Professional Documents

Culture Documents

مواصفات الجيم

Uploaded by

Mujahed Khatib0 ratings0% found this document useful (0 votes)

29 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views6 pagesمواصفات الجيم

Uploaded by

Mujahed KhatibCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Qatar Media Corporation

Technical affairs department.

Maintenance section 2021

Construction of the new GYM North Gate Bldg.

No description of works Unit Quantity Rate Amount

1-Preparing site

Demolish, Dismantle and dispose the following of outside QMC camp: -

. Inner building in center of security gate.

· All the Debris.

· Contractors should transport all demolished materials to item

outside QMC campus daily.

Prepare and clean the floor surface properly.

. All interlock and curbstones.

Contractor is responsible to relocate and shift all the ground services. item

Supply and casting 15cm thick ready-mix concrete for all area with m2 488

8mm wire mesh and gage1000 plastic sheet.

2-PAINTING WORKS

Apply two coats of stucco marble paint for the inner walls of m2 66

the entrance as properly and engineer’s instructions.

3- Cement board walls

1-Lay steel sub frames, secure well to the flooring side walls and

soffits.

2- Lay 12mm thick cement board walls. Apply appropriate fillet &

primer and overlay all the newly laid walls. m2 42

3- Execute the cement board walls as per the attached drawings.

4-The contractor must be use rubber mesh in the joints before

starting the Painting for the walls.

5-The contractor is responsible to fix the cement boards properly

otherwise it will be refused.

5 4- GLASS DOOR

I)- supply and Fix 10 to 12mm thick new

double leaves with frameless tempered glass No 2

transparent, floor surface door

closers and all fittings are to be heavy-duty stainless-steel ones.

ii)-Provide &Fix stainless steel frame on the around of the door. item

iii) supply and lay two stainless steel locks at center and

bottom.

vi)- Bilingual name logo for QMC is to be written

on the transparent door. item

complete accessories of door as:-

Supply and fix automatic Door closure machine, Door stopper,

Locks and kick plate.

* 5- Steel structure frame FOR GLASS WALL

1- The contractor is responsible to put supports galvanized steel

columns with dimensions (150*200) mm at the corners and middle Lump sum

span and as per engineer’s instructions (12 columns).

Supply and lay stainless steel hinges and to be fix in glass panels

and steel columns

2-Supply and lay I beam steel (100*100) mm dimensions to be welded

with all columns from up and crossing with itself. (Lump sum).

All steel work is to be as per sketch and engineer’s instructions.

Contractor should take in his consider and his design that steel

structure may be will be loaded by mezzanine.

Steel structure (chassis) ceiling for corridors

1-Supply and lay I beam steel (100*100) mm dimensions for

the ceiling. The distance between each beam and another one is m2 25

70 cm and crossing with itself. (Lump sum).

2- The chassis system is loaded on the cement board walls and

should be connected(welded) with the supports .

6-Floor

• Supply & fix new 5mm PVC sheet for the flooring m2 488

with grade1quality (European type). with all required materials.

7-Polyurethane Sprayfoam Insulation with protective coating for roof

Prior to start spray foam, clean & wash the area properly.

and then

Supply and spray Polyurethane foam of average thick -

ness around 30- 35 mm. Density 40 -45 kg/ m³. 488

All holes on roof Kirby are to be closed & sealed properly

with waterproofing or any bonding agent equivalent to same

as waterproofing materials. Submit warranty.

Cover the spray foam by applying 2 coats of protective

coating or liquid applied waterproofing coating.

Warranty: Submit written warranty of 7 to 10 years.

Use safety helmets, shoes, overall, hand gloves and safety

Supply and fix tempered double glazed glass panels thermal

insulation and sealed with 8 mm thick. And reflection with pure

viewing with tubular aluminum frame. m2 270

supply and lay all accessories stainless steel(hinges,plates,bolts,

sealant) for the glass walls and all requirements.

Supply and fix sand blast with logo on the external glass.

If any existing structures damaged during the work must be

item

repaired

properly.

CONTRACTOR IS RESPONSIPLE OF THE CLEANLINESS AND TIDINESS item

OF THE SITE.

Contractors are responsible to take all measurements.

9-concrete and blockworks

Raft footing

Supply and casting raft foundation with its reinforcement

as per design which contractor will submit it.

Reinforced columns

m2

Supply and casting the column with its L.S

reinforcement as per design which contractor will submit it

Reinforced beams

Supply and casting the beams with its

reinforcement as per design which contractor will submit it

10-Aluminum windows

Supply and fix tempered double-glazed glass windows with 4mm

thick. And reflection with pure viewing with tubular aluminum NO 8

Frame (0.60x1.0)m

11-External Walls

ii) Lay blockwork walls with insulation of the same thickness of

existing wall including mesh &other accessories for blockwork

joints.

If the height is more than 3 m then provide concrete lintels of m2 105

size 20 cm x width of the existing wall. Fix mesh and all other

accessories at all vertical & horizontal joints when laying

blockworks.

Make plastering for the wall.

Make full maintenance for all existing inner marble walls properly.

Paint work

Apply two coats of fenomastic JOTUN paint same as matching colors m2 190

with the existing walls in the same area.

Marble

Supply marble type grade A for the external wall with all its m2 170

requirements and fix it mechanical.

Supply and fix powder coated aluminum louver panel to all

existing windows.

Main entrance

Supply marble type grade A for the steps of the entrance with m2 10

all its requirements.

Make sure that the insurance of all of your labors

who will work at this site and as well the insurance of the work.

You will not be allowed to start the work, if you do not submit

the insurance & if you do not follow all the safety measures

as stated above.

All samples must be approved from the engineer

Time of works: - 140days from work order date.

You might also like

- Detailed Technical Specification For Civil WorkDocument8 pagesDetailed Technical Specification For Civil WorkShivhar Menkudle100% (2)

- Specification WritingDocument5 pagesSpecification WritingJaycel AquinoNo ratings yet

- 1.09 Item Wise Detailed DescriptionDocument37 pages1.09 Item Wise Detailed DescriptionRajesh ChowhanNo ratings yet

- General Specifications: 1. EarthworksDocument7 pagesGeneral Specifications: 1. Earthworksenvironmental100% (1)

- Method Statement Construction of Chambers-Concrete WorksDocument6 pagesMethod Statement Construction of Chambers-Concrete WorksLovemore Makora MukondomiNo ratings yet

- ANNEX-B-Bill-of-Qunatities-BOQs BuildingDocument42 pagesANNEX-B-Bill-of-Qunatities-BOQs Buildingmuhammad iqbalNo ratings yet

- Buldg Specifications v1Document9 pagesBuldg Specifications v1Adel JaNo ratings yet

- Proposed Hostel Block for CumminsDocument4 pagesProposed Hostel Block for CumminssplashierprinceNo ratings yet

- Construction MethodologyDocument6 pagesConstruction Methodologyadrianalbacete75No ratings yet

- Const Specs (Gutierrez Residence)Document6 pagesConst Specs (Gutierrez Residence)Ernane RitaNo ratings yet

- Chapter I. A: Rchitecture Wooden WorkDocument17 pagesChapter I. A: Rchitecture Wooden WorkFengwei ShihNo ratings yet

- Scope of Work DuplexDocument7 pagesScope of Work Duplexjet toledo100% (1)

- General notes and specifications for one-storey residenceDocument5 pagesGeneral notes and specifications for one-storey residenceJillian Flaire VillarNo ratings yet

- Until The Architects or Engineers Judgment, A Goo Level Is Reached For Foundations, EtcDocument5 pagesUntil The Architects or Engineers Judgment, A Goo Level Is Reached For Foundations, EtcJillian Flaire VillarNo ratings yet

- 1 General Requirements 1.1 GeneralDocument9 pages1 General Requirements 1.1 GeneralAsica MusicaNo ratings yet

- Specifications - Proposed Four Storey Apartment BuildingDocument6 pagesSpecifications - Proposed Four Storey Apartment BuildingEpp0% (1)

- Schedule of QuantityDocument10 pagesSchedule of QuantityMuhammad SafdarNo ratings yet

- Specifications Master FormatDocument10 pagesSpecifications Master FormatJane Guiron AballaNo ratings yet

- Outline Specifications (One 1 Storey Residential)Document5 pagesOutline Specifications (One 1 Storey Residential)mark manalang100% (1)

- Proposed 2-Storey Restaurant Building SpecsDocument9 pagesProposed 2-Storey Restaurant Building SpecsDAP Ysabelle Marie FuentesNo ratings yet

- Core & Shell BOQ - ArchDocument58 pagesCore & Shell BOQ - ArchashokNo ratings yet

- Material and Work SPECIFICATIONS for PROPOSED TWO-STOREY RESIDENCEDocument5 pagesMaterial and Work SPECIFICATIONS for PROPOSED TWO-STOREY RESIDENCEMark Gregory RimandoNo ratings yet

- Albert Joshua ZuñigaCENG 125Document4 pagesAlbert Joshua ZuñigaCENG 125Joshua ZunigaNo ratings yet

- Residential Specs GuideDocument3 pagesResidential Specs GuideBernie RomeroNo ratings yet

- General Specifications Allanalbano (2524)Document7 pagesGeneral Specifications Allanalbano (2524)Allan AlbanoNo ratings yet

- BrickDocument3 pagesBrickSyed IhyaNo ratings yet

- Specifications - BUILDING PERMIT - LANIE SISTERWAYDocument4 pagesSpecifications - BUILDING PERMIT - LANIE SISTERWAYCivil EngineerNo ratings yet

- Actvity 3 FinalDocument4 pagesActvity 3 FinalKaparaz, Ronald Allan B. Sec-CNo ratings yet

- Method of Brick Masonry WorkDocument3 pagesMethod of Brick Masonry WorkTAHER AMMARNo ratings yet

- Boq AliaDocument126 pagesBoq AliaMuhammad Shakil JanNo ratings yet

- PROJECT-02-SPECIFICATIONDocument16 pagesPROJECT-02-SPECIFICATIONDUMLAO, ANGELIE M.No ratings yet

- I. General Conditions ADocument7 pagesI. General Conditions ASamuel LacarNo ratings yet

- SL - No Description Unit Qty: 1 SQM 672or 30 30Document38 pagesSL - No Description Unit Qty: 1 SQM 672or 30 30Solomon KasahunNo ratings yet

- Material SpecsDocument4 pagesMaterial SpecsSharon AtanacioNo ratings yet

- Proposed Two Specification WritingDocument4 pagesProposed Two Specification WritingKelly Santiago100% (1)

- Permits, inspections, protection for all trades workDocument6 pagesPermits, inspections, protection for all trades workmwaseem2011No ratings yet

- Archi TranslationDocument17 pagesArchi TranslationTianyi MuseNo ratings yet

- Boq PDFDocument63 pagesBoq PDFGULED FELEKENo ratings yet

- Tech Specs BrickDocument53 pagesTech Specs BrickCumhur MalgilNo ratings yet

- General Specifications AlbalateDocument8 pagesGeneral Specifications Albalatejhnrynalbalate95xNo ratings yet

- Structural Works: 1.1 Substructure Works 1.2 Earthwork in ExcavationDocument3 pagesStructural Works: 1.1 Substructure Works 1.2 Earthwork in ExcavationNishan GajurelNo ratings yet

- Project Specification: Title: Bruna Bautista Ville CPM Location: Rizal Santiago CityDocument7 pagesProject Specification: Title: Bruna Bautista Ville CPM Location: Rizal Santiago Citymelvin bautistaNo ratings yet

- Bill of Quntity 1 (استرداد)Document9 pagesBill of Quntity 1 (استرداد)ahmedNo ratings yet

- Technical SpecificationDocument4 pagesTechnical SpecificationblaisetabinunbagNo ratings yet

- RTT and GBT Site ScopeDocument19 pagesRTT and GBT Site ScopeAnish RanaNo ratings yet

- Technical Specification For Proposed OneDocument5 pagesTechnical Specification For Proposed OneAngel JinHiroNo ratings yet

- Estimate 29 - 11Document19 pagesEstimate 29 - 11Ositha WarunaNo ratings yet

- Raised Floor Works-SpecsDocument5 pagesRaised Floor Works-SpecsdenisjayNo ratings yet

- Costruction SpecificationDocument5 pagesCostruction Specificationjendel manahanNo ratings yet

- Proposed 3BR Vacation House Scope of WorksDocument5 pagesProposed 3BR Vacation House Scope of WorksMel FNo ratings yet

- Aluminium Work Method StatementDocument4 pagesAluminium Work Method StatementChezy629100% (3)

- Interior Fit-Out of Pomodoro Pizza Pasta KitchenDocument5 pagesInterior Fit-Out of Pomodoro Pizza Pasta KitchenAngel AbrajanoNo ratings yet

- Specification: Project:-Church Owner: - Weyra MedhanialemDocument3 pagesSpecification: Project:-Church Owner: - Weyra MedhanialemAbenezerNo ratings yet

- Specification of Toilet BlockDocument2 pagesSpecification of Toilet BlockKuldeep ChakerwartiNo ratings yet

- Exconde Building TechDocument5 pagesExconde Building TechAllyson ExcondeNo ratings yet

- Aluminium Formwork Work ProcedureDocument4 pagesAluminium Formwork Work ProcedurePrasanta ParidaNo ratings yet

- DSR 2012 SupplementDocument59 pagesDSR 2012 SupplementNagaraju PogulakondaNo ratings yet

- Building-Specifications Reynal RamosDocument5 pagesBuilding-Specifications Reynal Ramoserwin sarmientoNo ratings yet

- Project: Proposed Two (2) Storey Residential With BasementDocument4 pagesProject: Proposed Two (2) Storey Residential With BasementCasthiel SorianoNo ratings yet

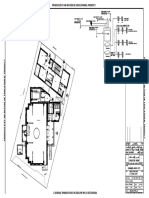

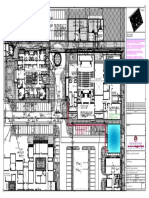

- PA-01-G.FLOOR-P.A SYSTEM-LAYOUT - ModelDocument1 pagePA-01-G.FLOOR-P.A SYSTEM-LAYOUT - ModelMujahed KhatibNo ratings yet

- Ba-808-St-E01-Site Electrical & ElvDocument1 pageBa-808-St-E01-Site Electrical & ElvMujahed KhatibNo ratings yet

- Cooper (Eaton) FaDocument1 pageCooper (Eaton) FaMujahed KhatibNo ratings yet

- Stores Building: Key PlanDocument1 pageStores Building: Key PlanMujahed KhatibNo ratings yet

- Ba-808 - Store Structure-R1-St-01Document1 pageBa-808 - Store Structure-R1-St-01Mujahed KhatibNo ratings yet

- Gree-Electrical Appliances: Air Conditioner (Split Unit)Document1 pageGree-Electrical Appliances: Air Conditioner (Split Unit)Mujahed KhatibNo ratings yet

- Ontec G Exit & EmergencyDocument1 pageOntec G Exit & EmergencyMujahed KhatibNo ratings yet

- MKDocument760 pagesMKThiraviam AyyappanNo ratings yet

- MK AccesoriesDocument35 pagesMK AccesoriesMujahed KhatibNo ratings yet

- KG Plastic Product CatalogueDocument16 pagesKG Plastic Product CatalogueQNBNo ratings yet

- Basement Construction MethodDocument25 pagesBasement Construction Methodrohit jaiswalNo ratings yet

- KDK Exhaust Fans DatasheetsDocument44 pagesKDK Exhaust Fans DatasheetsMujahed KhatibNo ratings yet

- Bill of MaterialsDocument10 pagesBill of Materialshallel jhon butacNo ratings yet

- Glass Fibre NonwovensDocument4 pagesGlass Fibre NonwovensSachin ShindeNo ratings yet

- Shear Wall DesignDocument22 pagesShear Wall DesignHarold Jackson Mtyana100% (1)

- Structural Analysis & Design of MSBDocument29 pagesStructural Analysis & Design of MSBthak49100% (1)

- UnderpinningDocument6 pagesUnderpinningBori GeorgeNo ratings yet

- ROB Estimate (Br. Proper & Approaches Etc.)Document2 pagesROB Estimate (Br. Proper & Approaches Etc.)Bilal A BarbhuiyaNo ratings yet

- Construction Cost Estimate: By: Engr. Erniel Dave A. GuyoDocument29 pagesConstruction Cost Estimate: By: Engr. Erniel Dave A. GuyoMica Joice FernandezNo ratings yet

- EVPD - Full - Exposed Floors - KingpsanDocument1 pageEVPD - Full - Exposed Floors - Kingpsandeboline mitraNo ratings yet

- RFI-3458 - Daily Fit Up Inspection Report-OKDocument24 pagesRFI-3458 - Daily Fit Up Inspection Report-OKnguyennamxmNo ratings yet

- DPWH Standard SpecificationsDocument6 pagesDPWH Standard SpecificationsNiño Donayre Wariza100% (1)

- Bulon Neo PDFDocument11 pagesBulon Neo PDFNinh Quang LinhNo ratings yet

- Study of Strength of RC Shear Wall at Different Location On Multi-Storied Residential BuildingDocument6 pagesStudy of Strength of RC Shear Wall at Different Location On Multi-Storied Residential BuildingSyed Ehtesham AliNo ratings yet

- Pages From Inter-Model, - Analytical, - and - eDocument15 pagesPages From Inter-Model, - Analytical, - and - eRise CompanyNo ratings yet

- Collage House / S+Ps ArchitectsDocument8 pagesCollage House / S+Ps ArchitectsChanchal SoniNo ratings yet

- Structural SSDA Report: Mosman High SchoolDocument17 pagesStructural SSDA Report: Mosman High SchoolKesavan DhuraisamyNo ratings yet

- SSC Apg001 enDocument20 pagesSSC Apg001 enapi-279886039No ratings yet

- SMACNA Architecturalmanual PPDocument74 pagesSMACNA Architecturalmanual PPRonald Kahora50% (4)

- Cooling Tower DiscussionDocument10 pagesCooling Tower Discussiondhanu_lagwankar100% (1)

- Section 6.5 - Timber JoistDocument14 pagesSection 6.5 - Timber Joistfreddyguzman3471No ratings yet

- RAV MAMAD - Eng DefensetrchsDocument21 pagesRAV MAMAD - Eng DefensetrchsdefensetechsNo ratings yet

- Fire Resistance Assessment of Concrete StructuresDocument81 pagesFire Resistance Assessment of Concrete StructuresJevgenijsKolupajevsNo ratings yet

- Structural Design of Light Gauge SteelDocument80 pagesStructural Design of Light Gauge SteelMujjo Sahb100% (1)

- Lightolier Classic White Track & Downlights Brochure 1987Document6 pagesLightolier Classic White Track & Downlights Brochure 1987Alan MastersNo ratings yet

- Residential Building Cost Estimation and Project DetailsDocument38 pagesResidential Building Cost Estimation and Project DetailsmnmusorNo ratings yet

- Project Construction ScheduleDocument1 pageProject Construction ScheduleZied Ben SalahNo ratings yet

- Chapter C3: Ventilation of Non-Domestic BuildingsDocument15 pagesChapter C3: Ventilation of Non-Domestic BuildingsAli AimranNo ratings yet

- Civic Centre structural designDocument4 pagesCivic Centre structural designnicholasomodingNo ratings yet

- ZERO-Code REFERENCIAS DE EIUDocument16 pagesZERO-Code REFERENCIAS DE EIUDianys RocafuerteNo ratings yet

- Perimeter Fence Plan RevisedDocument1 pagePerimeter Fence Plan RevisedArjay ArzadonNo ratings yet

- PC Spun PilesDocument2 pagesPC Spun PilesFaridah Zahra100% (1)