Professional Documents

Culture Documents

Neom 10 Spine Infrastructure: 10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 1 of 18

Neom 10 Spine Infrastructure: 10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 1 of 18

Uploaded by

Bassam KhairyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Neom 10 Spine Infrastructure: 10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 1 of 18

Neom 10 Spine Infrastructure: 10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 1 of 18

Uploaded by

Bassam KhairyCopyright:

Available Formats

NEOM ‐10 SPINE INFRASTRUCTURE

Work Order No. 003

Work Order Title RD 12

Contract No. 1100001342

Contract Title Masco Preparation Framework

Document Title WO 03‐Method Statement for Double Handling of Excavation

Materials‐RD12

Revision No. 01

Date 26 September 2021

Reason for Issue Approval

Revision History Revision Date Revision Description

01 26 September 2021 WO 03‐ Method Statement

for Double Handling of

Excavation Materials‐RD12

02

03

Originator internal Review and Approval

Originator Name Position Signature

Prepared by Tamer I QC Manager

Abouzied

Reviewed by Hassan Najar Project

Manager

Approved by Gregg Magee Project Director

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 1 of 18

METHOD STATEMENT

1100001342/003 – METHOD STATEMENT FOR

Double Handling of Excavation Materials

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 2 of 18

Document history

Revision code Description of changes Purpose of issue Date

01 First Issue Issued for Approval 26.09.2021

Document approval

Prepared by Reviewed by Approved by

Name Tamer I Abouzied Shahid Ahmed Hassan El-Naggar

Job Title QA/QC Manager HSE Manager Project Manager

Signature

26/09/2021 26/09/2021 26/09/2021

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 3 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

PROJECT TITLE: CONSTRUCTION OF ROAD 12 (RD‐12)

CONTRACT NUMBER: 1100001342-003

PREPARED BY:

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 4 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

TABLE OF CONTENTS

1. SCOPE OF WORK

2. MACHINERY AND EQUIPMENT

3. MATERIALS

4. WORK PROCEDURE

4.1 General

4.2 Work Execution

5. RESPONSIBILITIES.

6. HEALTH AND SAFETY.

7. QUALITY ASSURANCE.

8. RISK ASSESSMENT.

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 5 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

Excavation(Cut and Topsoil)

Satisfactory Unsatisfactory

materials materials

Disposal Disposal

Processing

Haulage

Double

Handling

Crushing Screening

Backfilling

/Embankment

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 6 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

1. SCOPE OF WORK

1.1. To ensure that all excavation and cutting are executed safely and in accordance

with the contract requirements and that all quality assurance / control activities

are conducted in a systematic manner, works are inspected and conformance is

verified and documented.

1.2. To ensure that disposal and haulage of materials and related activities are

executed safely and in accordance with the contract requirements and that all

quality assurance / control activities are conducted in a systematic manner,

works are inspected and conformance is verified and documented.

2. MACHINERY AND EQUIPMENT

The major equipment used for construction of Box Culvert, but are not limited to the

following: -

- Excavators (Bucket and hydraulic rock breaking hammer).

- Bulldozers.

- Graders.

- Wheel Loaders.

- Dump Trucks

- Vibrating Rollers.

- Water Tankers.

- Mesh Screens.

3. MATERIALS

The major materials used for Excavation, but are not limited to the following: -

- Warning Tapes

- Temporary Sign Boards

- Temporary Road Signs

- Safety Barriers

- Traffic Cones

- Grade Stakes

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 7 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

4. WORK PROCEDURE

4.1. General

4.1.1. Codes and Standards: perform work in accordance with:

1. The requirements of the Authorities.

2. BS 6349, BS 812 and ASTM D 1557.

3. Recommendations of Construction Industry Research and Information

Association (CIRIA) Special Publication No.83 (SP 83).

4.1.2. Excavation: Removal of material encountered above subgrade elevations and to

lines and dimensions indicated.

1. Authorized Additional Excavation: Excavation below subgrade elevations or

beyond indicated lines and dimensions as directed by the Engineer. Authorized

additional excavation and replacement material will not be paid.

2. Bulk Excavation: Excavation more than 3 m in width and more than 9 m in

length.

3. Unauthorized Excavation: Excavation below subgrade elevations or beyond

indicated lines and dimensions without direction by the Engineer. Unauthorized

excavation, as well as remedial work directed by the Engineer, shall be without

additional compensation.

4.2. Work Execution

4.2.1. Geotechnical Testing Agency Qualifications: Qualified according to ASTM E 329

to conduct soil materials testing, as documented according to and ASTM D 3740

and ASTM E 548 for testing indicated. As in option a, before start of excavation,

a soil classification will be done by the approved third-party laboratory to define

the Satisfaction of soil and determine the depth of soil replacement if required

(if the type of soil is A-1a, A-1b or A-2-4, then no soil replacement is required)

otherwise soil improvement will be conducted as per laboratory

recommendations.

4.2.2. Setting out- A survey team will take levels and set out the excavation area by

use of pegs to mark points on the ground.

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 8 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

4.2.3. Upon acceptance of the setting out by the Engineer, excavations will be started

after the acceptance of the Engineer.

4.2.4. During the progress of excavation, material taken from the cut and topsoil areas

shall be sectioned as following: -

4.2.4.1. Unsatisfactory Soils: -

- Soils outside the Limit of Work (Classification Groups GC, SC, CL, ML, OL, CH, MH,

OH, and PT according to ASTM D 2487 or Groups A-2-6, A-2-7, A-4, A-5, A-

6, and A-7 according to AASHTO M 145, or a combination of these groups) in

the opinion of the Engineer, are potentially unsatisfactory and liable to slide

or encroach into the Limit of Work.

- Dispose and collecting of Unsatisfactory Soils outside of the Excavation section. A

disposal plan shall be submitted to the Engineer.

- Haulage of Unsatisfactory Soils outside of the project. A Haulage plan, including

written permission from the owner(s) of the property used for material

Haulage and distance shall be submitted to the Engineer.

4.2.4.2. Satisfactory Soils: -

- Soils cut from the excavations and shall be used as Embankments, subgrade,

shoulders, slopes, bedding and backfill (Classification Groups GW, GP, GM,

SW, SP, and SM according to ASTM D 2487 or Groups A-1, A-2-4, A-2-5, and

A-3 according to AASHTO M 145, or a combination of these groups; free of

rock or gravel larger than 75 mm in any dimension, debris, waste, vegetation,

and other deleterious matter. Plasticity Index: <20%).

- Dispose of satisfactory Soils outside of the Excavation section to: -

* Processing area: If material suitable (According to Specs) to be used direct, material

shall be disposed and collected in stockpiles and mixed with water to be

Double handling as Embankment, subgrade, shoulders, slopes, bedding and

backfill.

* Processing area: If material contain rock or gravel larger than 75 mm in any

dimension, material shall be disposed to be screened with Mesh “70 X 70 mm”

and collected the passing material into stockpiles, mixed with water to be

Double handling as Embankment, subgrade, shoulders, slopes, bedding and

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 9 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

backfill. Retained material shall be crushed by mobile Crusher till material

contain rock or gravel less than 75 mm in any dimension, which shall be

collected into stockpiles, mixed with water to be Double handling as

Embankment, subgrade, shoulders, slopes, bedding and backfill

5. RESPONSIBILITIES.

5.1. The Project Manager has overall authority and responsibility for all aspects of the

Project.

5.2. The Construction Manager will coordinate with Site Engineer and ensure that the

necessary resources to implement the approved method statement.

5.3. The Project QA/QC Manager directs activities of the Project Quality Organization,

reporting directly to the General Manager.

5.4. The Site Engineer will ensure that the site preparation activities are conducted

according to the approved method statement.

5.5. QC Inspector‐Managing Quality Control functions for the Project including planning

of Quality Control inspections and preparation of reports.

5.6. The Material Engineer will ensure that the materials being used are in accordance to

the project specifications.

5.7. The Site Supervisor will organize the work in a safe manner to ensure that safety and

protective equipment are being properly utilized. He must also assure the project

specification and the method statement procedure is followed.

6. HEALTH AND SAFETY

6.1. Prior to the commencement of any activities, the workforce will receive an induction

talk on the project Safety Manager. This induction talk will include both activity safety

issues, as well as general safety requirements.

6.2. Where possible hazards may arise from placing of select fill material activities, the

necessary safety measures will be taken to prevent accident or injury at all times.

This may include barriers, warning tape/ net, signage, flagman, and proper lighting.

6.3. Safety Officer will enforce that Personal Protective Equipment be worn by site

personnel at all times during construction activities.

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 10 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

6.4. Heat Stress Training will be provided.

6.5. Provisions of adequate cool drinking water, shade, and salt water tablets will be in

place.

6.6. Equipment will be provided back‐up alarms, lights, and all other applicable safety

devices.

6.7. Permit Requirement

6.7.1. Prior commencing the construction activities, information about all existing

underground services such as gas, water, telephone lines, sewage lines,

electrical cables, etc. shall be obtained from concerned agencies.

6.7.2. Work permit will be as per the Engineer Program procedure.

7. QUALITY ASSURANCE

7.1. All checking, inspecting and testing shall comply with applicable standards specified and

as indicated in specification and drawings.

7.2. The quality control procedures shall satisfy all technical requirements providing the

same degree of quality test and other quality control procedure specified.

7.3. All records and reports shall be arranged and maintained to ensure traceability between

material and test reports.

7.4. All testing equipment shall comply with applied standards and shall be available on the

project site in complete calibrated condition.

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 11 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

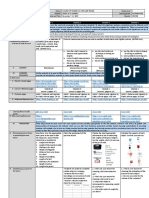

8. RISK ASSESSMENT

RISK ASSESSMENT MATRIX

CONSEQUENCE

RISK MATRIX 5 4 3 2 1

Catastrophic High Medium Low Insignificant

LIKELIHOOD

5 H H S M M

ALMOST CERTAIN

25 20 15 10 5

4 H H M M L

LIKELY

20 16 12 8 4

3 S

POSSIBLE M M M L

15

12 9 6 3

2

UNLIKELY M M M L L

10 8 6 4 2

1

M L L L L

RARE

5 4 3 2 1

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 12 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

RISK MATRIX CATEGORY DEFINITIONS (COLOR CODE)

HIGH/UNACCEPTABLE

JOB/TASK IS UNSAFE – STOP WORK IMMEDIATELY/ DONOT START WORK

Stop work immediately, secure area and report hazard to the superior for

rectification and control.

Any existing Method Statement must be reviewed and authorized before the work

commences.

If NO Method Statement exists, secure and provide MS in conjunction with JSEA for

SA approval before work commence.

Approval must be obtained from SA HSE before commencing the works.

SIGNIFICANT

JOB/TASK HAVE SIGNIFICANT HAZARDS- WORK SHOULD NOT BE STARTED UNTIL:

Hazard Controls are implemented.

Where work involves tasks in progress, urgent action is to be taken.

Approval must be obtained from SA HSE before commencing the works.

MODERATE

JOB/TASK HAS SOME MINOR HAZARDS:

Risk reduction measures are to be implemented within a defined period.

JSEA and Method Statement to be updated.

Control any identified hazards.

Record and report new hazards and control actions are already taken prior

commences work.

LOW / ACCEPTABLE

JOB/TASK IS SAFE – GO AHEAD

Continue working using JSEA and Method of Statement.

Control any identified hazards.

Record and report new hazards and control actions are already taken prior

commences work.

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 13 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

CONSEQUENCE OF HAZARD

1- Minor injury or spill

2- Medical treatment, small contained spill

3- LTI, large contained spill

4- Permanent disability, small uncontained spill

5- Fatality, large uncontained release

LIKELIHOOD OF HAZARD OCCURING

1- Not expected to occur

2- Unlikely to occur or may have occurred once in a lifetime

3- May occur sometime or happen once per year

4- Known to occur of happens once a month

5- Certain to occur or happens daily to weekly

CONTROL IN ORDER OF PREFERENCE

ELIMINATE – hazard / step

SUBSTITUTE – for safer method

ENGINEER - modify to make safe

ISOLATE – hazard from people

ADMINISTRATIVE MEASURES – signs, documentation

PPE – personal protective equipment

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 14 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

Raw Risk without Raw Risk after

S.No Job steps Hazards/Risks control control

C L R Control and Actions C L R

Proper housekeeping

Slip, trip and fall

Worker should wear proper PPE

01 Surveying Dust inhalation 4 5 20 2 2 4

Heat stress Frequently rest and hydrates

Permit must be obtained from the

authorities prior to commence activities.

Ensure inspection has been conducted

Physical or serious Injuries to workers 4 5 20 on the whole are. 2 2 4

Area to be cleaned up for trip hazard and

access.

02 Obtain work permit from All the utility services should be marked

MASCO before starting the work.

Ensure inspection has been conducted

Damage to property on the whole are.

4 4 16 2 2 4

The manhole should protect by steel

plates if any equipment has to work on

that otherwise barricade should be

around the manholes.

Safety induction training should be

provided to all personals prior to starting

the work.

Training for the concerned Physical or serious Injuries to workers

03 4 5 20 Daily toolbox talks should be conducted 2 2 4

personal

by site foremen/supervisor before

starting the work as per the scope of

work.

Review general terrain and identified

surface conditions. Look for uneven

terrain.

underground utilities and Slips trips and falls walking in general area of intended All the utility services should be marked

04 4 3 12 2 1 2

obstructions inspection excavation before starting the work.

Ensure inspection has been conducted

on the whole are.

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 15 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

No unauthorized entry.

Trainings like induction, toolbox talks

should be provided before starting the

work.

Physical or serious Injuries to workers 3 5 15 All the utility services should be marked 1 3 3

before starting the work.

Ensure inspection has been conducted

on the whole are.

All workers are to wear reflective traffic

vests. The competent person is

Struck workers with equipment 4 4 16 2 2 4

responsible for determining need.

Mobilizing of equipment’s

No unauthorized entry.

Bulldozes , excavator, Roller

05 Restrict outside vehicular traffic in the job

compacter and Wheel

loader, site.

Struck by site vehicles 4 3 12 Use flaggers and a specific traffic route if 2 1 2

necessary.

3rd party certificate should be provided.

Equipment/machinery not

06 Damage to plant or property 4 4 16 A daily equipment check list should 2 2 4

inspected and certified

complete before starting the work.

Incompetent operator and A competent/certified operator must be

07 Physical injury to workers 4 5 20 1 3 3

flagman appointed.

Ensure that during all the time of

equipment movement flagmen should be

Equipment hit the people due to lack of watch and a proper in place.

08 Equipment movement 4 5 20 All workers are to wear reflective traffic 2 2 4

precautions vests.

Safety warning signage must be in place.

The slopes of the excavation shall be

made in 45 degrees.

Excavated area shall be barricaded.

Excavation material shall be put 1 meter

09 Excavation Cave ins from unsupported sides of excavation 5 4 20 away from the edge. 3 3 9

All personnel entering to the trench or

excavation to wear a hard hat.

Keep material at least 1 meter away from

the edge of excavation.

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 16 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

Barricade off any hazardous areas to

prevent personnel waling near the edge

when work is in progress

Access ladder for every 7.5 meters

Tool box talk for the job (manual

handling) before to start the operation.

Only competent personnel for the job.

10 Manual Handling Back Injury, hand injury 4 3 12 2 1 2

Use mechanical puller if it is required.

Proper PPE (e.g. hand gloves, hard hat

safety boots)

11 Ensure competent person on

Serious or fatal injuries for workers, Ensure workers on site must wear high

Transport of material Damage of properties visibility vest and proper PPE for manual

4 5 20 handling for rebar’s and others. 3 2 6

Designated vehicle routes must be in

place.

Water spray should be done in different

intervals on daily bases.

Speed limits 20 km/hr shall be

maintained and speed signage shall be in

place.

Dust emission 3 5 15 1 2 2

Backfill material screening shall be not

12 Backfilling Operation allowed at site. It shall be made some

other area.

Dust mask shall be provided to all

workers.

Flagman shall be in place to control the

traffic

Wear ear plugs or ear muff where noise

Noise Exposure 3 4 12 level is 85 dB or more 1 2 2

Proper maintenance of the equipment

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 17 of 18

Doc No: 10-661120-1100001342-MAG-CIV-MST-000005

Initial Issue Date September 26, 2021

Revision Date:

Revision No. 01

MOHAMMED ALI AL-SWAILEM COMPANY

(MASCO)

1100001342-003 – METHOD STATEMENT FOR Double Handling of Excavation Materials

COMMUNICATION FORM

I, THE UNDERSIGNED HEREBY ACKNOWLEDGE THAT THIS JOB SAFETY ENVIRONMENTAL ANALYSIS HAS BEEN DISCUSSED WITH ME AND THAT I UNDERSTAND

THE CONTENTS AND THE RISKS INVOLVED IN THE TASK TO BE PERFORMED. I HAVE ALSO BEEN INSTRUCTED ON THE SAFE METHODS TO PERFORM THIS TASK.

NAME DESIGNATION EMP. NO. SIGNATURE

1

2

3

4

5

6

7

8

9

10

10-661120-1100001342-MAG-CIV-MST-000005 Rev.01 Page 18 of 18

You might also like

- Method Statement For Underground UPVC Duct & Fittings Installation For Utility ServicesDocument21 pagesMethod Statement For Underground UPVC Duct & Fittings Installation For Utility ServicessyzeeshanNo ratings yet

- Method Statement For Excavation and Backfilling WorksDocument15 pagesMethod Statement For Excavation and Backfilling WorksĐặng Quang Huy100% (6)

- 10211-TCW-DS-RPT-003 Rev01 Geotechnical Design (Cover Page & Review Sheet)Document78 pages10211-TCW-DS-RPT-003 Rev01 Geotechnical Design (Cover Page & Review Sheet)Sayan MahapatraNo ratings yet

- MST For Manhole ConstructionDocument17 pagesMST For Manhole ConstructionDelta akathehusky0% (1)

- A Study On Marketing Strategy of Peter England in LucknowDocument5 pagesA Study On Marketing Strategy of Peter England in LucknowChandan Srivastava100% (1)

- Saes A114 Excavation and BackfillDocument19 pagesSaes A114 Excavation and BackfillKhyle Laurenz Duro100% (1)

- 14 662000 4800000322 Mob Mec MST 000021 - 01Document21 pages14 662000 4800000322 Mob Mec MST 000021 - 01HassanNo ratings yet

- Method Statement Hot InsulationDocument14 pagesMethod Statement Hot InsulationSaleem AkhtarNo ratings yet

- BK91-1310-CPF-000-CNS-PCD-0058 - 0 - Procedure For Material Identification and Traceability-C1Document12 pagesBK91-1310-CPF-000-CNS-PCD-0058 - 0 - Procedure For Material Identification and Traceability-C1Panneer SelvamNo ratings yet

- MOS CeilingDocument7 pagesMOS CeilingKHAIRULSHAH FIRDAUSNo ratings yet

- AKKE2211-SDO-MOS-01 - Mobilization & Preliminary WorkDocument9 pagesAKKE2211-SDO-MOS-01 - Mobilization & Preliminary WorkMuhammad Hamidy KamarulZamanNo ratings yet

- WQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers WorksDocument68 pagesWQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers Worksmuhammad.younisNo ratings yet

- MS-NDM-01 For NDRC Works Rev 02Document14 pagesMS-NDM-01 For NDRC Works Rev 02ahmed maherNo ratings yet

- T00-O00C01-ARI-MTS-ST-0013 Method Statement of Marine WorksDocument28 pagesT00-O00C01-ARI-MTS-ST-0013 Method Statement of Marine Worksmuhammadibraheem5017No ratings yet

- BK91-1310-CPF-000-CNS-CHK-0001 - 0 - Welding and Welding Consumable Control Checklist-C1Document11 pagesBK91-1310-CPF-000-CNS-CHK-0001 - 0 - Welding and Welding Consumable Control Checklist-C1Panneer SelvamNo ratings yet

- MISCL QCCP 0012 Site Non Electrical ProcdureDocument9 pagesMISCL QCCP 0012 Site Non Electrical ProcdureKhyle Laurenz DuroNo ratings yet

- Rigging - Procedure - Rev - 0 (Editing)Document21 pagesRigging - Procedure - Rev - 0 (Editing)Julian AngeloNo ratings yet

- Wall & Column at Basement MS.06Document13 pagesWall & Column at Basement MS.06Anonymous kWfNFbNo ratings yet

- ATMS MDCBP Method Statement For Masonry Works CHB Laying Plastering TB OnlyDocument8 pagesATMS MDCBP Method Statement For Masonry Works CHB Laying Plastering TB OnlycuanicochorielynjuviNo ratings yet

- NB2 EMS 2022 001 EMS ProceduresDocument9 pagesNB2 EMS 2022 001 EMS ProceduresMark Nicko Yabut ZablanNo ratings yet

- Main Building Raft Foundation MS-005 R1Document11 pagesMain Building Raft Foundation MS-005 R1Anonymous kWfNFbNo ratings yet

- GENERAL NCR R0 RevDocument6 pagesGENERAL NCR R0 RevGanjar Dreadlocks NugrahaNo ratings yet

- Mas-Rtcf-Ms-El-001-Cable TrayDocument10 pagesMas-Rtcf-Ms-El-001-Cable TrayASHIQUE ZAFARNo ratings yet

- 10-603131-1100001343-AIC-CIV-MST-000009 - 01 - Compressed (1) - 1-169 (1) - 1-85Document85 pages10-603131-1100001343-AIC-CIV-MST-000009 - 01 - Compressed (1) - 1-169 (1) - 1-85Ali RazaNo ratings yet

- 622 SR 022Document3 pages622 SR 022chandana kumarNo ratings yet

- 8175-MOS-0001 - 00 Loading, Unloading and Positioning Container With Mobile Crane - 110158Document34 pages8175-MOS-0001 - 00 Loading, Unloading and Positioning Container With Mobile Crane - 110158Klizman AmineNo ratings yet

- Method Statement For Earthwork.Document13 pagesMethod Statement For Earthwork.Muhammad zaman100% (2)

- Method Statement For Road WorksDocument20 pagesMethod Statement For Road WorksJezrel Gempisao100% (1)

- Demobilization Plan For Quarry 30Document15 pagesDemobilization Plan For Quarry 30Faisal Chohan100% (1)

- 02 622320 0000100120 Dah Des Sow 000001 - ADocument84 pages02 622320 0000100120 Dah Des Sow 000001 - AJafffar Mahasneh100% (2)

- Method of Statement For Excavation, Trenching, Backfilling & Compaction WorkDocument9 pagesMethod of Statement For Excavation, Trenching, Backfilling & Compaction WorkAhmed Ibrahim100% (1)

- 0309WD-S-WM-PW02-CI-CPK-1003 Rev C01Document20 pages0309WD-S-WM-PW02-CI-CPK-1003 Rev C01sadeqmajed94No ratings yet

- VIBRO Replacement (Stone Columns) For Central Reservoir Dammam 5Document63 pagesVIBRO Replacement (Stone Columns) For Central Reservoir Dammam 5mohamed ghalyNo ratings yet

- NWTF PSBR Report A01Document33 pagesNWTF PSBR Report A01f9gxz646jnNo ratings yet

- Jazan Refinery & IGCC Industrial Support Facilities Jazan, Kingdom of Saudi ArabiaDocument5 pagesJazan Refinery & IGCC Industrial Support Facilities Jazan, Kingdom of Saudi Arabiamoytabura96No ratings yet

- Rock Garden ClearanceDocument5 pagesRock Garden ClearanceirvisionresumeNo ratings yet

- 562qlt Bp12 MMJV TMP QL 002 RevDocument183 pages562qlt Bp12 MMJV TMP QL 002 RevSangram PatilNo ratings yet

- Method Statement For Pile Joint WorkDocument12 pagesMethod Statement For Pile Joint Workkholif noviantiNo ratings yet

- Alsoqoof Building Contracting LLC Land Transport Safety ManagementDocument21 pagesAlsoqoof Building Contracting LLC Land Transport Safety ManagementSaleem AkhtarNo ratings yet

- BK91 1310 CPF 000 QAC PCD 0006 - 0 - Corrective and Preventive Action Procedure - C1Document11 pagesBK91 1310 CPF 000 QAC PCD 0006 - 0 - Corrective and Preventive Action Procedure - C1Panneer SelvamNo ratings yet

- 0309WD-S-WM-PW02-CI-CPK-1004 Rev C01Document21 pages0309WD-S-WM-PW02-CI-CPK-1004 Rev C01sadeqmajed94No ratings yet

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Document10 pagesJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- T00 O00C01 ARI MTS ST 0007 Method Statement For WaterproofingDocument18 pagesT00 O00C01 ARI MTS ST 0007 Method Statement For Waterproofingmuhammadibraheem5017No ratings yet

- BK91-1310-CPF-999-MAW-SPC-0009 - 1 - Specification For Piping Welding - C1Document28 pagesBK91-1310-CPF-999-MAW-SPC-0009 - 1 - Specification For Piping Welding - C1Panneer SelvamNo ratings yet

- Soil Investigation SpecificationDocument121 pagesSoil Investigation Specificationalqadad ahmadNo ratings yet

- Method Statement OF Well Development by Airlifting MethodDocument5 pagesMethod Statement OF Well Development by Airlifting MethodJason PaquibulanNo ratings yet

- Method Statement For Hydro Test (Hdpe Pipes, Fire Fighting Pipeline, Manholes & Domestic Water and Drainage Network)Document32 pagesMethod Statement For Hydro Test (Hdpe Pipes, Fire Fighting Pipeline, Manholes & Domestic Water and Drainage Network)mohdshahul543No ratings yet

- JSA-RA-Updated 26-02-2024 With Night WorkDocument11 pagesJSA-RA-Updated 26-02-2024 With Night Workhaseebzaheer787No ratings yet

- BRDF MEC QAC DJS 502 007 - 1 - SAT Procedure For Overhead CraneDocument16 pagesBRDF MEC QAC DJS 502 007 - 1 - SAT Procedure For Overhead CraneIchsan BahrilNo ratings yet

- Examination Procedure For Magnetic Particle InspectionDocument21 pagesExamination Procedure For Magnetic Particle InspectionOsilonya HenryNo ratings yet

- METHOD STATEMENT FOR PIPING REV 01 16 June 2021Document20 pagesMETHOD STATEMENT FOR PIPING REV 01 16 June 2021Moh'd SameerNo ratings yet

- NCC-NGPD-CON-MOS-001 - Rev C Method Statement For Scaffolding WorksDocument28 pagesNCC-NGPD-CON-MOS-001 - Rev C Method Statement For Scaffolding WorksbabjihanumanthuNo ratings yet

- 18-1039 Draft Report (Nuberg Engg.) Complete PDFDocument73 pages18-1039 Draft Report (Nuberg Engg.) Complete PDFYatendra TyagiNo ratings yet

- MST For Concret CoatingDocument6 pagesMST For Concret CoatingDelta akathehusky100% (1)

- BK91 1310 CPF 000 QAC PLN 0001 - 0 - Project Quality Plan C1Document92 pagesBK91 1310 CPF 000 QAC PLN 0001 - 0 - Project Quality Plan C1Panneer SelvamNo ratings yet

- Document Review Status: Sarawak Energy BerhadDocument14 pagesDocument Review Status: Sarawak Energy BerhadSaldan Mohammad HadoumiNo ratings yet

- Method Statement of Rotating Equipment InstallationDocument14 pagesMethod Statement of Rotating Equipment InstallationLai Kai SiangNo ratings yet

- TEC-033000 - MET-DoR-PIV-P635 (Method Statement For Casting Sloped RCC Elements)Document13 pagesTEC-033000 - MET-DoR-PIV-P635 (Method Statement For Casting Sloped RCC Elements)Tomi Wiryandi SaputraNo ratings yet

- Guidelines for Chemical Transportation Safety, Security, and Risk ManagementFrom EverandGuidelines for Chemical Transportation Safety, Security, and Risk ManagementNo ratings yet

- SynopsisDocument11 pagesSynopsisDheeraj ChauhanNo ratings yet

- Mahindra - Bolero Moulded Roof Wrinkles - Mechanical Engg. (ME) Summer Training Project ReportDocument44 pagesMahindra - Bolero Moulded Roof Wrinkles - Mechanical Engg. (ME) Summer Training Project ReportVinnie SinghNo ratings yet

- ABUSWAILEMDocument5 pagesABUSWAILEMSharprileyNo ratings yet

- Lander's Veterinary ToxicologyDocument337 pagesLander's Veterinary ToxicologyYaserAbbasiNo ratings yet

- Ce 6010 - Construction Contracts & Specifications July - November 2018Document3 pagesCe 6010 - Construction Contracts & Specifications July - November 2018YELLAMANDA SANKATINo ratings yet

- P75247ea F5U502 F5U503Document112 pagesP75247ea F5U502 F5U503Fabian PerezNo ratings yet

- BJ PowerSim FeaturesDocument3 pagesBJ PowerSim FeaturesJuan SantosNo ratings yet

- The Royal Geographical Society (With The Institute of British Geographers)Document8 pagesThe Royal Geographical Society (With The Institute of British Geographers)rei377No ratings yet

- Radish Lab ReflectionDocument5 pagesRadish Lab Reflectionapi-253056885No ratings yet

- Math7 Q2W2Document6 pagesMath7 Q2W2Meryl Fe P. GumeraNo ratings yet

- Gravimetric Determination of Moisture and Phosphorus Content in Fertilizer SampleDocument7 pagesGravimetric Determination of Moisture and Phosphorus Content in Fertilizer SampleAljan TabsNo ratings yet

- 4102.0 - Australian Social Trends, 2007Document9 pages4102.0 - Australian Social Trends, 2007tina m fayzaNo ratings yet

- NPTEL Lecture SeriesDocument30 pagesNPTEL Lecture Seriesh_badgujarNo ratings yet

- 2015 Year 7 Science PhysicsaepstudentDocument3 pages2015 Year 7 Science Physicsaepstudentapi-222503660No ratings yet

- CH01Document9 pagesCH01دقدق المناويشيNo ratings yet

- CV Ing. Aratz Ulil Hernandez SolisDocument1 pageCV Ing. Aratz Ulil Hernandez SolisAratz HernandezNo ratings yet

- Leviathans at The Gold Mine by Alex GolubDocument35 pagesLeviathans at The Gold Mine by Alex GolubDuke University PressNo ratings yet

- .............. ......... in Worlds and A Is Another Common Appear Since AccountDocument1 page.............. ......... in Worlds and A Is Another Common Appear Since AccountrprasanthnairNo ratings yet

- Strategic Asset Management FrameworkDocument16 pagesStrategic Asset Management FrameworkReisya El ShaninaNo ratings yet

- NetApp Data Ontap Simulator Cookbook 1.1Document17 pagesNetApp Data Ontap Simulator Cookbook 1.1Catán PatánNo ratings yet

- Case FirstTennBankDocument5 pagesCase FirstTennBankpangdownloadlangNo ratings yet

- The Vietnamese Student Stress Survey ReportDocument9 pagesThe Vietnamese Student Stress Survey ReportĐào Việt PhúcNo ratings yet

- Loading FrameDocument15 pagesLoading FramejayanthikrishnanNo ratings yet

- User Manual Jamicon 3vaav eDocument15 pagesUser Manual Jamicon 3vaav ematwan29No ratings yet

- GPU QuicksortDocument22 pagesGPU QuicksortKriti JhaNo ratings yet

- Understanding Angular ScopeDocument10 pagesUnderstanding Angular ScopeLMNo ratings yet

- Interaction in Second Language ClassroomsDocument6 pagesInteraction in Second Language ClassroomsPablo Esteban AedoNo ratings yet

- Muhammad HSE Engineer + Cover LetterDocument3 pagesMuhammad HSE Engineer + Cover LetterMuhammad Zeeshan Ahmed100% (1)

- Tendering Process For Design of Railways BridgesDocument54 pagesTendering Process For Design of Railways BridgesYasir SiddiqNo ratings yet