaNo ratings yet

- RESOLUTIONs - Guideline For Safety of Tow - Res.A.765Document3 pagesRESOLUTIONs - Guideline For Safety of Tow - Res.A.765Mostafa IsmaelNo ratings yet

- RA For Traffic & Directional Signs Installation-RajDocument11 pagesRA For Traffic & Directional Signs Installation-RajRaj100% (1)

- m1 Practice Signs 1Document34 pagesm1 Practice Signs 1Jacinta GNo ratings yet

- I. Choose The Word Whose Underlined Part in Pronounced Differently From The RestDocument6 pagesI. Choose The Word Whose Underlined Part in Pronounced Differently From The RestAnna VanNo ratings yet

- Chapters 1 - 5Document143 pagesChapters 1 - 5Anjo SemaniaNo ratings yet

- Booklet Course 8 Chapter 4Document22 pagesBooklet Course 8 Chapter 4Mayis Monzón100% (1)