Professional Documents

Culture Documents

Notes On The Replacement of The Exhaust Valve Guide: Applicable Engine Models PS, PL, DS, DL

Uploaded by

ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑ0 ratings0% found this document useful (0 votes)

23 views2 pagesOriginal Title

Bulletin #D6E

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views2 pagesNotes On The Replacement of The Exhaust Valve Guide: Applicable Engine Models PS, PL, DS, DL

Uploaded by

ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Bulletin #D6 - English

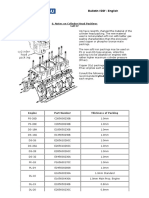

Notes on the Replacement of the Exhaust Valve Guide

applicable engine models PS, PL, DS, DL

SK87-02 & SK85-08

The replacement of the exhaust valve guide is a

straight forward job. However, when replacing

the valve guide you must ensure good contact of

the rim of the exhaust valve guide with the valve

cage seat (figure 1).

If the valve guide is installed with the rim

floating as in figure 2, it will obstruct the free

movement of the stem seal ring (figure 3) and

will result in earlier wear of the valve stem and

valve guide due to the lack of lubrication oil

being supplied to these parts.

To ensure proper installation, be sure to check

the depth of the valve guide "H" (figure 1) once

you have pushed the valve guide into position.

Consult the following table for the value of "H"

for each engine type.

Engine model "H" (mm)

PS-26 H 33.7 - 34.4

DS-22 63.3 - 63.5

PL-24 37.8 - 38.0

DS-26 37.8 – 38.0

DS-26 A 39.8 - 40.0

DS-28 49.8 - 50.0

Figure 1, 2 DS-32 49.8 - 50.0

DL-19 51.3 - 51.5

DL-20 56.3 - 56.5

DL-22 63.3 - 63.5

DL-24 63.3 - 63.5

DL-26 39.8 - 40.0

DL-28 49.8 - 50.0

DL-32 49.8 - 50.0

In engines where heavy fuel oil is being used,

DAIHATSU has been using Ni-resist iron valve

guides (figure 4). The material has excellent

Figure 3 anti-corrosive properties and a high temperature

resistance.

However, unlike other iron alloys, Ni-resist iron

exhibits expansion rather than contraction when

cooled by liquid nitrogen at -198 C. This unusual

property is caused by a shift in the metallic

structure of the alloy which is attributed to the

sudden excessive cooling to -198 C.

Therefore, note that when shrink-fitting the Ni-

resist iron exhaust valve guide DO NOT USE

LIQUID NITROGEN to cool it down, or else you

will cause it irrecoverable damage.

Instead either

use the hydraulic press, with no shrinkage

or

simply soak the valve guide into dry-ice

and alcohol to shrink it

but DO NOT USE LIQUID NITROGEN

Applicable engine models

PL-24 with valve cage and groove

DS-22 without valve cage

DS-26A with valve cage and groove

DS-28 with valve cage and groove

DS-32 with valve cage and groove

DL-16 without valve cage

DL-19 without valve cage

DL-20 without valve cage

DL-22 without valve cage

DL-24 with valve cage

DL-26 with valve cage and groove

DL-28 with valve cage and groove

DL-32 with valve cage and groove

DL-40 with valve cage

Figure 4

Figure 5

Note: The groove located at the bottom of the valve guide (figure 5) is provided for

identification purposes.

All other models which are not mentioned above, follow the rules described in this

technical bulletin.

Legal Notice

Copyright 2000 by marine industrial concerns s.a..

All rights reserved. E-mail comments to Webmaster

Updated 09.11.2004

You might also like

- Legend: Hydraulic/Hydrostatic Schematic 320/320L (S/N 223811001 - 223812346) 322 (S/N 223511001 - 223514376)Document2 pagesLegend: Hydraulic/Hydrostatic Schematic 320/320L (S/N 223811001 - 223812346) 322 (S/N 223511001 - 223514376)Леонид Юртаев100% (1)

- Helac Basket Rotator L20 ManualDocument24 pagesHelac Basket Rotator L20 ManualStuart Sainsbury100% (1)

- Low Boy Ganzo DollyDocument55 pagesLow Boy Ganzo DollyDaniel Vargas RibeiroNo ratings yet

- Oliver Plow 4240 TextDocument58 pagesOliver Plow 4240 TextDianaCreangă100% (2)

- Transmision 580HDocument43 pagesTransmision 580Hroadparts86% (7)

- Asme VIII Div1 2010-2011a PDFDocument86 pagesAsme VIII Div1 2010-2011a PDFJohan ConradieNo ratings yet

- Ball ValvesDocument32 pagesBall ValvesWom GroupsNo ratings yet

- Ejectors and Jet Pumps - Design For Steam Driven FlowDocument92 pagesEjectors and Jet Pumps - Design For Steam Driven FlowtjutjuNo ratings yet

- Piping BasicsDocument10 pagesPiping Basicstulasirao.nammiNo ratings yet

- ENG.001 Mechanical EngineDocument44 pagesENG.001 Mechanical EngineOmar Diaz Segura100% (1)

- Clariant Brochure Catalysts and Adsorbents For Syngas 2017 ENDocument9 pagesClariant Brochure Catalysts and Adsorbents For Syngas 2017 ENAbdul Wasay100% (1)

- Analysis of Non Newtonian FluidDocument25 pagesAnalysis of Non Newtonian FluidManakhJyotiPhukanNo ratings yet

- 0 0 25 Feb 2016 1108554031AnnexureManufacturing&EffluentTreatmentProcessDocument28 pages0 0 25 Feb 2016 1108554031AnnexureManufacturing&EffluentTreatmentProcessNeerav Indrajit GadhviNo ratings yet

- A. For Structural Identification See .: Learjet 20/30 Series Structural Repair ManualDocument29 pagesA. For Structural Identification See .: Learjet 20/30 Series Structural Repair ManualMartin RicciutiNo ratings yet

- Lws-27ii - 2711BDocument13 pagesLws-27ii - 2711BEsau MaldonadoNo ratings yet

- DCS6 Manual Twin Alternating SystemDocument27 pagesDCS6 Manual Twin Alternating SystemDHINAKARAN KumarNo ratings yet

- Re24751 2020 03Document40 pagesRe24751 2020 03Emrah BinayNo ratings yet

- Yanmar Engine l70n6 VemkjyiDocument24 pagesYanmar Engine l70n6 VemkjyiАндрій КарасьNo ratings yet

- Parts List Fisher 2500TDocument3 pagesParts List Fisher 2500TDur MuhammadNo ratings yet

- Twad Sor - 2020-21 Final - FieldDocument333 pagesTwad Sor - 2020-21 Final - FieldRamesh BabuNo ratings yet

- Backhoe (Control Valve) (W - 5 Sections) (709) (709FDS) - (S - N A54M00101 & Above, A5F300101 & Above) - BackhoeDocument3 pagesBackhoe (Control Valve) (W - 5 Sections) (709) (709FDS) - (S - N A54M00101 & Above, A5F300101 & Above) - Backhoegerman gualavisiNo ratings yet

- Directional Spool Valves, Pilot-Operated, With Hydraulic or Electro-Hydraulic Actuation Type WEH and WHDocument40 pagesDirectional Spool Valves, Pilot-Operated, With Hydraulic or Electro-Hydraulic Actuation Type WEH and WHlayetajNo ratings yet

- 212 Impact Tool PartsDocument4 pages212 Impact Tool PartsFredy Sierra100% (1)

- YUKEN Modular ValvesDocument136 pagesYUKEN Modular ValvestungNo ratings yet

- 02 enDocument32 pages02 enYu SaNo ratings yet

- D4CC Miniature Limit SwitchDocument11 pagesD4CC Miniature Limit SwitchMuhamad PriyatnaNo ratings yet

- 41310Document14 pages41310Fathi MusaNo ratings yet

- CDK SeriesDocument25 pagesCDK Seriesli geneNo ratings yet

- Throttle Check ValveDocument8 pagesThrottle Check Valvevinoth.kumarNo ratings yet

- CATALOG - Valves and Actuators (EN) PDFDocument64 pagesCATALOG - Valves and Actuators (EN) PDFflorentinNo ratings yet

- Check Valve, Pilot Operated: RE 21548, Edition: 2013-06, Bosch Rexroth AGDocument12 pagesCheck Valve, Pilot Operated: RE 21548, Edition: 2013-06, Bosch Rexroth AGRidha AbbassiNo ratings yet

- WDAAA116787 - B - 25 Steam SystemDocument14 pagesWDAAA116787 - B - 25 Steam SystemRenee Boy GunitaNo ratings yet

- Level Glass Gauge Tightening ProcedureDocument2 pagesLevel Glass Gauge Tightening ProcedureUsman Aslam100% (1)

- ENG0011 DB DE Mechanical EngineDocument44 pagesENG0011 DB DE Mechanical Enginefrezgi birhanuNo ratings yet

- VENTECH Catalogue Air Diffuser and GrillesDocument64 pagesVENTECH Catalogue Air Diffuser and GrillesIshan PereraNo ratings yet

- Directional Control Valves Vincke: HydraulicsDocument53 pagesDirectional Control Valves Vincke: HydraulicsJean De Dieu KasongoNo ratings yet

- Spare Parts List CompleteDocument2 pagesSpare Parts List CompleteMnM Technical ServicesNo ratings yet

- Fuel System - S450Document4 pagesFuel System - S450Gabriel Pereira SilvaNo ratings yet

- Logic Valves PDFDocument7 pagesLogic Valves PDFOgulcan CafNo ratings yet

- BVA300 Series Pneumatic Actuators For Use With Spirax Sarco Ball ValveDocument8 pagesBVA300 Series Pneumatic Actuators For Use With Spirax Sarco Ball ValveneoNo ratings yet

- PR LC Lfa e PDFDocument68 pagesPR LC Lfa e PDFmanjappahNo ratings yet

- Enerpac g3 1gh 002Document60 pagesEnerpac g3 1gh 002JODAROANNo ratings yet

- Dbaw Re - 25891 - 2021-08Document32 pagesDbaw Re - 25891 - 2021-08Johnny JessingNo ratings yet

- Pioneer Deh-2200ub 2250ub KeyboardDocument6 pagesPioneer Deh-2200ub 2250ub KeyboardYEMC YEMC0% (1)

- Deh-2200ub, 2250ub (CRT4478)Document6 pagesDeh-2200ub, 2250ub (CRT4478)qqwweeaassdd8311No ratings yet

- Pioneer DEH 2200UB 2250UB EptDocument76 pagesPioneer DEH 2200UB 2250UB EptJuliana RibeiroNo ratings yet

- Sistema Lubricacion Motor Lycoming 0-235Document10 pagesSistema Lubricacion Motor Lycoming 0-235Mariano RigottiNo ratings yet

- Workshop MaxiDocument39 pagesWorkshop Maxiesteban marinkovicNo ratings yet

- Catalogo ManiglieDocument108 pagesCatalogo Maniglietecnico5No ratings yet

- 40 N177Document1 page40 N177ferasqdiaNo ratings yet

- Rolls - Royce Compressor Section - Maintenance Practices: 250 - C20 Series Operation and MaintenanceDocument42 pagesRolls - Royce Compressor Section - Maintenance Practices: 250 - C20 Series Operation and MaintenancedyjaoliverNo ratings yet

- 108Document2 pages108aliasghar yadegariNo ratings yet

- HMBD 50B Drain ManualDocument14 pagesHMBD 50B Drain Manualindra bayujagadNo ratings yet

- Sacvanging ValveDocument12 pagesSacvanging Valvemohammed sulaimanNo ratings yet

- Final de Carrera D4enDocument14 pagesFinal de Carrera D4enJonatan Ferney Valenzuela ForeroNo ratings yet

- Material List: GANZ TransformerDocument3 pagesMaterial List: GANZ TransformerMohammed ShoaibNo ratings yet

- Service Bulletin: CK20S & 22 Gear Pump Improvement (Updated)Document3 pagesService Bulletin: CK20S & 22 Gear Pump Improvement (Updated)DmitryNo ratings yet

- Catalogo IrritrolDocument58 pagesCatalogo IrritrolArshavin Watashi WaNo ratings yet

- Unloading Relief Valves: Pressure ControlsDocument6 pagesUnloading Relief Valves: Pressure ControlsmdkhandaveNo ratings yet

- Shut-Off Butterfly Valves 3 0 enDocument12 pagesShut-Off Butterfly Valves 3 0 en윤병택No ratings yet

- Bulletin #D19EDocument2 pagesBulletin #D19EΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin #D2 - English: DSE9002 (Revised)Document3 pagesBulletin #D2 - English: DSE9002 (Revised)ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin #D2 - English: DSE9002 (Revised)Document3 pagesBulletin #D2 - English: DSE9002 (Revised)ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin #D4EDocument2 pagesBulletin #D4EΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin #D19EDocument2 pagesBulletin #D19EΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Maintenance Manual For Long Term Storage: Bulletin #D14 - EnglishDocument4 pagesMaintenance Manual For Long Term Storage: Bulletin #D14 - EnglishΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- New Intake Valve Guide For PS-26D and VS-26D EnginesDocument1 pageNew Intake Valve Guide For PS-26D and VS-26D EnginesΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin 36Document4 pagesBulletin 36ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin #D1 EDocument4 pagesBulletin #D1 EΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- ISO Metric Threads: 5. Use of ISO Metric Threads On PS-26D (E) Engine Parts DAIHATSU Has Marketed The PS-26H Engine, AnDocument1 pageISO Metric Threads: 5. Use of ISO Metric Threads On PS-26D (E) Engine Parts DAIHATSU Has Marketed The PS-26H Engine, AnΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Notes On Cylinder Head Packings: Bulletin #D3f - EnglishDocument2 pagesNotes On Cylinder Head Packings: Bulletin #D3f - EnglishΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 8902Document1 pageSK 8902ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Cam and Tappet Width Increase On PS-26D, VS-26D, DS-22 and DV-22 EnginesDocument2 pagesCam and Tappet Width Increase On PS-26D, VS-26D, DS-22 and DV-22 EnginesΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Modification of Piston Crown On DS-26 Engines: Bulletin #D3d - EnglishDocument1 pageModification of Piston Crown On DS-26 Engines: Bulletin #D3d - EnglishΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Item Maintenance Interval Inspection Every 8,000 12,000 Hours Renewal of O-Ring Every 8,000 12,000 Hours Renewal of Crown Bolt Every 20,000 HoursDocument1 pageItem Maintenance Interval Inspection Every 8,000 12,000 Hours Renewal of O-Ring Every 8,000 12,000 Hours Renewal of Crown Bolt Every 20,000 HoursΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin #D3b - English: Marine Industrial Concerns S.ADocument2 pagesBulletin #D3b - English: Marine Industrial Concerns S.AΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Modification of Oil Ring On DS-Series Engines: Bulletin #D3c - EnglishDocument2 pagesModification of Oil Ring On DS-Series Engines: Bulletin #D3c - EnglishΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin #D20 EDocument1 pageBulletin #D20 EΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Mitsubishi S6U-Mtk: Conrod Bearing STD 1Document1 pageMitsubishi S6U-Mtk: Conrod Bearing STD 1ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 9006Document1 pageSK 9006ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Item Maintenance Interval Inspection Every 8,000 12,000 Hours Renewal of O-Ring Every 8,000 12,000 Hours Renewal of Crown Bolt Every 20,000 HoursDocument1 pageItem Maintenance Interval Inspection Every 8,000 12,000 Hours Renewal of O-Ring Every 8,000 12,000 Hours Renewal of Crown Bolt Every 20,000 HoursΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 8806Document1 pageSK 8806ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Bulletin #D20 EDocument1 pageBulletin #D20 EΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 8903Document1 pageSK 8903ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 8903Document1 pageSK 8903ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 9006Document1 pageSK 9006ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 8902Document1 pageSK 8902ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 8803Document1 pageSK 8803ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- SK 8903Document1 pageSK 8903ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Section 3. High Pressure Manifold Fittings: MSS-SP-75 ANSI B31.3 ASME B16.9 Asme Viii Api 6A NACE MR-01-75Document7 pagesSection 3. High Pressure Manifold Fittings: MSS-SP-75 ANSI B31.3 ASME B16.9 Asme Viii Api 6A NACE MR-01-75jkhgvdj mnhsnjkhgNo ratings yet

- J Cep 2004 05 009Document10 pagesJ Cep 2004 05 009Sahand NekoeianNo ratings yet

- Hydraulic PumpsDocument23 pagesHydraulic PumpsArth LubayNo ratings yet

- Chemlube 215 229 230 501 751 822Document2 pagesChemlube 215 229 230 501 751 822Suprastowo Bin SarinoNo ratings yet

- SIEC-Bag FilterDocument13 pagesSIEC-Bag FilterMahendra RathoreNo ratings yet

- FMMDocument4 pagesFMMMohanraj KabilanNo ratings yet

- Particulate Control-2 Fabric Filters Particulate Scrubbers: Prof. Dr. Dentel Notes and Prof. Dr. Chang-Yu WuDocument53 pagesParticulate Control-2 Fabric Filters Particulate Scrubbers: Prof. Dr. Dentel Notes and Prof. Dr. Chang-Yu WuTushar KadgaleNo ratings yet

- Travel Motor: Systems OperationDocument5 pagesTravel Motor: Systems OperationAllan LariosaNo ratings yet

- PerpanDocument7 pagesPerpanT Bagus Tri LusmonoNo ratings yet

- Question Paper Code: X60843: (10×2 20 Marks)Document3 pagesQuestion Paper Code: X60843: (10×2 20 Marks)Keesanth Geetha ChandrasekaranNo ratings yet

- Synthetic MIL-PRF-83282) Was Developed Which Is Superior ToDocument1 pageSynthetic MIL-PRF-83282) Was Developed Which Is Superior ToTrong Tuan NguyenNo ratings yet

- Solid Gas FluidizationDocument9 pagesSolid Gas FluidizationHaris PratamaNo ratings yet

- Libo GS: Document / Drawing Submission Status Proyek Penyesuaian Pompa RokanDocument5 pagesLibo GS: Document / Drawing Submission Status Proyek Penyesuaian Pompa RokanekyyyNo ratings yet

- Process Control Design and PracticeDocument230 pagesProcess Control Design and PracticeAndrés Felipe AcostaNo ratings yet

- 52 - Model FP 43q BFDocument2 pages52 - Model FP 43q BFAdriano Moyses OutlookNo ratings yet

- Boundary Layer AnalysisDocument17 pagesBoundary Layer AnalysiscaltechNo ratings yet

- Hyd - 7Document2 pagesHyd - 7SamNo ratings yet

- Boiler Question & Answer For COC ExamDocument46 pagesBoiler Question & Answer For COC ExamAmir MahmoudjanlouNo ratings yet

- MP513ENDocument132 pagesMP513ENAnonymous H3I29yjNo ratings yet

- 112.09 Heat Exchangers BrochureDocument4 pages112.09 Heat Exchangers BrochureAlexandru DinaNo ratings yet

- Shell Tellus s2 V 46Document3 pagesShell Tellus s2 V 46rstec pyNo ratings yet

- Dual Contrabalance BoschDocument2 pagesDual Contrabalance BoschTiagoNo ratings yet

- 4.3 Product Leaflet OnlineVac 2018Document2 pages4.3 Product Leaflet OnlineVac 2018Jose LiraNo ratings yet

- Spentwash ManagementDocument30 pagesSpentwash ManagementAbhinav Farshi100% (1)

- HeuristicsDocument78 pagesHeuristicsJames Edward DoolittleNo ratings yet