Professional Documents

Culture Documents

Engineering Office: General Specifications Division 3 - Concrete

Uploaded by

MØhãmmed ØwięsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Office: General Specifications Division 3 - Concrete

Uploaded by

MØhãmmed ØwięsCopyright:

Available Formats

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 3 - CONCRETE

SECTION 03600 – GROUT

PART 1 - GENERAL

1.1 SECTION INCLUDES

A. Furnish all labour, materials, tools and equipment and perform all services and operations

necessary for the complete supply and installation of grouts:

1. Cementitious Grouts.

2. Anchoring Grouts

3. Bedding Mortars

1.2 RELATED SECTIONS

A. Related work to be coordinated and used in conjunction with this specification includes but is not

restricted to:

1. Section 03300 - Cast-In-Place Concrete

2. Section 03400 - Precast Concrete

3. Section 05120 - Structural steel-

4. Section 05500 - Metal Fabrication

1.3 QUALITY ASSURANCE

A. Control Sample: Complete a sample of the premixed and site mixed work in an approved location

and obtain approval before proceeding. Additive Manufacturer's representative to be present to

supervise control sample.

1.4 STANDARDS

A. The publications listed below form a part of this specification to the referenced material.

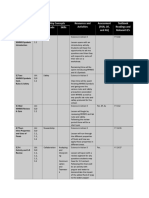

Table: 03600-1A

ASTM C 1107 Standard specification for Packaged Dry Hydraulic cement Grout (Non-Shrink).

ASTM C 579 Standard Test Methods for Compressive Strength of Chemical resistant grout.

ASTM C 881 Standard Specification for Epoxy Resin – Base bonding system for concrete.

ASTM C 109 Standard Test Method for Compressive strength of hydraulic cement mortars.

1.5 DEFINITIONS

A. The following definitions shall pertain to works or phrases as utilized in this Section.

1. ‘Cementitious Grout’ is a mixture of cementitious materials and water, proportioned to

produce a pourable (fluid) consistency without segregation of the constituents.

2. ‘Anchoring Grouts’ are grouts specifically materials designed for anchoring purposes.

3. ‘Mortars’ are cementitious or chemical materials proportioned to produce a trowelable

consistence for vertical and overhead repairs or bedding purposes.

1.6 GENERAL REQUIREMENTS

A. Product manufacturer, testing and installation shall comply with the following requirements, unless

otherwise approved:

1. Cementitious grout shall typically be used where it is necessary to eliminate shrinkage

when filling the void between a base plate and a substrate such as the grouting of

stanchion bases.

2. Anchoring grouts shall be used to secure anchor bolts, rebar, or fill in tie rod holes.

03600 GROUT Page 1/4 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 3 - CONCRETE

3. Grout manufacturer shall operate under a certified ISO 9000 Quality System.

1.7 SUBMITTALS

A. Samples:

1. Submit sample of any proposed additives before delivery of material generally.

2. Submit sample of any proposed premixed grout before delivery of material generally.

B. Product Data:

1. Submit name of manufacturer of premixed grout and additives and specific brand name.

2. Submit 2 copies of manufacturer's technical data.

3. Submit 2 copies of manufacturer's recommended mixing and placing instructions.

C. Methods:

1. Prior to commencing work submit details of methods and techniques proposed for the

design and execution of the work.

1.8 DELIVERY, STORAGE AND HANDLING

A. Storage:

1. Store grout bags as per recommendations of the grout manufacturers.

2. Store out of direct sunlight, clear of the ground on pallets protected from rainfall.

B. Handling:

1. Grout: Use grout within 30 minutes of mixing or in the time recommended by the

manufacturer of the additives.

PART 2 - PRODUCTS

2.1 CEMENTITIOUS GROUTS

A. Cementitious grout shall comply with the following requirements.

1. Cementitious grout shall be a single pack special purpose product which requires only the

addition of water at site and shall comply with the following:

a. Non-shrink

b. Non-metallic

c. Chloride free

d. Minimum Compressive Strength (fluid consistency).

2

i. 30 N/mm at 7 days.

2

ii. 40 N/mm at 28 days.

2. Cementitious grouts shall comply with the following Standards:

a. ASTM C230 for workability.

b. ASTM C232 for bleed water.

c. ASTM C878 for expansion.

2.2 EPOXY GROUT

A. Grout for anchoring rebar, bolts or other anchors shall be a pre-measured two or epoxy resin

specifically developed for anchoring purposes.

1. The resin must be non-expansive and tolerant to wet or damp surfaces.

2

2. Minimum compressive strength : 90 N/mm (1 day)

2

3. Minimum flexural strength : 100 N/mm (7 days)

03600 GROUT Page 2/4 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 3 - CONCRETE

2

4. Minimum tensile strength : 14N/mm (7 days)

2.3 BEDDING MORTARS

A. Bedding mortars for pre-cast elements shall be pre-bagged cementitious products requiring

only the addition of water at site.

1. Minimum compressive strength at 28 days: 40 N/mm².

2. Site mixed sand / cement mortars are not allowed.

3. Bonding Agent: As recommended by the Manufacturer.

2.3 OTHER MATERIALS

A. Additives: Subject to approval.

B. Water: As specified in Section 03300 for Concrete.

o

1. In hot weather, use cold water to bring the mixed grout temperature to less than 30 C.

2.4 MIXES

A. Mixing to be done as per recommendation of the manufacturer.

2.5 FORMWORK

A. As specified in Section 03100 Concrete.

B. For smaller areas to manufacturer's instructions.

PART 3 - EXECUTION

3.1 EXAMINATION

A. Examine surfaces and conditions to which the Work of this Section is to be applied to ensure

that they are adequate to provide a satisfactory application.

B. Report any unsatisfactory conditions.

3.2 PREPARATION

A. Scrabble concrete surfaces to provide key.

B. Ensure spaces to receive grout are clean and free from debris.

C. Thoroughly wet surfaces and allow free water to disperse prior to application of grout.

3.3 FORMWORK

A. Fix edge formwork where necessary.

B. Ensure formwork is secure and watertight to prevent movement and leaking during the

placing and curing of the grout.

C. Edge formwork to base plates to be to the level of the plate.

D. Strike formwork within 24 hours of filling.

3.4 APPLICATION

A. Place grout in accordance with manufacturer's instructions in relationship to temperature and

workability conditions.

03600 GROUT Page 3/4 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 3 - CONCRETE

B. Strike edges clean and compress to conditions as indicated on the drawings.

C. Materials shall be applied in position within one hour of mixing (unless manufacturer's

literature states otherwise). After half an hour discard any grout mix that shows signs of

stiffening.

D. As soon as grout sets, cure exposed surfaces with curing compound applied in strict

accordance with manufacturer’s instructions.

3.5 CLEAN-UP

A. Promptly, as the Work proceeds and upon completion, scrape off and remove all grout

materials from adjacent surfaces. Clean up and remove any surplus material and rubbish

resulting from the work of this Section.

END OF SECTION-03600

03600 GROUT Page 4/4 Rev.1 - 02 Aug 2015

You might also like

- 03 6000 - GroutingDocument4 pages03 6000 - GroutingAngelo Carlo MalabananNo ratings yet

- Specifications for Cementitious, Chemical and Anchoring GroutsDocument6 pagesSpecifications for Cementitious, Chemical and Anchoring GroutsTEC PlantNo ratings yet

- 07 92 16 Rigid Joint Sealants Spal Pro RS65 2020Document4 pages07 92 16 Rigid Joint Sealants Spal Pro RS65 2020crowNo ratings yet

- Grout Specification and RequirementsDocument5 pagesGrout Specification and RequirementsFurgoToyotaNo ratings yet

- Bitexco Financial Tower Exterior Stone PavingDocument8 pagesBitexco Financial Tower Exterior Stone Pavinghuumanhcdn8No ratings yet

- MASONRY SPECIFICATIONS FOR ENGINEERING OFFICEDocument14 pagesMASONRY SPECIFICATIONS FOR ENGINEERING OFFICEMØhãmmed ØwięsNo ratings yet

- 03 39 00 Concrete CuringDocument4 pages03 39 00 Concrete Curingdicky1969No ratings yet

- Section - 03 35 00 - Polished Concrete FinishingDocument4 pagesSection - 03 35 00 - Polished Concrete FinishingEliseo LagmanNo ratings yet

- US CORPS of Engineer CRD-C-621Document3 pagesUS CORPS of Engineer CRD-C-621Khin Sandi KoNo ratings yet

- Section 09220Document5 pagesSection 09220Im ChinithNo ratings yet

- Non-shrink grout specificationsDocument7 pagesNon-shrink grout specificationsIm ChinithNo ratings yet

- SECTION 07180 Cement-Based Waterproof CoatingDocument2 pagesSECTION 07180 Cement-Based Waterproof CoatingIm ChinithNo ratings yet

- SECTION 03 30 53 (Short-Form) Cast-In-Place ConcreteDocument13 pagesSECTION 03 30 53 (Short-Form) Cast-In-Place ConcreteJuanPaoloYbañezNo ratings yet

- 03 06 00 - Schedules For ConcreteDocument5 pages03 06 00 - Schedules For ConcreteHardeo Dennis ChattergoonNo ratings yet

- Related SpecsDocument13 pagesRelated SpecsAhmed GhariebNo ratings yet

- SECTION 07920 Sealants and Calking Part 1 - General 1.1 SummaryDocument5 pagesSECTION 07920 Sealants and Calking Part 1 - General 1.1 SummaryIm ChinithNo ratings yet

- Concrete Topping SpecificationsDocument7 pagesConcrete Topping SpecificationsTEC PlantNo ratings yet

- 01/31/2018 DESIGN No. 016626 SECTION 03733 Concrete Repair Work Part 1 - General 1.01 Description of WorkDocument13 pages01/31/2018 DESIGN No. 016626 SECTION 03733 Concrete Repair Work Part 1 - General 1.01 Description of WorkDino HodzicNo ratings yet

- Structural Concrete Mix Design and Placement SpecificationsDocument10 pagesStructural Concrete Mix Design and Placement SpecificationsJonathanPobletePerezNo ratings yet

- Spec For Concrete Patch RepairDocument9 pagesSpec For Concrete Patch RepairHamidah RamaleyNo ratings yet

- Cast in Place ConcreteDocument16 pagesCast in Place ConcreteabdouNo ratings yet

- SP ConcreteDocument11 pagesSP ConcreteAl Patrick Dela CalzadaNo ratings yet

- 06 Specification Section036000 GroutingDocument4 pages06 Specification Section036000 GroutingOtceliban SarlNo ratings yet

- Special Concrete FinishesDocument5 pagesSpecial Concrete FinishesTaher AmmarNo ratings yet

- Wood DeckingDocument4 pagesWood DeckingDee Jay VillanuevaNo ratings yet

- Section 03 06 00-Division 03Document39 pagesSection 03 06 00-Division 03Alexander MasongsongNo ratings yet

- Construction of Residential Villas Concrete ToppingDocument8 pagesConstruction of Residential Villas Concrete ToppingStraus WaseemNo ratings yet

- 03 30 00 - Cast in Place Concrete PDFDocument17 pages03 30 00 - Cast in Place Concrete PDFsyedNo ratings yet

- UNIT PAVING SPECIFICATIONDocument8 pagesUNIT PAVING SPECIFICATIONery achjariNo ratings yet

- Section 03370-ShotcreteDocument7 pagesSection 03370-ShotcreteMØhãmmed ØwięsNo ratings yet

- AAB 042200 Concrete Unit MasonryDocument6 pagesAAB 042200 Concrete Unit MasonrytewodrosNo ratings yet

- Quikrete Guide Specification: Quikrete® Concrete Bonding Adhesive (No. 9902)Document3 pagesQuikrete Guide Specification: Quikrete® Concrete Bonding Adhesive (No. 9902)Gonzalo AlvarezNo ratings yet

- 03 01 30mapDocument11 pages03 01 30mapmp4 ghad mp4No ratings yet

- Construction of 32 Villas and Services BlocksDocument4 pagesConstruction of 32 Villas and Services BlocksStraus WaseemNo ratings yet

- Grout Rev.c PDFDocument6 pagesGrout Rev.c PDFMithun UdayanarayanaNo ratings yet

- 07 16 13 - Polymer Modified Cement WaterproofingDocument4 pages07 16 13 - Polymer Modified Cement WaterproofingMutaz Hashim MirganyNo ratings yet

- 03 01 30mapDocument12 pages03 01 30mapTaher AmmarNo ratings yet

- 03 01 30mapDocument12 pages03 01 30mapTaher AmmarNo ratings yet

- Aquafin-2K/M Two-Component Cement-Based Acrylic-Based Waterproofing Guide Aquafin, Inc. SpecificationDocument5 pagesAquafin-2K/M Two-Component Cement-Based Acrylic-Based Waterproofing Guide Aquafin, Inc. SpecificationalpegambarliNo ratings yet

- BASF Master Builders Solutions Integral Waterproofing Guide Specifications 941508Document4 pagesBASF Master Builders Solutions Integral Waterproofing Guide Specifications 941508Kishore Nayak kNo ratings yet

- BT 4Document9 pagesBT 421-03606No ratings yet

- SpecsDocument16 pagesSpecsLea Ann BellenNo ratings yet

- Eucocrete Supreme Guide Specifications b653Document4 pagesEucocrete Supreme Guide Specifications b653Ogbedande Awo OrunmilaNo ratings yet

- All Specs - P34 PDFDocument1,243 pagesAll Specs - P34 PDFscoodivNo ratings yet

- Masonry Mortar SpecificationDocument6 pagesMasonry Mortar SpecificationJuanPaoloYbañezNo ratings yet

- Section 03490-Glass-Fiber-Reinforced Precast ConcreteDocument5 pagesSection 03490-Glass-Fiber-Reinforced Precast ConcreteMØhãmmed ØwięsNo ratings yet

- SECTION 07550 Protected Membrane Roofing Part 1 - General 1. 1Document6 pagesSECTION 07550 Protected Membrane Roofing Part 1 - General 1. 1Im ChinithNo ratings yet

- Section 035216 - Lightweight Insulating ConcreteDocument5 pagesSection 035216 - Lightweight Insulating ConcreteWENDING HUNo ratings yet

- Key IWS CoatingDocument6 pagesKey IWS Coatingfaisal hanifNo ratings yet

- Section 03300 Cast-In-Place Concrete: Part 1 - General 1.1 ScopeDocument18 pagesSection 03300 Cast-In-Place Concrete: Part 1 - General 1.1 Scopeاحمد علي احمدNo ratings yet

- MF (1) 1Document24 pagesMF (1) 1Suranga ManuNo ratings yet

- KOSTER NB1 Grey Specification For Cementitious Crystallizing WaterproofingDocument7 pagesKOSTER NB1 Grey Specification For Cementitious Crystallizing WaterproofingMosul SpaceNo ratings yet

- Asphalt Concrete PavingDocument10 pagesAsphalt Concrete Pavingsethu1091No ratings yet

- Cementitious Sheathing SpecificationDocument4 pagesCementitious Sheathing SpecificationJuanPaoloYbañezNo ratings yet

- Section 321443 - Porous Unit Paving: Part 1 - GeneralDocument7 pagesSection 321443 - Porous Unit Paving: Part 1 - Generalery achjariNo ratings yet

- 03300-Cast in Place Concrete - Doc 03300 - 1Document10 pages03300-Cast in Place Concrete - Doc 03300 - 1Sylvestre UbaNo ratings yet

- Brick Masonry SpecificationDocument14 pagesBrick Masonry SpecificationHeak Hor100% (1)

- FLOOR HARDENER SPEC FOR ANZ BANK CAMBODIADocument3 pagesFLOOR HARDENER SPEC FOR ANZ BANK CAMBODIAIm ChinithNo ratings yet

- Cast in Place ConcreteDocument13 pagesCast in Place ConcreteAicxy100% (1)

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- St-104 - Overall Ground Floor PlanDocument1 pageSt-104 - Overall Ground Floor PlanMØhãmmed ØwięsNo ratings yet

- St-112 - Lower Roof PlanDocument1 pageSt-112 - Lower Roof PlanMØhãmmed ØwięsNo ratings yet

- 242 20190319 Sheet - 105 - PV Canopy PlanDocument1 page242 20190319 Sheet - 105 - PV Canopy PlanMØhãmmed ØwięsNo ratings yet

- St-502 - Foundation SectionsDocument1 pageSt-502 - Foundation SectionsMØhãmmed ØwięsNo ratings yet

- St-102 - Foundation Plan Part-2Document1 pageSt-102 - Foundation Plan Part-2MØhãmmed ØwięsNo ratings yet

- St-03 - General Notes Sheet-2Document1 pageSt-03 - General Notes Sheet-2MØhãmmed ØwięsNo ratings yet

- St-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1Document1 pageSt-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1MØhãmmed ØwięsNo ratings yet

- Guest Bedroom Furniture SpecsDocument5 pagesGuest Bedroom Furniture SpecsMØhãmmed ØwięsNo ratings yet

- Section 12090 UpholsteryDocument4 pagesSection 12090 UpholsteryMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Table of ContentsDocument1 pageDivision 12 Furnishing - Table of ContentsMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Cover PageDocument1 pageDivision 12 Furnishing - Cover PageMØhãmmed ØwięsNo ratings yet

- Interior Plant SpecificationsDocument10 pagesInterior Plant SpecificationsMØhãmmed ØwięsNo ratings yet

- SGP ST RPT 0001 Rev CDocument139 pagesSGP ST RPT 0001 Rev CMØhãmmed ØwięsNo ratings yet

- CURTAINS AND DRAPES SPECIFICATIONSDocument4 pagesCURTAINS AND DRAPES SPECIFICATIONSMØhãmmed ØwięsNo ratings yet

- Section 10810 Toilet and Bath AccessoriesDocument7 pagesSection 10810 Toilet and Bath AccessoriesMØhãmmed ØwięsNo ratings yet

- Decorative Lamps Specification for Office Furnishing ProjectDocument3 pagesDecorative Lamps Specification for Office Furnishing ProjectMØhãmmed ØwięsNo ratings yet

- Section 12494 Roller ShadesDocument5 pagesSection 12494 Roller ShadesMØhãmmed ØwięsNo ratings yet

- Section 10520 Fire Protection SpecialitiesDocument7 pagesSection 10520 Fire Protection SpecialitiesMØhãmmed ØwięsNo ratings yet

- Section 09960 Protective CoatingsDocument17 pagesSection 09960 Protective CoatingsMØhãmmed ØwięsNo ratings yet

- Louvers and Vents SpecificationsDocument3 pagesLouvers and Vents SpecificationsMØhãmmed ØwięsNo ratings yet

- Interior Stone Facing SpecificationsDocument10 pagesInterior Stone Facing SpecificationsMØhãmmed ØwięsNo ratings yet

- Section 09680 CarpetDocument7 pagesSection 09680 CarpetMØhãmmed ØwięsNo ratings yet

- WALL COVERING SPECIFICATIONSDocument4 pagesWALL COVERING SPECIFICATIONSMØhãmmed ØwięsNo ratings yet

- Section 09300 TilesDocument11 pagesSection 09300 TilesMØhãmmed ØwięsNo ratings yet

- Section 09260 Gypsum Board AssembliesDocument10 pagesSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNo ratings yet

- Section 09380 Dimension Stone TilesDocument9 pagesSection 09380 Dimension Stone TilesMØhãmmed ØwięsNo ratings yet

- Engineering Office Paint SpecificationDocument13 pagesEngineering Office Paint SpecificationMØhãmmed ØwięsNo ratings yet

- Division9 Finishes - Cover PageDocument1 pageDivision9 Finishes - Cover PageMØhãmmed ØwięsNo ratings yet

- Division 9 Finishes - Table of ContentsDocument1 pageDivision 9 Finishes - Table of ContentsMØhãmmed ØwięsNo ratings yet

- Section 09220 Portland Cement PlasterDocument9 pagesSection 09220 Portland Cement PlasterMØhãmmed ØwięsNo ratings yet

- Unit 6 HL Paper 1 QuestionsDocument13 pagesUnit 6 HL Paper 1 Questionsselina 04No ratings yet

- Standard Test Method For Oxidation Stability of Gasoline (Induction Period Method)Document8 pagesStandard Test Method For Oxidation Stability of Gasoline (Induction Period Method)Gregorio ToroNo ratings yet

- CalorimetroDocument7 pagesCalorimetroYaraNo ratings yet

- Jadwal EAS Gasal 2223Document8 pagesJadwal EAS Gasal 2223M ANNAS ALBAB FAUZINo ratings yet

- Raman Shift Standards For Spectrometer CalibrationDocument11 pagesRaman Shift Standards For Spectrometer CalibrationEric GozzerNo ratings yet

- GenChemistry2 12 Mod8 Stoichiometric Calculations For Reactions in Solution First Edition 2020Document14 pagesGenChemistry2 12 Mod8 Stoichiometric Calculations For Reactions in Solution First Edition 2020Diana May Margareth MuliNo ratings yet

- DS - Epilux - 4 - HB - Epoxy - Finish F-6BDocument2 pagesDS - Epilux - 4 - HB - Epoxy - Finish F-6Bparvez_ameenNo ratings yet

- VXC Evaporative Condensers: Operating and Maintenance InstructionsDocument36 pagesVXC Evaporative Condensers: Operating and Maintenance InstructionsRafael FerreiraNo ratings yet

- Engineering Chemistry Lab ManualDocument31 pagesEngineering Chemistry Lab Manual19303 Anumula RohithNo ratings yet

- Resume YaluChenDocument1 pageResume YaluChenSha HuaNo ratings yet

- Estimation of Optimum Coagulant Dose by Jar Test ApparatusDocument6 pagesEstimation of Optimum Coagulant Dose by Jar Test ApparatusDani MughalNo ratings yet

- Quality Control Formulas: 1. Loss On Ignition (LOI) (CO2 From Calcination)Document5 pagesQuality Control Formulas: 1. Loss On Ignition (LOI) (CO2 From Calcination)Dharmendra AmetaNo ratings yet

- Lipidi: Hemija Prirodnih Organskih JedinjenjaDocument48 pagesLipidi: Hemija Prirodnih Organskih JedinjenjaLana TodorovicNo ratings yet

- Vistalon™ 8600: Ethylene Propylene Diene Terpolymer RubberDocument1 pageVistalon™ 8600: Ethylene Propylene Diene Terpolymer RubberMaram YasserNo ratings yet

- Day 4 - Stoichiometry WSDocument6 pagesDay 4 - Stoichiometry WSJohn Elisha SandranNo ratings yet

- Chem Terengganu Trial Sem 1 ChemistryDocument21 pagesChem Terengganu Trial Sem 1 ChemistryNurieen KameeliaNo ratings yet

- Introduction To Chemical Engineering Thermodynamics: (7th Edition)Document3 pagesIntroduction To Chemical Engineering Thermodynamics: (7th Edition)Shanice CabrilesNo ratings yet

- Keep That Mimosa: Mimosa Tenuiflora ( M. Hostilis) Root-BarkDocument5 pagesKeep That Mimosa: Mimosa Tenuiflora ( M. Hostilis) Root-BarkjajcabNo ratings yet

- H2S Scavenger Rev.01Document62 pagesH2S Scavenger Rev.01Youcef Chorfa100% (1)

- Cracks in ConcreteDocument23 pagesCracks in Concreteapi-3766593100% (12)

- Scope ToxicologyDocument18 pagesScope Toxicologyshubhamatilkar04No ratings yet

- LG 1.3 Nomenclature of Organic CompoundsDocument11 pagesLG 1.3 Nomenclature of Organic CompoundswangmorisNo ratings yet

- Test Bank Stoichiometry 1Document64 pagesTest Bank Stoichiometry 1FatmaNo ratings yet

- Science 8 Unit A PlanDocument11 pagesScience 8 Unit A Planapi-485112258No ratings yet

- Davidson's and Bouin's SolutionDocument2 pagesDavidson's and Bouin's SolutionvtyltkttdNo ratings yet

- Australian Product HandbookDocument88 pagesAustralian Product HandbookjarwokoesoemoNo ratings yet

- ProQuestDocuments 2015-05-11Document11 pagesProQuestDocuments 2015-05-11JohnNo ratings yet

- Ch-254 Chemical Reaction Engineering - I L-T-P (3-1-0) 4 Credits Teaching Plan Lecture ScheduleDocument2 pagesCh-254 Chemical Reaction Engineering - I L-T-P (3-1-0) 4 Credits Teaching Plan Lecture ScheduleLade VarshithaNo ratings yet

- Internship Report of A Textile MillDocument29 pagesInternship Report of A Textile MillMUHAMMAD SAGHEER100% (1)

- Stereoisomers Test Answers+ QuestionsDocument8 pagesStereoisomers Test Answers+ QuestionsNandakumar SNo ratings yet