Professional Documents

Culture Documents

SECTION 15152 Residential Drainage and Vent Piping Rev 0

Uploaded by

Munir RasheedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SECTION 15152 Residential Drainage and Vent Piping Rev 0

Uploaded by

Munir RasheedCopyright:

Available Formats

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

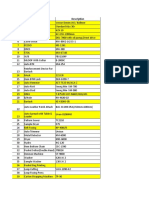

TABLE OF CONTENTS

Item No Title Page No

PART 1 GENERAL............................................................................................................ 1

1.01 DESCRIPTION OF WORK .................................................................................. 1

1.02 SECTION INCLUDES .......................................................................................... 1

1.03 RELATED SECTIONS ......................................................................................... 1

1.04 REFERENCES..................................................................................................... 2

1.05 SUBMITTALS....................................................................................................... 5

1.06 QUALITY CONTROL ........................................................................................... 6

1.07 HEALTH AND SAFETY CONSIDERATIONS...................................................... 6

1.08 DESIGN CRITERIA.............................................................................................. 6

1.09 PERFORMANCE REQUIREMENTS ................................................................... 8

1.10 DELIVERY, HANDLING AND STORAGE ........................................................... 8

PART 2 PRODUCTS ....................................................................................................... 10

2.01 GENERAL .......................................................................................................... 10

2.02 PIPE AND FITTINGS ......................................................................................... 10

2.03 PIPING COMPONENTS .................................................................................... 13

2.04 INTERCEPTORS ............................................................................................... 16

2.05 WASTE FOOD GRINDERS ............................................................................... 16

PART 3 EXECUTION ...................................................................................................... 18

3.01 INSPECTION ..................................................................................................... 18

3.02 PREPARATION ................................................................................................. 18

3.03 INSTALLATION.................................................................................................. 18

3.04 FLASHING INSTALLATION............................................................................... 25

3.05 PIPE HANGERS AND SUPPORTS................................................................... 26

Rev 0 i Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

TABLE OF CONTENTS (Contd.)

Item No Title Page No

3.06 FLUSHING AND CLEANING ............................................................................. 27

3.07 TESTING............................................................................................................ 27

3.08 SCHEDULES ..................................................................................................... 28

Rev 0 ii Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

PART 1 GENERAL

1.01 DESCRIPTION OF WORK

A. The Contractor shall provide all labor, materials, equipment and services required for

the furnishing, installation and testing of the residential sanitary waste and vent

piping; and storm drainage piping.

1.02 SECTION INCLUDES

A. Residential Soil and Waste, Sanitary Drainage and Vent Piping

B. Residential Storm Drainage Piping

C. Interceptors

D. Waste Food Crushers

1.03 RELATED SECTIONS

A. Section 01320 Construction Progress Documentation

B. Section 01330 Submittal Procedures

C. Section 01410 Regulatory Requirements

D. Section 01450 Quality Control

E. Section 01650 Product Delivery Requirements

F. Section 01660 Product Storage and Handling Requirements

G. Section 02085 Underground Piping Material

H. Section 02315 Excavation and Fill

I. Section 02530 Sanitary Sewerage System

J. Section 15055 General Requirements for Piping System

K. Section 15060 Hangers and Supports

L. Section 15075 Mechanical Identification

M. Section 15085 Welding, Brazing and Soldering of Piping

N. Section 15092 Residential Basic Mechanical Materials and Methods

O. Section 15142 Residential Water System

P. Section 15145 Flushing, Cleaning and Treatment of Water Piping

Rev 0 1 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

Q. Section 15160 Storm Drainage Piping

R. Section 15195 Testing of Piping

S. Section 15412 Residential Plumbing Fixtures

1.04 REFERENCES

A. The referred codes and standards are intended to provide an acceptable level of

quality for materials, products and workmanship. In case of conflict between these

standards and the text of this Specification, the Specification text shall govern.

B. The latest revision of the referred codes and standards shall be used wherever

applicable. In case of conflict, the Contractor shall propose equipment, materials and

processes conforming to one group of codes and standards.

C. RCPC Royal Commission Plumbing Code

D. SASO Saudi Arabian Standards Organization

1. SASO 1209 Unplasticized Polyvinyl Chloride (uPVC) Pipes for

Soil, Waste and Vent inside the Buildings

2. SASO 1395 Unplasticized Polyvinyl Chloride (uPVC) Pipes for

Buried, Drains and Sewers

3. SASO 1396 Methods of Testing Unplasticized Polyvinyl Chloride

(uPVC) Pipes For Buried, Drains and Sewers

4. SASO 1397 Unplasticized Polyvinyl Chloride (uPVC) Pipe Fittings

for Buried Drains and Sewers

5. SASO 1398 Methods of Test for Unplasticized Polyvinyl Chloride

(uPVC) Pipe Fittings for Buried Drains And Sewers

6. SASO 1399 Unplasticized Polyvinyl Chloride (uPVC) Pipe Fittings

for Soil, Waste and Vent inside Buildings

7. SASO 1400 Methods of Test for Unplasticized Polyvinyl Chloride

(uPVC) Pipe Fittings for Soil, Waste and Vent inside

Buildings

E. ANSI American National Standards Institute

1. ANSI A 112.21.1 Floor Drains

2. ANSI A 112.36.2 Metallic Cleanouts

F. ASME American Society of Mechanical Engineers

1. ASME B16.23 Cast Copper Alloy Solder Joint Drainage Fittings -

DWV

Rev 0 2 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

2. ASME B16.29 Wrought Copper and Wrought Copper Alloy Solder

Joint Drainage Fittings – DWV

3. ASME B16.32 Cast Copper Alloy Joint Fittings for Drainage

Systems

4. ASME B31.9 Building Services Piping

G. ASTM American Society for Testing and Materials

1. ASTM A74 Standard Specification for Cast Iron Soil Pipe and

Fittings

2. ASTM A518M Standard Specification for Corrosion-Resistant High-

Silicon Iron Castings

3. ASTM A746 Standard Specification for Ductile Iron Gravity Sewer

Pipe

4. ASTM A861 Standard Specification for High-Silicon Iron Pipe and

Fittings

5. ASTM A888 Standard Specification for Hubless Cast Iron Soil

Pipe and Fittings for Sanitary and Storm Drain,

Waste, and Vent Piping Applications

6. ASTM B32 Standard Specification for Solder Metal

7. ASTM B306 Standard Specification for Copper Drainage Tube

(DWV)

8. ASTM C14M Standard Specification for Concrete Sewer Storm

Drain and Culvert Pipe [Metric]

9. ASTM C443M Standard Specification for Joints for Concrete Pipe

and Manholes, Using Rubber Gasket [Metric]

10. ASTM C564 Standard Specification for Rubber Gaskets for Cast

Iron Soil Pipe and Fittings

11. ASTM C1053 Standard Specification for Borosilicate Glass Pipe

and Fittings for Drain, Waste, and Vent (DWV)

Applications

12. ASTM C1277 Standard Specification for Shielded Couplings

Joining Hubless Cast Iron Soil Pipe and Fittings

13. ASTM D698 Standard Test Method for Laboratory Compaction

Characteristics of Soil Using Standard Effort

12,400 ft-lb-f/ft3 (600 kN-m/m3)

14. ASTM D1785 Standard Specification for Polyvinyl Chloride (PVC)

Plastic Pipe, Schedules 40, 80, and 120

Rev 0 3 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

15. ASTM D2235 Standard Specification for Solvent Cement

Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe

and Fittings

16. ASTM D2466 Standard Specification for Polyvinyl Chloride (PVC)

Plastic Pipe Fittings, Schedule 40

17. ASTM D2564 Standard Specification for Solvent Cements for

Polyvinyl Chloride (PVC) Plastic Piping Systems

18. ASTM D2661 Standard Specification for Acrylonitrile-Butadiene-

Styrene (ABS) Schedule 40 Plastic Drain, Waste and

Vent Pipe and Fittings

19. ASTM D2665 Standard Specification for Polyvinyl Chloride (PVC)

Plastic Drain, Waste, and Vent Pipe and Fittings

20. ASTM D2680 Standard Specification for Acrylonitrile-Butadiene-

Styrene (ABS) and Poly (Vinyl Chloride) (PVC)

Composite Sewer Piping

21. ASTM D2729 Standard Specification for Polyvinyl Chloride (PVC)

Sewer Pipe and Fittings

22. ASTM D2751 Standard Specification for Acrylonitrile-Butadiene-

Styrene (ABS) Sewer Pipe and Fittings

23. ASTM D2855 Standard Practice for Making Solvent-Cemented

Joints with Poly (Vinyl Chloride) (PVC) Pipe and

Fittings

24. ASTM D2996 Standard Specification for Filament-Wound

"Fiberglass" (Glass-Fiber-Reinforced Thermosetting-

Resin) Pipe

25. ASTM D2997 Standard Specification for Centrifugally Cast

"Fiberglass" (Glass-Fiber-Reinforced Thermosetting-

Resin) Pipe

26. ASTM D3034 Standard Specification for Type PSM Polyvinyl

Chloride (PVC) Sewer Pipe and Fittings

27. ASTM D3212 Standard Specification for Joints for Drain and Sewer

Plastic Pipes Using Flexible Elastomeric Seals

28. ASTM D3262 Standard Specification for "Fiberglass" (Glass-Fiber-

Reinforced Thermosetting-Resin) Sewer Pipe

29. ASTM D3517 Standard Specification for Fiberglass (Glass-Fiber-

Reinforced Thermosetting-Resin) Pressure Pipe

30. ASTM D3754 Standard Specification for Fiberglass (Glass-Fiber-

Reinforced Thermosetting-Resin) Sewer and

Industrial Pressure Pipe

Rev 0 4 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

31. ASTM D3840 Standard Specification for "Fiberglass" (Glass-Fiber-

Reinforced Thermosetting-Resin) Pipe Fittings for

Non-pressure Applications

32. ASTM F477 Standard Specification for Elastomeric Seals

(Gaskets) for Joining Plastic Pipe

33. ASTM F628 Standard Specification for Acrylonitrile-Butadiene-

Styrene (ABS) Schedule 40 Plastic Drain, Waste and

Vent Pipe with a Cellular Core

34. ASTM F656 Standard Specification for Primers for Use in Solvent

Cement Joints of Poly Vinyl Chloride (PVC) Plastic

Pipe and Fittings

35. ASTM F679 Standard Specification for Poly (Vinyl Chloride)

(PVC) Large-Diameter Plastic Gravity Sewer Pipe

and Fittings

H. CISPI Cast Iron Soil Pipe Institute

1. CISPI 301 Standard Specification for Hubless Cast Iron Soil

Pipe and Fittings for Sanitary and Storm Drain,

Waste, and Vent Piping Applications

2. CISPI 310 Specification for Coupling for Use in Connection With

Hubless Cast Iron Soil Pipe and Fittings Sanitary and

Storm Drain, Waste, and Vent Piping Applications

3. CISPI HSN Specification for Neoprene Rubber Gaskets for Hub

Iron Soil Pipe and Fittings

I. IPC International Plumbing Code

1.05 SUBMITTALS

A. The Contractor shall submit to the Royal Commission, under the provisions of

SECTION 01330, the following items for review and approval before commencing

Work:

1. Product Data

a) For pipe, tube, fittings, and couplings. Include rated capacities and

shipping, installed, and operating weights. Indicate materials, finishes,

dimensions, required clearances, and methods of assembly of

components; and piping and wiring connections for the following:

1) Floor drains and trench drains.

2) Air-admittance valves, vent caps, vent terminals, and roof flashing

assemblies.

3) Sleeve penetration systems.

Rev 0 5 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

2. Field Test Reports

a) Indicate and interpret test results for compliance with performance

requirements.

3. Project Record Documents

a) As-Built Drawings, showing locations of cleanouts.

1.06 QUALITY CONTROL

A. The Contractor shall be responsible for the quality of work and shall develop and

propose programs and methods of construction and testing to achieve the specified

quality to the approval of the Royal Commission in accordance with

SECTION 01450.

B. Drainage system shall be left unconcealed and uncovered until it has been

inspected, tested and approved by the Royal Commission.

C. Piping materials shall bear label, stamp or other markings of specified testing

agency.

1.07 HEALTH AND SAFETY CONSIDERATIONS

A. All works undertaken in relation to this Specification are to be completed in full

accordance with the respective health and safety requirements established by the

following:

1. Kingdom of Saudi Arabia

a) Legislation, Regulation, Standards and Codes.

2. Royal Commission Regulations

a) Standards, Contractual Conditions, and Health and Safety Systems.

3. Contractor

a) Health and Safety Standards and Systems as accepted by the Royal

Commission.

B. In the absence of any of the above, best accepted industry practice shall be

employed throughout.

1.08 DESIGN CRITERIA

Rev 0 6 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

A. General

1. Water services and distribution mains shall be located horizontally a minimum

3 m (10 ft.) center line to center line of existing or proposed water and storm

lines.

2. Where sanitary sewer lines cross water mains, the water main pipe shall have

a minimum 450 mm (18 in.) clear distance vertically above the sanitary sewer

pipe. If this clear distance is not feasible or the sanitary sewer line is above the

water line, the crossing must be designed and constructed, using pipe

encasement on the sanitary sewer main, to protect the water main. Where the

sanitary sewer main is already constructed, the pipe encasement shall be

placed on the water main.

3. Storm sewers shall have the same restrictions as sanitary sewer and other

utilities.

4. Each structure and each subdivided lot shall be served by separate service

lines.

5. All lots shall have separate sewer services without crossing any adjacent

properties.

6. Service lines shall have a maximum velocity of 3 m/s (10 fps).

7. The service line shall flow maximum half full at peak design flow.

8. The minimum allowable service line size is 100 mm (4 in.).

9. The minimum horizontal distance required from building sewers shall be as per

Table 7-7 of IPC. The bottom of the water pipe, at all points shall be at least

305 mm (12 in.) above the top of the sewer or drain line.

10. Service lines may not be installed in trenches with other conduits. A service

line shall be separated from other conduits a minimum 3 m (10 ft.) horizontally.

11. Clean-outs shall be located at all points of deflection (i.e. bends) and every

30 m (100 ft.) in a service or in a straight pipeline with the following exception:

a) No clean out shall be located within a public right-of-way.

12. Each lot or separate building site shall have tees or tapping saddles for service

connections.

13. Riser connections for sanitary services shall be prohibited.

14. All service lines greater than 150 mm (6 in.) diameter shall be connected at a

manhole. This service connection shall channel the flow through the manhole

bench to the invert unless the difference in invert elevations are greater than

600 mm (24 in.).

B. Design Flow

1. The sanitary sewer collection system design shall include consideration for

Rev 0 7 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

providing service for the entire area tributary to the outfall point. Estimates for

sanitary sewage flows shall use the following guidelines:

a) Residential sewage contribution shall be based on 81 gpcd (gallons per

day per capita) average flow.

b) The average daily wastewater flow shall be calculated as 80% of the

potable water demand excluding leakage and irrigation, unless detailed

analysis of the proposed service area indicates differently.

c) Estimates shall include allowances for a maximum infiltration of

50 gallons per day per inch diameter per mile of pipe.

1.09 PERFORMANCE REQUIREMENTS

A. Provide components and installation capable of producing piping systems with the

following minimum working-pressure ratings, unless otherwise indicated:

1. Soil, Waste, and Vent Piping

a) 30 kPa (10 ft. head of water) at 15.6°C (60°F).

B. The sanitary sewerage system shall provide an adequate circulation of air in all pipes

with no danger of siphonage, aspiration, or forcing of trap seals under conditions of

ordinary use.

C. Sanitary sewerage systems in the desert area shall be so installed, that soil water

containing excreta is kept separate from the other waste water, and therefore a split-

pipe system is necessary.

1.10 DELIVERY, HANDLING AND STORAGE

A. The Contractor shall deliver, handle and store equipment and material units in

accordance with SECTIONS 01650 and 01660, as well as the following

requirements:

1. The Contractor shall be responsible for proper transportation, unloading,

handling, storage and security of all equipment and materials to be provided as

part of this Specification in accordance with manufacturer’s recommendation.

2. Materials shall be stored in such a manner as to prevent damage or

degradation. Any materials damaged prior to installation shall be removed from

the Project and replaced with new materials at no additional cost to the Royal

Commission. Lost or stolen materials shall be replaced at no additional cost.

3. Load and unload pipe, fittings, valves and accessories by lifting with hoists or

skidding so as to avoid shock or damage. Do not skid or roll pipe on skid ways

against pipe already on the ground.

4. Stacked on a reasonably flat surface free from sharp projections, stones or

other protuberances likely to deform them. The pipes must be uniformly

supported throughout their length.

Rev 0 8 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

5. When socketed pipes are stacked, the sockets shall be placed at alternate

ends of the stack with the sockets protruding so that pipes are evenly

supported along their entire length.

6. Pipes of different sizes or wall thickness shall be stored separately or where it

is not possible, those with larger diameters and thicker walls shall be at the

bottom.

7. No piping shall be exposed to the direct sunlight for more than 2 weeks during

storage, transportation, handling or installation.

8. Fittings shall be stored under shade conditions preferably in boxes or sacks

which allow free passage of air.

Rev 0 9 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

PART 2 PRODUCTS

2.01 GENERAL

A. All goods and products covered by these Specifications shall be procured, when

available, from an in-Kingdom manufacturer. Procurement of all goods and products

manufactured out-of-Kingdom must be approved by the Royal Commission.

B. All Drainage piping shall be sized at 50 mm minimum and larger in accordance with

the Royal Commission requirements.

2.02 PIPE AND FITTINGS

A. Below Grade Sanitary Sewer Piping

1. PVC Pipe

a) PVC pipe shall conform to ASTM D2665 or D3034.

b) Fittings shall be PVC.

c) Joints shall be solvent welded, with ASTM D2564 solvent cement and

ASTM F656 Primer.

2. PVC Pipe

a) PVC pipe shall conform to ASTM D2665 or D3034.

b) Fittings shall be PVC.

c) Joints shall be push-on, using ASTM F477 elastomeric gaskets.

3. ABS Pipe

a) ABS pipe shall conform to ASTM D2751 or F628.

b) Fittings shall be ABS.

c) Joints shall be solvent welded with ASTM D2235 cement.

4. ABS Pipe

a) ABS pipe shall conform to ASTM D2661 or D2751.

b) Fittings shall be ABS.

c) Joints shall be solvent welded with ASTM D2235 cement.

5. Fiberglass Pipe

a) Fiberglass pipe shall conform to ASTM D3262.

Rev 0 10 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

b) Fittings shall comply with ASTM D3840.

c) Joints shall be Epoxy.

6. Fiberglass Pipe

a) Fiberglass pipe shall conform to ASTM D3754, D3517, D2996, or

D2997.

b) Fittings shall be custom laminated Fiberglass.

c) Joints shall be Epoxy.

B. Above Grade Sanitary Sewer Piping

1. PVC Pipe

a) PVC pipe shall conform to ASTM D2729.

b) Fittings shall be PVC.

c) Joints shall be solvent welded, with ASTM D2564 solvent cement.

2. PVC Pipe

a) PVC pipe shall conform to ASTM D2665.

b) Fittings shall be PVC.

c) Joints shall be solvent welded, with ASTM D2564 solvent cement.

3. PVC Pipe

a) PVC pipe shall conform to ASTM D1785 Schedule 40.

b) Fittings shall be PVC, ASTM D2466.

c) Joints shall be solvent welded, with ASTM D2564 solvent cement.

4. ABS Pipe

a) ABS pipe shall conform to ASTM D2751 or F628.

b) Fittings shall be ABS.

c) Joints shall be solvent welded with ASTM D2235 cement.

5. ABS Pipe

a) ABS pipe shall conform to ASTM D2661 or D2751.

b) Fittings shall conform to ASTM D2661, ABS.

Rev 0 11 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

c) Joints shall be solvent welded with ASTM D2235 cement.

6. Fiberglass Pipe

a) Fiberglass pipe shall conform to ASTM D3262.

b) Fittings shall conform to ASTM D3840.

c) Joints shall be Epoxy.

7. Fiberglass Pipe

a) Fiberglass pipe shall conform to ASTM D3754, D3517, D2996, or

D2997.

b) Fittings shall be custom laminated Fiberglass.

c) Joints shall be Epoxy.

C. Below Grade Storm Water Piping

1. Concrete Pipe

a) Concrete pipe shall conform to ASTM C14M Class 1 Nonreinforced.

b) Fittings shall conform to ASTM C14M Class 1 Nonreinforced.

c) Joints shall be elastomeric gaskets; ASTM C443M.

2. ABS Pipe

a) ABS pipe shall conform to ASTM D2680 or D2751.

b) Fittings shall be ABS.

c) Joints shall be solvent welded with ASTM D2235 cement.

3. PVC Pipe

a) PVC pipe shall conform to ASTM D2665 or D3034.

b) Fittings shall be PVC.

c) Joints shall be solvent welded, with ASTM D2564 solvent cement.

4. PVC Pipe

a) PVC pipe shall conform to ASTM D2665, D3034, or F679.

b) Fittings shall be PVC.

c) Joints shall be push-on, using ASTM F477 elastomeric gaskets.

Rev 0 12 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

D. Above Grade Storm Water Piping

1. ABS Pipe

a) ABS pipe shall conform to ASTM D2680 or D2751.

b) Fittings shall be ABS.

c) Joints shall be solvent welded with ASTM D2235 cement.

2. PVC Pipe

a) PVC Pipe shall conform to ASTM D2665 or D3034.

b) Fittings shall be PVC.

c) Joints shall be solvent welded, with ASTM D2564 solvent cement.

E. Plastic Pipe Usage Limitations

1. Polyvinyl Chloride (PVC) Plastic pipe installations shall be limited to those

structures where combustible construction is allowed.

2. Polyvinyl Chloride (PVC) Plastic pipe may be used for above ground when

piping is enclosed in 1 hour fire rated pipe chase.

3. Polyvinyl Chloride (PVC) Plastic pipe shall not penetrate firewalls.

4. Gaskets and couplings shall be from same manufacturer, whenever possible.

2.03 PIPING COMPONENTS

A. Cleanouts

1. General

a) Cleanouts shall comply with ANSI A112.36.2.

b) uPVC Cleanouts are not permitted within buildings, unless otherwise

approved.

c) Size

1) Cleanouts shall be the same nominal size as the pipes they serve;

except where cleanouts are required in pipes 100 mm and larger,

provide 100 mm cleanouts.

d) Accessibility

1) Cleanouts must be accessible. Adequate clearance for drain

cleaning shall be maintained.

e) Locations

Rev 0 13 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

1) Where indicated on the Contract Drawings. Exact locations as per

the approved Shop Drawings.

2) At all horizontal offsets.

3) At 30 m maximum intervals in all horizontal runs within the

building lines.

4) At base of all stacks.

2. Floor Cleanouts

a) Floor cleanouts shall be supplied with:

1) Cast iron body with adjustable housing.

2) Inside caulk connection suitable for PVC or other drain pipe

connection.

3) Closure

(a) Brass plug with straight threads and gasket.

4) Adjustable Housing Material

(a) Cast iron with threads.

5) Frame and Cover Material and Finish

(a) Nickel-bronze, copper or stainless steel to suite room finish.

6) Frame and Cover Shape

(a) Round.

7) Ferrule with plug.

8) Round polished brass top, secured.

3. Wall Cleanouts

a) Wall cleanouts shall be suitable for installation in PVC or other pipe and

shall be supplied with:

1) Ferrule with brass plug.

2) 150 mm diameter secured stainless steel access cover.

4. Cleanout Plugs

a) Suitable cleanout plugs of same material as pipe shall be provided for

closing ends of horizontal drainage pipe above slab.

B. Floor Drains

1. General

a) Floor drains shall comply with ANSI A112.21.1.

b) The Contractor shall provide all gaskets and accessories required to

install floor drains in PVC drain pipe.

Rev 0 14 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

c) Open hub drains for indirect or equipment waste shall be as indicated on

the Contract Drawings.

d) Floor drains serving water heater areas shall be of deep seal type or

shall be discharged to the indirect waste funnel (IWF).

e) Self-priming floor drains shall be permitted only where indicated on the

drawings and approved in advance by the Royal Commission.

2. Floor drains shall be supplied with:

a) Body Material: Gray iron.

b) Seepage Flange: Required.

c) Clamping Device: Required.

d) Outlet: Bottom.

e) Top or Strainer Material: Nickel bronze.

f) Top of Body and Strainer Finish: Satin Nikaloy.

g) Top Shape: Round

h) Top Loading Classification: Light Duty.

i) Inlet Fitting: Gray iron, with threaded inlet and threaded or spigot outlet.

j) Trap Material: Cast iron.

k) Trap Pattern: Deep-seal P-trap.

l) Trap Features: Trap seal primer valve drain connection.

m) Bottom inside caulk connection suitable for PVC pipe connection.

n) Flashing clamp and waterproofing membrane.

o) Leveling adjustment.

p) Floor Drain Strainer/Cover Top

1) 150 mm diameter, polished bronze, for rest rooms, toilets,

laboratory rooms and first aid areas.

2) 220 mm diameter, cast iron for equipment rooms.

C. Roof Drains

1. Coated cast iron roof drain with sealing gasket, large vandalproof cast iron

locking dome, non-puncturing clamp ring with internal gravel stop, adjustable

top with wide roof flange, under deck clamp assembly, large sump with anchor

flange and bottom outlet inside caulk connection.

Rev 0 15 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

2.04 INTERCEPTORS

A. Grease Interceptors

1. Construction

a) Material

1) Epoxy coated fabricated steel.

b) Rough-In

1) On floor.

c) Accessories

1) Multi-weir baffle assembly, integral deep seal trap, removable

integral flow control, sediment bucket.

d) Cover

1) Steel, epoxy coated, non-skid with gasket, securing handle, hinge

typed cover, recessed for floor finish and enzyme injection port.

B. Oil Interceptors

1. Construction

a) Material

1) Epoxy coated fabricated steel.

b) Rough-In

1) On floor.

c) Accessories

1) Integral deep seal trap, removable integral flow control, adjustable

draw-off assembly, sediment bucket.

d) Cover

1) Steel, epoxy coated, non-skid with gasket, securing handle, and

enzyme injection port, recessed for floor finish.

2.05 WASTE FOOD GRINDERS

A. Waste food grinders shall be small freestanding type disposers for both continuous

and batch feeding that allows continuous feeding of food waste into the disposer. The

cover shall prevent accidental contact with the rotary shedder by the operator. If the

cover is lifted, a limit switch in the control circuit shall stop the motor rotating the

shredder.

B. Series disposer parts shall be made of alloys suitable for use with salt seawater for

flushing ground food waste and disposer housing or cabinet manufactured with an

Rev 0 16 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

AISI 316 stainless steel construction.

1. Batch Feed with Magnitop Plug System.

2. Continuous Feed with Magnitube.

3. Industrial Grade Cast Stainless Steel Grinding System.

4. High Torque ¾ hp Induction Motor.

5. Extended and Brass Sink Bushes.

6. 220 to 240 V AC.

7. Average Amps 3 to 4.

8. Maximum Sink Thickness 20 mm.

9. Maximum Sink Thickness with Bush 32 mm.

10. Drain Connection 38 mm Standard Trap.

Rev 0 17 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

PART 3 EXECUTION

3.01 INSPECTION

A. Verify that excavations are to required grade, dry and not over-excavated.

B. Immediately before laying, examine accessories, each pipe and joint again for

soundness and cleanliness and make sure that material and surfaces which form

part of a joint are clean and dry before commencing their assembly. All defective

material shall be replaced.

C. Check that the position and levels of existing drains and services have been

established.

3.02 PREPARATION

A. Ream pipe and tube ends. Remove burrs. Bevel plain end ferrous pipe.

B. Remove scale and dirt, on inside and outside before assembly.

C. Prepare piping connections to equipment with flanges or unions.

3.03 INSTALLATION

A. General

1. Install in accordance with manufacturer's instructions.

2. Horizontal sanitary drainage piping 75 mm and smaller pipes shall be sloped in

the direction of flow by 2%, 100 mm and larger pipes shall be sloped by 1%,

unless otherwise noted.

3. Horizontal sanitary drainage piping outside the building shall be sloped in the

direction of flow by 1%, unless otherwise indicated.

4. No portion of the drainage system underground or below a floor slab,

basement or cellar shall be less than 50 mm nominal diameter.

5. Waste lines shall not be less than 50 mm nominal diameter.

6. Drain piping for condensate waste from air conditioning cooling coils shall be

indirectly connected to a floor drain, or shall be indirectly connected into the

inlet side of a P-trap or indirect waste funnel.

7. All floor drains and cleanouts location shall be installed as shown on the

Contract Drawings and on the approved Shop Drawings.

8. Install cleanouts at grade and extend to where building sanitary drains connect

to building sanitary sewers.

9. Install cleanout fitting with closure plug inside the building in sanitary force-

Rev 0 18 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

main piping.

10. Install cast-iron sleeve with waterstop and mechanical sleeve seal at each

service pipe penetration through foundation wall. Select number of interlocking

rubber links required to make installation watertight. Refer to SECTION 15092

for sleeves and mechanical sleeve seals.

11. The top of each floor drain shall be leveled flush with finished floor and drain

shall be at the lowest point if floor is sloped to drain.

12. Floor cleanouts shall be adjusted for level flush with finished floor or slabs and

secured.

13. Carpet markers shall be installed for cleanouts in carpeted areas.

14. Access covers for wall cleanouts shall be adjusted to fit tightly to finished wall.

15. Install wall penetration system at each service pipe penetration through

foundation wall. Make installation watertight.

16. Make changes in direction for soil and waste drainage and vent piping using

appropriate branches, bends, and long-sweep bends. Straight tees, elbows,

and crosses may be used on vent lines. Do not change direction of flow more

than 90°. Use proper size of standard increasers and reducers if pipes of

different sizes are connected. Reducing size of drainage piping in direction of

flow is prohibited.

17. Lay buried building drainage piping beginning at low point of each system.

Install true to grades and alignment indicated, with unbroken continuity of

invert. Place hub ends of piping upstream. Install required gaskets according

to manufacturer's written instructions for use of lubricants, cements, and other

installation requirements. Maintain swab in piping and pull past each joint as

completed.

18. Install soil and waste drainage and vent piping at the following minimum

slopes, unless otherwise indicated:

a) Building Sanitary Drain

1) 2% downward in direction of flow for piping NPS 80 mm (3 in.)

and smaller.

2) 1% downward in direction of flow for piping NPS 100 mm (4 in.)

and larger.

b) Horizontal Sanitary Drainage Piping Inside the Building

1) 2% downward in direction of flow.

c) Vent Piping

1) 1% down toward vertical fixture vent or toward vent stack.

19. Install engineered soil and waste drainage and vent piping systems in

locations indicated and as follows:

Rev 0 19 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

a) Combination Waste and Vent

1) Comply with standards of the Royal Commission and IPC.

20. Sleeves are not required for cast-iron soil piping passing through concrete

slabs-on-grade if slab is without membrane waterproofing.

21. Do not enclose, cover, or put piping into operation until it is inspected and

approved by the Royal Commission.

B. Vents

1. Trap seals shall be protected from siphonage or back pressure by the use of

vents.

2. All vent and branch vent pipes shall be graded and connected so they drip

back into the sewerage pipe by gravity.

3. All the vent pipes shall be located at a minimum of 1.5 m apart from the fresh

air intake of the air conditioning systems installed on the roof top.

4. Where vent pipes connect to a horizontal sanitary sewerage pipe, the vent

shall be taken off above the center line of the soil pipe or at an angle not more

than 45° from the vertical and the vent pipe shall rise vertically.

5. Vents shall extend (full size) 300 mm above roof and flash with approved

material. Return flashing in to pipe section minimum 50 mm.

6. Vents penetrating roofed areas to maintain integrity of roof assembly.

7. Vents from chemical and acid waste systems shall not be connected to any

waste venting system, unless otherwise approved.

8. Vents shall be provided to the first manhole, if any.

C. Roof Ventilators

1. In most situations, two roof ventilation products are required to provide a

reliable airflow and to comply with the Regulations. The first of these can be

termed ‘primary’ roof ventilators. That is, they facilitate the intake of air from

the atmosphere in to the roof space. These are usually housed in the soffit

board or above the fascia board and comprise a slotted or meshed grille that

allows the air to flow freely but prevents birds and large insects gaining access

to the roof space.

2. The size of the slots or mesh should be approximately 4 mm in width, which is

small enough to keep out bees or wasps, but large enough to allow, free

unobstructed airflow.

3. In addition to these primary roof vents ‘secondary’ ventilation components are

often required. In a typical pitched roof situation there is always a danger that

the ventilation path could be blocked at eaves level where the roofing felt and

insulation meet. It is at this point when secondary roof ventilators are required

in order to maintain a ventilation channel between the roofing felt and

Rev 0 20 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

insulation.

4. Airflow Requirements

a) Primary Roof Vents

1) Primary roof ventilators, that is, the air intake components fall into

two airflow categories.

(a) A standard pitched roof of at least 15° pitch must be

provided with ventilation at least equal to a continuous

10 mm opening along the eaves.

(b) Roof ventilation equivalent to a 25 mm opening is required

in some other situations. These include pitched roofs below

15°, flat roofs and roofs where the ceiling and insulation

follow the same line as the rafters - such as dormer or

mansard roof constructions.

b) Secondary Roof Vents

1) Secondary roof ventilators, that is, those which maintain airflow

between insulation and roofing felt, fall into two categories similar

to those described for primary roof vents

(a) 10 mm Primary Airflow requires 25mm Secondary Airflow.

(b) 25 mm Primary Airflow requires 50mm Secondary Airflow.

5. Common Venting

a) A common vent is a vent connecting at the junction of two fixture drains

and serving as a vent for both fixtures.

b) A common vent may be used for two fixtures set on the same floor level

but connecting at different levels in the stack, provided the vertical drain

is one pipe diameter larger than the upper fixture drain but in no case

smaller than the lower fixture drain.

c) An individual vent, installed vertically, may be used as a common vent

for two fixture traps when both fixture drains connect with a vertical drain

at the same level.

d) The diameter of an individual vent shall be not less than 50 mm nor less

than one-half of the diameter of the drain to which it is connected.

11. Wet Venting

a) A wet vent is a stack which receives the discharge from wastes other

than water closets.

b) A single-bathroom group of fixtures may be installed with the drain from

a back-vented lavatory, kitchen sink, or combination fixture serving as a

wet vent for a bathtub or shower stall and for the water closet, provided

that:

Rev 0 21 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

c) Not more than one fixture unit is drained into a 40 mm diameter wet vent

or not more-than 4 fixture units drain into a 50 mm diameter wet vent.

d) The horizontal branch connects to the stack at the same level as the

water closet drain or below the water closet drain when installed on the

top floor. It may also connect to the water closet bend.

e) The wet vent and its extension to the vent stack is 50 mm in diameter.

f) Each water closet below the top floors is individually back-vented.

12. Circuit or Loop Venting

a) A branch soil or waste pipe to which 2 but not more than 8 water closets

(except blowout type), pedestal urinals, standard floor traps, shower

stalls, or floor drains are connected in battery shall be vented by a circuit

or loop vent which shall take off in front of the last fixture connection. In

addition, lower-floor branches serving more than 3 water closets shall be

provided with a relief vent taken off in front of the first fixture connection.

When lavatories or similar fixtures discharge above such branches, each

vertical branch shall be provided with a continuous vent.

b) When parallel horizontal branches serve a total of 8 water closets (4 on

each branch), each branch shall be provided with a relief vent at a point

between the 2 most distant water closets. When other fixtures (besides

water closets) discharge above the horizontal branch, each such fixture

shall be vented.

c) When the circuit, loop, or relief vent connections are taken off the

horizontal branch, the vent branch connection shall be taken off at a

vertical angle or from the top of the horizontal branch.

13. Relief Vents

a) Sewerage stacks in a building having more than 10 branch intervals

shall be provided with a relief vent at each tenth interval installed,

beginning with the top floor. The size of the relief vent shall be equal to

the size of the vent stack to which it connects.

b) The lower end of each relief vent shall connect to the sewerage stack

through a "Y" branch below the horizontal branch serving the floor, and

the upper end shall connect to the vent stack through a "Y" branch not

less than 1 m above the floor level.

D. Traps

1. Traps shall be installed in waste system for each floor drain, hub drain, and

basin drain and connected to drains (unless trap is an integrated part of the

plumbing product).

2. Trap Seals used in pressurized buildings shall have a minimum trap seal of

110 mm.

E. Pipe Identification/Labelling

Rev 0 22 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

1. Refer to SECTION 15075.

F. Piping Installation

1. Provide non-conducting dielectric connections wherever jointing dissimilar

metals.

2. Route piping in orderly manner and maintain gradient. Route parallel and

perpendicular to walls.

3. Install piping to maintain headroom, conserve space, and not interfere with use

of space.

4. Group piping whenever practical at common elevations.

5. Install piping to allow for expansion and contraction without stressing pipe,

joints, or connected equipment.

6. Install expansion joints on vertical risers, stacks, and conductors if indicated.

7. Provide clearance in hangers and from structure and other equipment for

installation of insulation and access to valves and fittings.

8. Provide access where valves and fittings are not exposed.

9. Establish elevations of buried piping outside the building to ensure not less

than required length of cover.

10. Install vent piping penetrating roofed areas to maintain integrity of roof

assembly.

11. Where pipe support members are welded to structural building framing,

scrape, brush clean, and apply 1 coat of zinc rich primer to welding.

12. Prepare exposed, unfinished pipe, fittings, supports, and accessories ready for

finish painting.

13. Install bell and spigot pipe with bell end upstream.

14. Pipe vents from gas pressure reducing valves to outdoors and terminate in

weatherproof hood.

15. PVC Pipe

a) Make solvent-welded joints in accordance with ASTM D2855.

16. Sleeve pipes passing through partitions, walls and floors.

G. Cleanouts

1. Install cleanouts in aboveground piping and building drain piping according to

the following, unless otherwise indicated:

Rev 0 23 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

a) Size same as drainage piping up to NPS 100 mm (4 in.). Use NPS

100 mm (4 in.) for larger drainage piping unless larger cleanout is

indicated.

b) Locate at each change in direction of piping greater than 45°.

c) Locate at minimum intervals of 15 m (50 ft.) for piping NPS 100 mm

(4 in.) and smaller and 30 m (100 ft.) for larger piping.

d) Locate at base of each vertical soil and waste stack.

2. Install cleanout deck plates with top flush with finished floor, for floor cleanouts

for piping below floors.

3. Install cleanout wall access covers, of types indicated, with frame and cover

flush with finished wall, for cleanouts located in concealed piping.

H. Floor Drains

1. Install floor drains at low points of surface areas to be drained. Set grates of

drains flush with finished floor, unless otherwise indicated.

a) Position floor drains for easy access and maintenance.

b) Set floor drains below elevation of surrounding finished floor to allow

floor drainage. Set with grates depressed according to the following

drainage area radii:

1) Radius, 750 mm (30 in.) or Less

(a) Equivalent to 1% slope, but not less than 6.35 mm (¼ in.)

total depression.

2) Radius, 750 to 1500 mm (30 to 60 in.)

(a) Equivalent to 1% slope.

3) Radius, 1500 mm (60 in.) or Larger

(a) Equivalent to 1% slope, but not greater than 25 mm (1 in.)

total depression.

c) Install floor-drain flashing collar or flange so no leakage occurs between

drain and adjoining flooring. Maintain integrity of waterproof membranes

where penetrated.

d) Install individual traps for floor drains connected to sanitary building

drain, unless otherwise indicated.

I. Roof Drains

1. Roof drains type, designation and sizes shall be as indicated on drawings.

2. Roof Drain (General Purpose) Cast-iron body with combined flashing collar

and gravel stop, cast-iron dome.

3. Roof Drain (controlled flow) Cast-iron body, combined flashing collar and

Rev 0 24 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

gravel stop, cast-iron dome with adjustable flow rate control assembly.

4. Roof Drain (steel roof decks) Cast-iron body, combined flashing collar and

gravel stop, cast-iron dome.

5. Roof Drain (parapet roofs) Cast-iron body, flashing device, loose set grate.

J. Inserts

1. Provide inserts for placement in concrete formwork.

2. Provide inserts for suspending hangers from reinforced concrete slabs and

sides of reinforced concrete beams.

3. Provide hooked rod to concrete reinforcement section for inserts carrying pipe

over 100 mm (4 in.).

4. Where concrete slabs form finished ceiling, locate inserts flush with slab

surface.

5. Where inserts are omitted, drill through concrete slab from below and provide

through-bolt with recessed square steel plate and nut above slab.

3.04 FLASHING INSTALLATION

A. Fabricate flashing from single piece unless large pans, sumps, or other drainage

shapes are required. Join flashing according to the following if required:

1. Lead Sheets

a) Burn joints of lead sheets 30 kg/m2 (6 lb/ft2), 2.4 mm (0.0938 in.)

thickness or thicker. Solder joints of lead sheets 20 kg/m2 (4 lb/ft2),

1.6 mm (0.0625 in.) thickness or thinner.

B. Install sheet flashing on pipes, sleeves, and specialties passing through or

embedded in floors and roofs with waterproof membrane.

1. Pipe Flashing

a) Sleeve type, matching pipe size, with minimum length of 250 mm

(10 in.), and skirt or flange extending at least 200 mm (8 in.) around

pipe.

2. Sleeve Flashing

a) Flat sheet, with skirt or flange extending at least 200 mm (8 in.) around

sleeve.

3. Embedded Specialty Flashing

a) Flat sheet, with skirt or flange extending at least 200 mm (8 in.) around

specialty.

Rev 0 25 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

C. Set flashing on floors and roofs in solid coating of bituminous cement.

D. Secure flashing into sleeve and specialty clamping ring or device.

3.05 PIPE HANGERS AND SUPPORTS

A. Install in accordance with ASME B31.9.

B. Drain, Waste, and Vent Piping

1. Conform to ASME B31.9.

2. Hangers for Pipe Sizes 15 to 40 mm

a) Malleable iron, adjustable swivel, split ring.

3. Hangers for Pipe Sizes 50 mm and Over

a) Carbon steel, adjustable, clevis.

4. Multiple or Trapeze Hangers

a) Steel channels with welded spacers and hanger rods.

5. Wall Support for Pipe Sizes to 80 mm

a) Support shall be cast iron hook.

6. Wall Support for Pipe Sizes 100 mm and Over

a) Support shall be welded steel bracket and wrought steel clamp.

7. Vertical Support

a) Vertical support shall be steel riser clamp.

8. Floor Support

a) Floor support shall be Cast iron adjustable pipe saddle, lock nut, nipple,

floor flange, and concrete pier or steel support.

C. Support horizontal piping as scheduled.

D. Install hangers to provide minimum 15 mm (½ in.) space between finished covering

and adjacent work.

E. Place hangers within 300 mm (12 in.) of each horizontal elbow.

F. Use hangers with 40 mm (1½ in.) minimum vertical adjustment. Design hangers for

pipe movement without disengagement of supported pipe.

G. Support vertical piping at every other floor. Support riser piping independently of

Rev 0 26 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

connected horizontal piping.

H. Where several pipes can be installed in parallel and at same elevation, provide

multiple or trapeze hangers.

I. Provide copper plated hangers and supports for copper piping.

J. Prime coat exposed steel hangers and supports. Refer to SECTION 15060. Hangers

and supports located in crawl spaces, pipe shafts and suspended ceiling spaces are

not considered exposed.

K. Provide hangers adjacent to motor driven equipment with vibration isolation; refer to

SECTION 15070.

L. Support cast iron drainage piping at every joint.

3.06 FLUSHING AND CLEANING

A. Refer to SECTION 15145.

B. Plugs

1. All open pipe ends or fitting openings shall be plugged or capped immediately

during construction.

C. The Contractor shall clear the interior of the pipe of dirt and other material as the

work progresses.

D. Protect drains during remainder of construction period to avoid clogging with dirt and

debris and to prevent damage from traffic and construction work.

3.07 TESTING

A. Refer to SECTION 15195.

B. Test sanitary drainage and vent piping according to procedures of authorities having

jurisdiction or, in absence of published procedures, as follows:

1. Test for leaks and defects in new piping and parts of existing piping that have

been altered, extended, or repaired. If testing is performed in segments,

submit separate report for each test, complete with diagram of portion of piping

tested.

2. Leave uncovered and unconcealed new, altered, extended, or replaced

drainage and vent piping until it has been tested and approved. Expose work

that was covered or concealed before it was tested.

3. Roughing-In Plumbing Test Procedure

a) Test drainage and vent piping, except outside leaders, on completion of

roughing-in. Close openings in piping system and fill with water to point

Rev 0 27 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

of overflow, but not less than 30 kPa (10 ft. head of water) at 15.5°C

(60°F). From 15 minutes before inspection starts to completion of

inspection, water level must not drop. Water to stand in piping for a

period of 24 hour. Inspect joints for leaks.

4. Finished Plumbing Test Procedure

a) After plumbing fixtures have been set and traps filled with water, test

connections and prove they are gastight and watertight. Plug vent-stack

openings on roof and building drains where they leave building.

Introduce air into piping system equal to pressure of 250 Pa (1 in. wg).

Use U-tube or manometer inserted in trap of water closet to measure

this pressure. Air pressure must remain constant without introducing

additional air throughout period of inspection. Inspect plumbing fixture

connections for gas and water leaks.

5. Repair leaks and defects with new materials and retest piping, or portion

thereof, until satisfactory results are obtained.

6. Prepare reports for tests and required corrective action.

3.08 SCHEDULES

A. Pipe Hanger Spacing

1. Metal Piping

a) Pipe Size 15 to 32 mm (½ to 1¼ in.)

1) Maximum hanger spacing shall be 2 m (6.5 ft.).

2) Hanger rod diameter shall be 9 mm (3/8 in.).

b) Pipe Size 40 to 50 mm (1½ to 2 in.)

1) Maximum hanger spacing shall be 3 m (10 ft.).

2) Hanger rod diameter shall be 9 mm (3/8 in.).

c) Pipe Size 65 to 75 mm (2½ to 3 in.)

1) Maximum hanger spacing shall be 3 m (10 ft.).

2) Hanger rod diameter shall be 15 mm (½ in.).

d) Pipe Size 100 to 150 mm (4 to 6 in.)

1) Maximum hanger spacing shall be 3 m (10 ft.).

2) Hanger rod diameter shall be 15 mm (½ in.).

e) Pipe Size 200 to 300 mm (8 to 12 in.)

1) Maximum hanger spacing shall be 4.25 m (14 ft.).

2) Hanger rod diameter shall be 22 mm (7/8 in.).

Rev 0 28 of 29 Contract No:

SECTION 15152

RESIDENTIAL DRAINAGE AND VENT PIPING

f) Pipe Size 350 mm (14 in.) and Over

1) Maximum hanger spacing shall be 6 m (20 ft.).

2) Hanger rod diameter shall be 25 mm (1 in.).

2. Plastic Piping

a) All Sizes

1) Maximum hanger spacing shall be 1.8 m (6 ft.).

2) Hanger rod diameter shall be 9 mm (3/8 in.).

B. Pipe Support Details

1. Conform to ASME B31.9.

2. Hangers for Pipe Sizes 12.5 to 40 mm (½ to 1½ in.)

a) Malleable iron, adjustable swivel, split ring.

3. Hangers for Pipe Sizes 50 mm (2 in.) and Over

a) Carbon steel, adjustable, clevis.

4. Multiple or Trapeze Hangers

a) Steel channels with welded spacers and hanger rods.

5. Wall Support for Pipe Sizes to 75 mm (3 in.)

a) Cast iron hook.

6. Wall Support for Pipe Sizes 100 mm (4 in.) and Over

a) Welded steel bracket and wrought steel clamp.

7. Vertical Support

a) Steel riser clamp.

8. Floor Support

a) Cast iron adjustable pipe saddle, lock nut, nipple, floor flange and

concrete pier or steel support.

9. Copper Pipe Support

a) Carbon steel ring, adjustable, copper plated.

END OF SECTION

Rev 0 29 of 29 Contract No:

You might also like

- SECTION 15160 Storm Drainage Piping Rev 0Document11 pagesSECTION 15160 Storm Drainage Piping Rev 0mohamad damerlyNo ratings yet

- SECTION 15150 Sanitary Waste and Vent Piping Rev 0Document18 pagesSECTION 15150 Sanitary Waste and Vent Piping Rev 0mohamad damerlyNo ratings yet

- SECTION 15105 Pipes and Tubes Rev 0Document60 pagesSECTION 15105 Pipes and Tubes Rev 0Munir RasheedNo ratings yet

- Underground Piping Materials Rev 0Document56 pagesUnderground Piping Materials Rev 0MohamedOmar83No ratings yet

- SECTION 15190 Fuel Piping Rev 0Document34 pagesSECTION 15190 Fuel Piping Rev 0mohamad damerlyNo ratings yet

- SECTION 15142 Residential Water Piping Rev 0Document28 pagesSECTION 15142 Residential Water Piping Rev 0Munir RasheedNo ratings yet

- SECTION 15120 Piping Specialties Rev 0Document35 pagesSECTION 15120 Piping Specialties Rev 0Azhar Ali50% (2)

- SECTION 15180 Heating and Cooling Piping Rev 0Document34 pagesSECTION 15180 Heating and Cooling Piping Rev 0mohamad damerlyNo ratings yet

- SECTION 15085 Welding, Brazing and Soldering of Piping Rev 0Document28 pagesSECTION 15085 Welding, Brazing and Soldering of Piping Rev 0Munir RasheedNo ratings yet

- Piping Standard and SpecificationDocument22 pagesPiping Standard and SpecificationMuhamad Firdaus Bin Azizan100% (5)

- SECTION 15412 Residential Plumbing Fixtures, Rev 0Document35 pagesSECTION 15412 Residential Plumbing Fixtures, Rev 0Munir RasheedNo ratings yet

- SECTION 15195 Testing of Piping Rev 0Document28 pagesSECTION 15195 Testing of Piping Rev 0mohamad damerlyNo ratings yet

- Sanitary Waste and Vent Piping 15150Document15 pagesSanitary Waste and Vent Piping 15150Munir RasheedNo ratings yet

- SECTION 15340 Water Spray Fixed Systems Rev 0Document28 pagesSECTION 15340 Water Spray Fixed Systems Rev 0Basil OguakaNo ratings yet

- SECTION 15410 Plumbing Fixtures Rev 0Document38 pagesSECTION 15410 Plumbing Fixtures Rev 0Munir RasheedNo ratings yet

- SECTION 15060 Hangers and Supports Rev 0Document43 pagesSECTION 15060 Hangers and Supports Rev 0jaseel kNo ratings yet

- Specification For Fabrication, Construction & Testing of Steel Pipe SystemDocument43 pagesSpecification For Fabrication, Construction & Testing of Steel Pipe SystemALINo ratings yet

- Ductile Iron Pipe For Sewers 012221Document9 pagesDuctile Iron Pipe For Sewers 012221สุภรัตน์ จันทร์คุณาภาสNo ratings yet

- SECTION 15375 Standpipe and Hose Systems Rev 0Document32 pagesSECTION 15375 Standpipe and Hose Systems Rev 0Munir RasheedNo ratings yet

- Abu Dhabi Sewerage Services Company (Adssc)Document16 pagesAbu Dhabi Sewerage Services Company (Adssc)NoorudheenEVNo ratings yet

- SECTION 15140 Domestic Water Piping General 1.1Document20 pagesSECTION 15140 Domestic Water Piping General 1.1Munir RasheedNo ratings yet

- Specification For Carbon Steel Pipes & FittingsDocument27 pagesSpecification For Carbon Steel Pipes & FittingsNoor Anter100% (1)

- 06-Div 2-Sec02205 - uPVCDocument17 pages06-Div 2-Sec02205 - uPVCSheeba BensonNo ratings yet

- 23 21 13 Hydronic PipingDocument15 pages23 21 13 Hydronic PipingSoumojit SamantaNo ratings yet

- SECTION 16510 Interior Luminaires Rev 0Document23 pagesSECTION 16510 Interior Luminaires Rev 0Ahmed HashimNo ratings yet

- Mep Spec8Document13 pagesMep Spec8fatREVITNo ratings yet

- Csi 2018 Mechanical Division 15Document303 pagesCsi 2018 Mechanical Division 15Taner Demirezen100% (1)

- Specification For Steel PipingDocument28 pagesSpecification For Steel Pipingfelixrich100% (2)

- Kuwait Oil Company (K.S.C.) : Engineering GroupDocument15 pagesKuwait Oil Company (K.S.C.) : Engineering GroupAravindan Ganesh KumarNo ratings yet

- Pipe & Pipe FittingsDocument10 pagesPipe & Pipe FittingsSalim BakhshNo ratings yet

- SECTION 15190 Fuel Piping General 1.1Document14 pagesSECTION 15190 Fuel Piping General 1.1Munir RasheedNo ratings yet

- 22 11 13 - Facility Water Distribution Piping PDFDocument11 pages22 11 13 - Facility Water Distribution Piping PDFmasoodaeNo ratings yet

- DWS1160 - Design, Manufacture, Supply and Installation of PVC Pressure PipesDocument26 pagesDWS1160 - Design, Manufacture, Supply and Installation of PVC Pressure PipesleeNo ratings yet

- DRP001-OUF-SPE-C-000-007-B3 (Storm Sewers & Culverts)Document10 pagesDRP001-OUF-SPE-C-000-007-B3 (Storm Sewers & Culverts)Kannan MurugesanNo ratings yet

- Domestic Water SystemsDocument20 pagesDomestic Water Systemsabdullah sahibNo ratings yet

- Section 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesDocument23 pagesSection 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesMohammed HarrisNo ratings yet

- Revised 4/2008Document10 pagesRevised 4/2008Richabson OsmanNo ratings yet

- SECTION 15080 Mechanical Insulation Rev 0Document53 pagesSECTION 15080 Mechanical Insulation Rev 0Munir RasheedNo ratings yet

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidDocument14 pagesRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidThinh NguyenNo ratings yet

- SECTION 16130 Raceway and Boxes Rev 0Document19 pagesSECTION 16130 Raceway and Boxes Rev 0Ahmed HashimNo ratings yet

- Addendum No. 1 Specifications (PDFDrive)Document98 pagesAddendum No. 1 Specifications (PDFDrive)fatimahNo ratings yet

- Pipe & Pipe Fittings - RevDocument15 pagesPipe & Pipe Fittings - RevLuis Gabriel BautistaNo ratings yet

- SECTION 15312 Residential Fire Protection Systems Rev 0Document45 pagesSECTION 15312 Residential Fire Protection Systems Rev 0Munir RasheedNo ratings yet

- TET-SS-5003 Carbon Steel Pipes and Fittings v1 2 PDFDocument8 pagesTET-SS-5003 Carbon Steel Pipes and Fittings v1 2 PDFrod allinasNo ratings yet

- Fire Protection SpecificationDocument34 pagesFire Protection Specification22-09441No ratings yet

- Water and ArregationDocument9 pagesWater and ArregationYasser FathiNo ratings yet

- SECTION 15970 Building Management System (BMS) Part 1 GeneralDocument75 pagesSECTION 15970 Building Management System (BMS) Part 1 GeneralMunir RasheedNo ratings yet

- SECTION 15815 Sheet Metal Duct Work Part 1 - General 1.1 Related DocumentsDocument14 pagesSECTION 15815 Sheet Metal Duct Work Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- Meters and Gauges 15122 - PageDocument4 pagesMeters and Gauges 15122 - PageMunir RasheedNo ratings yet

- SECTION 15411 Hvac Piping and Fitting Materials Part 1 - General 1.1 Related DocumentsDocument10 pagesSECTION 15411 Hvac Piping and Fitting Materials Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15440 Plumbing Pumps General 1.1Document6 pagesSECTION 15440 Plumbing Pumps General 1.1Munir RasheedNo ratings yet

- SECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15855 Air Outlets and Inltes Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15855 Air Outlets and Inltes Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15761 Electrical Heaters Part 1 - General 1.1 General RequirementsDocument3 pagesSECTION 15761 Electrical Heaters Part 1 - General 1.1 General RequirementsMunir RasheedNo ratings yet

- SECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Document10 pagesSECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Munir RasheedNo ratings yet

- Water Treatment and Chemical Cleaning System 15189Document2 pagesWater Treatment and Chemical Cleaning System 15189Munir RasheedNo ratings yet

- SECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesDocument4 pagesSECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesMunir RasheedNo ratings yet

- SECTION 15850 Air Outlets and Inlets Rev 0Document31 pagesSECTION 15850 Air Outlets and Inlets Rev 0Munir RasheedNo ratings yet

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- Alys - Technical-Datasheet - en CATALOGDocument2 pagesAlys - Technical-Datasheet - en CATALOGMunir RasheedNo ratings yet

- Sanitary Waste and Vent Piping 15150Document15 pagesSanitary Waste and Vent Piping 15150Munir RasheedNo ratings yet

- SECTION 11470 Darkroom Equipment Rev 0Document12 pagesSECTION 11470 Darkroom Equipment Rev 0Munir RasheedNo ratings yet

- PumpsDocument6 pagesPumpsMunir RasheedNo ratings yet

- Mechancial Process PacakgeDocument8 pagesMechancial Process PacakgeMunir RasheedNo ratings yet

- SECTION 11130 Audio-Visual Equipment Rev 0Document14 pagesSECTION 11130 Audio-Visual Equipment Rev 0Munir RasheedNo ratings yet

- Design Basis Format: First Seven (7) Chapter Are Same in Specification and MRDocument3 pagesDesign Basis Format: First Seven (7) Chapter Are Same in Specification and MRMunir RasheedNo ratings yet

- SECTION 11450 Residential Equipment Rev 0Document21 pagesSECTION 11450 Residential Equipment Rev 0Munir RasheedNo ratings yet

- DIALux Module InformationDocument5 pagesDIALux Module InformationMunir RasheedNo ratings yet

- SECTION 15935 Building Systems Controls Rev 0Document70 pagesSECTION 15935 Building Systems Controls Rev 0Munir RasheedNo ratings yet

- With - Load - New Equipment Data (Main File)Document8 pagesWith - Load - New Equipment Data (Main File)Munir RasheedNo ratings yet

- SECTION 15670 Refrigerant Condensing Units Rev 0Document24 pagesSECTION 15670 Refrigerant Condensing Units Rev 0Munir RasheedNo ratings yet

- Electrical ScheduleDocument4 pagesElectrical ScheduleMunir RasheedNo ratings yet

- SECTION 15340 Water Spray Fixed Systems Rev 0Document43 pagesSECTION 15340 Water Spray Fixed Systems Rev 0Munir RasheedNo ratings yet

- SECTION 15410 Plumbing Fixtures Rev 0Document38 pagesSECTION 15410 Plumbing Fixtures Rev 0Munir RasheedNo ratings yet

- SECTION 15955 Testing, Adjusting and Balancing Rev 0Document40 pagesSECTION 15955 Testing, Adjusting and Balancing Rev 0Munir RasheedNo ratings yet

- SECTION 15920 Pneumatic Controls Rev 0Document39 pagesSECTION 15920 Pneumatic Controls Rev 0Munir RasheedNo ratings yet

- Chapter 9 Polymeric Materials From Petroleum ModDocument21 pagesChapter 9 Polymeric Materials From Petroleum ModAbdurabu AL-MontaserNo ratings yet

- Predicting Heat Buildup in PVC Building Products: Standard Test Method ForDocument5 pagesPredicting Heat Buildup in PVC Building Products: Standard Test Method ForLito EstimosNo ratings yet

- Raven P5 Ultra: Pipe Film Fiber PVC SealantDocument2 pagesRaven P5 Ultra: Pipe Film Fiber PVC SealantalpeshNo ratings yet

- Atap Sejuk Tahan KaratDocument4 pagesAtap Sejuk Tahan KaratFaat Y Gama, ST, MScNo ratings yet

- Arkema Mbs Impact Modifiers PDFDocument8 pagesArkema Mbs Impact Modifiers PDFgjvoraNo ratings yet

- D3034 & F679 Sewer Specification DataDocument2 pagesD3034 & F679 Sewer Specification DataRaul ArmendarizNo ratings yet

- Part Number: 9841: RS485, 1 PR #24 STR TC, PO Ins, OS+TC BRD, PVC JKT, CMDocument3 pagesPart Number: 9841: RS485, 1 PR #24 STR TC, PO Ins, OS+TC BRD, PVC JKT, CMLeonardoAcevedoNo ratings yet

- FMDS0778Document18 pagesFMDS0778hhNo ratings yet

- Chapter 10 Variable Load ProblemsDocument127 pagesChapter 10 Variable Load ProblemsMarc BitangNo ratings yet

- Main Chemicals Used in PVC Cement - XueyanghuDocument2 pagesMain Chemicals Used in PVC Cement - XueyanghuTychNo ratings yet

- Aluminum Copper Cable CompareDocument4 pagesAluminum Copper Cable Comparesaronnolu100% (1)

- Heliogen Blue K 7090: Technical Information Plastic AdditivesDocument6 pagesHeliogen Blue K 7090: Technical Information Plastic Additiveshai nguyenNo ratings yet

- N2Xfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesN2Xfgby 2 X (1.5-300) MM 0.6/1 KVRince OktavianaNo ratings yet

- Ipex Fusible PVCDocument6 pagesIpex Fusible PVCmabj68No ratings yet

- ANSEL Master Catalog - en - 1339472561 PDFDocument120 pagesANSEL Master Catalog - en - 1339472561 PDFbandara123No ratings yet

- 2015 04 20 PVC Recycling Brochure EnglishDocument50 pages2015 04 20 PVC Recycling Brochure EnglishsyNo ratings yet

- Application & Technical Manual 10 Penetration SealsDocument62 pagesApplication & Technical Manual 10 Penetration SealskenwongwmNo ratings yet

- Ramcroil - Instrumentation Cable: Multi-Pair, HT 105°-Insulation, Collective Screen, PVC-Sheath, Sunlight ResistantDocument1 pageRamcroil - Instrumentation Cable: Multi-Pair, HT 105°-Insulation, Collective Screen, PVC-Sheath, Sunlight ResistantOrlando SantofimioNo ratings yet

- List of Profitable Business Ideas in Electrical and Electronics Products Manufacturing Industries and Power Projects.-51597 PDFDocument78 pagesList of Profitable Business Ideas in Electrical and Electronics Products Manufacturing Industries and Power Projects.-51597 PDFrajavinugmailcomNo ratings yet

- Arkema Mbs Impact Modifiers PDFDocument8 pagesArkema Mbs Impact Modifiers PDFGaurav VoraNo ratings yet

- Sirim 9 - 2017 - Azeeta Pipe - 30.9.2020Document22 pagesSirim 9 - 2017 - Azeeta Pipe - 30.9.2020akmamanan85No ratings yet

- Grade 12 FOODFISH TVL Q3WK5-6Document20 pagesGrade 12 FOODFISH TVL Q3WK5-6Mario Reynaldo CicatNo ratings yet

- Process of Plastic RecyclingDocument15 pagesProcess of Plastic Recyclingn_amarsinh9938No ratings yet

- Solutions Manual For Chemist 2Document193 pagesSolutions Manual For Chemist 2tomzhongNo ratings yet

- Mepl CPCLCBR Eil Qap&Ds 002 2022 2023 Rev 0Document51 pagesMepl CPCLCBR Eil Qap&Ds 002 2022 2023 Rev 0Mathi Vinoth PillaiNo ratings yet

- Final Detail Report On Project No - 1 - 11 PDFDocument56 pagesFinal Detail Report On Project No - 1 - 11 PDFSagarika Aditya100% (1)

- Steinel - Heat Gun HandbookDocument14 pagesSteinel - Heat Gun HandbookHewa PCNo ratings yet

- MSDS 1343 Eng. Exp. Rev. 1 - 14Document4 pagesMSDS 1343 Eng. Exp. Rev. 1 - 14Lord StarkNo ratings yet

- Baby & Childrens ProductsDocument56 pagesBaby & Childrens ProductsAmit AroraNo ratings yet

- Bs-En 14879-5 - 2007Document64 pagesBs-En 14879-5 - 2007Patricio G. ArrienNo ratings yet