Professional Documents

Culture Documents

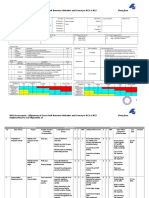

Incident Compliance Tracker - Electrical

Uploaded by

Anonymous kWfNFb0 ratings0% found this document useful (0 votes)

11 views3 pagesOriginal Title

1. Incident Compliance Tracker_Electrical

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views3 pagesIncident Compliance Tracker - Electrical

Uploaded by

Anonymous kWfNFbCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Compliance Status Checklist

Project Name : M 912

Project Manager: Joydip Saha

Work Activity : CIVIL WORKS

Inspection Date & Time : 5th Sep 2021

Action Target Compliance

S.No. Description Status of Compliance Responsible Remark

Required Date date

Adding the details of line crossing at each section in micro plan

1 YES

& briefing the same to site engineers.

Preparation of specific location wise method statement for

2 each line crossing with line diagram and making supervisor, YES

engineers, Section incharge, EHSO aware about the same.

Preparation of location specific Risk assessment based on

3 method statement prepared. Putting our cable underground so YES

as to work when shutdown is not there.

Right now no shut

4 Getting documented work permit for shut down from Client NA

down works

Ensuring shutdown by following the LOTO Process till

5 YES

completion of the shutdown work

Strict adherence of LOTO process:

Locking & Tagging at source end

6 Yes

Fixing of Discharge rod for Each

Confirming line discharge through VAV detection

No poles are

available.

7 Use of insulated ladder for climbing on pole NA

Scaffolding system is

in place.

Checking & recording of earth resistance of discharge rods at

8 Yes

location.

Comments :

Signed by RM-EHS/Safety officer: Sudhakar B Signed by Project Manager/SM: Joydip Saha

Compliance Status Checklist

Project Name : M 912

Project Manager: Joydip Saha

Work Activity : 132/11kv Substation

Inspection Date & Time : 5th Sep 2021

Action Target Compliance

S.No. Description Status of Compliance Responsible Remark

Required Date date

Sufficient quantity Snake repellent available at store for workmen Conducting disinfection

1

camp according to number of tents in the location activity on daily basis

Spray the snake repellent at least once in a week for continuous

Conducting disinfection

2 protection and record/register (with photographic evidence) to be

activity on daily basis

maintained for each such applications.

Trench excavation to be done on all sides of tent/camp to avoid

3 entry of snake. Trench size shall be 3ft (depth)* 2ft (Width) and All opening gaps are closed.

barricading to be done on all four sides.

Is electronic snake repellents (battery/solar based) available in all

4 NA

tents area as additional protection

Is emergency Response Plan displayed at all workmen camps and

5 YES

periodic mock drill conducted for snake bite and recorded.

Is toilet facility (mobile toilets) available near to tents and it should

6 YES

not be more than 20m from the tent

Is proper arrangement for sleeping like beds & mattress available in

7 YES

tent as per SOP.

8 Is temporary lighting available in tent or camp. YES

9 Grass need to be removed from around the camp time to time basis YES

Awareness trainings to be given for workmen on prevention of

10 snake bites, Dos & Don’ts of snake bites & Emergency Response YES

plan for snake bites

Comments :

Signed by RM-EHS/Safety officer : Sudhakar B Signed by Project Manager: Joydip Saha

Compliance Status Checklist

Project Name : M 912

Project Manager: Joydip Saha

Work Activity : Loading and Unlaoding of general materials by Mobile Crane

Inspection Date & Time : 5th Sep 2021

Action Target Compliance

S.No. Description Status of Compliance Responsible Remark

Required Date date

Safe staking and storage method to be prepared and adehre for

the store covering all aspects:

e.g. maximum staking heights; safe distances between

stacks , stack positioning, size and shape of different

1 YES

types of stacks , bonding/ securing of stacks, Safe

rules for destacking and re stacking, MHE

requirements, route map for safe stack movement,

area wise accountability matrix for safe stacking etc.

Using mobile crane

2 Replacement of Old generation to new generation hydra. NA

when it is required.

Strict Adherence of operator competence (must be having valid

3 licence and gone through medical fitness, training and YES

authorisation)

Display ( or Place barriers )of material stacking height limit and

4 YES

Display of do & don’t at store area.

Review Risk Assessment of Finish Yard to identify additional

5 YES

controls.

Conduct Mass awareness communication/ stand down

6 meetings in the plant to sensitize the workforce of the incident YES

and safety measures to be taken

Install reverse horns in all the Hydras in operation and ensure

7 signal man in critical material handling and movement. NA

Implementation of Guying arrangement for material shifting

8 Improve Safety visual displays across in the plant. YES

Comments :

Signed by RM-EHS/Safety officer: Sudhakar B Signed by Project Manager: Joydip Saha

You might also like

- Safety Check For Lube Oil Flushing: SI. No. Description Observation Yes/No/NA RemarksDocument1 pageSafety Check For Lube Oil Flushing: SI. No. Description Observation Yes/No/NA RemarksRísês ÃfrözNo ratings yet

- AB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main DeckDocument2 pagesAB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main Deckvikrant911No ratings yet

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- JSA For Hydro Jetting, Removal and Cleaning of SludgeDocument18 pagesJSA For Hydro Jetting, Removal and Cleaning of Sludgesk sajidNo ratings yet

- Installation of Solar PanelsDocument4 pagesInstallation of Solar PanelsManafNo ratings yet

- Mechanical Demolish JhaDocument2 pagesMechanical Demolish JhafatimahNo ratings yet

- Risk Assessment For FlushingDocument9 pagesRisk Assessment For FlushingABDUL BASITHNo ratings yet

- Annexure 06 Hse ChecklistsDocument21 pagesAnnexure 06 Hse ChecklistsAnilPagoluNo ratings yet

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- Projects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SDocument6 pagesProjects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SAnonymous kWfNFbNo ratings yet

- Daily Cradle Inspection Sheet: No Type of Check Operational Status RemarksDocument1 pageDaily Cradle Inspection Sheet: No Type of Check Operational Status RemarksZubair Khan100% (1)

- 00-Site InstructionDocument7 pages00-Site InstructionSyed Munawar AliNo ratings yet

- Job Safety Analysis (Jsa) : Country / Location: MZLN-09 Date Description of Job or Work Activity: Rig: Jsa #Document2 pagesJob Safety Analysis (Jsa) : Country / Location: MZLN-09 Date Description of Job or Work Activity: Rig: Jsa #madjid bobNo ratings yet

- LOCO - SOP - E - 0005 Inspection of LocoDocument10 pagesLOCO - SOP - E - 0005 Inspection of LocoFiron Kumar RanaNo ratings yet

- Aea 1305 WC El MS 0002Document14 pagesAea 1305 WC El MS 0002Adil HasanovNo ratings yet

- 4.9 - Sample SWMSDocument10 pages4.9 - Sample SWMSmehdiNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument20 pagesJSA For Scaffolding Erection Dismantling and Modification Workbagas prakoso100% (1)

- JSA For Erection and Repair Work of TanksDocument19 pagesJSA For Erection and Repair Work of TanksMohamed Farouk100% (2)

- Masterpact Maintenance ProcedureDocument94 pagesMasterpact Maintenance ProcedureYassin Alkady100% (1)

- Daily Activity Report Axon Structured Cabling Global City, Taguig DNE-DAR-015-AXN Wednesday, 7 July 2021Document1 pageDaily Activity Report Axon Structured Cabling Global City, Taguig DNE-DAR-015-AXN Wednesday, 7 July 2021Charmaine Marie CabreraNo ratings yet

- Break Out and Laying Down BhaDocument3 pagesBreak Out and Laying Down BhakhurramNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- PEB Shop Check ListDocument1 pagePEB Shop Check Listkiran m vNo ratings yet

- 1.daily Work PermitDocument1 page1.daily Work PermitIndraNo ratings yet

- SWMS SampleDocument5 pagesSWMS SampleVipin Kumar ParasharNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument30 pagesJSA For Scaffolding Erection Dismantling and Modification Workkmohamedkeita906No ratings yet

- Water Proofing JhaDocument2 pagesWater Proofing JhafatimahNo ratings yet

- Ezeh Solomon Onyekachi (B.Eng.) : Experience ContactDocument4 pagesEzeh Solomon Onyekachi (B.Eng.) : Experience ContactOnyekachi JackNo ratings yet

- 7 - HSE-SOP-007 Radiography Permit FormDocument2 pages7 - HSE-SOP-007 Radiography Permit FormEngr. Muhammad Hassan AzizNo ratings yet

- SOP 032 - QC Hoist Wire Rope Replacement - V 2.0Document6 pagesSOP 032 - QC Hoist Wire Rope Replacement - V 2.0ncthanhck0% (1)

- SOP For Duct OSP - 20141230Document20 pagesSOP For Duct OSP - 20141230khinmaungkywe2211No ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- EHS Officer Inspection-SAB, RosslynDocument6 pagesEHS Officer Inspection-SAB, RosslynAmukelaniNo ratings yet

- Construction SV Checklists 18 Aug 2022 REVDocument235 pagesConstruction SV Checklists 18 Aug 2022 REVFiqih MuhammadNo ratings yet

- Scaffolding Work Permit New FORMDocument1 pageScaffolding Work Permit New FORMRaka NusantaraNo ratings yet

- Safety Work Permit: Purok Lansong, Barangay Tambler, General Santos City Tel. No.: (083) 552-1831Document1 pageSafety Work Permit: Purok Lansong, Barangay Tambler, General Santos City Tel. No.: (083) 552-1831glenn umaliNo ratings yet

- MS - Gondola System Rev 2Document6 pagesMS - Gondola System Rev 2Non Etabas Gadnatam100% (1)

- FrogLink Riveted Anchor Maintenance Check ListDocument3 pagesFrogLink Riveted Anchor Maintenance Check ListNirooban VigneswaranNo ratings yet

- Adjust Brake On Draw WorksDocument1 pageAdjust Brake On Draw WorksDQE040 HSSENo ratings yet

- Job No. Customer Job Description Location/Section Takreer Scaffolding Service For Maintenance RUWAIS RefineryDocument2 pagesJob No. Customer Job Description Location/Section Takreer Scaffolding Service For Maintenance RUWAIS RefineryNazim NazarNo ratings yet

- Jsa 05 136Document5 pagesJsa 05 136Viron BaxhiaNo ratings yet

- JSA For Coating and Raping Activity in TankDocument7 pagesJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNo ratings yet

- 07 Nov 19 KFDP Site HSE Daily ReportDocument7 pages07 Nov 19 KFDP Site HSE Daily ReportEdo-Abasi EkereNo ratings yet

- Aea 1305 WC El MS 0003Document15 pagesAea 1305 WC El MS 0003Adil HasanovNo ratings yet

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- On Latest JPO On Stabling Loads DT 18.06.21Document10 pagesOn Latest JPO On Stabling Loads DT 18.06.21Naveen Kushwaha100% (3)

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- JSA For Scaffolding and Shed ErectionDocument1 pageJSA For Scaffolding and Shed ErectionAnonymous voA5Tb0No ratings yet

- Control of Sewerage and Surface Water DrainageDocument4 pagesControl of Sewerage and Surface Water DrainageMichaelJamesBanawisNo ratings yet

- JSA For Blinding and De-Blinding (Opening Process Equipment)Document11 pagesJSA For Blinding and De-Blinding (Opening Process Equipment)Thái Đạo Phạm Lê100% (1)

- RSA-A4-PR-WI-03 (Painting) - Rev 0Document1 pageRSA-A4-PR-WI-03 (Painting) - Rev 0Abhishek KadamNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- Mobile Scaffold Inspection Checklist: Scaffold Location / Number: Complies? Y Yes N No N/A Not ApplicableDocument1 pageMobile Scaffold Inspection Checklist: Scaffold Location / Number: Complies? Y Yes N No N/A Not ApplicableMyolwinooNo ratings yet

- LOCO - SOP - E - 0021 Main Alternator ChangingDocument7 pagesLOCO - SOP - E - 0021 Main Alternator ChangingFiron Kumar RanaNo ratings yet

- 515021&515022-PLT-DZ-077-2011 Replace FIP, Fuel Injector, and Turbo Charge of DozerDocument8 pages515021&515022-PLT-DZ-077-2011 Replace FIP, Fuel Injector, and Turbo Charge of DozerMuhammad Fatur Dipo GribaldyNo ratings yet

- Production Welding Check List - Overlay - (Updated)Document16 pagesProduction Welding Check List - Overlay - (Updated)samuelarelianopsNo ratings yet

- PPR Installation & Pressure Testing RADocument19 pagesPPR Installation & Pressure Testing RAJomy JohnyNo ratings yet

- FE MonitoringDocument1 pageFE MonitoringJezreel TolentinoNo ratings yet

- Electrical Work: Phase Hazard AnalysisDocument10 pagesElectrical Work: Phase Hazard AnalysisBNCHNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 5 out of 5 stars5/5 (2)

- BSI Standards Publication: Methods For Rating and Assessing Industrial and Commercial SoundDocument76 pagesBSI Standards Publication: Methods For Rating and Assessing Industrial and Commercial SoundAnonymous kWfNFbNo ratings yet

- Main Building Raft Foundation MS-005 R1Document11 pagesMain Building Raft Foundation MS-005 R1Anonymous kWfNFbNo ratings yet

- Sanders Lodge, Rushden, Northamptonshire, Nn10 6Bq: Page 1 of 11Document11 pagesSanders Lodge, Rushden, Northamptonshire, Nn10 6Bq: Page 1 of 11Anonymous kWfNFbNo ratings yet

- Night Shift FormDocument2 pagesNight Shift FormAnonymous kWfNFbNo ratings yet

- Raft Foundation-RA 005Document20 pagesRaft Foundation-RA 005Anonymous kWfNFbNo ratings yet

- Wall & Column at Basement MS.06Document13 pagesWall & Column at Basement MS.06Anonymous kWfNFbNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- HSE PlanDocument57 pagesHSE PlanAnonymous kWfNFbNo ratings yet

- Emeregency Reporting ProceduresDocument1 pageEmeregency Reporting ProceduresAnonymous kWfNFbNo ratings yet

- Risk Assessment TrainingDocument5 pagesRisk Assessment TrainingAnonymous kWfNFbNo ratings yet

- Rescue TrainingDocument25 pagesRescue TrainingAnonymous kWfNFbNo ratings yet

- Fire Mock DrillDocument15 pagesFire Mock DrillAnonymous kWfNFbNo ratings yet

- Projects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SDocument5 pagesProjects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SAnonymous kWfNFb100% (1)

- Training Matrix For Nov & Dec - 1Document1 pageTraining Matrix For Nov & Dec - 1Anonymous kWfNFbNo ratings yet

- Incident Compliance Tracker-Rev1Document1 pageIncident Compliance Tracker-Rev1Anonymous kWfNFbNo ratings yet

- Mom 59Document14 pagesMom 59Anonymous kWfNFb100% (1)

- Incident Compliance Tracker - ElectricalDocument3 pagesIncident Compliance Tracker - ElectricalAnonymous kWfNFbNo ratings yet

- Electrical Safety RequirementDocument8 pagesElectrical Safety RequirementAnonymous kWfNFb100% (1)

- Electrical Safety RequirementDocument8 pagesElectrical Safety RequirementAnonymous kWfNFb100% (1)

- Incident Compliance Tracker-Rev1Document1 pageIncident Compliance Tracker-Rev1Anonymous kWfNFbNo ratings yet

- Projects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SDocument6 pagesProjects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SAnonymous kWfNFbNo ratings yet

- Mom 59Document14 pagesMom 59Anonymous kWfNFb100% (1)

- Superviosr Pre - Activity ChecklistDocument1 pageSuperviosr Pre - Activity ChecklistAnonymous kWfNFbNo ratings yet

- Jurong Island Cargo Tec RA Alignment of Cover Belt BC1 & BC2Document3 pagesJurong Island Cargo Tec RA Alignment of Cover Belt BC1 & BC2Anonymous kWfNFb100% (1)

- Revised RA For PnelDocument11 pagesRevised RA For PnelAnonymous kWfNFbNo ratings yet

- Projects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SDocument6 pagesProjects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SAnonymous kWfNFbNo ratings yet

- Coring MOSDocument1 pageCoring MOSAnonymous kWfNFbNo ratings yet

- Trunking MOSDocument1 pageTrunking MOSAnonymous kWfNFbNo ratings yet

- # 20 Installation of Cable Tray Trunking (SWP)Document5 pages# 20 Installation of Cable Tray Trunking (SWP)Anonymous kWfNFbNo ratings yet

- Corporations OutlineDocument44 pagesCorporations Outlinecflash94100% (1)

- Nism Equity Derivatives Study NotesDocument27 pagesNism Equity Derivatives Study NotesHemant bhanawatNo ratings yet

- Chapter 1Document94 pagesChapter 1Narendran SrinivasanNo ratings yet

- Global Migration: Amayna, Arabello, Basilio, Gabio, Marco, RonquilloDocument15 pagesGlobal Migration: Amayna, Arabello, Basilio, Gabio, Marco, RonquilloBrian Angelo Montalvo BasilioNo ratings yet

- Code of EthicsDocument2 pagesCode of EthicsHimani sailabNo ratings yet

- CPI Trac Nghiem 30 CâuDocument6 pagesCPI Trac Nghiem 30 Câunessyhen6No ratings yet

- Plant Assets, Natural Resources, and Intangible AssetsDocument68 pagesPlant Assets, Natural Resources, and Intangible Assetsdwi studyNo ratings yet

- M3 Assignment Internal Control Group 9 AUDIT SPECIAL INDUSTRYDocument5 pagesM3 Assignment Internal Control Group 9 AUDIT SPECIAL INDUSTRYReginald ValenciaNo ratings yet

- Fundamentals of Financial Management Lecture Notes 21mar2021Document311 pagesFundamentals of Financial Management Lecture Notes 21mar2021Ruchita SinghalNo ratings yet

- India Discovers $410 Billion Lithium DepositDocument9 pagesIndia Discovers $410 Billion Lithium DepositELC2024-ANo ratings yet

- Module 2 - Audit Planning Risk-Based AuditDocument10 pagesModule 2 - Audit Planning Risk-Based AuditCha DumpyNo ratings yet

- 360 Karting Solutions Project GuideDocument13 pages360 Karting Solutions Project GuideRahul Singh100% (1)

- CFO Controller VP Finance in Albuquerque NM Resume Patricia FrerkesDocument2 pagesCFO Controller VP Finance in Albuquerque NM Resume Patricia FrerkesPatriciaFrerkesNo ratings yet

- Assgiment 1: Joy Movie SummaryDocument4 pagesAssgiment 1: Joy Movie SummaryFaiz FadzliNo ratings yet

- Regulatory Framework For Business Transactions Page 1 of 16Document16 pagesRegulatory Framework For Business Transactions Page 1 of 16Christopher Michael OnaNo ratings yet

- JLPT Application Form Method-July 2024Document4 pagesJLPT Application Form Method-July 2024Sanjyot KolekarNo ratings yet

- Income Statement Information For The Last YearDocument2 pagesIncome Statement Information For The Last YearAtif KhanNo ratings yet

- Account Opening Questionnaire and Documents Checklist (May 2022)Document6 pagesAccount Opening Questionnaire and Documents Checklist (May 2022)skyanikinNo ratings yet

- Zakaria - Abakar@utp - Edu.my: This Letter Is A Computer-Generated Printout, and No Signature Is RequiredDocument145 pagesZakaria - Abakar@utp - Edu.my: This Letter Is A Computer-Generated Printout, and No Signature Is RequiredSyed HanafieNo ratings yet

- Online Syllabus: Arts Marketing Sample Llams 13/Hm&Fn Art 502Document15 pagesOnline Syllabus: Arts Marketing Sample Llams 13/Hm&Fn Art 502Agnes Tika SetiariniNo ratings yet

- MSEW Paraweb ManualDocument34 pagesMSEW Paraweb ManualJonas Kañombi MukwatuNo ratings yet

- UCSP - Second Quarter - M07Document19 pagesUCSP - Second Quarter - M07Clyde Lester GabitoNo ratings yet

- Chapter-1 Introduction PDFDocument78 pagesChapter-1 Introduction PDFRaunak YadavNo ratings yet

- Resume of Md. Monna Pattern MasterDocument2 pagesResume of Md. Monna Pattern MasterSamiul BasirNo ratings yet

- Questionnaire of A SurveyDocument3 pagesQuestionnaire of A Surveynur naher muktaNo ratings yet

- Form G-ENDocument3 pagesForm G-ENCurren leeNo ratings yet

- Entrep TQ-3rdDocument3 pagesEntrep TQ-3rdIvy Rose RarelaNo ratings yet

- Shibbu Parmar CV 2022Document2 pagesShibbu Parmar CV 2022rohitNo ratings yet

- Bank Reconciliation StatementDocument3 pagesBank Reconciliation StatementFarhannah Clave DalidigNo ratings yet

- Social Value Menu For CEBDocument40 pagesSocial Value Menu For CEB樊乙琳No ratings yet