Professional Documents

Culture Documents

Gad Lus

Uploaded by

Arun K RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gad Lus

Uploaded by

Arun K RajCopyright:

Available Formats

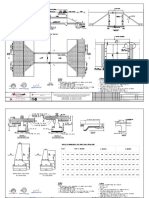

NOTE:-

1. ALL DIMENSIONS ARE IN MILLIMETRES UNLESS OTHERWISE STATED.

2. PROPOSALS ARE SHOWN IN RED IN SITE PLAN AND LONGITUDINAL CROSS SECTIONS

MDU END VPT END 101 C

L OF BG TRACK & DOUBLING TRACK 3. FOR DETAILS OF PROPOSED PRE-CAST RCC BOX & BASE SLABS REFER DRG.NO. CBE/TP/259/ 2012

PRO.PRE-CAST RCC BOX TO SIZE 1 x 4500 x 4500 AS C.L.OF LUS

- SHEET 1 (ALT-3) AND CBE/TP/259/ 2012 - SHEET 2 .

PER Similar to DRG.NO.CBE/TP/259/2012-Sh1(A-3) 100

4. FOR DETAILS OF TROUGH AND RETAINING WALL REFER SIMILAR TO DRG. NO: CBE/TP/261/2012

RAIL LEVEL 99.930 99

5. THIS DRAWING IS PREPARED BASED ON THE DETAILS GIVEN BY SSE/PW/VPT Lr.No.VPT/19LC

675

FORMATION LEVEL 99.255

650

98 DT.20.09.2014 .

EXG.GL 98.980

5000 6. FOR LEVELLING COURSE - M-10, PLAIN CONCRETE WORKS - M-20 AND RCC WORKS - M-25 OF WEIGH

200

200

5825

5825

97 AX)

0(M

IN 2

4500 E1 BATCHING OF CONTROLLED CONCRETE SHOULD BE USED.

SLO S LOP

96 PE 1

7175

RCC CAST IN SITU SEEPAGE IN 2

0(M 7. THE JOINTS OF RCC SEGMENTAL BOXES & JOINTS OF RCC BASE SLABS SHOULD BE STAGGERED WITH

950

AX)

500

ARRESTING WALL 95 LENGTH OF SEGMENTAL BOX.

500

CROSS SECTION OF EMBANKMENT 8. EXCEPT FOR ROCK A SAND GRAVEL MIXTURE LAYER OF 200mm TO BE SPREAD AND WELL CONSOLIDATED

94 103.96m 6m 18.580m 6m 117.14m

(NOT TO SCALE)

250 4500 BELOW THE RCC BASE SLAB.

PRO. ROAD LEVEL 94.105 93

1350

650

9. A GAP OF 20mm TO BE PROVIDED IN BETWEEN TWO BOXES. AFTER ERECTION OF BOXES IN ALIGNMENT

100.010

100.000

120 99.960

100 99.800

99.600

-120 99.320

-100 99.250

99.200

99.180

99.270

99.950

99.930

99.810

99.510

99.390

99.520

99.670

EXG.RL

250

PRO. BOF. 92.755

200

AND AFTER ALLOWING INITIAL SETTLEMENT OF BOXES THE GAP BETWEEN THE BOX JOINTS ARE TO BE

6500 DISTANCE(m)

-80

-60

-40

-20

PRESSURE GROUTED WITH CEMENT / EPOXY SUITABLY.

20

40

60

80

-4

4

250 TH CC PRE-CAST RCC BASE

200 TH. COARSE TO MEDIUM SAND WITH

SLAB IN M.25 GRADE

GRAVEL MIXTURE TO BE WELL COMPACTED 10. SUITABLE BED SLOPE IN THE BARREL LENGTH OF THE BOX TO BE GIVEN IN THE WEARING COURSE.

BEFORE PLACING THE BASE SLAB UNITS.

LONGITUDINAL SECTION OF ROAD

11. NO CONSTRUCTION JOINTS SHALL BE NORMALLY ALLOWED IN CONCRETE WORKS WITHOUT SPECIAL

HALF ELEVATION AND HALF SECTION

KAR

LHS SITE PLAN PRECAUTIONS AS PER RELEVANT BRIDGE CODE AND SUITABLE PROTECTIVE PAINTING OF APPROVED MAKE

UV

[NOT TO SCALE]

SHOULD BE USED TO PAINT THE UNDERSIDE OF CONCRETE.

ELA

B

20550

HEIGHT

MPA

C.L.OF LUS GAUGE

20000

12. SUITABLE HEIGHT GAUGES TO BE PROVIDED AT THE BEGINNING OF THE APPROACHES AND LUS ON EITHER

TTI

IOC Building SIDES.

C

L OF PRO. SUBWAY

HEIGHT GAUGE 13. NECESSARY GUARD RAILS TO BE PROVIDED AT THE LUS LOCATION.

HEIGHT GAUGE

10000

Ty.SHORING 14. THE ENGINEER-IN-CHARGE WILL PROVIDE ADEQUATE FOUNDS TO SUIT THE SBC OF SOIL.

200 TH. COARSE TO MEDIUM SAND WITH GRAVEL MIXTURE TO BE WELL

SPEED BRAKER SPEED BREAKER 10m

6m

2000 15. THE ENGINEER-IN-CHARGE SHOULD VERIFY THE FEASIBILITY AT SITE FOR HANDLING, LIFTING AND

BPCL BOTTLING PLANT

RCC RETAINING WALL

6000

SLOPE

TY.C.C.CRIB AS PER PLACING OF PRE-CAST BOX UNITS BY CRANE OR ANY OTHER MEANS FOR THEIR CAPACITY BEFORE

PRO. PRE-CAST RCC. BOX

m

CULTIVATION FIELD

1000

DRAIN DRG.NO. RDSO/B-1484/5

117.14

DRAIN 1x4500x4500 AS PER CASTING THE RCC BOX UNITS / BEFORE PLACING THE BOX UNITS IN FINAL POSITION.

ALT - 2

1 IN 2

DRG.NO.CBE/TP/258/2012-Sh-2

16. THIS WORK WILL BE CARRIED OUT BY CUT AND CONNECTION AND OPEN EXCAVATION METHOD UNDER

RCC RETAINING WALL

0

SIMILAR TO DRG.NO. LINE / POWER BLOCK OF REQUIRED DURATION WITHOUT ANY TEMPORARY ARRANGEMENTS FOR TRACK

COMPACTED BEFORE PLACING THE BASE SLAB UNITS.

CBE/TP/261/2012 EXG.LC NO: 373 SUPPORT BY IMPOSING SUITABLE CAUTION.

117.14m

RAILWAY BOUNDARY

1 IN 20

SLOPE

PRO. RCC BOX

6m PRO. SIDING

15.50m

MDU END VPT END

4200

MDU END

18.580m

CL OF BG TRACK VPT END L

C OF BG TRACK MODUS OPERANDI:-

20

PRO. DOUBLING

6m

17.50m PRELIMINARY:-

RAILWAY BOUNDARY

1 IN

RAILWAY BOUNDARY KEEP READY THE PRE-CAST BASE SLABS AND PRE-CAST BOX UNITS NEAR THE SITE. IMPOSE

SLOPE 1 IN 20

KM 506/000 KM 506/100

103.96m

NON-STOP AND TEMPORARY SPEED RESTRICTION OF 20 Kmph WITH NECESSARY TEMPORARY

18580

3400

ENGINEERING INDICATORS AT THE APPROACHES.

P Q UNDER LINE BLOCK:-

CULTIVATION FIELD CULTIVATION FIELD

6000

DISCONNECT THE TRACK TO THE REQUIRED LENGTH. CUT OPEN THE FORMATION TO THE REQUIRED

6000

SPEED BREAKER

6m LENGTH AND DEPTH ACCORDING TO SITE CONDITION.

10m HEIGHT GAUGE

FILL UP SAND GRAVEL MIXTURE FOR 200 THICK AND RAM IT WELL. LAY THE PRE-CAST BASE SLABS

500

AND PRE-CAST RCC BOX UNITS IN POSITION BY USING CRANE. FILL THE SIDES UP TO FORMATION

EXG.WIDTH 6.00 m

PRO.PRE-CAST RCC BOX

RHS KOOTHIYARKUNDU CLOF PROPOSED DOUBLING LEVEL AND CONSOLIDATE FULLY.

LINK THE TRACK AND ALLOW TRAFFIC AT RESTRICTED SPEED.

CENTRELINE OF NEW LUS NO. 1519A @ Km 506.050 BETWEEN TRAINS: COMPLETE ALL OTHER WORKS INCLUDING CONSTRUCTION OF PARAPET WALLS

15.50m

675 LENGTH OF

500

CAUTION LONGEST GOODS

PRO.PRE-CAST RCC BOX 1200 AND LAYING OF WEARING COURSE.

FLOW

INDICATOR @ TRAIN [677 m] TERMINATION INDICATOR

KM 504.840

30 m

@ KM 506.737 RESTORE NORMAL SPEED IN STAGES AS PER PARA 238(g) OF IRPWM.

FLOW

SPEED INDICATOR

(20 kmph) @ 506.010

T

20

PRO.ROAD LEVEL 94.105

12 NOS OF 1530 LONG RCC BOXES WITH

MDU END MNM END

11 GAPS OF [6 x 20 = 120]=18580

MDU END C.L.OF TRACK VPT END C.L. OF TRACK BG

1676

SPEED INDICATOR (20 CAUTION MODUS OPERANDI:-

kmph) @ KM 506.090

T

20

INDICATOR @ STAGE I:

LONGITUDINAL SECTION

KM 507.260 PRELIMINARY:-

LENGTH OF

4500 TERMINATION INDICATOR

LONGEST GOODS 30 m

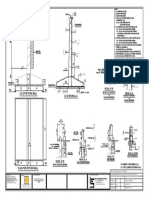

PLAN OF TY.GIRDER ARRANGEMENT 1. IMPOSE SPEED RESTRICTION OF NON-STOP 20 KMPH DULY PROVIDING ENGINEERING

@ KM 505.363

5000 TRAIN [677 m] 1200 INDICATORS AS SHOWN. KEEP READY ONE SET OF TY.GIRDER. ALSO SUFFICIENT NO OF

4500

WOODEN SLEEPERS, STEEL CRIBS AT WORK SITE.

20

UNDER LINE BLOCK:-

6990

20

6990

2. DISCONNECT THE TRACK TO THE REQUIRED LENGTH. CUT OPEN THE FORMATION TO THE

650

TEMPORARY SIGNALLING ARRANGEMENTS REQUIRED LENGTH AND DEPTH ACCORDING TO SITE CONDITION AND ERECT SLEEPER

BASE SLAB IN M.25 GRADE

250 TH CC PRE-CAST RCC

(NOT TO SCALE)

CRIBS "P & Q" AS SHOWN.

3. INSTALL TY.GIRDERS OVER THE CRIBS "P & Q" LINK THE P-WAY AND ALLOW THE TRAFFIC.

LEVEL

18580

BETWEEN THE TRAINS:

4. COMMENCE THE EARTH WORK EXCAVATION FROM FORMATION TO THE REQUIRED DEPTH

AND LENGTH FOR L.U.S

PRO. DOUBLING PRO. DOUBLING 5. FILL UP SAND GRAVEL MIXTURE FOR 200mm THICK AND RAM IT WELL. LAY THE PRE-CAST

BASE SLABS IN POSITION BY USING CRANE.

OVERALL LENGTH - 20550 NOTE:-

STAGE II

EFFECTIVE SPAN 20000 1. ALL DIMENSIONS ARE IN MILLIMETRES UNLESS OTHERWISE STATED. PRELIMINARY:-

6. KEEP READY THE PRE-CAST BOX UNITS NEAR THE SITE.

2. PROPOSALS ARE SHOWN IN RED .

UNDER THE LINE BLOCK:

TY.GIRDER TO DRG. NO. 3. TEMPORARY ARRANGEMENTS ARE SHOWN IN GREEN. 7. DISCONNECT THE P-WAY TO REQUIRED LENGTH AND REMOVE THE TEMPORARY GIRDER

C

L OF PRO. SUBWAY BE.1228 / 84 BG ALT-2 . AND SLEEPER CRIBS AT P & Q.

RAIL LEVEL 99.930 4. FOR DETAILS OF TY.GRIDER SEE DRG NO BE.1228 / 84 BG ALT - 2 AND TY.C.C.CRIBS SEE DRG NO 8. COMPLETE ERECTION OF PRECAST RCC BOX TO REQUIRED LENGTH WITH HELP OF HEAVY

17.50m

DUTY CRANE OF 120 T CAPACITY (MIN) CRAWLER TYPE) ALONG WITH STANDBY CRANE OF

675

RDSO/B-1484/5 ALT - 2

EXG.GL 98.980 TY.C.C.CRIB AS PER DRG.NO. SAME CAPACITY.

256

650

RDSO/B-1484/5 ALT-2 5. FOR GAD REFER DRG NO. LUS/13/16 ALT-1 SHEET 1 OF 2

508

9. FILL THE SIDES UP TO FORMATION LEVEL AND CONSOLIDATE FULLY.

5000 10. LINK THE TRACK AND ALLOW TRAFFIC AT RESTRICTED SPEED.

600

600

6. THIS WORK WILL BE CARRIED OUT BY CUT AND CONNECTION AND OPEN EXCAVATION METHOD

500

650

200

200

BETWEEN TRAINS:

254

254

500

6500 1800x3600 300 1800x3600 UNDER LINE / POWER BLOCK OF REQUIRED DURATION WITH TEMPORARY GIRDER ARRANGEMENTS 11. COMPLETE ALL OTHER WORKS INCLUDING CONSTRUCTION OF PARAPET WALLS AND

4500

W 3400 X 4200

6000

300

O LAYING OF WEARING COURSE.

6000

FL FOR TRACK SUPPORT BY IMPOSING SUITABLE CAUTION.

COLLECTION WELL

3400x4200

7175

12. RESTORE NORMAL SPEED IN STAGES AS PER PARA 238(g) OF IRPWM.

SUMP Q 13. ACTUAL CONSTRUCTION WORK SHOULD BE DONE ONLY UNDER CONTINUOUS

WITH PUMP

P

FORMATION LEVEL 99.255

600x600x600

SUPERVISION OF ENGINEER IN CHARGE

4682

00mm

IPE 2

RCC P

RAIL LEVEL 99.930

250

4500

00°

45.

20

Ty.SHORING

650

1 IN

250

234

4448

200

300

RAILWAY BOUNDARY

103.96m

6500

1 IN 20

PB ITEM NO: 317/2016-17

SLOPE

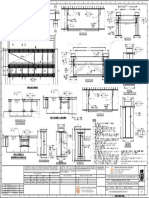

RCC RETAINING WALL ELEVATION OF TY.GIRDER ARRANGEMENT SOUTHERN RAILWAY वववववव ववववव

MADURAI DIVISION ववववव वववव

CC ROAD

DEN /SOUTH

DRN BY

वववववव [A.THIRUMAL]

ववववव

1000

DRAIN

[V.MURUGAN]

MADURAI - VIRUDUNAGAR (BG) SECTION Sr.DEN / Co.or.

RAIL PEGS @ 600 THIS LC WILL BE CLOSED PERMANENTLY AFTER COMPLETION OF

SPEED 6000 600 C/C

LIMITED USE SUBWAY VIDE DISTRICT COLLECTOR CHD BY

BETWEEN TIRUPPARANKUNDRAM AND TIRUMANGALAM ववववववव

/व [D.SARANGAPANI]

BREAKER 2000

10000 ----------------- LR NO : ---------------- DT -------------- वववव STATIONS

ADRM

वववववववव

234235

[P.V.MURALI KRISHNA.]

PRO. CONSTRUCTION OF A DRM

BOTTOM OF FOUNDATION

A

SCALE :- 1 : 100 ववववववव

300

NEW LUS NO. 1519A (1 x 4.50mX 4.50m) RCC BOX [SUNIL KUMAR GARG.]

THIS IS TO CERTIFY THAT THE PROPOSED BRIDGE HAS BEEN

ववववव

STEEL SHEET 6mm THICK

HALF PLAN IN LIEU OF EXG LC NO:373 (M) AT KM 506/000-100 TO XEN / Hqrs

TEMPORARY SHORING ARRANGEMENTS DESIGNED TO SUIT THE 25 ' t ' AXLE LOADING - 2008 .

NOT TO SCALE

AT TOP AND AT BOTTOM 25 't' AXLE LOADING-2008 STANDARD

DYCE / Br

GENERAL ARRANGEMENTS

CBE / MAS

DY.CE / BR. CBE / MAS. PLAN NO:- TRACING NO.

ववववव वव वववववव वव

You might also like

- Modified LVUP DrawingsDocument1 pageModified LVUP DrawingsAldrinNo ratings yet

- Tracked Vehicle-Problem SolvingDocument7 pagesTracked Vehicle-Problem SolvingF. Hakimi0% (1)

- Healthway Branches & Consultation HoursDocument12 pagesHealthway Branches & Consultation Hours7761430No ratings yet

- JMPT Fob 28-01-2021 - V1 - Dyce-B&f-Bbs - P27Document1 pageJMPT Fob 28-01-2021 - V1 - Dyce-B&f-Bbs - P27RVNLPKG6B VBL-GTLM100% (1)

- Dimns. & Reinf. of Pier CapDocument1 pageDimns. & Reinf. of Pier Capsantosh yevvariNo ratings yet

- Steel Drawing For LvupDocument1 pageSteel Drawing For LvupvivekNo ratings yet

- Superstructure design drawing of a 4 lane flyoverDocument1 pageSuperstructure design drawing of a 4 lane flyoverarif_rubinNo ratings yet

- 40 M COMPOSITE GIRDER New-ModelDocument1 page40 M COMPOSITE GIRDER New-Modelabhijeet sahuNo ratings yet

- M Bow String Girder-10409-9Document1 pageM Bow String Girder-10409-9prejithNo ratings yet

- Box Culvert ArrangementDocument3 pagesBox Culvert Arrangementbakhteyar shaikhNo ratings yet

- Rly. Platform DrawingDocument1 pageRly. Platform DrawingAtul Kumar MishraNo ratings yet

- GAD of Structure - A-13 - 2 PDFDocument30 pagesGAD of Structure - A-13 - 2 PDFmayank007aggarwal0% (1)

- DRGS 0401 0201Document1 pageDRGS 0401 0201AJAY SHINDENo ratings yet

- Boundary Wall ProjectDocument1 pageBoundary Wall ProjectMuhammad Wazim AkramNo ratings yet

- 60 M.bow String Girder-10411-5-RDocument1 page60 M.bow String Girder-10411-5-RkesharinareshNo ratings yet

- Major BR - No.607 OHE Mast - V1 - SSE-BR-DRG-6 - P16Document1 pageMajor BR - No.607 OHE Mast - V1 - SSE-BR-DRG-6 - P16dipakNo ratings yet

- Notes:: Section A-A Section B-B Section C-CDocument1 pageNotes:: Section A-A Section B-B Section C-CAnkush SharmaNo ratings yet

- North Western Railway: Sr. Den (Co) /JP CBE....... JPDocument1 pageNorth Western Railway: Sr. Den (Co) /JP CBE....... JPEr Navneet JassiNo ratings yet

- Package V bridge drawingsDocument67 pagesPackage V bridge drawingsMandeep Singh100% (1)

- Steel composite girder designDocument3 pagesSteel composite girder designAnkush SharmaNo ratings yet

- Re Wall Design As Per Irc 102Document16 pagesRe Wall Design As Per Irc 102munnijhaNo ratings yet

- HCC DLB PIER 44.687 Final Approved 301106 ModelDocument1 pageHCC DLB PIER 44.687 Final Approved 301106 ModelRama KrishnaNo ratings yet

- To Barmer To Jalore: GL GLDocument2 pagesTo Barmer To Jalore: GL GLBarmer JaloreNo ratings yet

- M-20 Concrete Fence Panel DetailsDocument1 pageM-20 Concrete Fence Panel DetailsjitendraNo ratings yet

- Typical NavigationalDocument3 pagesTypical NavigationalShashank SrivastavaNo ratings yet

- 001.gad Bow String Steel Bridge 200 M SpanDocument1 page001.gad Bow String Steel Bridge 200 M SpanManvendra NigamNo ratings yet

- C of Symmetry L: Section F F (At Joint U3&U4)Document1 pageC of Symmetry L: Section F F (At Joint U3&U4)Srikanth Patel DspNo ratings yet

- DrawingsStrutures PKG III PDFDocument71 pagesDrawingsStrutures PKG III PDFMandeep SinghNo ratings yet

- PE Claim 1Document7 pagesPE Claim 1ravindrarao_mNo ratings yet

- 3 Detail-1: Reference Drawings / NotesDocument2 pages3 Detail-1: Reference Drawings / NotesTarun MauryaNo ratings yet

- Retaining wall reinforcement detailsDocument1 pageRetaining wall reinforcement detailsSunetra DattaNo ratings yet

- Ilfs-Nagpur Metro-cn-1011-Details of Steel I Girder at Platform Level-17m SpanDocument1 pageIlfs-Nagpur Metro-cn-1011-Details of Steel I Girder at Platform Level-17m SpanrohitNo ratings yet

- Proposed bridge sectional elevation for Shimla to Mataur highway projectDocument1 pageProposed bridge sectional elevation for Shimla to Mataur highway projectvenkatd123603No ratings yet

- Br. No. 276-1 97919Document1 pageBr. No. 276-1 97919Krushana GiteNo ratings yet

- 1x1.2x1.2 BOX CULVERT GAD-4-LANE PDFDocument1 page1x1.2x1.2 BOX CULVERT GAD-4-LANE PDFbakhteyar shaikhNo ratings yet

- Retaining Wall - 10MDocument1 pageRetaining Wall - 10MManupriya KapleshNo ratings yet

- RDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDDocument1 pageRDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDSrikanth Patel DspNo ratings yet

- Vup - ch.500+978 - DrgdocDocument95 pagesVup - ch.500+978 - DrgdocSubhamNo ratings yet

- Case Study Tech AbutmentDocument7 pagesCase Study Tech AbutmentGajendra BishtNo ratings yet

- Ottankadu - Punalvasal - SafeDocument6 pagesOttankadu - Punalvasal - SafeRenugopalNo ratings yet

- Design of Pilecaps - Extract From Reinforced Concrete Design (Limit State) by Varghese P.CDocument18 pagesDesign of Pilecaps - Extract From Reinforced Concrete Design (Limit State) by Varghese P.Cprabhu81No ratings yet

- Do - 049 - s2018 Bridge Aesthetics GuidelinesDocument67 pagesDo - 049 - s2018 Bridge Aesthetics GuidelinesBrian PaulNo ratings yet

- Retaining WallDocument1 pageRetaining WallVivek KumarNo ratings yet

- Notes: Traffic Direction MP238Document1 pageNotes: Traffic Direction MP238alvaroNo ratings yet

- R. D. S. O.: Rdso/b - 10408/6Document1 pageR. D. S. O.: Rdso/b - 10408/6MUTHU PANDINo ratings yet

- 36 MTR SpanDocument13 pages36 MTR SpanAnonymous sfkedkymNo ratings yet

- Gorakhpur Bypass Flyover PlanDocument1 pageGorakhpur Bypass Flyover PlanvivekNo ratings yet

- Pier Detail Drawing With Waler BeamDocument1 pagePier Detail Drawing With Waler BeamSayantan PaulNo ratings yet

- Voided Slab MopaDocument14 pagesVoided Slab MopaSreekanth SattirajuNo ratings yet

- RCC T Girder & Deck Slab For Major Bridge 02 - Sup-19Document1 pageRCC T Girder & Deck Slab For Major Bridge 02 - Sup-19mrinal kayalNo ratings yet

- Optimization PSC Bridge An ExampleDocument13 pagesOptimization PSC Bridge An Exampleani4576No ratings yet

- MJB 16+785 DC 201 AbutDocument63 pagesMJB 16+785 DC 201 AbutChandra BabuNo ratings yet

- FULL VS PARTIAL HEIGHT RE WALL COSTSDocument2 pagesFULL VS PARTIAL HEIGHT RE WALL COSTSNaresh SharmaNo ratings yet

- Sub. Abut. & PierDocument7 pagesSub. Abut. & PierAnkush SharmaNo ratings yet

- Traffic Final Report Group 7Document86 pagesTraffic Final Report Group 7erlyn alagonNo ratings yet

- Sankhuwa Supstr+Substr-Design DwgsDocument12 pagesSankhuwa Supstr+Substr-Design DwgsPrakash Singh RawalNo ratings yet

- Arrangement of pot PTFE bearings diagramDocument1 pageArrangement of pot PTFE bearings diagramkesharinaresh100% (1)

- Report on Improvement of Raisuan-Mahadeijoda-Kusumita RoadDocument16 pagesReport on Improvement of Raisuan-Mahadeijoda-Kusumita RoadRanjan Kumar SahooNo ratings yet

- Name of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshDocument4 pagesName of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshUpadhyayula Subba RaoNo ratings yet

- Typical T Intersection On Rural Local Road With Left Turn LanesDocument1 pageTypical T Intersection On Rural Local Road With Left Turn Lanesahmed.almakawyNo ratings yet

- Typical T Intersection On Rural Local Road With Left Turn LanesDocument1 pageTypical T Intersection On Rural Local Road With Left Turn Lanesahmed.almakawyNo ratings yet

- Geotechnical DrawingsDocument21 pagesGeotechnical DrawingsWaleed FayezNo ratings yet

- Mooring Line As A Spring Mass SystemDocument29 pagesMooring Line As A Spring Mass SystemArun K RajNo ratings yet

- Ussor AorDocument1 pageUssor AorArun K RajNo ratings yet

- Indian Railways Standard GCC Contract TitleDocument124 pagesIndian Railways Standard GCC Contract TitleDurgesh Pandey (Durgesh)No ratings yet

- Manchette Tube SystemDocument4 pagesManchette Tube SystemThanh Khiet Ung100% (1)

- Grouped SlorDocument26 pagesGrouped SlorArun K RajNo ratings yet

- Very Large Floating StructuresDocument30 pagesVery Large Floating StructuresArun K RajNo ratings yet

- Objective TypeDocument8 pagesObjective TypeArun K RajNo ratings yet

- 5 6066685101381518772Document20 pages5 6066685101381518772Arun K RajNo ratings yet

- Geosynthetics ReportDocument24 pagesGeosynthetics ReportArun K Raj100% (1)

- StairsDocument57 pagesStairsArun K RajNo ratings yet

- Details of Various Proforma Used For Track Renewal Work.: Assignment OnDocument8 pagesDetails of Various Proforma Used For Track Renewal Work.: Assignment OnArun K Raj100% (1)

- Civil-2017-A 95626562Document18 pagesCivil-2017-A 95626562sateesh888No ratings yet

- Objective QDocument2 pagesObjective QArun K RajNo ratings yet

- List of Je'sDocument2 pagesList of Je'sArun K RajNo ratings yet

- Details of Various Proforma Used For Track Renewal Work.: Assignment OnDocument8 pagesDetails of Various Proforma Used For Track Renewal Work.: Assignment OnArun K Raj100% (1)

- Bridge Gad DetailsDocument4 pagesBridge Gad DetailsArun K RajNo ratings yet

- Arun FRNT PageDocument6 pagesArun FRNT PageArun K RajNo ratings yet

- IRBM 1301,1302 ArunDocument2 pagesIRBM 1301,1302 ArunArun K RajNo ratings yet

- Gad LusDocument1 pageGad LusArun K RajNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelArun K RajNo ratings yet

- Name: Arun K Raj Designation: Tr. JE/Design, Drawing and Estimation Division: EWS/AJJ/SR TOPIC: IRBM/1301,1302 (Training For Bridge Staff)Document2 pagesName: Arun K Raj Designation: Tr. JE/Design, Drawing and Estimation Division: EWS/AJJ/SR TOPIC: IRBM/1301,1302 (Training For Bridge Staff)Arun K RajNo ratings yet

- Project ValidationDocument53 pagesProject ValidationArun K RajNo ratings yet

- 120517Document324 pages120517Arun K RajNo ratings yet

- Arun FRNT PageDocument6 pagesArun FRNT PageArun K RajNo ratings yet

- Main Seminar3Document28 pagesMain Seminar3Arun K RajNo ratings yet

- Project ValidationDocument53 pagesProject ValidationArun K RajNo ratings yet

- Skewed Bridge DesignDocument2 pagesSkewed Bridge DesignArun K RajNo ratings yet

- Report 27 - 5 - 17Document84 pagesReport 27 - 5 - 17Arun K RajNo ratings yet

- New Exp Disp TMDDocument445 pagesNew Exp Disp TMDArun K RajNo ratings yet

- Topic C: Geografi PenerbanganDocument46 pagesTopic C: Geografi Penerbangannurlinda_polijbNo ratings yet

- Memorandum Circular No. 105Document7 pagesMemorandum Circular No. 105DC ANo ratings yet

- Major Events in Nissan's HistoryDocument3 pagesMajor Events in Nissan's HistoryMehdi RostamiNo ratings yet

- September 13, 2021 List of Pre-Owned Vehicles For Sale: Cut-Off Is Every SundayDocument4 pagesSeptember 13, 2021 List of Pre-Owned Vehicles For Sale: Cut-Off Is Every SundayDanver GalvezNo ratings yet

- A Look at The New MP Transfer CaseDocument4 pagesA Look at The New MP Transfer CaseКостя СеверинNo ratings yet

- 9660 STS 9760 STS and 9860 STS Series Combines Filter Overview With Service Intervals and CapacitiesDocument2 pages9660 STS 9760 STS and 9860 STS Series Combines Filter Overview With Service Intervals and CapacitiesRodrigo RojasNo ratings yet

- Regenerative Braking SystemDocument8 pagesRegenerative Braking Systemsanjay sureshNo ratings yet

- TH 0608Document8 pagesTH 0608sylvaniaheraldNo ratings yet

- PARTSDocument61 pagesPARTStuannhocutNo ratings yet

- Service/ PPM Report - CD PUMPDocument2 pagesService/ PPM Report - CD PUMPYasir MehmoodNo ratings yet

- Specs Chassis e CarroceriaDocument4 pagesSpecs Chassis e CarroceriaRodrigo Alexis Montecinos VásquezNo ratings yet

- Compound Word ListDocument15 pagesCompound Word ListAngela MorilloNo ratings yet

- Weapons - of.WWII - truePDF Fall.2015Document116 pagesWeapons - of.WWII - truePDF Fall.2015Ron Lebert100% (3)

- PROPOSALDocument7 pagesPROPOSALBrynn EnriquezNo ratings yet

- Rare Motorcycle - TVS Suzuki ShogunDocument34 pagesRare Motorcycle - TVS Suzuki ShogunAshok ShenoyNo ratings yet

- Unit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Document29 pagesUnit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Zara Nabilah76% (33)

- Eastem Railway, Fairly Place, Kolkata-700 001: Northern Railway, Western Railway, ChurchgateDocument2 pagesEastem Railway, Fairly Place, Kolkata-700 001: Northern Railway, Western Railway, ChurchgateOS WSNo ratings yet

- Energisation of Q50 Relay for Traction and BrakingDocument2 pagesEnergisation of Q50 Relay for Traction and BrakingCTLC SURNo ratings yet

- CMVR-chapter2 1 PDFDocument28 pagesCMVR-chapter2 1 PDFbhavana borkerNo ratings yet

- HotSheet Helm Master EXDocument12 pagesHotSheet Helm Master EXKittipat officeNo ratings yet

- ASME B3022-2005 Articulating Boom Cranes - 221206 - 123014Document42 pagesASME B3022-2005 Articulating Boom Cranes - 221206 - 123014jesus rosasNo ratings yet

- Class 4Document20 pagesClass 4kfupgessytogimmbhmNo ratings yet

- Advancement in Technology in Water TransportDocument8 pagesAdvancement in Technology in Water TransportAnkur BansalNo ratings yet

- Essar Oil LTD 2013-2014Document3 pagesEssar Oil LTD 2013-2014jnr roadwaysNo ratings yet

- Capitol Corridor Schedule: Auburn / Sacramento - and - San Francisco Bay Area - and - San JoseDocument8 pagesCapitol Corridor Schedule: Auburn / Sacramento - and - San Francisco Bay Area - and - San Joseusama zedanNo ratings yet

- Neighbourhood Unit - Clarence Arthur Perry B.arch Sem8Document15 pagesNeighbourhood Unit - Clarence Arthur Perry B.arch Sem8Krupa NidhiNo ratings yet

- Public Bus Business Model Canvas Testing MethodsDocument11 pagesPublic Bus Business Model Canvas Testing MethodsRaniag PwdNo ratings yet

- Automated TransmissionsDocument33 pagesAutomated TransmissionsHERNAN CORTEZ FARFANNo ratings yet