Professional Documents

Culture Documents

Beam Design As Per BNBC 2020 and ACI 318-08

Uploaded by

আসিফ মাহমুদOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beam Design As Per BNBC 2020 and ACI 318-08

Uploaded by

আসিফ মাহমুদCopyright:

Available Formats

578508372.

xls

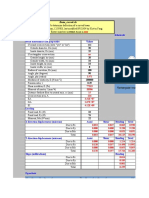

Project: Project

Location: Location

Client: Client

Job No.: 1 Calc. by: RCF Checked by: RCF

Subject: Beam Date: 26-Mar-11 Revision: -

ANALYSIS & DESIGN OF RC BEAM AS PER ACI 318-08

INPUT DATA

MATERIAL PROPERTIES Cs

fc' = 20.68 Mpa CONCRETE STRENGTH

fy = 413 Mpa REBAR YIELD STRESS Ct

fys = 413 Mpa LINKS YIELD STRESS

Es = 200,000 Mpa Steel Modulus of Elasticity

Ec = 21,373 Mpa Ec = 4700*SQRT(f'c)

B

DIMENSIONS d =

L = 5.18 m BEAM LENGTH As =

Layer

B = 300 mm BEAM WIDTH

space

H = 450 mm BEAM HEIGHT Cc

Ct = 40 mm COVER TO TOP REINFORCEMENT d =

Cc = 40 mm COVER TO BOTTOM REINFORCEMENT As =

Cs = 40 mm COVER TO SIDE BARS H

As =

STEEL REINFORCEMENT d =

LEFT SUPPORT MIDSPAN RIGHT SUPPORT

TOP REINFORCEMENT TOP REINFORCEMENT TOP REINFORCEMENT

layer 1 layer 2 layer layer 1 layer 2 layer layer 1 layer 2 layer

no. mm no. mm space no. mm no. mm space no. mm no. mm space

3 Ø 16 0 Ø 16 25 2 Ø 16 0 Ø 16 25 3 Ø 16 0 Ø 16 25

As =

BOTTOM REINFORCEMENT BOTTOM REINFORCEMENT BOTTOM REINFORCEMENT

layer 1 layer 2 layer layer 1 layer 2 layer layer 1 layer 2 layer

no. mm no. mm space no. mm no. mm space no. mm no. mm space

1 Ø 16 0 Ø 20 0 3 Ø 16 0 Ø 16 25 3 Ø 16 0 Ø 16 25

HOOPS STIRRUPS ADDITIONAL LONGITUDINAL BARS

no. spacing no. spacing legs mm spacing no. mm d =

1 50 0 75 2 Ø 10 200 0 Ø 12

APPLIED FORCES

LEFT SUPPORT MIDSPAN RIGHT SUPPORT

Mu = 104.00 kN-m Mu = 47.00 kN-m Mu = 97.00 kN-m d =

Ma = 93.60 kN-m Ma = 43.00 kN-m Ma = 87.00 kN-m As =

Vu = 84.00 kN Vu = 81.00 kN

Tu = 22.00 kN-m Tu = 19.00 kN-m

Pu = kN-m Pu = kN-m d =

As =

OUTPUT RESULTS As =

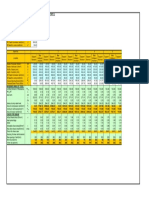

FLEXURAL CAPACITY CHECKS d =

LEFT SUPPORT

b1 = 0.85 b1 = max. of: 0.85-(0.05*(f'c-28)/7) and 0.65

c = 53.03 mm Solve for "c" in: As*fy = 0.85*f'c*b1*c*b+A's*(c-d')/c*ec*Es

a = 45.07 mm a = b1*c

r = 0.0050 r = As/(b*d) f=

r(min) = 0.0034 r(min) >= 0.25*SQRT(f'c)/fy >= 1.4/fy fVc =

rb = 0.0214 rb = 0.85*b1*f'c/fy*(600/(600+fy)

rg = 0.0060 rg = (As+A's)/(b*h) fVs =

r(max) = N.A. r(max) = As(max)/(b*d) fVs(req'd) =

As(min) = 408.81 mm2 As(min) = r(min)*b*d fVn =

As(max) = 1,835.2 mm2 As(max) = (0.85*f'c*b1*c*b+A's*(c-d')/c*ec*Es)/fy for c = ec*d/(ec+0.005)

fVs(max) =

ec = 0.003 ec = 0.003 (assumed concrete strain) Av(prov) =

e's = 0.0003 e's = ec*(c-d')/c < fy/Es, f's does not yield Av(min) =

f's = 56.87 Mpa f's = e's*Es Av(req'd) =

As2 = 27.68 mm2 As2 = A's*f's/fy for f's > 0 s(max) =

As1 = 575.50 mm2 As1 = As-As2 for f's > 0

et = 0.0197 et = ec*(d-c)/c = (fy/Es+ec)/(r/rb)-ec >= 0.005, Tension-controlled

f = 0.90 f = 0.65+0.25*(et-fy/Es)/(0.005-fy/Es) <= 0.90

fMn = 84.82 kN-m < Mu = 104 kN-m, Failed!

f=

MIDSPAN fVc =

b1 = 0.85 b1 = max. of: 0.85-(0.05*(f'c-28)/7) and 0.65

c = 51.71 mm Solve for "c" in: As*fy = 0.85*f'c*b1*c*b+A's*(c-d')/c*ec*Es fVs =

a = 43.96 mm a = b1*c fVs(req'd) =

r = 0.0050 r = As/(b*d) fVn =

r(min) = 0.0034 r(min) >= 0.25*SQRT(f'c)/fy >= 1.4/fy fVs(max) =

rb = 0.0214 rb = 0.85*b1*f'c/fy*(600/(600+fy) Av(prov) =

rg = 0.0074 rg = (As+A's)/(b*h) Av(min) =

r(max) = N.A. r(max) = As(max)/(b*d) Av(req'd) =

As(min) = 408.81 mm2 As(min) = r(min)*b*d s(max) =

As(max) = 2,034.3 mm2 As(max) = (0.85*f'c*b1*c*b+A's*(c-d')/c*ec*Es)/fy for c = ec*d/(ec+0.005)

ec = 0.003 ec = 0.003 (assumed concrete strain)

e's = 0.0002 e's = ec*(c-d')/c < fy/Es, f's does not yie

f's = 43.07 Mpa f's = e's*Es

As2 = 41.94 mm2 As2 = A's*f's/fy for f's > 0 S(max)=

As1 = 561.25 mm2 As1 = As-As2 for f's > 0

et = 0.0203 et = ec*(d-c)/c = (fy/Es+ec)/(r/rb)-ec >= 0.005, Tension-controlled

f = 0.90 f = 0.65+0.25*(et-fy/Es)/(0.005-fy/Es) <= 0.90

fMn = 84.80 kN-m > Mu = 47 kN-m, O.K.

RIGHT SUPPORT

b1 = 0.85 b1 = max. of: 0.85-(0.05*(f'c-28)/7) and 0.65 f=

c = 50.93 mm Solve for "c" in: As*fy = 0.85*f'c*b1*c*b+A's*(c-d')/c*ec*Es xo =

a = 43.29 mm a = b1*c yo =

r = 0.0050 r = As/(b*d) Acp =

r(min) = 0.0034 r(min) >= 0.25*SQRT(f'c)/fy >= 1.4/fy Ag =

rb = 0.0214 rb = 0.85*b1*f'c/fy*(600/(600+fy) Pcp =

rg = 0.0089 rg = (As+A's)/(b*h) Ph =

r(max) = N.A. r(max) = As(max)/(b*d) Aoh =

As(min) = 408.81 mm2 As(min) = r(min)*b*d Ao =

As(max) = 2,233.4 mm2 As(max) = (0.85*f'c*b1*c*b+A's*(c-d')/c*ec*Es)/fy for c = ec*d/(ec+0.005) Tcr =

ec = 0.003 ec = 0.003 (assumed concrete strain) Tu(limit) =

e's = 0.0002 e's = ec*(c-d')/c < fy/Es, f's does not yie Tu(max) =

f's = 34.52 Mpa f's = e's*Es At(prov) =

As2 = 50.42 mm2 As2 = A's*f's/fy for f's > 0 At(req'd) =

As1 = 552.76 mm2 As1 = As-As2 for f's > 0 At(min) =

et = 0.0207 et = ec*(d-c)/c = (fy/Es+ec)/(r/rb)-ec >= 0.005, Tension-controlled

Al(req'd) =

f = 0.90 f = 0.65+0.25*(et-fy/Es)/(0.005-fy/Es) <= 0.90 Al(min) =

fMn = 84.78 kN-m < Mu = 97 kN-m, Failed!

SHEAR CAPACITY CHECKS Total (Av+t) =

@ 2H for Seismic Provision for transverse Reinforcements per Sec.21.5.3.2 Total (Av+t)(min) =

S(max)= smallest of ==> S(max) = d/4

S(max) = 8db (smallest longitudinal bar)

S(max) = 100.50 mm.o.c. S(max) = 24db (diameter of hoop bar)

> 75mm, O.K. S(max) = 300mm Es =

Ec =

For Shear Reinforcements n=

fVc = 69.93 kN fVc = 0.17*l*SQRT(f'c)bd fs =

fVs = 97.80 kN fVs = f*fy*d*Av(stirrup)/s >= 0 fs(used) =

fVn = 167.72 kN >=Vu = 84.00 kN, O.K. s(max) =

fVs(max) = 271.47 kN >= Vu-(phi)Vc = 14.07 kN, O.K.

Av(prov) = 157.08 mm2

Av(req'd) = 50.68 mm2 <= Av(prov) = 157.08 mm^2, O.K.

Av(min) = 50.85 mm2 <= Av(prov) = 157.08 mm^2, O.K. Es =

s(max) = 201.00 mm >= s = 200 mm, O.K. Ec =

n=

For Torsion Reinforcements fs =

Tc = 3.44 kN-m < 22.00 kN-m, must consider torsion! fs(used) =

Tumax = 49.52 kN-m >= Tu = 22 kN-m, O.K. s(max) =

Atprov = 53.20 mm2 (Av+t(used)-Av(req'd))/2

Atreq'd = 0.10 mm2 <= At(prov) = 53.2 mm^2, O.K.

Atmin = 0.08 mm2 <= At(prov) = 53.2 mm^2, O.K. Es =

Alreq'd = 0.30 mm2 < Al(min) = 549.32 mm^2, thus use Al(min) Ec =

Almin = 549.32 mm2 >= Al(req'd) = 0.3 mm^2, thus use Al(min) n=

Alprov = 804.25 mm2 add'l web bars are not required! fs =

fs(used) =

For Combined Shear and Torsion: s(max) =

Total (Av+t) = 50.89 mm2 <= Av+t(prov) = 157.08 mm^2, O.K.

Total (Av+t)min = 50.85 mm2 <= Av+t(prov) = 157.08 mm^2, O.K.

CRACK CONTROL

Es = 200,000 MPa Steel Modulus of Elasticity

Ec = 21,373 MPa Ec = 4700*SQRT(f'c)

n = 9.36 n = Es/Ec

LEFT SUPPORT

fs = 1,858.18 MPa fs = Ma/(As*d*(1-(SQRT(2*As/(b*d)*n+(As/(b*d)*n)^2)-As/(b*d)*n)/3))

fs(used) = 275.33 MPa fs(used) = minimum of: fs and 2/3*fy

s(max) = 261.44 mm s(max) = minimum of: 380*280/fs(used)-2.5*Cc and 300*280/fs(used)

s(min) = 25.00 mm

s(act) = 66.67 mm s(min) <= s(act) <= s(max), O.K.!

MIDSPAN

fs = 826.48 MPa fs = Ma/(As*d*(1-(SQRT(2*As/(b*d)*n+(As/(b*d)*n)^2)-As/(b*d)*n)/3))

fs(used) = 275.33 MPa fs(used) = minimum of: fs and 2/3*fy

s(max) = 261.44 mm s(max) = minimum of: 380*280/fs(used)-2.5*Cc and 300*280/fs(used)

s(min) = 25.00 mm

s(act) = 66.67 mm s(min) <= s(act) <= s(max), O.K.!

RIGHT SUPPORT

fs = 1,776.66 MPa fs = Ma/(As*d*(1-(SQRT(2*As/(b*d)*n+(As/(b*d)*n)^2)-As/(b*d)*n)/3))

fs(used) = 275.33 MPa fs(used) = minimum of: fs and 2/3*fy

s(max) = 261.44 mm s(max) = minimum of: 380*280/fs(used)-2.5*Cc and 300*280/fs(used)

s(min) = 25.00 mm

s(act) = 66.67 mm s(min) <= s(act) <= s(max), O.K.!

Page 1 of 1

You might also like

- Aci318-08 RC BeamDocument3 pagesAci318-08 RC BeamKhải TrươngNo ratings yet

- Cast in Situ Pile Capacity-18inchDocument1 pageCast in Situ Pile Capacity-18inchayatNo ratings yet

- Earthquake Analysis According To BNBC 2020Document42 pagesEarthquake Analysis According To BNBC 2020SayeedNo ratings yet

- Geo-Report NalbariDocument17 pagesGeo-Report NalbariShashankSinghNo ratings yet

- Span/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span FactorDocument1 pageSpan/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span Factorshamen amarasekaraNo ratings yet

- Reinforcement: V, F: Project: Staircase Design - STC 1Document4 pagesReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNo ratings yet

- Job: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Document55 pagesJob: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Shamitha KanchanaNo ratings yet

- Isoleted Footing Design 02 WSD+USDDocument6 pagesIsoleted Footing Design 02 WSD+USDMd. Nahid HossainNo ratings yet

- Cantilever Beam Deflection CalculatorDocument2 pagesCantilever Beam Deflection CalculatorHemant SonawadekarNo ratings yet

- All Beams UpdatedDocument34 pagesAll Beams UpdatedChristian Jeremiah TevesNo ratings yet

- Base Plate - 09-08-2018Document6 pagesBase Plate - 09-08-2018zakaria200811060No ratings yet

- Wind Load BNBC-2017 & ASCE 7-05Document13 pagesWind Load BNBC-2017 & ASCE 7-05naimNo ratings yet

- SLAB DESIGN CALCULATIONS BY MUHAMMAD SARMADDocument13 pagesSLAB DESIGN CALCULATIONS BY MUHAMMAD SARMADMuhammad Sarmad SonyalNo ratings yet

- Beam Design 1Document22 pagesBeam Design 1shamen amarasekaraNo ratings yet

- Calculating Bulk Volumes Using Simpson's RuleDocument10 pagesCalculating Bulk Volumes Using Simpson's RuleEng Ravi Kant SharmaNo ratings yet

- 2911 3Document44 pages2911 3rambinodNo ratings yet

- Concrete Frame Multi Storey Cost EstimateDocument2 pagesConcrete Frame Multi Storey Cost Estimateaddrien danielNo ratings yet

- Schematic Beam Dimensions and Properties ValuesDocument4 pagesSchematic Beam Dimensions and Properties ValuesFredy Campos FloresNo ratings yet

- Columnsteel 1Document1 pageColumnsteel 1Gelbert SilotNo ratings yet

- Beam Design TorsionDocument20 pagesBeam Design Torsionmailmaverick8167100% (1)

- STAAD - Pro Report: Job InformationDocument18 pagesSTAAD - Pro Report: Job InformationApoorv SinghalNo ratings yet

- Project: ต่อเติมบ้านพักอาศัย Date: Owner: 0 Slap No: Location: 0 FloorDocument13 pagesProject: ต่อเติมบ้านพักอาศัย Date: Owner: 0 Slap No: Location: 0 FloorSurat WaritNo ratings yet

- Design of Shear Connector For Composite Bending ActionDocument2 pagesDesign of Shear Connector For Composite Bending ActionankitNo ratings yet

- Footings Design ProcedureDocument19 pagesFootings Design ProcedureJanakiram GoudNo ratings yet

- Column Splicing Structural Analysis and Computation ReportDocument41 pagesColumn Splicing Structural Analysis and Computation ReportForceNo ratings yet

- Slab Design of Partially Fixed Circular SlabDocument4 pagesSlab Design of Partially Fixed Circular SlabBithika DattaNo ratings yet

- Hipped Plate RoofDocument7 pagesHipped Plate RoofgvgbabuNo ratings yet

- b4 PDFDocument1 pageb4 PDFCARL JAMESNo ratings yet

- Combined Footing Design ES en 2015Document24 pagesCombined Footing Design ES en 2015Dino AbdelaNo ratings yet

- NBC105-2020 Torsion Irregularity Check-2021!08!12Document2 pagesNBC105-2020 Torsion Irregularity Check-2021!08!12Prakash Singh RawalNo ratings yet

- Stair Case CalcuationsDocument2 pagesStair Case CalcuationsraghavendraNo ratings yet

- Wind Load - BNBC-2020-Arched RoofDocument8 pagesWind Load - BNBC-2020-Arched RoofFaridUddinNo ratings yet

- FCK Fy B H D D': Grade of Concrete (N/MM) Grade of Reinf Steel (N/MM)Document1 pageFCK Fy B H D D': Grade of Concrete (N/MM) Grade of Reinf Steel (N/MM)Manoj Kumar PalNo ratings yet

- Staadpro2006 Module-1 WorkbookDocument32 pagesStaadpro2006 Module-1 Workbooksaistructure3500No ratings yet

- Purlin DesignDocument35 pagesPurlin DesignAtul WanodeNo ratings yet

- Ductile Detailing Rect. ColDocument12 pagesDuctile Detailing Rect. Colankkeshmundra1No ratings yet

- RCC Slab DesignDocument4 pagesRCC Slab DesignarghyadeepNo ratings yet

- RCC14 Crack WidthDocument2 pagesRCC14 Crack WidthMohammad Twaha JaumbocusNo ratings yet

- Comprehensive Water Supply Improvements for VizianagaramDocument24 pagesComprehensive Water Supply Improvements for VizianagaramNaga Bharath ReddyNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument1 pageLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- T - Sections Half H.E.A.: X XB XT X X y y y M T / 2 2 4 3 3 4 3 - 2 2 / 2 / WebDocument1 pageT - Sections Half H.E.A.: X XB XT X X y y y M T / 2 2 4 3 3 4 3 - 2 2 / 2 / WebAlden CayagaNo ratings yet

- Column design details for rectangular columnDocument27 pagesColumn design details for rectangular columnnsureshbabu0% (1)

- Roof DeckDocument2 pagesRoof DeckRayodcNo ratings yet

- Bar Bending ScheduleDocument15 pagesBar Bending ScheduleNAqash ArshadNo ratings yet

- Aci 318-08 Development and Splices of Reinforcement - Editing ProtectedDocument6 pagesAci 318-08 Development and Splices of Reinforcement - Editing Protectedbryamdv23No ratings yet

- Beam and Slab Type Combined FootingDocument6 pagesBeam and Slab Type Combined FootingAlphyl BalasabasNo ratings yet

- RCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementDocument5 pagesRCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementdsanandaNo ratings yet

- Check For The Edge Distance and Stress in Plates Connected in ROB in Lieu of LC No. KA-161Document5 pagesCheck For The Edge Distance and Stress in Plates Connected in ROB in Lieu of LC No. KA-161SERNo ratings yet

- DBR How To MakeDocument15 pagesDBR How To Maketanmay271100% (1)

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsJule LobresNo ratings yet

- REINFORCED CONCRETE COLUMN STRENGTH ANALYSISDocument7 pagesREINFORCED CONCRETE COLUMN STRENGTH ANALYSISAmit Kumar Paul100% (1)

- CF1 and CF2 footing design and slab reinforcement checkDocument2 pagesCF1 and CF2 footing design and slab reinforcement checkakhilNo ratings yet

- 2, Hence One Way SlabDocument6 pages2, Hence One Way Slabashn_604No ratings yet

- RC Beam Analysis and DesignDocument3 pagesRC Beam Analysis and DesignTarek Abulail0% (1)

- ACI318-08 RC Beam - XLS: Material PropertiesDocument3 pagesACI318-08 RC Beam - XLS: Material PropertiesEdgardo ArriesgadoNo ratings yet

- Final-RCD-with-Macros - Design (Beam)Document5 pagesFinal-RCD-with-Macros - Design (Beam)Kaizen MinnaNo ratings yet

- Beam DesignDocument4 pagesBeam Designbarcoma.mylene.nNo ratings yet

- UB 610 X 179 - BP - PinnedDocument3 pagesUB 610 X 179 - BP - PinnedArivoli JayaramanNo ratings yet

- Manual: Engineering Calculation TemplateDocument8 pagesManual: Engineering Calculation TemplateHamiNo ratings yet

- Baseplate MonorailDocument31 pagesBaseplate Monorailmohamad chandraNo ratings yet

- Two Way Slab Design (WSD)Document14 pagesTwo Way Slab Design (WSD)আসিফ মাহমুদNo ratings yet

- Center of mass and eccentricity analysisDocument1 pageCenter of mass and eccentricity analysisআসিফ মাহমুদNo ratings yet

- 32.5 ft Foundation Estimation and Cost CalculationDocument11 pages32.5 ft Foundation Estimation and Cost Calculationআসিফ মাহমুদNo ratings yet

- Soft Story IrregularityDocument4 pagesSoft Story IrregularitySuson DhitalNo ratings yet

- Soft Story IrregularityDocument4 pagesSoft Story IrregularitySuson DhitalNo ratings yet

- Access Engineering: Combined Footing Design Based On ACI 318-99Document7 pagesAccess Engineering: Combined Footing Design Based On ACI 318-99আসিফ মাহমুদNo ratings yet

- C1F1Document2 pagesC1F1Sharif UddinNo ratings yet

- 32.5 ft Foundation Estimation and Cost CalculationDocument11 pages32.5 ft Foundation Estimation and Cost Calculationআসিফ মাহমুদNo ratings yet

- Two Way Slab Design (USD)Document17 pagesTwo Way Slab Design (USD)আসিফ মাহমুদNo ratings yet

- Civil Engineering Drift Limitation CheckDocument8 pagesCivil Engineering Drift Limitation Checkআসিফ মাহমুদNo ratings yet

- Base-Shear Check (Seismic Value)Document23 pagesBase-Shear Check (Seismic Value)আসিফ মাহমুদNo ratings yet

- Pile CapacityDocument5 pagesPile Capacityআসিফ মাহমুদNo ratings yet

- Chpater 82 Piling ProblemsDocument12 pagesChpater 82 Piling ProblemsGan Khai SianNo ratings yet

- Design of Straight Retaining Wall For Height 5.5m FROM G.L & NBC 100 KN/SQMDocument24 pagesDesign of Straight Retaining Wall For Height 5.5m FROM G.L & NBC 100 KN/SQMShivam SharmaNo ratings yet

- REFRESHER COURSE ON APPLICATION OF NEW SEISMIC CODE FOR HIGHWAY BRIDGESDocument69 pagesREFRESHER COURSE ON APPLICATION OF NEW SEISMIC CODE FOR HIGHWAY BRIDGESNeeraj SharmaNo ratings yet

- Floor Framing PlanDocument9 pagesFloor Framing PlanJacob ChirayilNo ratings yet

- Lesson 2. Statically Determinate Structures - Part 5 Influence Lines For BeamsDocument19 pagesLesson 2. Statically Determinate Structures - Part 5 Influence Lines For BeamsCharizza Montarin CENo ratings yet

- 33-11 KV Substation Equip FoundationDocument1 page33-11 KV Substation Equip FoundationSantoshNo ratings yet

- ADAPT-Builder 20 Tutorial - Single Level Two-Way SlabDocument198 pagesADAPT-Builder 20 Tutorial - Single Level Two-Way SlabSyllasNo ratings yet

- Steel GirderDocument42 pagesSteel GirderPutri PuttNo ratings yet

- Mohon & Kadam, 2016Document6 pagesMohon & Kadam, 2016Pats LitumaNo ratings yet

- Apartment - Final Case - 40Document1 pageApartment - Final Case - 40alexanderNo ratings yet

- Dowswell - Calc of Transfer Forces in Steel StrucDocument7 pagesDowswell - Calc of Transfer Forces in Steel StrucRaghu GuptaNo ratings yet

- Aircraft Structural Analysis MethodsDocument20 pagesAircraft Structural Analysis Methodsfebry mulyaNo ratings yet

- Effect of corncob ash as partial cement substitute in concreteDocument5 pagesEffect of corncob ash as partial cement substitute in concreteAngelic JoyseNo ratings yet

- PETRAPeikko Group 003 TMAWebDocument34 pagesPETRAPeikko Group 003 TMAWebSales ConstructionNo ratings yet

- (Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualDocument75 pages(Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualPankaj BansalNo ratings yet

- adminteknika,+10.+JT V3N2 APRIL+2020 HAL198-207Document10 pagesadminteknika,+10.+JT V3N2 APRIL+2020 HAL198-207Rifki AbrarNo ratings yet

- Vertikal Cement MillDocument8 pagesVertikal Cement MillMohamad Taufik (abang topek)No ratings yet

- Reinforcement details sheetDocument1 pageReinforcement details sheetRites limitedNo ratings yet

- Cement Consumption Report for CBUSDocument4 pagesCement Consumption Report for CBUSBISWAJIT DASNo ratings yet

- PSC Girder Over River Surma - Bangladesh - Good Construction ExampleDocument6 pagesPSC Girder Over River Surma - Bangladesh - Good Construction ExampleAnand Shah100% (1)

- Why Midas CivilDocument54 pagesWhy Midas CivilJorge MartinezNo ratings yet

- GITC 4th Floor C N D Repairs BOQDocument4 pagesGITC 4th Floor C N D Repairs BOQAbhisheK MishrANo ratings yet

- Reinforced Concrete Beam: Graitec Innovation 17 Burospace 91572 BièvresDocument4 pagesReinforced Concrete Beam: Graitec Innovation 17 Burospace 91572 BièvresFreizerNo ratings yet

- Expansion Joint Pelat Injak T 300 Granular Backfill (Well Compacted)Document1 pageExpansion Joint Pelat Injak T 300 Granular Backfill (Well Compacted)Anonymous 5OUozYNo ratings yet

- CIP03-Crazing Concrete SurfacesDocument2 pagesCIP03-Crazing Concrete Surfaces7774R105No ratings yet

- Steel Joists and Joist Girders 1 PDFDocument216 pagesSteel Joists and Joist Girders 1 PDFhilander2k2No ratings yet

- Lecture 3 - Reinforced Concrete Framed StructuresDocument18 pagesLecture 3 - Reinforced Concrete Framed StructuresYI HEN ONGNo ratings yet

- Gps PillarDocument6 pagesGps PillarKosygin LeishangthemNo ratings yet

- Architect & Engineer Instruction Variation OrderDocument4 pagesArchitect & Engineer Instruction Variation OrderaimiNo ratings yet

- Earthqui IS CODE 1893Document41 pagesEarthqui IS CODE 1893Santosh PotdarNo ratings yet