Professional Documents

Culture Documents

It P Galvanised

It P Galvanised

Uploaded by

Tadaya KasaharaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

It P Galvanised

It P Galvanised

Uploaded by

Tadaya KasaharaCopyright:

Available Formats

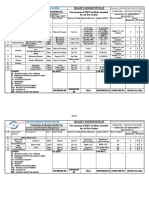

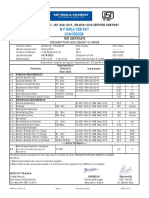

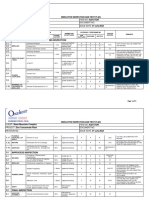

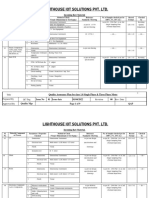

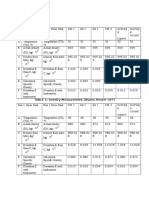

Inspection and Test Plan - Hot Dip Galvanising

IDBF-ED-JSPDS-F0005

DEFINITIONS

1. Hold Point (H) - An activity identified in the ITP beyond which further work shall not proceed without

the attendance of the nominated inspector. In case of a "Hold Point" of the Company ( BP), the

Contractor shall not proceed with the WORK without the Company (BP) or its representative being

present, except where the Company ( BP) has notified the Contractor in writing that it may proceed

2. Witness Point ( W ) - An activity identified in the ITP required to be witnessed by nominated inspector.

In the case of a "Witness Point" of the Company ( BP), the Contractor may proceed with the inspection

a n d / or testing activity if the Company ( BP) or its representative is not present after being provided with

the required written notice

3. Review Point (R) - The process of verifying by examination of documentary evidence that nominated

inspections and / or tests have been satisfactorily conducted. This evidence must be offered to the

Company ( BP) for review as soon as practicable. This will not hold any activities.

4. Monitoring Point (M) - random check by direct or indirect inspection of the conformance of the item or

activity.

ABBREVIATIONS USED

BP = BRITISH PETROLEUM (COMPANY)

PRO = PROSPERA BRILLAR INDONESIA (SUBCONTRACTOR)

SIKB = SAIPEM (CONTRACTOR)

SGPL = SUPER GALVANISING PTE LTD(VENDOR)

INSPECTION & TEST PLAN - HOT DIP GALVANISING

QUALITY CONTROL ACCEPTANCE INSPECTION SURVEILLANCE VERIFIYING

No, ACTIVITY IN5P.BY CRITERIA I PRO [ SIKB I BP DOCUMENTS

1.0 RECEIVING & JIGGING MATERIALS

l:Roeeivo ,:�ome.,.s pa1U/

MD & Gelo

1.1 Artiles including ICC Rocelvin Dopl Super-01 GP

Pass/Delivery Order

Inspection

Confirm perts/adicls received

MRD & Gal

1.2 as par imitlel ARD (1m & MD Receiving Dept Super-01 GP

Puss/Delivery Order

Details

Ensure suitable material ta

1.3 gavoniso and bolas f

or hanging Wu Tying Dept Super-01 GP MD(Depl Copy)

and safety ext

Tying of materials t

o Jig

1.4 gecuroly wth suitable wire typo ware Tying Dept Super.01Gp RD(Dept

Copy)

according to material weight

lssua Job Sheet and record jig

number and verify quantity ts

1.5 Wting Dopf Super-01 GP MRD(Dept Copy)

per MD after fgging +

complete

2.0 PRETREATMENT & SURFACE PREPARATION

Ascertain presence of grease

2. 1 and duration for caustic soda Chemical Dept Super-01 G Job Sheot

mets/on

Withdraw from caustic toda

22 and check for remaining grease Chemical Dept Super-01GP Job Sheet

an into of with water

Immerse to suitable acid tank

2.3 according t tho ztato and Chemical Dept Super.01 GP Job Sheot

amount of rut/nil tales

Check to ensure thoroughly

2.4 leaned tee than proceed to Chemical Dopl Sup0r.01 GP Job Shoot

flax tank after rinsing

Flux treatment according to

2.5 material thickenoss prior to Chomicsl Dept Sup6r-01 Gp Job Shot

galvanising

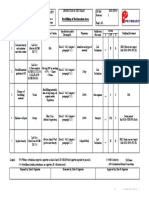

3.0 HOT DIP GALVANISING MATERIAL

Eneur total overage of flux

3.1 tolutlon on steal zutaco and all Galvanising Dept Sp6r-01 GP Job Saet

popor hole presont

pehoat prior to immorslon into

3.2 zi

nc bath, ailmmnlng to be done Galvanising Dept Super-01Gp Job Shoat

boor¢ immersion

wahdrawal ofter skimming and

adoquale bath timo, clot

3.3 Galvanising Dept Sup6r-01 GP Job Sect

0xcos zinc and tomovo ath if

accessible

4.0 QUENCHING

Pe.ooling by air prior to

4.f Galvanising 0opt Supor.01 GP Job Soet

musing into quench tank,

Un,ig and racking followed by

vorifying and indication of client Job Sheet & MRD(Dept

4.2 Witing Dopt Super-01 GP

nano and MD number on Copy)

maloriels

5.0 FINISHING

rnsfer t

o finishing area

Job Sheet & ARD(Dept

5. specific t

o molerial lypo for Finl±ting Dept Super-01 GP

Copy)

touch-up

Remove any sharp pikes and

Job Sheet & MRDept

5.2 exos zing, chock for bare Finishing Dpt Super-01 GP

Copy)

tpots and touch up accordingly

6.0 INSPECTION

Perform lnpocion as per

Super.01 GP

AST-A123 r0qui emonts with Job Sbeet & ARD'Dept

61 0C Dept AST1M-A123

otltoctor Coating thickness Copy)

IDBF-ED-JSPDS-F0005

reader

7.0 DELIVERY

Verify ARD umber ond

material quantlos bolero Reloaso Noto &

71 Delivery Dept Sup6r01 GP

loading to vehicto raturning t

o MD(Dept Copy)

client sito

You might also like

- CPF Overall Start-Up and Mercury De-Sorption Operation: GTG-EXP-000-EXP-PRO-0010Document19 pagesCPF Overall Start-Up and Mercury De-Sorption Operation: GTG-EXP-000-EXP-PRO-0010Boussebha NoureddineNo ratings yet

- PVT Report - 140319 - Zone - 8 - May'17 Separator SampleDocument28 pagesPVT Report - 140319 - Zone - 8 - May'17 Separator SampleIBIKUNLENo ratings yet

- Itp and Test Plan Rubber Fender Rev. 0Document5 pagesItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- Astm C 1135-2005Document4 pagesAstm C 1135-2005zeqs9100% (1)

- GTG-EXP-000-EXP-PRO-0010 - Desorption Procedure Rev 01Document19 pagesGTG-EXP-000-EXP-PRO-0010 - Desorption Procedure Rev 01Boussebha NoureddineNo ratings yet

- Expansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)Document14 pagesExpansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- BOP Function Test SOPDocument1 pageBOP Function Test SOPRajesh SharmaNo ratings yet

- Chemical Dosing Unit (Cdu) : Rabigh II Project Interconnecting Package (UO1)Document19 pagesChemical Dosing Unit (Cdu) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- C211034-Mo-Me-Itp-3001Document6 pagesC211034-Mo-Me-Itp-3001Suaib VCSNo ratings yet

- QAP For Pipes For Hydrant and Sprinkler SystemDocument3 pagesQAP For Pipes For Hydrant and Sprinkler SystemCaspian DattaNo ratings yet

- Hot Water Generator (HW) : Rabigh II Project Interconnecting Package (UO1)Document18 pagesHot Water Generator (HW) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- Borl Qap R1Document2 pagesBorl Qap R1infoNo ratings yet

- Qap Wo 7 r0 (Ion Exchange)Document1 pageQap Wo 7 r0 (Ion Exchange)KailasNo ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- Manufacturing Quality PlanDocument4 pagesManufacturing Quality PlanDIENSHNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- I1912 Ai Opr Itp 0070 00 Itp For Pelmet WorkDocument4 pagesI1912 Ai Opr Itp 0070 00 Itp For Pelmet WorkAiplshubh ChavanNo ratings yet

- Inspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Document6 pagesInspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Vidyut UjalaNo ratings yet

- Process Upset Reporting: Description of EventDocument6 pagesProcess Upset Reporting: Description of EventAhmedNo ratings yet

- 8 D For ShrinkageDocument6 pages8 D For ShrinkageSachin KumbharNo ratings yet

- Inspection Test Plan For Eot CraneDocument4 pagesInspection Test Plan For Eot CraneBikash ShreshthaNo ratings yet

- Tata A2239 Qap Rev.00Document4 pagesTata A2239 Qap Rev.00PRASHANTNo ratings yet

- Backfilling of Reclamation Area: Document Ref - CORP-SYS-01F01 Rev1Document1 pageBackfilling of Reclamation Area: Document Ref - CORP-SYS-01F01 Rev1Belal hassanNo ratings yet

- Daily Progress Drumshell 03.01.23Document3 pagesDaily Progress Drumshell 03.01.23kehlmathias07No ratings yet

- Job Hazard Analysis Worksheet: Cold Cutting in Open AreaDocument2 pagesJob Hazard Analysis Worksheet: Cold Cutting in Open AreaAbdul Hakam Mohamed Yusof0% (1)

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document2 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- Process Upset ReportingDocument6 pagesProcess Upset ReportingAhmedNo ratings yet

- MTC OPC43G 2022 Concrecem 52Document1 pageMTC OPC43G 2022 Concrecem 521995.ram.ram.singhNo ratings yet

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocument3 pagesWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleNo ratings yet

- Graña y Montero Petrolera: Lote IV Lomitos 13682 Orig CompletionDocument2 pagesGraña y Montero Petrolera: Lote IV Lomitos 13682 Orig CompletionErick OlanoNo ratings yet

- 04 ItpDocument1 page04 ItpShubhamShuklaNo ratings yet

- Process Upset ReportingDocument4 pagesProcess Upset ReportingAhmedNo ratings yet

- Process Upset ReportingDocument2 pagesProcess Upset ReportingAhmedNo ratings yet

- MD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFDocument8 pagesMD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFTran KhuynhNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- Raw Material & Bought Out Items InspectionDocument3 pagesRaw Material & Bought Out Items InspectionSuraj ShettyNo ratings yet

- BC044 - HPT - 11mar16Document1 pageBC044 - HPT - 11mar16Hery KurniawanNo ratings yet

- Bharat Oman QAPDocument6 pagesBharat Oman QAPJJ VAPINo ratings yet

- NO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2Document2 pagesNO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2sonnu151No ratings yet

- Reservior Skid Assl Qap AlfaDocument1 pageReservior Skid Assl Qap AlfaajmainNo ratings yet

- 4 Avu&Srlpg Sop P-007abc FailureDocument5 pages4 Avu&Srlpg Sop P-007abc Failure00083583rfNo ratings yet

- K-003ab C&e 2012-05-09Document5 pagesK-003ab C&e 2012-05-09rcpuram01No ratings yet

- BGRL (Satara-Sangli) - Spur Spread-3 - JP-Arc Strike - R0 - Code A - 26.02.2021Document6 pagesBGRL (Satara-Sangli) - Spur Spread-3 - JP-Arc Strike - R0 - Code A - 26.02.2021Aditya IngawaleNo ratings yet

- Vakkal Impex - Combined CFO & HWA Verification Report - Format - 2007Document7 pagesVakkal Impex - Combined CFO & HWA Verification Report - Format - 2007api-3809359No ratings yet

- Yyyyyyyyyyyyyyyyyyyyyy With LinksDocument34 pagesYyyyyyyyyyyyyyyyyyyyyy With Linksumeshchandra yadavNo ratings yet

- Quality Assurance PlanDocument9 pagesQuality Assurance PlanQAD LotusNo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- Quality PLan Fabrication of Expansion Spool For BN8Document1 pageQuality PLan Fabrication of Expansion Spool For BN8Aldrin HernandezNo ratings yet

- Quality PLan Fabrication of Expansion Spool For BN8Document1 pageQuality PLan Fabrication of Expansion Spool For BN8Aldrin HernandezNo ratings yet

- Soot Blowing SystemDocument8 pagesSoot Blowing SystemShambhu Mehta100% (1)

- Inspection and Test Paln For LSAWDocument4 pagesInspection and Test Paln For LSAWkbpatel123No ratings yet

- Field Installation Work Procedure - PipingDocument76 pagesField Installation Work Procedure - Pipingsaif aliNo ratings yet

- Annexure 6 - ITP For Alloy Steel Welded Fittings A234 WP11 CL2 Fornormal NACE & IBRDocument2 pagesAnnexure 6 - ITP For Alloy Steel Welded Fittings A234 WP11 CL2 Fornormal NACE & IBRPranav JadhavNo ratings yet

- I&C - Safety Document Request: I&C - SDR 07-02-2022 Night 1 2 I&C - SDR 08-02-2022 MorningDocument4 pagesI&C - Safety Document Request: I&C - SDR 07-02-2022 Night 1 2 I&C - SDR 08-02-2022 MorningNaveed IrshadNo ratings yet

- 8D CT Interchnaged - NNLDocument10 pages8D CT Interchnaged - NNLAbhinav SinghNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- GGL New Skid Commissioning Job - 23.01.2024Document2 pagesGGL New Skid Commissioning Job - 23.01.2024Anuj BhardwajNo ratings yet

- Burner Capacity Curves For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberDocument4 pagesBurner Capacity Curves For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberMuhammad IrfanNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- PBI-CCP-QA-0001 QA Welding Consumable Control ProcedureDocument15 pagesPBI-CCP-QA-0001 QA Welding Consumable Control ProcedureTadaya KasaharaNo ratings yet

- Project Quality Control Plan Endorsment For Welding2Document23 pagesProject Quality Control Plan Endorsment For Welding2Tadaya KasaharaNo ratings yet

- TEP-1265561-P99-0003 Material Receiving and Traceability ProcedureDocument14 pagesTEP-1265561-P99-0003 Material Receiving and Traceability ProcedureTadaya Kasahara100% (2)

- PBI-WI 005 Dimensional Control Procedure Rev.0Document5 pagesPBI-WI 005 Dimensional Control Procedure Rev.0Tadaya KasaharaNo ratings yet

- Final Dossier IndexDocument2 pagesFinal Dossier IndexTadaya Kasahara50% (2)

- Project Schedule HDG Tertiary Structure - Gta Hub/ Terminal FacilitiesDocument1 pageProject Schedule HDG Tertiary Structure - Gta Hub/ Terminal FacilitiesTadaya KasaharaNo ratings yet

- PT Prospera Brillar Indonesia: Hse Organization ChartDocument1 pagePT Prospera Brillar Indonesia: Hse Organization ChartTadaya KasaharaNo ratings yet

- PBI-HSE 003 Hazard Identification Risk Assesment & Control Rev.0Document11 pagesPBI-HSE 003 Hazard Identification Risk Assesment & Control Rev.0Tadaya KasaharaNo ratings yet

- HDG Tertiary Structure: Daily Progress Report - PT Prospera Brillar IndonesiaDocument3 pagesHDG Tertiary Structure: Daily Progress Report - PT Prospera Brillar IndonesiaTadaya KasaharaNo ratings yet

- PL-PBI-HSE 001 Project HSE PlanDocument22 pagesPL-PBI-HSE 001 Project HSE PlanTadaya KasaharaNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- PRO-HSE-015 - HSE Manual GuidanceDocument21 pagesPRO-HSE-015 - HSE Manual GuidanceTadaya KasaharaNo ratings yet

- Note: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldDocument2 pagesNote: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldTadaya KasaharaNo ratings yet

- PRO-PQP-QA-0001 Project Quality Plan - Rev.0ADocument15 pagesPRO-PQP-QA-0001 Project Quality Plan - Rev.0ATadaya KasaharaNo ratings yet

- RED-NDT-MT-00001 Rev ADocument11 pagesRED-NDT-MT-00001 Rev ATadaya KasaharaNo ratings yet

- Specification 103 Rev. 8 - Supplier Document RequirementsDocument16 pagesSpecification 103 Rev. 8 - Supplier Document RequirementsTadaya KasaharaNo ratings yet

- Supplier Deliverable RegisterDocument4 pagesSupplier Deliverable RegisterTadaya KasaharaNo ratings yet

- Dab20702 - Bab 1Document29 pagesDab20702 - Bab 1Nur IffatinNo ratings yet

- LCA Baterias Dolci2016Document15 pagesLCA Baterias Dolci2016catalina ramirezNo ratings yet

- Frigaard2017 Article BinghamSModelInTheOilAndGasIndDocument24 pagesFrigaard2017 Article BinghamSModelInTheOilAndGasIndCoolProphetNo ratings yet

- Establishing Shipbuilding Quality Requirements For Hull Structure, Outfitting, and CoatingsDocument75 pagesEstablishing Shipbuilding Quality Requirements For Hull Structure, Outfitting, and CoatingsNavnath GawasNo ratings yet

- BM 5-ConcreteDocument81 pagesBM 5-ConcreteArch Reem AlzyoudNo ratings yet

- Result: TABLE 1: Density Measurement (Water, Heater OFF)Document6 pagesResult: TABLE 1: Density Measurement (Water, Heater OFF)Zulfitri ZulkarnainNo ratings yet

- Self-Tapping Saddle Tees Foruse: PVC PipeDocument22 pagesSelf-Tapping Saddle Tees Foruse: PVC PipeJacques BlueqNo ratings yet

- ASHP Guidelines On Preventing Medication Errors in HospitalsDocument9 pagesASHP Guidelines On Preventing Medication Errors in HospitalsMedarabiaNo ratings yet

- CH 10Document9 pagesCH 1000gp1200r100% (1)

- Mankind Pharmact ProductDocument24 pagesMankind Pharmact Productbhagya ratneNo ratings yet

- Assignment 2Document4 pagesAssignment 2eja70No ratings yet

- A Look at Perfusion - The Upstream Continuous ProcessDocument2 pagesA Look at Perfusion - The Upstream Continuous ProcessFISHNo ratings yet

- Material Safety Data Sheet Material Safety Data Sheet Cosmetic Pure Argan OilDocument3 pagesMaterial Safety Data Sheet Material Safety Data Sheet Cosmetic Pure Argan OilOriental Group SARL AUNo ratings yet

- NAME Aneela Aftab Semester Second Subject Fiber Science Submitted To Sir Muhammad QasimDocument22 pagesNAME Aneela Aftab Semester Second Subject Fiber Science Submitted To Sir Muhammad QasimAnila AftabNo ratings yet

- Symbols in P&idDocument19 pagesSymbols in P&idhatiniNo ratings yet

- Tray Dryer Objectives: Calculate The Percentage Moisture Content of Wet Rice Husk Removed in A Rotary Drier byDocument4 pagesTray Dryer Objectives: Calculate The Percentage Moisture Content of Wet Rice Husk Removed in A Rotary Drier byHajra AamirNo ratings yet

- Rmhoffman Bonnoc Ax68 Oil Sds 2015Document7 pagesRmhoffman Bonnoc Ax68 Oil Sds 2015javier100% (1)

- Effects Ofs Eaweed Laminaria Japonica MoisturizingDocument15 pagesEffects Ofs Eaweed Laminaria Japonica MoisturizingCosNo ratings yet

- Iplex UPVC Pipes and Fittings CatalogueDocument18 pagesIplex UPVC Pipes and Fittings Cataloguemanoj thankachan100% (1)

- Diesel Fuel Injection PumpsDocument10 pagesDiesel Fuel Injection PumpsRsjBugtong100% (1)

- Stepan Formulation 926Document2 pagesStepan Formulation 926Moaz SiddigNo ratings yet

- Membrane Technology in Water Treatment ApplicationsDocument11 pagesMembrane Technology in Water Treatment ApplicationsleechulmiuNo ratings yet

- Pristine: Create Simplified Labels With Quality, Clean Label IngredientsDocument2 pagesPristine: Create Simplified Labels With Quality, Clean Label Ingredientshweta173No ratings yet

- CHE3161 - Semester1 - 2011 - SolutionsDocument12 pagesCHE3161 - Semester1 - 2011 - Solutionsvenkiee50% (2)

- Quiz No 1Document8 pagesQuiz No 1LJ ValdezNo ratings yet

- ROENGEL Organe de PrindereDocument56 pagesROENGEL Organe de Prinderetanase_marius_vladNo ratings yet

- Model No 20501Document5 pagesModel No 20501Achmad HambaliNo ratings yet

- Policy Statement Concerning Tissue Paper Kitchen Towels and Napkins v1 September 2004 PDFDocument43 pagesPolicy Statement Concerning Tissue Paper Kitchen Towels and Napkins v1 September 2004 PDFMahmoud DomourNo ratings yet

- Top Plant - Kajang Waste-to-Energy Plant, Semenyih, MalaysiaDocument3 pagesTop Plant - Kajang Waste-to-Energy Plant, Semenyih, MalaysiaPeter Varun DsouzaNo ratings yet