Professional Documents

Culture Documents

MITP For Excavation and Backfilling Approved

Uploaded by

Mogu MohanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MITP For Excavation and Backfilling Approved

Uploaded by

Mogu MohanCopyright:

Available Formats

Restricted

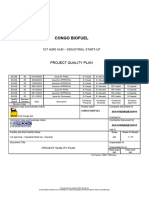

MODEL INSPECTION TEST PLAN – MITP

CONSTRUCTION

Excavation and Backfilling

STD-00-000000-QA-5733-00057-0000

(PCAP Control ID # NA)

(Criticality Rating CR # 4)

Mandhari, Amira Busaidi, Said Abdulfattah,

02 08/08/2021 Approved

PDTQ26 PDTQ16 Mohamed PDTQ7

Mandhari, Amira Busaidi, Said Abdulfattah,

01 22/03/2021 Issued for Review & comments

PDTQ26 PDTQ16 Mohamed PDTQ7

Rev. Date Reason for Issue Originator Checker Approver

Page | 1 STD-00-000000-QA-5733-00057-0000 Rev 02

Accountable/Approval (ATA/IFA) Distribution List:

Name Function Signature / Date

Please refer Cover Sheet

Abdulfattah, Mohamed PDTQ7 QMS Lead

Responsible/Reviewer / Checker (RTA/IFR) Distribution List:

Name Function Signature / Date

DLQ Team Quality Project IFR

UEQ Team Quality Function IFR

DEV Team Civil Engg. Projects IFR

Informed (IFI CI) Distribution List:

Name Function Signature / Date

Ghafri, Ahmed DLQ Projects Quality Head IFI

00 Revision History

Revision No. Date Author Scope / Remarks

01 22/03/2020 Mandhari, Amira PDTQ26 Issued for Review & Comments

02 08/08/2021 Al Shaibani, Mohammed UEQ216 Approved

01 Holds List

NIL

Reference Description Revision Revision Date

Page | 2 STD-00-000000-QA-5733-00057-0000 Rev 02

SP-1279 Specification for Civil Construction Works 5 May 2021

SP-1208 Pipeline Construction Specification 6 Mar 2021

PR-1172

Permit to Work Procedure 8.1 Oct 2014

PR-1002 Operations Excavation Procedure 7 Nov 2017

BS-1377 Methods of Test for Soils for Civil Engineering Purposes

REFERENCES

CONDITIONS

Note No. Note

01 Issuer shall not delete or change any of the Notes 1-14 without written agreement from PDO.

Adding additional notes is Permitted with the following requirements: additional notes shall not

conflict with any of the previous notes.

02 MITP shall be considered as base line requirements as an input for first revision. Contractor and

PDO, based on each project requirements, can amend and issue first project revision.

03 Any changes to this MITP shall be towards elevating the requirements only. Issuer may add new

steps or activities but shall not delete any of already added information.

04 H = HOLD (Relevant Work shall be inspected by company representative and shall not proceed

without company presence or permission)

05 W = Witness (Relevant Work Shall be inspected by company representative but may proceed if

no show from company representative on agreed time or Permitted by PDO)

06 M = Monitor (Relevant Work will be witnessed via ad-hoc verifications based on agreed sampling

percentage; work can always proceed)

07 A = Document Approval is MUST before the start of any relevant work

08 R = Document Review only required

09 Issuer to add the relative record NO. in all ITP clauses in column head “Records”

10 Issuer to substitute the Main and sub executer with actual names of contractors or vendors

11 Criticality rating, if added, shall be considered minimum CR and any change shall be towards

elevation to next level.

12 If sub-executer is NOT engaged, delete assigned inspection intervention level and add “NA”

13 Approved project procedure and MS reference NO. to be added in column head “References”

14 All Cross-discipline Activities to be reviewed by Relevant TA2

Page | 3 STD-00-000000-QA-5733-00057-0000 Rev 02

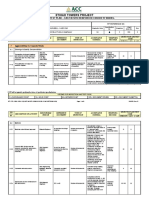

Excavation and Backfilling STD-00-000000-QA-5733-00057-0000 Rev 02

Sub- Main- PDO

No. Activity Reference Documents Acceptance Criteria Frequency Responsibility Record Remarks

Executer Executer /TPI

1 General

Approved Drawings or

Approval of Drawings Standard Client Civil Supervisor/

1.1 Verify if Drawings are approved for Construction All Drawings - H H R

Drawing. (Contractor QC Inspector

Scope of Work)

Every area to be Civil Supervisor/ Closed out RFI

1.2 SP-1279 Stable Ground Condition H M M

Nature of Ground excavated QC Inspector

Civil Supervisor/

Closed out RFI

1.3 SP-1279 Manual / Mechanical As per excavation Permit Every Permit QC Inspector H M M

Method of Excavation

Civil Supervisor/

No potential Hazardous identified in Hazard Closed out RFI

1.4 Hazard Analysis PR-1172 Every Permit QC Inspector H M M

Register as per authorized Work Permit

SP-1279 Excavation Permit signed by PDO Civil Supervisor

1.5 Excavation Permit Every Permit - H M M

PR-1172 Work Permit available at place of work or Permit Holder

2 Underground Existing Services

Checking for underground Underground Services/ Existing Services by Cable Civil Supervisor/

2.1 SP-1279 All Excavation H H W

existing services. (If any) Detector or GPR - Ground penetrating Radar. QC Inspector

Exposed pipe shall be supported with struts every

Checking for location and Civil Supervisor/

2M interval and at every joint. All Underground

2.2 protection of underground SP-1279 QC Inspector H M M

Exposed cables shall be supported at every 1M. Services

services.

Wooden planks/boards to be provided above

Cables.

Civil Supervisor/

Installation of proper signs & Closed out RFI

2.3 PR-1002 As per Work Permit All Excavation QC Inspector/ H W M

barriers. (Temporary)

HSE Officer

Check of explosive for Civil Supervisor/

2.4 SP-1279 Written approval from authority (PDO / ROP) All Hard Rock Report H H H

blasting of rock. (if required) QC Inspector

Hard Ground & Position of Civil Supervisor/

2.5 SP-1279 As per direction from PDO All Excavation Report H M M

Rock QC Inspector

3 Shoring Excavations

Site Engineer/

Prevent from slipping (or) Falling-Shore the side of Method Statement

3.1 Verify shoring requirement SP-1279 All Excavation Supervisor / H W M

excavation for Structures

QC Inspector

Civil Supervisor/ Report

3.2 Verify removal of shoring SP-1279 Approval from PDO All Excavation H W M

QC Inspector

Preservation of Excavated Civil Supervisor/

3.3 SP-1279 Free from water All Excavation Closed out RFI H W M

Area QC Inspector

Civil Supervisor/ Report

3.4 Oversize Excavation SP-1279 PDO approval for filling All Excavation H W M

QC Inspector

Page | 4 STD-00-000000-QA-5733-00057-0000 Rev 02

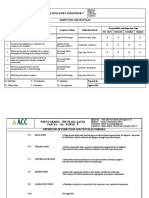

Excavation and Backfilling STD-00-000000-QA-5733-00057-0000 Rev 02

Sub- Main- PDO

No. Activity Reference Documents Acceptance Criteria Frequency Responsibility Record Remarks

Executer Executer /TPI

Civil Supervisor/

3.5 Dimension of Excavation Approved Drawings Dimensions as per Drawings All Excavation Report H W M

QC Inspector

Bottom & Faces shall be properly trimmed and Permit Holder or

Report

3.6 Formation Level SP-1279 cleared of all loose material and foreign matter All Excavation Civil Supervisor/ H W W

-Approval from PDO QC Inspector

Soft soil to be removed until solid formation, Permit Holder or

Soft Area & Unsound

3.7 SP-1279 refilled and Compacted with approved material All Excavation Civil Supervisor/ Report H M M

Ground

from PDO QC Inspector

4 Spoil

Soil heaps shall be kept minimum 1M away from

the edge of excavation

Permit Holder or

-Different class of excavated material required for Closed out RFI

4.1 Spoil SP-1279 All Excavation Civil Supervisor/ H W M

backfilling or landscaping shall be kept separately

QC Inspector

excess soil shall be carted away to the location

approved by PDO.

5 Trench Works

All Trenches shall be free from rocks, stones, tree

roots or other harmful matter.

Excavation should be made with vertical sides in

compact and cohesive soil. Construction

Trench Excavation SP-1279 Where trench excavation is in loose sand, a Engineer /

5.1 All Excavation H H W

suitable batter shall be formed with approval. QC Inspector

Excavated material shall be kept at least one

meter away from the edge of the trench

excavation. Fill material shall not be placed on

services until the service is inspected & approved.

Construction

SP-1279 Dimensions of the trenches should be as

5.2 Dimensions of the trenches All Excavation Engineer / H H W

per approved Drawings.

QC Inspector

Material Approval

Site Engineer/

Source Approval from PDO MSE following Sheet Third Party

Approval of source (borrow Supervisor/

5.3 SP-1279 concurrence from PDO Site Management. All Sources (Borrow pit) Soil Analysis test H H R

pit) for backfill materials QC Inspector

Sources shall be clearly identified. report landmark

approved by PDO

One complete analysis

Soil Test Certificate,

on every: -5000 m³ of

Site Engineer/ Material / Landmark

SP-1279 fill-2000 m³ of formation

Ensuring backfill material is Supervisor / Approval Sheet and

5.4 Conformance to specification. in cutting, from top 300 H H W

offered for soil analysis test QC Inspector Third-Party soil

BS:1377 mm below formation

Analysis test

level.

Change of material.

Free from deleterious materials like rocks,

5.5 Received Material SP-1279 Lot wise QC Inspector Report H H M

concrete rubbles, roots, loose organic matters etc.

Shall be clean and free from organic matter, waste QC Inspector Water Analysis

5.6 Water Analysis SP-1279 Random H W M

material and other harmful substances. Report

Page | 5 STD-00-000000-QA-5733-00057-0000 Rev 02

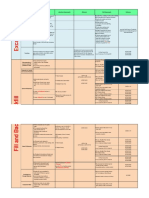

Excavation and Backfilling STD-00-000000-QA-5733-00057-0000 Rev 02

Sub- Main- PDO

No. Activity Reference Documents Acceptance Criteria Frequency Responsibility Record Remarks

Executer Executer /TPI

Free from water, rocks tree roots and other

Inspection of backfill area QC Inspector Report

5.7 SP-1279 harmful materials. Complete area H W M

before backfilling

No loose material in backfilled area- No soft area

Manual/Mechanical as per valid work Permit.

Backfill to foundation, wall, trench, pipeline not

exceeding 150mm.

Site Engineer/

Difference in fill levels for block work=300mm

Supervisor / Report

5.8 Method of backfilling SP-1279 maximum. All Backfilling H W W

QC Inspector

Backfill material shall not be dropped from a height

exceeding 2 mtrs

-Mechanical rammer shall not be used within

300mm of the top of any pipe.

Cable-100 mm thick clean sand

Bedding on top and bottom and protection tiles

and warning tape in place. PVC ducts-embedding

in mass concrete/asperdrawing.min.50mm thick

sand bedding be low underpass coated pipe.

Site Engineer/

Min.150mm thick sand bedding all around for

Supervisor /

SP-1279 coated road crossing pipes. Sand shall be sieved Report

5.9 Protection during backfilling All Cables and Pipes QC Inspector H W W

SP-1208 75% 0.06 to 3.0mm & 25% 3.0 to 5.0 mm by

weight, fine, clean, free of rock, metal parts, roots,

clods& without sharp edges are around weep

holes in retaining walls shall be packed all around

with12 mm-16 mm size gravel for a thickness of

200mm.

Use Geotexfabric, where required.

6 Compaction

- For hard core filling, mechanical compaction with

plant having 10 Tons or equivalent weight

approved by PDO.

- Within 300 mm from top of services no

mechanical rammers shall be used.

Site Engineer/

- Hand compaction where necessary. (Over and

Supervisor / Report

6.1 Method of Compaction SP-1279 around top of underground services) All Compacted Area H W M

QC Inspector

- Thickness of each layer not more than 150mm

-Material spread & leveled by crawler tractor

weighing more than 15tons.

-Granular fill compaction 12 passes of a towed

vibratory roller (static mass per meter width of roll

of at least1800kg) or equivalent approved by PDO

- Field Density after compaction: -For foundations,

walls, trenches pipelines & site grading: not less

than 95% of maximum dry density. Site Engineer/

SP 1279 Every 1000m²of any Report

6.2 Tests on Compaction - For newly filled area: not less than 95% of Supervisor / H W W

BS:1377 layer or such small area.

maximum dry density. QC Inspector

- Moisture content shall be within1 to 2% of the

optimum moisture content.

Page | 6 STD-00-000000-QA-5733-00057-0000 Rev 02

Excavation and Backfilling STD-00-000000-QA-5733-00057-0000 Rev 02

Sub- Main- PDO

No. Activity Reference Documents Acceptance Criteria Frequency Responsibility Record Remarks

Executer Executer /TPI

Site Engineer/

Approved or Standard Report

6.3 Elevation As per Drawing Final Layer Supervisor / H W M

Drawings

QC Inspector

7 Termite Protection

SP-1279

Anti-Termite Treatment (if Approval of material from PDO. Material Approval

7.1 Manufacturer’s All Anti-termite materials QC Inspector H H M

applicable) Mixing ratio: as per Manufacturer’s Instruction. Sheet

Instruction

- Application/ Treatment shall be as per

Manufacturer’s Instruction.

- Soil under slabs at plinth level.

SP-1279

- Junction of wall and floor. All Anti-termite QC Inspector

7.2 Application of Anti-termite Manufacturer’s Method Statement H H M

- Critical areas such as soil under piers, floor applications

Instruction

drains etc.

- Soil along external perimeter of buildings to a

depth of 300mm.

8 Final Document Hand-Over

All Plan Completion QC Inspector or Plan Completion

8.1 Plan Completion Record - Plan Completion record signed off H H R

Records QA Engineer Record

Page | 7 STD-00-000000-QA-5733-00057-0000 Rev 02

You might also like

- Method Statement SampleDocument16 pagesMethod Statement Sampleuebdennis100% (1)

- Department of Mechanical Engineering Question Bank Subject Name: Heat & Mass Transfer Unit - I Conduction Part - ADocument3 pagesDepartment of Mechanical Engineering Question Bank Subject Name: Heat & Mass Transfer Unit - I Conduction Part - AkarthikNo ratings yet

- Itp For U-G2Document7 pagesItp For U-G2Ramzi MusthafaNo ratings yet

- Civil Earthworks and FoundationsDocument10 pagesCivil Earthworks and Foundationsmoytabura96100% (1)

- G42-LSP-CSC-S-MST-003 Bliding WorksDocument9 pagesG42-LSP-CSC-S-MST-003 Bliding WorksDan SarmientoNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniNo ratings yet

- J) Method Statement For Discharge of Stormwater and Rain WaterDocument4 pagesJ) Method Statement For Discharge of Stormwater and Rain WaterLee Tin YanNo ratings yet

- CP-206-Management of Change - CoP PDFDocument28 pagesCP-206-Management of Change - CoP PDFSyed Muhammad Mohsin100% (1)

- Mitp For Surveying Setting Out ApprovedDocument4 pagesMitp For Surveying Setting Out ApprovedMogu MohanNo ratings yet

- Fence ITP & ChecklistDocument27 pagesFence ITP & Checklistlike saddamNo ratings yet

- Site Logistics and Construction Plan TemplateDocument2 pagesSite Logistics and Construction Plan TemplatekapsarcNo ratings yet

- ITP Survey PHR (OK)Document2 pagesITP Survey PHR (OK)Giovanni ChristyoriniNo ratings yet

- J910-Dh02-P10zen-040010 - (Ahf) Field Itp For Precast Box Culvert Installation Work - Rev.aDocument16 pagesJ910-Dh02-P10zen-040010 - (Ahf) Field Itp For Precast Box Culvert Installation Work - Rev.arudi sarifudinNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Job Procedure For Earthwork Excavation and BackfillingDocument6 pagesJob Procedure For Earthwork Excavation and BackfillingJitesh SahiNo ratings yet

- Ma'Aden SpecificationDocument14 pagesMa'Aden Specificationahmed elesawyNo ratings yet

- Method Statement Excavation Civil WorksDocument9 pagesMethod Statement Excavation Civil WorksRanjith GabrielNo ratings yet

- Itp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)Document2 pagesItp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)wagwahkiabatheNo ratings yet

- Appendix H: Design and Construction Manual Design RequirementsDocument17 pagesAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelNo ratings yet

- Method of Statment CONCRETEDocument7 pagesMethod of Statment CONCRETESyed AtherNo ratings yet

- Inspection and Test Plan (ITP) - Civil WorksDocument1 pageInspection and Test Plan (ITP) - Civil WorksNaveen GladsonNo ratings yet

- MS 05Document21 pagesMS 05unnicyriacNo ratings yet

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDocument2 pagesKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanNo ratings yet

- MIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3Document40 pagesMIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3AmeerHamzaWarraichNo ratings yet

- Saes A 114Document2 pagesSaes A 114Nino Celso AstilleroNo ratings yet

- 835a) Method Statement For Ceramic Tile Marble Works - R0-SignedDocument23 pages835a) Method Statement For Ceramic Tile Marble Works - R0-Signedwaseq911No ratings yet

- 30a100dbqb23010 - Exde06 - 77 Project Quality PlanDocument81 pages30a100dbqb23010 - Exde06 - 77 Project Quality Plansamuel madisonNo ratings yet

- QCP - BuildingsDocument4 pagesQCP - BuildingsMitendra Kumar ChauhanNo ratings yet

- Method Statement Rev 0Document22 pagesMethod Statement Rev 0FarisNo ratings yet

- Quarantine Log #1 PDFDocument1 pageQuarantine Log #1 PDFmoytabura96No ratings yet

- Method Statement: Construction CompanyDocument8 pagesMethod Statement: Construction CompanyDhimas Surya NegaraNo ratings yet

- ITP For Structural Work-1Document5 pagesITP For Structural Work-1Mohammed MujahidNo ratings yet

- Inspection & Testing Plan For AggregatesDocument2 pagesInspection & Testing Plan For Aggregatesjerin sam kurian100% (1)

- Unops Daily ReportDocument2 pagesUnops Daily ReportFeraydoon NasratzadaNo ratings yet

- Rams CCTV Inspection Survey l5 Qat 273aDocument30 pagesRams CCTV Inspection Survey l5 Qat 273arajaNo ratings yet

- Method Statement For General ExcavationDocument7 pagesMethod Statement For General Excavationjing aytonaNo ratings yet

- Qa QC Inspection ReportDocument1 pageQa QC Inspection ReportUbaidullah KhanNo ratings yet

- Quality Inspection FormDocument3 pagesQuality Inspection FormTesfuNo ratings yet

- MS Site and FenceDocument11 pagesMS Site and FenceSahabzada AamirNo ratings yet

- Section 03 Site Clearance N Demolition PDFDocument11 pagesSection 03 Site Clearance N Demolition PDFlakmalperera1986100% (1)

- Method Statement For Earthwork Excavation & BackfillingDocument6 pagesMethod Statement For Earthwork Excavation & Backfillingjing aytonaNo ratings yet

- DT # 0232 Metod Statement For Steel ErectionDocument16 pagesDT # 0232 Metod Statement For Steel ErectionPangky AbasoloNo ratings yet

- SP-1157 - V 2 5 HSE Specification - HSE TrainingDocument135 pagesSP-1157 - V 2 5 HSE Specification - HSE TrainingSiva NandhamNo ratings yet

- TEC-033000.1-MET-DoR-002 (Method Statement For The Blinding Concrete (PCC) Works)Document8 pagesTEC-033000.1-MET-DoR-002 (Method Statement For The Blinding Concrete (PCC) Works)Haymanot BaynesagnNo ratings yet

- METHOD STATEMENT FOR Backfilling - Rev 0Document5 pagesMETHOD STATEMENT FOR Backfilling - Rev 0Osama MZNo ratings yet

- MS - Epoxy Coating SystemDocument23 pagesMS - Epoxy Coating SystembukhoriNo ratings yet

- QHSE Induction KGA Employees NewDocument30 pagesQHSE Induction KGA Employees NewlavheNo ratings yet

- RA - 18 - For Concrete Topping On Hollow Core SlabDocument14 pagesRA - 18 - For Concrete Topping On Hollow Core SlabIbrahim EsmatNo ratings yet

- PQPDocument18 pagesPQPIrene ionieNo ratings yet

- ProcurementDocument6 pagesProcurementDenmark CostanillaNo ratings yet

- Masterprotect 1855 TdsDocument2 pagesMasterprotect 1855 TdsShahsoor Shah Majeed100% (1)

- Logo of Client Logo of EngineerDocument3 pagesLogo of Client Logo of EngineerDawood Shaik Abdul CadarNo ratings yet

- Traffic Signage - Installation - ItpDocument1 pageTraffic Signage - Installation - Itpmoytabura96No ratings yet

- Dewatering Method StatementDocument6 pagesDewatering Method StatementMohsen KeramatiNo ratings yet

- Method Statement - Community Parks (Advance Copy) PDFDocument9 pagesMethod Statement - Community Parks (Advance Copy) PDFMGNo ratings yet

- M1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - ADocument48 pagesM1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - AAnandu AshokanNo ratings yet

- Procurement Requisition: Form No. Version No. 5.1Document1 pageProcurement Requisition: Form No. Version No. 5.1loveson glariyansNo ratings yet

- 00 091 PD 0009Document32 pages00 091 PD 0009VarunSharmaNo ratings yet

- Mobilization Construction Equipment & ToolsDocument1 pageMobilization Construction Equipment & ToolsallNo ratings yet

- Itp - EifsDocument22 pagesItp - Eifssathiyaprasath100% (1)

- As Built ReportDocument1 pageAs Built ReportWakil AhmadNo ratings yet

- MITP For Roofing Works ApprovedDocument7 pagesMITP For Roofing Works ApprovedMogu MohanNo ratings yet

- FPI CertificateDocument1 pageFPI CertificateMogu MohanNo ratings yet

- PR-2053 - Control of Product Non-ConformitiesDocument13 pagesPR-2053 - Control of Product Non-ConformitiesMogu MohanNo ratings yet

- GU-130 - GU-130 C-6 Specifications For RigsDocument16 pagesGU-130 - GU-130 C-6 Specifications For RigsMogu MohanNo ratings yet

- MITP For Roofing Works ApprovedDocument7 pagesMITP For Roofing Works ApprovedMogu MohanNo ratings yet

- Correlational ResearchDocument10 pagesCorrelational ResearchSari100% (1)

- Woodworking Plans - Childs RockerDocument16 pagesWoodworking Plans - Childs RockerBob Kowalski100% (1)

- MATLAB Modeling of SPT and Grain Size Data in Producing Soil-ProfileDocument5 pagesMATLAB Modeling of SPT and Grain Size Data in Producing Soil-Profileicv.xaviNo ratings yet

- Heat and Thermodynamics According To KPK Textbook & Sindh TextbookDocument15 pagesHeat and Thermodynamics According To KPK Textbook & Sindh Textbookswatmiandam44No ratings yet

- Workbook Theory Grade Six SampleDocument4 pagesWorkbook Theory Grade Six SampleRobert TseNo ratings yet

- 10 - Starting and ReversingDocument4 pages10 - Starting and ReversingAisha Zaheer100% (3)

- Jimma Institute of Technology Faculty of Mechanical EngineeringDocument38 pagesJimma Institute of Technology Faculty of Mechanical EngineeringIsmail Ibn BehailuNo ratings yet

- INA131 Burr-BrownCorporationDocument10 pagesINA131 Burr-BrownCorporationMartha H.TNo ratings yet

- DDP400 Open-Frame and U-Chassis :: ROAL Living EnergyDocument12 pagesDDP400 Open-Frame and U-Chassis :: ROAL Living EnergyroalscribdNo ratings yet

- Pick and Place Robotic Arm Controlled by Computer - TJ211.42.M52 2007 - Mohamed Naufal B. OmarDocument26 pagesPick and Place Robotic Arm Controlled by Computer - TJ211.42.M52 2007 - Mohamed Naufal B. OmarSAMNo ratings yet

- Excavators 1Document27 pagesExcavators 1Gold CubeNo ratings yet

- UM - HX204 - EN User ManualDocument32 pagesUM - HX204 - EN User Manuals7631040No ratings yet

- Chloride LINEAR MK II - Service ManualDocument32 pagesChloride LINEAR MK II - Service Manualfabio.perazzoloNo ratings yet

- IMMUNOHISTOCHEMDocument7 pagesIMMUNOHISTOCHEMJadys Merill DiezNo ratings yet

- Enerpac SQD-Series ManualDocument16 pagesEnerpac SQD-Series ManualTitanplyNo ratings yet

- Spe Math p2 Revision Yr7Document24 pagesSpe Math p2 Revision Yr7Hadizah JulaihiNo ratings yet

- Anthony Hans HL Biology Ia Database WM PDFDocument12 pagesAnthony Hans HL Biology Ia Database WM PDFYadhira IbañezNo ratings yet

- Notes of CH 6 Animal Tissues Class 9th ScienceDocument11 pagesNotes of CH 6 Animal Tissues Class 9th ScienceSingh JNo ratings yet

- Answer To The Question No: (A) : Pattern Recognition Is The Process of Recognizing Patterns by UsingDocument4 pagesAnswer To The Question No: (A) : Pattern Recognition Is The Process of Recognizing Patterns by UsingKhaled faisalNo ratings yet

- Speciifactions and Cross Reference Bosch Spark PlugDocument3 pagesSpeciifactions and Cross Reference Bosch Spark Plugcarlos puerto100% (1)

- C & Embedded QuestionsDocument109 pagesC & Embedded QuestionskalkikaliNo ratings yet

- Bacterial ClassificationDocument2 pagesBacterial ClassificationAndrew JavierNo ratings yet

- UACE BIO PAPER TWO SET 3 2023-JusanDocument3 pagesUACE BIO PAPER TWO SET 3 2023-JusanCampbell OGENRWOTNo ratings yet

- 17.alekhya Research ArticleDocument8 pages17.alekhya Research ArticleBaru Chandrasekhar RaoNo ratings yet

- University Insitute of Engineering Electrical EngineeringDocument85 pagesUniversity Insitute of Engineering Electrical EngineeringPyrenean IbexNo ratings yet

- Computer Programming: College of Civil Engineering - First StageDocument5 pagesComputer Programming: College of Civil Engineering - First StageAli ANo ratings yet

- Beckman Coulter GenomeLab TroubleshootDocument56 pagesBeckman Coulter GenomeLab TroubleshootChrisNo ratings yet

- Casing and Tubing Crossovers: ScopeDocument4 pagesCasing and Tubing Crossovers: Scopeislam atifNo ratings yet

- Irjet V4i10201 PDFDocument8 pagesIrjet V4i10201 PDFBesmir IsmailiNo ratings yet