Professional Documents

Culture Documents

BK91-1310-CPF-000-QAC-PCD-0006_0_Corrective and Preventive Action Procedure_C1

Uploaded by

Panneer SelvamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BK91-1310-CPF-000-QAC-PCD-0006_0_Corrective and Preventive Action Procedure_C1

Uploaded by

Panneer SelvamCopyright:

Available Formats

CORRECTIVE AND Doc. No.

BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 1 of 11

BLOCK 9 DEVELOPMENT PROJECT PHASE 1

EPCC OF CPF-OIL TREATMENT SYSTEM AND

AUXILIARY SYSTEMS PROJECT

CORRECTIVE AND PREVENTIVE ACTION

PROCEDURE

Document No: BK91-1310-CPF-000-QAC-PCD-0006

Approval Code

Remarks

Here

Code 1 √ Approved

With Minor Comments: Revise and

Code 2 Resubmit, Works may proceed

With Major Comments: Revise and

Code 3 Resubmit, Works may NOT Proceed

Code 4 Reference and information only.

Christian Berry/ Senior 2022/07/11

Civil/Structural Engineer

Approval Authority Signature Date

These comments do not relieve the Contractor/ Vendor and/ or their

Sub‐contractors of their responsibilities to meet the requirements of

the Contract.

ISSUED FOR Chen

0 07-07-2022 Shi Yuncheng Yu Nianchong Yang Zhigang

USE Wenliang

REV. DESCRIPTION DATE PREP’D CHK’D REV’D APP’D

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 2 of 11

REV DATE REVISION DETAILS

0 07/07/2022 Issued for Use

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 3 of 11

Contents

1.0 Purpose.................................................................................................................................... 4

2.0 Scope ....................................................................................................................................... 4

3.0 Reference................................................................................................................................. 4

4.0 Definition and Abbreviations.................................................................................................. 4

5.0 Responsibility.......................................................................................................................... 5

6.0 Procedure ................................................................................................................................ 5

6.1 General ..................................................................................................................................... 6

6.2 Collection/Analysis of Information ............................................................................................. 6

6.3 Issue and Registration Control of CAR / PAR ............................................................................ 7

6.4 Investigation, Establishment and Notification ............................................................................ 7

6.5 Verification & Follow-up Action for the Corrective / Preventive Action ....................................... 8

7.0 Quality Records....................................................................................................................... 8

8.0 Attachment .............................................................................................................................. 8

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 4 of 11

1.0 Purpose

The purpose of this procedure is to describe methods and responsibilities for ensuring that

conditions adverse to quality are promptly identified, documented, investigated, analyzed and

corrective and preventive actions established, initiated, and reported to the appropriate levels

of management.

2.0 Scope

The requirements of this procedure are applicable to all activities and personnel on the EPCC

OF CPF-OIL TREATMENT SYSTEM AND AUXILIARY SYSTEM PROJECT.

3.0 Reference

Document Title Document Number

Project Quality Plan BK91-1310-CPF-000-QAC-PLN-0001_0

Quality Record Control Procedure BK91-1310-CPF-000-QAC-PCD-0002_0

Non-Conformity Management and Control

BK91-1310-CPF-000-QAC-PCD- 0007_0

Procedure

4.0 Definition and Abbreviations

Item Definition

COMPANY Kuwait Energy Basra Limited (KEBL)

PMC China Huanqiu Contracting & Engineering Co., Ltd. (HQC)

Consortium of China CAMC Engineering Co., Ltd (CONTRACTOR)

CONTRACTOR

and CNOOC Petrochemical Engineering Co., Ltd (CNOOCPEC)

An all-inclusive term used in reference to any of the following: failures,

Conditions

malfunction, deficiencies, defective items/materials, and

Adverse to Quality

nonconformance.

Non-fulfillment of a specified requirement including any condition in

equipment or materials which does not comply with the required

Non-conformity drawings, specifications, codes or standards, documentation or

procedure which causes the quality of the equipment or material to

be unacceptable or indeterminate

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 5 of 11

Any action taken to eliminate the causes of a detected

Corrective Action

nonconformance or other undesirable situation

Any action taken to eliminate the cause of a potential

Preventive Action nonconformance, defect or other undesirable situation in order to

prevent occurrence

A request which identifies, as a minimum, the significant condition

Corrective /

adverse to quality, recommended action, the responsible

Preventive Action

organization for the performance of corrective action, and response

Report (CAR/PAR)

due date

An analysis which summarizes all Nonconformance Reports (NCRs),

Quality Trend

Audit results, Corrective Action Requests (CARs) to identify

Analysis

conditions adverse to quality

QSR Quality surveillance report

NCR Non-Conformance Report

PM Project Manager

PCM Project Control Manager

PPM Project Procurement Manager

PQM Project Quality Manager

5.0 Responsibility

1) Project Quality Manager is responsible to lead the root cause analysis of non-

conformance and review the proposed corrective action/preventive action plan.

2) The Projet Manager to approve the proposed corrective/preventive plan.

- Organized manpower for dispose of the CAR/PAR.

- Ensure and Deploy sufficient material /equipment resource for corrective and

preventive action.

3) QA/QC department is responsible for the followings:

- Analyzing and preparing the cause of findings/nonconformance.

- Preparing and submitting the corrective action plan, as required.

- Implementing the corrective/preventive action.

6.0 Procedure

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 6 of 11

6.1 General

Conditions not in compliance with the project requirements are identified and documented in

either Nonconformance Report(s) (NCRs) as a result of inspections/test at the vendor's shop

or on the job site, monitoring a specific work activity anywhere on the project, or through an

Audit Finding Report(s) (AFRs) as a result of an internal or external quality audit.

PQM or his designee shall review and analyze on a regular basis such NCR’s and AFR’s to

look for any quality trends that may be developing and shall initiate a investigation to find out

the cause of such nonconformance, analyzing the relevant processes, work operations,

concessions, quality records to detect and eliminate such causes.

A Corrective / Preventive Action Report (CAR/PAR) shall be raised by PQM as a result of

Nonconformance Reports of a repetitive nature or of a single significant occurrence, Audit

Finding Reports (AFRs) which indicate an adverse quality trend and/or when significant quality

related problems are detected during the execution of the work.

All Corrective/Preventive Action Report (CAR/PAR) shall be submitted to COMPANY/PMC, for

information.

6.2 Collection/Analysis of Information

1) Project Quality Manager shall collect the following information related to project organization

in home office and at the site.

- Problems discovered in monitoring for process of quality activities

- COMPANY/PMC complaints

- Controlling status of internal/external quality audit

2) Site Quality Control Manager shall collect the following information related to project

organization at the site.

- Causes and status of nonconformities generated

- Problems discovered in monitoring for process of quality activities

- COMPANY/PMC complaints

- Controlling status of internal/external quality audit

3) Project Quality Manager and Site Quality Control Manager shall execute monitoring for the

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 7 of 11

following quality activities on a weekly basis, and request the corrective and preventive

actions to the relevant organization, if any problems found.

- Main requirement defined in PQP

- Work item related to main process and discipline

- Main quality weakness point for relevant project

- Other main execution work for relevant project

4) All collected information shall be counted / analyzed on a quarterly basis and existing or

potential causes of nonconformities shall be pointed out and the corrective/preventive

actions shall be record using a CAR/PAR.

6.3 Issue and Registration Control of CAR / PAR

6.3.1 CAR / PAR Issue

The CAR / PAR (Refer to Attachment 1) to be issued for the following cases.

1) In case the quality system does not operate because the main requirements of Project

Quality Plan and Project Quality Procedure are not implemented.

2) In case the problems discovered during the monitoring do not resolve without any special

cause.

3) In case the similar types of COMPANY/PMC complaints are recurring by the same reason .

4) In case the completion due date of corrective action for external or Project quality audit

findings is exceeded without any cause.

5) In case the findings in similar matter recur in the same dept. or undesirable situation is

continued.

6.3.2 CAR / PAR Control

All the CAR / PAR shall be registered in CAR / PAR Log (Refer to Attachment 2) and status of

corrective action shall be controlled by PQM.

6.4 Investigation, Establishment and Notification

Non-conformance which need CAR/PAR shall conduct root cause analysis lead by PQM with

PM and related parties attend. QA/QC department and related parties shall investigation of

causes, Establishment and Notification of Corrective / Preventive Action Plan.

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 8 of 11

Responsible party shall propose action plan to PQM for review and PM for approval. With

reviewed by PQM and approved PM, CAR/PAR will issue to responsible party.

Approved action plan shall be implemented by responsible party, it shall respond by the

required response due date documenting the cause, action to be taken and date for

completion to PQM and PM. The responsible organization shall respond within 7 days from

issue date.

Upon receipt of CAR / PAR, responsible party shall investigate the fundamental cause and

implement counter-measure to prevent recurrence and implement corrective / preventive

action plan as required.

6.5 Verification & Follow-up Action for the Corrective / Preventive Action

The PQM shall review the responded causes, action to be taken and date for completion. If

responded contents are not acceptable, it shall be reported to the PM who will then return the

CAR / PAR to request more appropriate corrective / preventive action be taken.

The PQM shall verify the corrective / preventive action result within 14 days from the day for

completion and the verification results shall be reported to PM for approval for close . With

verified by PQM and approved by PM, CAR/PAR only can be closed. The CAR/PAR flow chart

refer to Attachment 3.

The PQM shall record the verification result of completed CAR / PAR and closing date on CAR

/ PAR Log. Reports of the status of CAR / PAR shall be provided to COMPANY/PMC on a

monthly basis, and notify the result of final verification to applicable organization.

7.0 Quality Records

CAR / PAR shall be controlled in accordance with "Quality Record Control Procedure" (BK91-

1310-CPF-000-QAC-PCD-0002-0).

8.0 Attachment

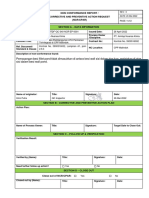

Attachment 1 Corrective / Preventive Action Report Form

Attachment 2 Corrective / Preventive Action Reort Log

Attachment 3 CAR/PAR Flow Chart

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 9 of 11

Attachment 1 Corrective / Preventive Action Report Form

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 10 of 11

Attachment 2 Corrective / Preventive Action Report Log.

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

CORRECTIVE AND Doc. No. BK91-1310-CPF-000-QAC-PCD-0006

PREVENTIVE Revision 0

ACTION Date of 07/07/2022

Issue

PROCEDURE Page 11 of 11

Attachment 3 CAR/PAR Flow Chart

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

You might also like

- Dimensional Control Procedure (Pipe Fit Assurance)Document17 pagesDimensional Control Procedure (Pipe Fit Assurance)Joe Ripa67% (3)

- 7022H 400 MS 0000 828 RCDocument18 pages7022H 400 MS 0000 828 RCA.A100% (1)

- Contoh Prosedur NCR - PT PPDocument10 pagesContoh Prosedur NCR - PT PPMuh Fajar Ramadhan100% (1)

- Ssg-Ng01012401-Gen-Aa-5880-00013 - C02 - Ssags Nigerian Content Human Capacity Building Training PlanDocument19 pagesSsg-Ng01012401-Gen-Aa-5880-00013 - C02 - Ssags Nigerian Content Human Capacity Building Training PlanStroom LimitedNo ratings yet

- LLC Option Award Letter and AgreementDocument8 pagesLLC Option Award Letter and AgreementSharon DrewNo ratings yet

- Substitute Form W-8BEN: (Certificate of Foreign Status of Beneficial Owner For United States Tax Withholding)Document1 pageSubstitute Form W-8BEN: (Certificate of Foreign Status of Beneficial Owner For United States Tax Withholding)Manuel Aguilar100% (1)

- CDM 2015 - Compliance ChecklistDocument1 pageCDM 2015 - Compliance Checklistrodidanpop100% (1)

- BK91-1310-CPF-000-CNS-PCD-0058_0_Procedure for Material Identification and Traceability-C1Document12 pagesBK91-1310-CPF-000-CNS-PCD-0058_0_Procedure for Material Identification and Traceability-C1Panneer SelvamNo ratings yet

- BK91-1310-CPF-000-PMT-MAN-0001 - A - Project Management ManualDocument8 pagesBK91-1310-CPF-000-PMT-MAN-0001 - A - Project Management Manualraaz.rocky.2023No ratings yet

- BK91-1310-CPF-000-PMT-MAN-0001 - A - Project Management Manual-C2Document8 pagesBK91-1310-CPF-000-PMT-MAN-0001 - A - Project Management Manual-C2raaz.rocky.2023No ratings yet

- BK91-1310-CPF-000-CNS-CHK-0001_0_Welding and Welding Consumable Control Checklist-C1Document11 pagesBK91-1310-CPF-000-CNS-CHK-0001_0_Welding and Welding Consumable Control Checklist-C1Panneer SelvamNo ratings yet

- Minimum RequirementsDocument9 pagesMinimum RequirementsSleyda MunozNo ratings yet

- Examination Procedure For Magnetic Particle InspectionDocument21 pagesExamination Procedure For Magnetic Particle InspectionOsilonya HenryNo ratings yet

- BK91-1310-CPF-000-QAC-PLN-0001_0_Project Quality Plan C1Document92 pagesBK91-1310-CPF-000-QAC-PLN-0001_0_Project Quality Plan C1Panneer SelvamNo ratings yet

- J910-DT03-P0ZEN-040005 SQCP-0104 (Risk Control) - Rev.1Document8 pagesJ910-DT03-P0ZEN-040005 SQCP-0104 (Risk Control) - Rev.1valent aviolandaNo ratings yet

- Installation of Security FenceDocument10 pagesInstallation of Security FenceBerry UmpolaNo ratings yet

- NCR 002 - Bengkokan Besi Slab Control RoomDocument2 pagesNCR 002 - Bengkokan Besi Slab Control RoomAl Farisi FirdausNo ratings yet

- NCR 001 - Fillet Wall PondDocument2 pagesNCR 001 - Fillet Wall PondAl Farisi FirdausNo ratings yet

- DQ - CRAB For Lyo LoadingDocument30 pagesDQ - CRAB For Lyo Loadingdhanu_lagwankarNo ratings yet

- T&D-HSE-POL-0006 Emergency Response PlanDocument32 pagesT&D-HSE-POL-0006 Emergency Response PlanDamalieNo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- WESM-FASMD-2.0 26 Jun 2021 (EWDO) 1Document11 pagesWESM-FASMD-2.0 26 Jun 2021 (EWDO) 1johncalupasNo ratings yet

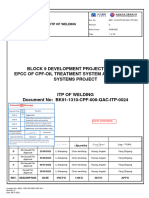

- BK91-1310-CPF-000-QAC-ITP-0024_D_ITP of Welding C1Document26 pagesBK91-1310-CPF-000-QAC-ITP-0024_D_ITP of Welding C1Panneer SelvamNo ratings yet

- T&D-HSE-PRC-0022 Operational Control ProcedureDocument4 pagesT&D-HSE-PRC-0022 Operational Control ProcedureDamalieNo ratings yet

- BK91-1310-CPF-999-MAW-SPC-0009_1_Specification for Piping Welding_C1Document28 pagesBK91-1310-CPF-999-MAW-SPC-0009_1_Specification for Piping Welding_C1Panneer SelvamNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument25 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- 26071-100-VSC-BD4-00028 - 00A - Work Method Statement For Bituminous Coating Rev.00A (R)Document13 pages26071-100-VSC-BD4-00028 - 00A - Work Method Statement For Bituminous Coating Rev.00A (R)rony_lesbtNo ratings yet

- DGP (M) 06-22Document15 pagesDGP (M) 06-22KHAIRANYNo ratings yet

- 3.5.3.f QA QC PlanDocument36 pages3.5.3.f QA QC PlanAlfyn alkhaNo ratings yet

- KCC Jec (Ons) 38281 MST 0126 00Document95 pagesKCC Jec (Ons) 38281 MST 0126 00Riaz AhmadNo ratings yet

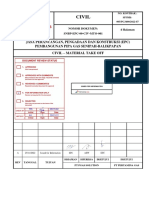

- Civil Material Take Off for Senipah-Balikpapan Gas Pipeline ProjectDocument15 pagesCivil Material Take Off for Senipah-Balikpapan Gas Pipeline ProjectSugi SuryandaruNo ratings yet

- Method Statement For Coring WorkDocument6 pagesMethod Statement For Coring Workadeniyi abiolaNo ratings yet

- Int 091 PD 0001Document43 pagesInt 091 PD 0001Jessica RodriguezNo ratings yet

- WESM-BSM-11.1 27aug2022 (DC2022-06-0025) Final 3Document58 pagesWESM-BSM-11.1 27aug2022 (DC2022-06-0025) Final 3NiggaNo ratings yet

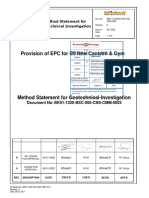

- BK91-1320-BSC-000-CNS-CMM-0003 - B - Method Statement For Geotechnical Investigation - C2Document9 pagesBK91-1320-BSC-000-CNS-CMM-0003 - B - Method Statement For Geotechnical Investigation - C2Berry UmpolaNo ratings yet

- GENERAL NCR R0 RevDocument6 pagesGENERAL NCR R0 RevGanjar Dreadlocks NugrahaNo ratings yet

- 6.) Metod Statement For Tie End ConnectionDocument13 pages6.) Metod Statement For Tie End Connectionsandeep reshmaNo ratings yet

- Quality Control Procedure Index) - Rev.2Document3 pagesQuality Control Procedure Index) - Rev.2valent aviolandaNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0003_1_Specification for Pressure Testing of Piping Systems-C1Document28 pagesBK91-1310-CPF-999-PIP-SPC-0003_1_Specification for Pressure Testing of Piping Systems-C1Panneer SelvamNo ratings yet

- Nabl 216Document17 pagesNabl 216Arssalaan Engineering EnterprisesNo ratings yet

- DRP001-OUF-PRO-Q-000-503 B1 NCR ProcedureDocument13 pagesDRP001-OUF-PRO-Q-000-503 B1 NCR ProcedureDaniel Martinez50% (2)

- Ofis 23059 Qa Pro NDT 00 04 Pmi ProcedureDocument15 pagesOfis 23059 Qa Pro NDT 00 04 Pmi ProcedureanandNo ratings yet

- Insulation Method for Zubair Oil Field PipingDocument14 pagesInsulation Method for Zubair Oil Field PipingSaleem AkhtarNo ratings yet

- Gen 00 104265 Qa 6050 00514 0000 03 PDFDocument11 pagesGen 00 104265 Qa 6050 00514 0000 03 PDFchandana kumarNo ratings yet

- TDG 0040 Ver 3 - 0 Item Specific Guidelines & Schedule of Technical Requirements For Manufacture and Supply of FISHPLATES and FISHPLATE BARSDocument16 pagesTDG 0040 Ver 3 - 0 Item Specific Guidelines & Schedule of Technical Requirements For Manufacture and Supply of FISHPLATES and FISHPLATE BARSPreeti goswamiNo ratings yet

- AD Ports Group Project: Document Number: 2106-209-V8-8999-00001Document75 pagesAD Ports Group Project: Document Number: 2106-209-V8-8999-00001NAVEEN VAMADEVAN100% (1)

- T&D-HSE-PRC-0061 Procurement ProcedureDocument12 pagesT&D-HSE-PRC-0061 Procurement ProcedureDamalieNo ratings yet

- Ims-Sop-F02-Ehv Tower Erection StringingDocument7 pagesIms-Sop-F02-Ehv Tower Erection StringingAnonymous cj7JdRbDbNo ratings yet

- 05 01 MST CCTV (AutoRecovered)Document17 pages05 01 MST CCTV (AutoRecovered)muhammedpmubarakNo ratings yet

- PQPDocument49 pagesPQPAbhishek RajaNo ratings yet

- Method Statement for HRSG ErectionDocument32 pagesMethod Statement for HRSG ErectionMIL RABNo ratings yet

- Weekly Program Monitoring 1Document34 pagesWeekly Program Monitoring 1wahyu hidayatNo ratings yet

- SEWA WATER TREATMENT PLANT PACKAGEDocument34 pagesSEWA WATER TREATMENT PLANT PACKAGEwahyu hidayatNo ratings yet

- Bilfinger Tebodin Middle East HSE ManualDocument122 pagesBilfinger Tebodin Middle East HSE ManualNibu P ShajiNo ratings yet

- BRDF MEC QAC DJS 502 007 - 1 - SAT Procedure For Overhead CraneDocument16 pagesBRDF MEC QAC DJS 502 007 - 1 - SAT Procedure For Overhead CraneIchsan BahrilNo ratings yet

- EPC Scope of Work OP201670-01-GN-SOW-001 EPC SOW Rev 1Document86 pagesEPC Scope of Work OP201670-01-GN-SOW-001 EPC SOW Rev 1Ahmed Moharram100% (2)

- Document Review Report SummaryDocument25 pagesDocument Review Report SummaryjennyNo ratings yet

- 000 SP Pi02 0221Document10 pages000 SP Pi02 0221Samuel ValbuenaNo ratings yet

- MS Audit Results SummaryDocument1 pageMS Audit Results SummaryygpNo ratings yet

- Attenchment - Pipe Support Specification and Drawings For Reference (Template)Document11 pagesAttenchment - Pipe Support Specification and Drawings For Reference (Template)Kingsly NovaNo ratings yet

- Specification of CP SystemDocument32 pagesSpecification of CP Systemmtuanlatoi9704100% (1)

- 6.5 MW Cogeneration Project Verification ReportDocument29 pages6.5 MW Cogeneration Project Verification ReportAtul TakarkhedeNo ratings yet

- 1310-U112-SO-HT-008Document5 pages1310-U112-SO-HT-008Panneer SelvamNo ratings yet

- BK91-1310-CPF-PIP-MT-0041-5Document1 pageBK91-1310-CPF-PIP-MT-0041-5Panneer SelvamNo ratings yet

- BK91-1310-CPF-000-QAC-ITP-0024_D_ITP of Welding C1Document26 pagesBK91-1310-CPF-000-QAC-ITP-0024_D_ITP of Welding C1Panneer SelvamNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0007_B_Specification for Piping Materials Line Class Summary_c1Document178 pagesBK91-1310-CPF-999-PIP-SPC-0007_B_Specification for Piping Materials Line Class Summary_c1Panneer SelvamNo ratings yet

- BK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentDocument67 pagesBK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentPanneer SelvamNo ratings yet

- 5.1 Vendor Quality PlanDocument52 pages5.1 Vendor Quality PlanPanneer SelvamNo ratings yet

- BK91-1318-01-FSF-000-PIP-RFI-0029 Request For Inspection of Carbon Steel Pipe Material - SignedDocument293 pagesBK91-1318-01-FSF-000-PIP-RFI-0029 Request For Inspection of Carbon Steel Pipe Material - SignedPanneer SelvamNo ratings yet

- Bk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersDocument8 pagesBk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersPanneer SelvamNo ratings yet

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 pageWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNo ratings yet

- BK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsDocument69 pagesBK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsPanneer SelvamNo ratings yet

- Ethics in Accounting and Corporate GovernanceDocument40 pagesEthics in Accounting and Corporate GovernanceDuyên Nguyễn Hồng MỹNo ratings yet

- Substantial Acquisition of Shares & Takeovers Regulations, 2011Document18 pagesSubstantial Acquisition of Shares & Takeovers Regulations, 2011Ravi JaiswalNo ratings yet

- Forfeiture of SharesDocument2 pagesForfeiture of Sharesmihir132002100% (2)

- Philippines Supreme Court rules on tax deduction for US citizensDocument92 pagesPhilippines Supreme Court rules on tax deduction for US citizens001nooneNo ratings yet

- Handout 2 Project Identification & ScreeningDocument5 pagesHandout 2 Project Identification & ScreeningShivani PandeyNo ratings yet

- Case Presentation On Anti Competitive AgreementsDocument10 pagesCase Presentation On Anti Competitive AgreementsGaurav Pratap Singh100% (1)

- Koutons Retail India LTDDocument4 pagesKoutons Retail India LTDVidya AdsuleNo ratings yet

- Bombo Radyo Phils. v. Secretary of Labor, Et AlDocument3 pagesBombo Radyo Phils. v. Secretary of Labor, Et AlAmberChanNo ratings yet

- Research Project (Low Kin Fai)Document62 pagesResearch Project (Low Kin Fai)Sunny Low Kin FaiNo ratings yet

- Manual: Telecom Regulatory Authority of IndiaDocument23 pagesManual: Telecom Regulatory Authority of Indiahariom chauhanNo ratings yet

- Admin Law & Agency ReviewDocument51 pagesAdmin Law & Agency ReviewIrina Marinescu100% (1)

- Bureau: MoneyDocument15 pagesBureau: MoneyChippa Chippa100% (1)

- Section I. Invitation To Bid: Department of EducationDocument15 pagesSection I. Invitation To Bid: Department of EducationHazel L IbarraNo ratings yet

- Quality Standards PDFDocument20 pagesQuality Standards PDFmudassarhussainNo ratings yet

- Local Government Taxation Cases: 1. Drilon Vs LimDocument47 pagesLocal Government Taxation Cases: 1. Drilon Vs LimDia Mia BondiNo ratings yet

- The Trade Unions Act, 1926Document3 pagesThe Trade Unions Act, 1926GauriNo ratings yet

- Reyes VS NLRCDocument2 pagesReyes VS NLRCClaudine Christine A VicenteNo ratings yet

- đề đầu ra mớiDocument9 pagesđề đầu ra mớiĐỗ Công TrìnhNo ratings yet

- Contract of Employment DriverDocument8 pagesContract of Employment DriverianlaynoNo ratings yet

- 295 - 2012!08!16 - Inspection of The Flap Support Arm Attachments - SB57-006Document5 pages295 - 2012!08!16 - Inspection of The Flap Support Arm Attachments - SB57-006Elijah Paul MertoNo ratings yet

- By-Laws Regulate, Stockholders Members Adopted Having AffairsDocument7 pagesBy-Laws Regulate, Stockholders Members Adopted Having AffairsEmmanuel PenullarNo ratings yet

- RBI/FED/2015-16/13 FED Master Direction No.18/2015-16 January 1, 2016Document135 pagesRBI/FED/2015-16/13 FED Master Direction No.18/2015-16 January 1, 2016harsh2709golchhaNo ratings yet

- 1 Demo Notes FEMA, 1999Document9 pages1 Demo Notes FEMA, 1999CA OFFICENo ratings yet

- Chapter 3Document54 pagesChapter 3koushik kumarNo ratings yet

- (BS en 772-11-2011) - Methods of Test For Masonry Units. Determination of Water Absorption of Aggregate Concrete, Autoclaved Aerated Concrete, Manufactured Stone andDocument12 pages(BS en 772-11-2011) - Methods of Test For Masonry Units. Determination of Water Absorption of Aggregate Concrete, Autoclaved Aerated Concrete, Manufactured Stone andStacy Wilson100% (1)

- High Point WSC, Talty SUD, and Markout WSC Petition Public Utilities Commission To Review City of Forney Water RatesDocument61 pagesHigh Point WSC, Talty SUD, and Markout WSC Petition Public Utilities Commission To Review City of Forney Water RatesinForney.comNo ratings yet

- Victoriano V Elizalde Rope Workers UnionDocument9 pagesVictoriano V Elizalde Rope Workers UnionCyndi OrolfoNo ratings yet